ICP-MS vs XRF: Which Offers Better Detection Limits in Minerals?

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Elemental Analysis Technology Background and Objectives

Elemental analysis techniques have evolved significantly over the past century, with increasingly sophisticated methods developed to meet the growing demands of various industries including mining, environmental monitoring, and materials science. The comparison between Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and X-Ray Fluorescence (XRF) represents a critical junction in analytical chemistry, particularly for mineral analysis applications where detection limits can significantly impact exploration decisions and resource valuation.

ICP-MS emerged in the 1980s as a revolutionary technique capable of detecting elements at parts per trillion (ppt) levels, while XRF technology has roots dating back to the 1950s but has seen remarkable advancements in recent decades with the development of more sensitive detectors and improved data processing algorithms. Both technologies have followed distinct evolutionary paths driven by different scientific principles—ICP-MS leveraging mass spectrometry and XRF utilizing the principles of atomic fluorescence.

The global market for elemental analysis equipment has been expanding at approximately 6-7% annually, with particular growth in mining and geological applications where precise determination of trace elements can provide crucial economic insights. This growth trajectory underscores the importance of understanding the comparative advantages of these technologies in mineral analysis contexts.

The primary technical objective in comparing ICP-MS and XRF for mineral analysis is to establish definitive performance parameters regarding detection limits across the periodic table, with particular emphasis on economically significant elements such as gold, silver, rare earth elements, and base metals. Secondary objectives include evaluating sample preparation requirements, throughput capabilities, and operational costs that may influence technology selection in different operational scenarios.

Recent technological innovations have narrowed some historical performance gaps between these techniques. Modern field-portable XRF devices now offer detection limits approaching parts per million (ppm) for many elements, while laboratory-based ICP-MS systems continue to push boundaries with detection capabilities in the parts per quadrillion (ppq) range for select elements. This evolving landscape necessitates a comprehensive reassessment of the relative merits of each technology.

The environmental impact of analytical methods has also become an increasingly important consideration, with ICP-MS typically requiring more complex sample preparation involving acids and generating more waste, while XRF offers generally non-destructive analysis with minimal sample preparation for many applications. This aspect represents an emerging dimension in technology evaluation beyond pure detection capabilities.

ICP-MS emerged in the 1980s as a revolutionary technique capable of detecting elements at parts per trillion (ppt) levels, while XRF technology has roots dating back to the 1950s but has seen remarkable advancements in recent decades with the development of more sensitive detectors and improved data processing algorithms. Both technologies have followed distinct evolutionary paths driven by different scientific principles—ICP-MS leveraging mass spectrometry and XRF utilizing the principles of atomic fluorescence.

The global market for elemental analysis equipment has been expanding at approximately 6-7% annually, with particular growth in mining and geological applications where precise determination of trace elements can provide crucial economic insights. This growth trajectory underscores the importance of understanding the comparative advantages of these technologies in mineral analysis contexts.

The primary technical objective in comparing ICP-MS and XRF for mineral analysis is to establish definitive performance parameters regarding detection limits across the periodic table, with particular emphasis on economically significant elements such as gold, silver, rare earth elements, and base metals. Secondary objectives include evaluating sample preparation requirements, throughput capabilities, and operational costs that may influence technology selection in different operational scenarios.

Recent technological innovations have narrowed some historical performance gaps between these techniques. Modern field-portable XRF devices now offer detection limits approaching parts per million (ppm) for many elements, while laboratory-based ICP-MS systems continue to push boundaries with detection capabilities in the parts per quadrillion (ppq) range for select elements. This evolving landscape necessitates a comprehensive reassessment of the relative merits of each technology.

The environmental impact of analytical methods has also become an increasingly important consideration, with ICP-MS typically requiring more complex sample preparation involving acids and generating more waste, while XRF offers generally non-destructive analysis with minimal sample preparation for many applications. This aspect represents an emerging dimension in technology evaluation beyond pure detection capabilities.

Market Demand for Mineral Analysis Solutions

The global mineral analysis market has witnessed substantial growth in recent years, driven primarily by increasing demand across mining, environmental monitoring, and materials science sectors. Current market valuations place the mineral analysis equipment sector at approximately $5.2 billion, with projections indicating a compound annual growth rate of 6.8% through 2028. This growth trajectory reflects the intensifying need for precise elemental analysis technologies that can deliver reliable results across diverse mineral matrices.

Mining operations represent the largest market segment, accounting for nearly 42% of the total demand for mineral analysis solutions. As ore grades continue to decline worldwide, mining companies face mounting pressure to implement more sensitive detection methods capable of identifying economically viable deposits with lower mineral concentrations. This trend has significantly accelerated interest in advanced analytical technologies like ICP-MS, which offers superior detection capabilities for trace elements that may indicate valuable mineral deposits.

Environmental compliance represents another rapidly expanding market driver, growing at 8.3% annually. Regulatory frameworks worldwide have established increasingly stringent limits for heavy metals and other contaminants in soil, water, and waste materials. Organizations must now detect elements at parts-per-billion or even parts-per-trillion levels, necessitating analytical solutions with exceptional sensitivity and accuracy.

Research institutions and academic laboratories constitute approximately 18% of the market demand, with particular focus on geochemical research and materials characterization. These settings typically require instruments capable of analyzing diverse sample types with minimal matrix interference, driving demand for versatile technologies that can handle complex mineral compositions.

Regional analysis reveals that Asia-Pacific represents the fastest-growing market for mineral analysis equipment, expanding at 9.2% annually, primarily driven by China's extensive mining operations and environmental remediation projects. North America and Europe maintain significant market shares, with particular emphasis on advanced technologies offering superior detection limits and multi-element capabilities.

Customer surveys indicate that detection limits rank as the primary purchasing consideration for 67% of end-users, followed by sample throughput (54%) and total cost of ownership (49%). This prioritization underscores the critical importance of detection capability in the competitive landscape of mineral analysis technologies, directly addressing the central question of whether ICP-MS or XRF better serves market requirements for detection sensitivity.

Mining operations represent the largest market segment, accounting for nearly 42% of the total demand for mineral analysis solutions. As ore grades continue to decline worldwide, mining companies face mounting pressure to implement more sensitive detection methods capable of identifying economically viable deposits with lower mineral concentrations. This trend has significantly accelerated interest in advanced analytical technologies like ICP-MS, which offers superior detection capabilities for trace elements that may indicate valuable mineral deposits.

Environmental compliance represents another rapidly expanding market driver, growing at 8.3% annually. Regulatory frameworks worldwide have established increasingly stringent limits for heavy metals and other contaminants in soil, water, and waste materials. Organizations must now detect elements at parts-per-billion or even parts-per-trillion levels, necessitating analytical solutions with exceptional sensitivity and accuracy.

Research institutions and academic laboratories constitute approximately 18% of the market demand, with particular focus on geochemical research and materials characterization. These settings typically require instruments capable of analyzing diverse sample types with minimal matrix interference, driving demand for versatile technologies that can handle complex mineral compositions.

Regional analysis reveals that Asia-Pacific represents the fastest-growing market for mineral analysis equipment, expanding at 9.2% annually, primarily driven by China's extensive mining operations and environmental remediation projects. North America and Europe maintain significant market shares, with particular emphasis on advanced technologies offering superior detection limits and multi-element capabilities.

Customer surveys indicate that detection limits rank as the primary purchasing consideration for 67% of end-users, followed by sample throughput (54%) and total cost of ownership (49%). This prioritization underscores the critical importance of detection capability in the competitive landscape of mineral analysis technologies, directly addressing the central question of whether ICP-MS or XRF better serves market requirements for detection sensitivity.

ICP-MS and XRF Technical Limitations and Challenges

Despite their widespread use in mineral analysis, both ICP-MS and XRF technologies face significant technical limitations that impact their detection capabilities. ICP-MS, while offering superior detection limits often in the parts per billion (ppb) or parts per trillion (ppt) range, encounters several challenges in practical applications. Sample preparation for ICP-MS is complex and time-consuming, requiring complete dissolution of mineral samples in strong acids, which can introduce contamination and affect measurement accuracy.

Matrix effects represent another major challenge for ICP-MS analysis, particularly with complex mineral samples containing high concentrations of certain elements. These matrix effects can suppress or enhance signals for target analytes, leading to inaccurate quantification. Polyatomic interferences, where molecular ions formed in the plasma have the same mass-to-charge ratio as analytes of interest, further complicate accurate detection, especially for elements like iron, calcium, and arsenic in mineral samples.

XRF technology, while more straightforward in operation, suffers from significantly higher detection limits, typically in the parts per million (ppm) range. This limitation makes XRF unsuitable for trace element analysis in minerals where concentrations fall below these thresholds. The physics of X-ray fluorescence itself imposes fundamental constraints on detection capability, particularly for lighter elements (Z<11), which exhibit poor fluorescence yield and are often undetectable in standard configurations.

Sample heterogeneity presents a particular challenge for XRF analysis, as the technique typically analyzes only the surface layer of samples (typically 1-100 μm depending on the element and matrix). This can lead to results that don't accurately represent the bulk composition of heterogeneous mineral samples. Additionally, spectral overlaps between emission lines of different elements can cause significant interference problems in complex mineral matrices.

Calibration challenges affect both technologies but manifest differently. ICP-MS requires matrix-matched standards that can be difficult to produce for complex mineral samples. XRF faces the "infinite thickness" problem, where sample thickness must exceed a certain threshold to achieve accurate quantification, which varies by element and matrix composition.

Technological advancements are addressing some of these limitations. For ICP-MS, collision/reaction cell technology helps mitigate polyatomic interferences, while improved sample introduction systems reduce matrix effects. In XRF, polarized and monochromatic X-ray sources enhance detection limits, while advanced algorithms improve spectral deconvolution capabilities. However, fundamental physical constraints continue to place ICP-MS at an advantage for trace element detection in minerals, despite its more complex operational requirements.

Matrix effects represent another major challenge for ICP-MS analysis, particularly with complex mineral samples containing high concentrations of certain elements. These matrix effects can suppress or enhance signals for target analytes, leading to inaccurate quantification. Polyatomic interferences, where molecular ions formed in the plasma have the same mass-to-charge ratio as analytes of interest, further complicate accurate detection, especially for elements like iron, calcium, and arsenic in mineral samples.

XRF technology, while more straightforward in operation, suffers from significantly higher detection limits, typically in the parts per million (ppm) range. This limitation makes XRF unsuitable for trace element analysis in minerals where concentrations fall below these thresholds. The physics of X-ray fluorescence itself imposes fundamental constraints on detection capability, particularly for lighter elements (Z<11), which exhibit poor fluorescence yield and are often undetectable in standard configurations.

Sample heterogeneity presents a particular challenge for XRF analysis, as the technique typically analyzes only the surface layer of samples (typically 1-100 μm depending on the element and matrix). This can lead to results that don't accurately represent the bulk composition of heterogeneous mineral samples. Additionally, spectral overlaps between emission lines of different elements can cause significant interference problems in complex mineral matrices.

Calibration challenges affect both technologies but manifest differently. ICP-MS requires matrix-matched standards that can be difficult to produce for complex mineral samples. XRF faces the "infinite thickness" problem, where sample thickness must exceed a certain threshold to achieve accurate quantification, which varies by element and matrix composition.

Technological advancements are addressing some of these limitations. For ICP-MS, collision/reaction cell technology helps mitigate polyatomic interferences, while improved sample introduction systems reduce matrix effects. In XRF, polarized and monochromatic X-ray sources enhance detection limits, while advanced algorithms improve spectral deconvolution capabilities. However, fundamental physical constraints continue to place ICP-MS at an advantage for trace element detection in minerals, despite its more complex operational requirements.

Current Analytical Methods Comparison

01 Detection limits of ICP-MS for trace element analysis

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) offers superior detection limits for trace element analysis, typically in the parts per trillion (ppt) to parts per billion (ppb) range. This technique is particularly advantageous for analyzing multiple elements simultaneously with high sensitivity. The detection capability can be further enhanced through sample preparation techniques and instrument optimization, making it suitable for applications requiring ultra-trace analysis in various matrices.- Detection limits of ICP-MS for trace element analysis: Inductively Coupled Plasma Mass Spectrometry (ICP-MS) offers superior detection limits for trace element analysis, typically in the parts per trillion (ppt) to parts per billion (ppb) range. This technique is particularly effective for analyzing multiple elements simultaneously in various sample matrices. The high sensitivity of ICP-MS makes it suitable for applications requiring detection of extremely low concentrations of elements, such as environmental monitoring, semiconductor manufacturing, and pharmaceutical quality control.

- Detection limits of XRF for elemental analysis: X-ray Fluorescence (XRF) spectroscopy typically provides detection limits in the parts per million (ppm) range, making it less sensitive than ICP-MS but still valuable for many applications. XRF is non-destructive and requires minimal sample preparation, allowing for rapid analysis of solid, liquid, and powder samples. The detection limits vary depending on the element being analyzed, with heavier elements generally having better detection limits than lighter elements due to their higher fluorescence yield.

- Factors affecting detection limits in analytical techniques: Several factors influence the detection limits of both ICP-MS and XRF techniques. These include sample preparation methods, matrix effects, instrument calibration, signal-to-noise ratio, and interference from other elements. For ICP-MS, plasma conditions, ion extraction efficiency, and mass spectrometer resolution significantly impact detection capabilities. In XRF analysis, factors such as excitation source intensity, detector efficiency, measurement time, and sample homogeneity play crucial roles in determining the lowest detectable concentration of elements.

- Improvements in detection limits through technological advancements: Recent technological advancements have significantly improved the detection limits of both ICP-MS and XRF techniques. For ICP-MS, innovations include collision/reaction cell technology to reduce interferences, improved ion optics, and more sensitive detectors. XRF technology has evolved with the development of more powerful X-ray tubes, advanced detectors with better energy resolution, and sophisticated data processing algorithms. These improvements have expanded the application range of both techniques in fields requiring high sensitivity and precision.

- Comparative analysis and complementary use of ICP-MS and XRF: While ICP-MS offers superior detection limits for trace elements, XRF provides advantages in terms of speed, non-destructive analysis, and minimal sample preparation. The complementary use of both techniques can provide comprehensive elemental analysis across a wide concentration range. ICP-MS is preferred for ultra-trace analysis and isotopic measurements, while XRF is advantageous for bulk elemental composition and high-throughput screening. The selection between these techniques depends on specific analytical requirements, sample characteristics, and the concentration range of target elements.

02 XRF detection limits and quantification capabilities

X-ray Fluorescence (XRF) spectroscopy typically provides detection limits in the parts per million (ppm) range, which is less sensitive than ICP-MS but offers non-destructive analysis capabilities. The detection limits vary significantly depending on the atomic number of the element, sample matrix, and instrument configuration. Handheld and portable XRF devices generally have higher detection limits compared to laboratory-based systems, but offer advantages in field applications and rapid screening.Expand Specific Solutions03 Comparative analysis of ICP-MS and XRF techniques

When comparing ICP-MS and XRF analytical techniques, ICP-MS generally provides superior detection limits (ppt-ppb range) but requires sample dissolution and is destructive, while XRF offers non-destructive analysis with moderate detection limits (ppm range). The selection between these techniques depends on the specific application requirements, including required detection limits, sample type, throughput needs, and whether sample preservation is necessary. For comprehensive elemental analysis, these techniques can be used complementarily to leverage their respective strengths.Expand Specific Solutions04 Improvements in detection limits through sample preparation and methodology

Detection limits for both ICP-MS and XRF can be significantly improved through advanced sample preparation techniques and methodological optimizations. For ICP-MS, preconcentration methods, matrix separation, and interference reduction strategies can lower detection limits by orders of magnitude. For XRF, sample preparation techniques such as thin-film preparation, matrix matching, and secondary target excitation can enhance sensitivity. Additionally, mathematical correction models and calibration strategies play crucial roles in achieving lower detection limits for both techniques.Expand Specific Solutions05 Application-specific detection limit requirements

Different applications require specific detection limits that influence the choice between ICP-MS and XRF techniques. Environmental monitoring, pharmaceutical quality control, semiconductor manufacturing, and geological surveys each have unique sensitivity requirements. For ultra-trace analysis in clinical samples or high-purity materials, ICP-MS is typically preferred due to its superior detection limits. Conversely, for bulk material analysis, quality control in manufacturing, or field screening applications where moderate detection limits are acceptable, XRF provides advantages in terms of speed, cost, and operational simplicity.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The mineral analysis market is currently in a growth phase, with ICP-MS and XRF technologies competing for dominance in detection capabilities. The global market size for elemental analysis is expanding rapidly, driven by increasing demands in mining, environmental monitoring, and materials science. While ICP-MS offers superior detection limits (parts-per-trillion) and is favored by research institutions like Sun Yat-Sen University and Peking University for trace element analysis, XRF technology has seen significant advancements from companies like Sigray and SPECTRO Analytical Instruments, offering non-destructive, field-deployable solutions with improving sensitivity. Industrial players such as Halliburton, China National Petroleum, and Samsung Electronics are increasingly adopting both technologies based on specific application requirements, with XRF gaining traction for rapid on-site analysis despite its higher detection limits.

Sigray, Inc.

Technical Solution: Sigray has developed revolutionary laboratory XRF technology specifically targeting improved detection limits in mineral analysis. Their patented AttoMap™ micro-XRF system utilizes unique doubly curved crystal optics that focus X-rays to achieve unprecedented flux density, resulting in detection limits approaching those of ICP-MS for many elements while maintaining XRF's non-destructive advantages. The company's proprietary X-ray source technology produces a high-brightness, low-background beam that significantly enhances signal-to-noise ratios compared to conventional XRF systems. Sigray's systems incorporate advanced silicon drift detectors with improved energy resolution (≤125 eV), enabling better separation of spectral peaks from adjacent elements in complex mineral matrices. Their QuantiMap™ software employs sophisticated fundamental parameter algorithms specifically optimized for geological materials, providing accurate quantification without the need for matrix-matched standards for each sample type. Additionally, Sigray's systems offer spatial mapping capabilities with resolution down to 10 μm, allowing for detailed analysis of mineral heterogeneity not possible with bulk techniques like ICP-MS.

Strengths: Non-destructive analysis preserving sample integrity, minimal sample preparation requirements, excellent spatial resolution for heterogeneous samples, and the ability to analyze both major and trace elements simultaneously. Their technology bridges the gap between traditional XRF and ICP-MS detection capabilities. Weaknesses: Still cannot match the ultimate detection limits of ICP-MS for many trace elements, particularly those below atomic number 20, and has more limited quantitative accuracy for complex matrices without proper calibration standards.

Chevron U.S.A., Inc.

Technical Solution: Chevron has developed a comprehensive analytical approach combining both ICP-MS and XRF technologies for mineral characterization in petroleum exploration and production. Their proprietary workflow integrates portable XRF for rapid field screening of drill cuttings and cores, followed by laboratory ICP-MS analysis of selected samples requiring lower detection limits. Chevron's method employs laser ablation ICP-MS (LA-ICP-MS) for direct solid sampling of minerals without chemical dissolution, preserving spatial relationships while achieving detection limits in the ppb range. Their analytical protocol includes specialized calibration procedures using matrix-matched reference materials specifically developed for petroleum-bearing formations. Chevron has also implemented advanced data integration systems that combine elemental data from both techniques with mineralogical information from XRD and petrographic analysis, creating comprehensive geochemical fingerprints of reservoir rocks. This integrated approach allows for improved reservoir characterization, correlation of stratigraphic units, and identification of potential production issues related to mineral composition.

Strengths: Comprehensive analytical capability combining the speed and field portability of XRF with the superior detection limits of ICP-MS. Their integrated approach provides both rapid screening and detailed characterization capabilities. Weaknesses: Requires significant capital investment in multiple analytical platforms, specialized expertise to interpret combined datasets, and careful quality control procedures to ensure data comparability between techniques.

Detection Limit Optimization Techniques

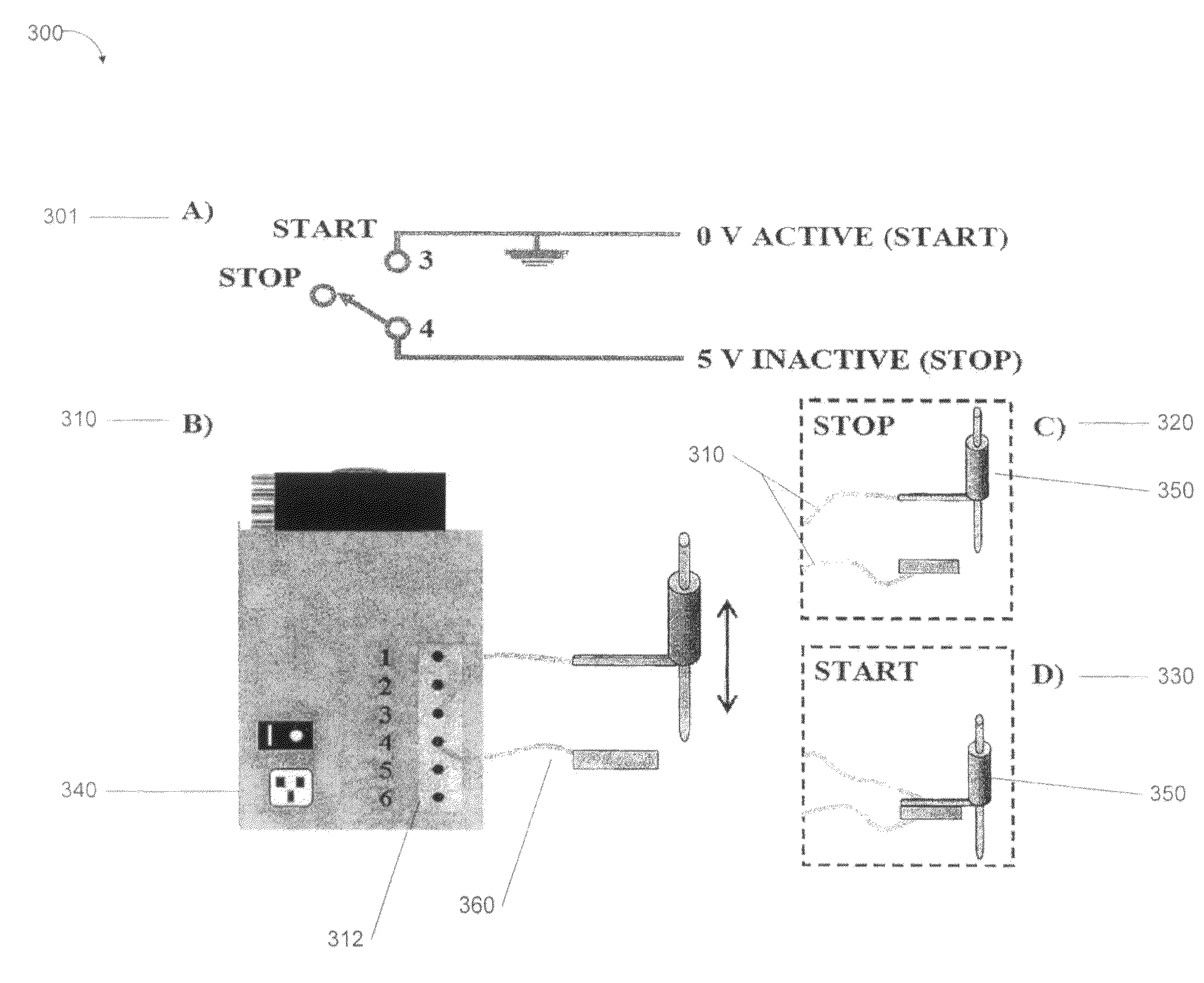

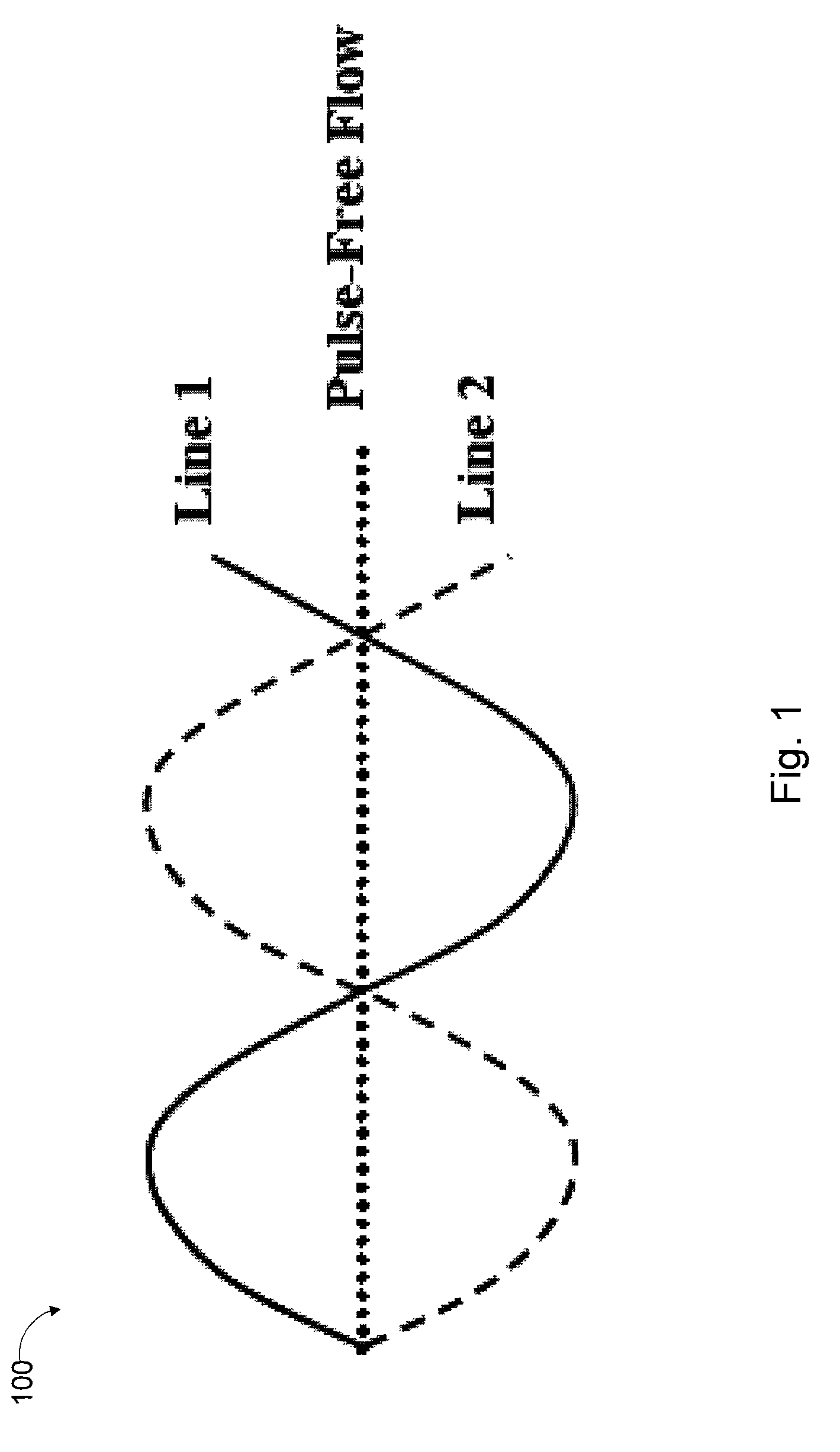

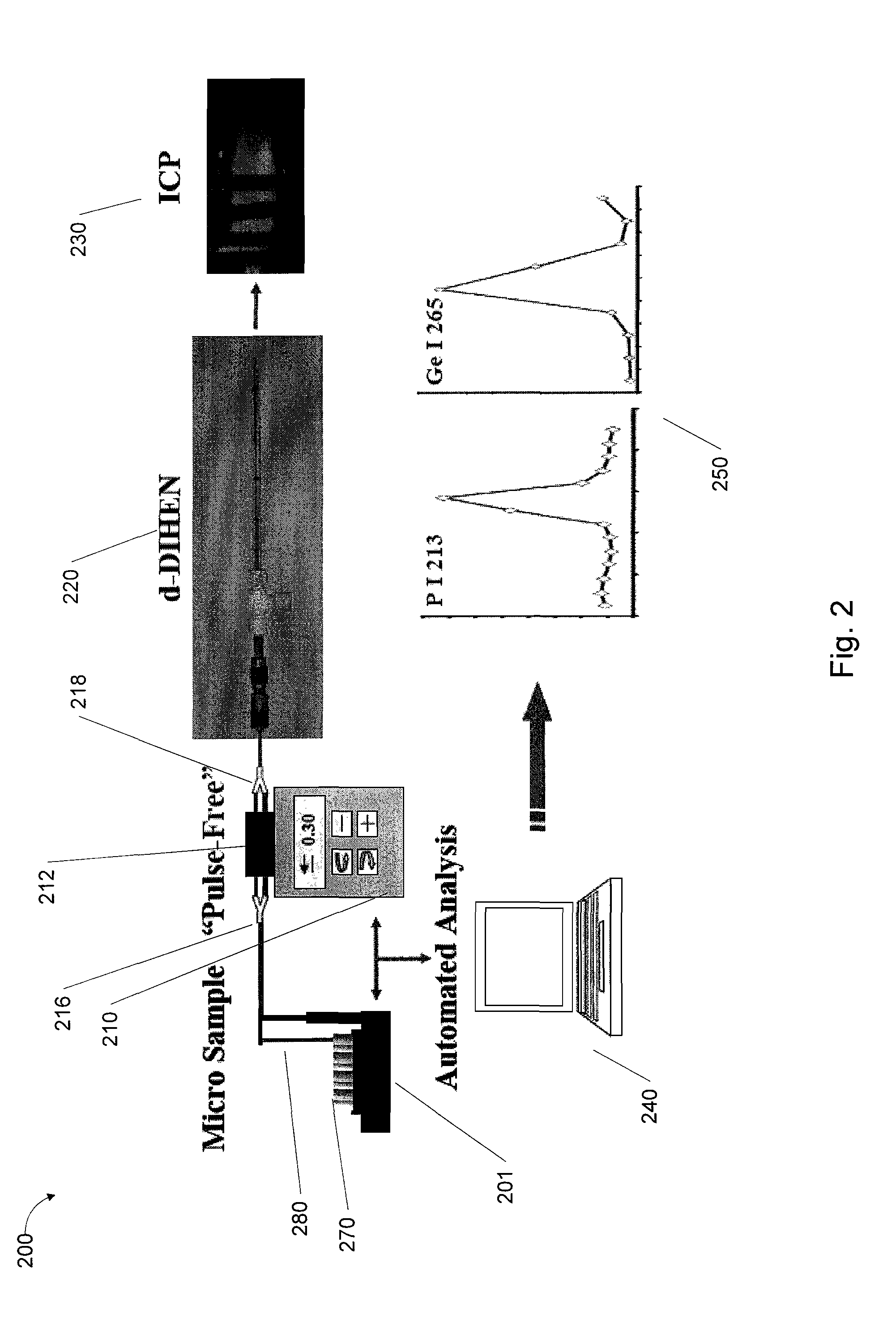

System and Method For Automated Sample Introduction

PatentInactiveUS20100229999A1

Innovation

- A demountable direct injection high efficiency nebulizer (d-DIHEN) system is integrated with HP-ICP-OES, enabling pulse-free sample aspiration and automated sampling, reducing sample consumption and increasing sensitivity, allowing for precise phosphorus content measurement in acid-digested nucleotides and DNA.

Sample Preparation Impact on Detection Accuracy

Sample preparation represents a critical determinant in the analytical performance of both ICP-MS and XRF techniques when analyzing mineral samples. The detection limits and overall accuracy of these methods are significantly influenced by how samples are processed before analysis, with each technique imposing distinct preparation requirements.

For ICP-MS analysis, sample preparation typically involves complete dissolution of the mineral matrix, requiring aggressive acid digestion procedures often utilizing hydrofluoric acid, nitric acid, and hydrogen peroxide combinations. This dissolution step introduces potential sources of contamination and analyte loss that can directly impact detection limits. Studies have demonstrated that incomplete dissolution of refractory minerals can lead to systematic underestimation of certain elements, particularly those bound in resistant mineral phases such as zircon or chromite.

XRF sample preparation, by contrast, generally follows two main approaches: pressed powder pellets or fused glass beads. The pressed powder method maintains the original mineral matrix while minimizing preparation-induced contamination, but suffers from particle size effects and mineralogical influences that can degrade detection limits. Fusion techniques eliminate mineralogical effects through complete sample homogenization but introduce dilution factors that raise detection limits by 5-10 times compared to optimally prepared pressed powders.

Grain size distribution represents another critical factor affecting detection accuracy in both techniques. For XRF, inconsistent particle size distribution creates variable surface roughness and micro-absorption effects that significantly impact precision. ICP-MS is less affected by physical particle characteristics but more sensitive to dissolution completeness, which correlates strongly with particle size reduction during grinding stages.

Moisture content presents different challenges for each technique. Residual moisture in XRF samples can cause significant matrix effects and spectral interference, while for ICP-MS, moisture primarily affects sample weighing accuracy and subsequent concentration calculations. Studies indicate that samples dried at 105°C versus 85°C can show analytical differences of 2-5% for hygroscopic minerals.

Cross-contamination during preparation represents a universal concern, though its impact varies by technique. ICP-MS, with its superior detection limits, is particularly vulnerable to trace contamination introduced during crushing, grinding, or dissolution steps. Documented cases show that improper cleaning protocols between samples can introduce errors exceeding 100% for trace elements at sub-ppm levels.

For ICP-MS analysis, sample preparation typically involves complete dissolution of the mineral matrix, requiring aggressive acid digestion procedures often utilizing hydrofluoric acid, nitric acid, and hydrogen peroxide combinations. This dissolution step introduces potential sources of contamination and analyte loss that can directly impact detection limits. Studies have demonstrated that incomplete dissolution of refractory minerals can lead to systematic underestimation of certain elements, particularly those bound in resistant mineral phases such as zircon or chromite.

XRF sample preparation, by contrast, generally follows two main approaches: pressed powder pellets or fused glass beads. The pressed powder method maintains the original mineral matrix while minimizing preparation-induced contamination, but suffers from particle size effects and mineralogical influences that can degrade detection limits. Fusion techniques eliminate mineralogical effects through complete sample homogenization but introduce dilution factors that raise detection limits by 5-10 times compared to optimally prepared pressed powders.

Grain size distribution represents another critical factor affecting detection accuracy in both techniques. For XRF, inconsistent particle size distribution creates variable surface roughness and micro-absorption effects that significantly impact precision. ICP-MS is less affected by physical particle characteristics but more sensitive to dissolution completeness, which correlates strongly with particle size reduction during grinding stages.

Moisture content presents different challenges for each technique. Residual moisture in XRF samples can cause significant matrix effects and spectral interference, while for ICP-MS, moisture primarily affects sample weighing accuracy and subsequent concentration calculations. Studies indicate that samples dried at 105°C versus 85°C can show analytical differences of 2-5% for hygroscopic minerals.

Cross-contamination during preparation represents a universal concern, though its impact varies by technique. ICP-MS, with its superior detection limits, is particularly vulnerable to trace contamination introduced during crushing, grinding, or dissolution steps. Documented cases show that improper cleaning protocols between samples can introduce errors exceeding 100% for trace elements at sub-ppm levels.

Cost-Benefit Analysis of Analytical Technologies

When evaluating analytical technologies like ICP-MS and XRF for mineral analysis, cost-benefit considerations are paramount for organizations making investment decisions. The initial capital expenditure for ICP-MS systems typically ranges from $150,000 to $300,000, significantly higher than XRF instruments which generally cost between $30,000 and $100,000 depending on capabilities. This substantial difference in upfront investment must be weighed against long-term analytical benefits.

Operational expenses further differentiate these technologies. ICP-MS requires specialized gases (argon), higher-grade reagents, and more extensive sample preparation, resulting in per-sample costs of $20-50. XRF, being non-destructive with minimal sample preparation, offers lower per-sample costs of $5-15, making it more economical for high-volume routine testing.

Maintenance requirements present another significant cost factor. ICP-MS systems demand regular specialized maintenance, with annual service contracts ranging from $10,000 to $20,000, plus consumables like cones and torches that require periodic replacement. XRF instruments generally have lower maintenance costs, typically $5,000 to $10,000 annually, with fewer consumable parts.

Personnel considerations also impact the total cost of ownership. ICP-MS operation requires highly trained specialists commanding higher salaries, while XRF can be operated by technicians with less specialized training after initial instruction. This difference in required expertise translates to varying staffing costs.

The return on investment timeline differs substantially between technologies. XRF typically achieves ROI within 1-3 years for mineral analysis applications, while ICP-MS may require 3-5 years to reach ROI, depending on sample volume and analytical requirements.

Productivity factors must also be considered. While XRF provides rapid results (often 1-5 minutes per sample), ICP-MS analysis typically requires 3-10 minutes per sample plus preparation time. This throughput difference significantly impacts laboratory efficiency and capacity, especially for high-volume operations.

When balancing detection capabilities against costs, organizations must consider their specific analytical needs. For trace element analysis at ppb levels, the higher cost of ICP-MS may be justified. For routine analysis of major and minor elements, XRF's lower cost structure often provides better value, despite higher detection limits.

Operational expenses further differentiate these technologies. ICP-MS requires specialized gases (argon), higher-grade reagents, and more extensive sample preparation, resulting in per-sample costs of $20-50. XRF, being non-destructive with minimal sample preparation, offers lower per-sample costs of $5-15, making it more economical for high-volume routine testing.

Maintenance requirements present another significant cost factor. ICP-MS systems demand regular specialized maintenance, with annual service contracts ranging from $10,000 to $20,000, plus consumables like cones and torches that require periodic replacement. XRF instruments generally have lower maintenance costs, typically $5,000 to $10,000 annually, with fewer consumable parts.

Personnel considerations also impact the total cost of ownership. ICP-MS operation requires highly trained specialists commanding higher salaries, while XRF can be operated by technicians with less specialized training after initial instruction. This difference in required expertise translates to varying staffing costs.

The return on investment timeline differs substantially between technologies. XRF typically achieves ROI within 1-3 years for mineral analysis applications, while ICP-MS may require 3-5 years to reach ROI, depending on sample volume and analytical requirements.

Productivity factors must also be considered. While XRF provides rapid results (often 1-5 minutes per sample), ICP-MS analysis typically requires 3-10 minutes per sample plus preparation time. This throughput difference significantly impacts laboratory efficiency and capacity, especially for high-volume operations.

When balancing detection capabilities against costs, organizations must consider their specific analytical needs. For trace element analysis at ppb levels, the higher cost of ICP-MS may be justified. For routine analysis of major and minor elements, XRF's lower cost structure often provides better value, despite higher detection limits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!