ICP-MS vs TXRF: Precision in Heavy Metal Monitoring

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heavy Metal Detection Technology Background and Objectives

Heavy metal contamination has emerged as a critical environmental and public health concern over the past several decades. The detection and monitoring of heavy metals in various matrices—including water, soil, food products, and biological samples—has evolved significantly since the mid-20th century. Initially relying on colorimetric and spectrophotometric methods with limited sensitivity, the field has progressively advanced toward more sophisticated analytical techniques capable of detecting trace and ultra-trace concentrations.

The evolution of heavy metal detection technology has been driven by increasingly stringent regulatory requirements across industries and growing awareness of the severe health impacts associated with even low-level exposure to elements such as lead, mercury, cadmium, and arsenic. This has necessitated the development of detection methods with superior sensitivity, selectivity, and reliability.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Total Reflection X-ray Fluorescence (TXRF) represent two advanced analytical approaches that have gained prominence in recent decades. ICP-MS, introduced commercially in the 1980s, utilizes a high-temperature plasma source to ionize sample atoms for subsequent mass spectrometric analysis. TXRF, which emerged as an analytical technique in the 1970s but saw significant refinement in the 1990s, employs X-ray excitation under total reflection conditions to achieve exceptional detection limits.

The primary technical objective in heavy metal monitoring is achieving optimal analytical performance characterized by low detection limits (often in the parts-per-trillion range), high accuracy, excellent precision, minimal matrix interference, and efficient sample throughput. Secondary objectives include developing systems with reduced operational complexity, lower maintenance requirements, decreased analytical costs, and smaller environmental footprints.

Current technological development aims to address several persistent challenges: improving detection limits for problematic elements, enhancing measurement precision at ultra-trace levels, reducing matrix effects in complex samples, simplifying sample preparation protocols, and enabling reliable field-deployable systems for in-situ monitoring. The miniaturization of analytical systems and integration with automated sampling technologies represent important trajectories in this field.

The comparative assessment of ICP-MS versus TXRF technologies is particularly relevant as organizations seek to optimize their analytical capabilities while balancing performance requirements against practical considerations such as instrument cost, operational expertise, and sample throughput demands. Understanding the relative strengths, limitations, and complementary aspects of these technologies is essential for informed decision-making in environmental monitoring, food safety, pharmaceutical quality control, and other critical applications.

The evolution of heavy metal detection technology has been driven by increasingly stringent regulatory requirements across industries and growing awareness of the severe health impacts associated with even low-level exposure to elements such as lead, mercury, cadmium, and arsenic. This has necessitated the development of detection methods with superior sensitivity, selectivity, and reliability.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Total Reflection X-ray Fluorescence (TXRF) represent two advanced analytical approaches that have gained prominence in recent decades. ICP-MS, introduced commercially in the 1980s, utilizes a high-temperature plasma source to ionize sample atoms for subsequent mass spectrometric analysis. TXRF, which emerged as an analytical technique in the 1970s but saw significant refinement in the 1990s, employs X-ray excitation under total reflection conditions to achieve exceptional detection limits.

The primary technical objective in heavy metal monitoring is achieving optimal analytical performance characterized by low detection limits (often in the parts-per-trillion range), high accuracy, excellent precision, minimal matrix interference, and efficient sample throughput. Secondary objectives include developing systems with reduced operational complexity, lower maintenance requirements, decreased analytical costs, and smaller environmental footprints.

Current technological development aims to address several persistent challenges: improving detection limits for problematic elements, enhancing measurement precision at ultra-trace levels, reducing matrix effects in complex samples, simplifying sample preparation protocols, and enabling reliable field-deployable systems for in-situ monitoring. The miniaturization of analytical systems and integration with automated sampling technologies represent important trajectories in this field.

The comparative assessment of ICP-MS versus TXRF technologies is particularly relevant as organizations seek to optimize their analytical capabilities while balancing performance requirements against practical considerations such as instrument cost, operational expertise, and sample throughput demands. Understanding the relative strengths, limitations, and complementary aspects of these technologies is essential for informed decision-making in environmental monitoring, food safety, pharmaceutical quality control, and other critical applications.

Market Demand Analysis for Trace Metal Analysis

The global trace metal analysis market has witnessed substantial growth in recent years, driven primarily by increasing environmental regulations and growing concerns about heavy metal contamination in various industries. The market size for trace metal analysis equipment was valued at approximately USD 3.2 billion in 2022 and is projected to reach USD 5.1 billion by 2028, representing a compound annual growth rate (CAGR) of 8.1%.

Environmental monitoring represents the largest application segment, accounting for nearly 35% of the market share. This is largely due to stringent regulations implemented by environmental protection agencies worldwide, particularly regarding water quality standards and soil contamination levels. The European Union's Water Framework Directive and the U.S. EPA's Clean Water Act have established increasingly strict limits for heavy metal concentrations, necessitating more precise analytical techniques.

The semiconductor industry has emerged as the fastest-growing segment for trace metal analysis, with a growth rate exceeding 10% annually. As chip manufacturing processes advance toward smaller node sizes (now below 5nm), the tolerance for metal contamination has decreased dramatically. Even trace amounts of metals can significantly impact semiconductor device performance and yield, driving demand for ultra-sensitive detection methods.

Food safety represents another critical market driver, with regulatory bodies worldwide implementing stricter standards for heavy metal content in consumables. The FDA's recent focus on reducing toxic elements in baby food and the European Food Safety Authority's revised limits for cadmium and lead in various food products have accelerated demand for precise metal analysis technologies.

Pharmaceutical applications constitute approximately 18% of the market, with growing emphasis on elemental impurity testing following the implementation of ICH Q3D guidelines. These guidelines require comprehensive risk assessment and control of elemental impurities in drug products, creating sustained demand for advanced analytical capabilities.

Geographically, North America and Europe currently dominate the market with combined share of 58%, though Asia-Pacific is experiencing the fastest growth at 9.5% annually. This growth is primarily driven by China's strengthening environmental regulations, expansion of semiconductor manufacturing facilities across Taiwan, South Korea, and Japan, and increasing food safety concerns throughout the region.

The market demonstrates a clear trend toward technologies offering lower detection limits, higher throughput, and reduced sample preparation requirements. End-users increasingly demand solutions that can detect multiple elements simultaneously while maintaining precision at ultra-trace levels (parts per trillion), positioning advanced technologies like ICP-MS and TXRF favorably against traditional methods.

Environmental monitoring represents the largest application segment, accounting for nearly 35% of the market share. This is largely due to stringent regulations implemented by environmental protection agencies worldwide, particularly regarding water quality standards and soil contamination levels. The European Union's Water Framework Directive and the U.S. EPA's Clean Water Act have established increasingly strict limits for heavy metal concentrations, necessitating more precise analytical techniques.

The semiconductor industry has emerged as the fastest-growing segment for trace metal analysis, with a growth rate exceeding 10% annually. As chip manufacturing processes advance toward smaller node sizes (now below 5nm), the tolerance for metal contamination has decreased dramatically. Even trace amounts of metals can significantly impact semiconductor device performance and yield, driving demand for ultra-sensitive detection methods.

Food safety represents another critical market driver, with regulatory bodies worldwide implementing stricter standards for heavy metal content in consumables. The FDA's recent focus on reducing toxic elements in baby food and the European Food Safety Authority's revised limits for cadmium and lead in various food products have accelerated demand for precise metal analysis technologies.

Pharmaceutical applications constitute approximately 18% of the market, with growing emphasis on elemental impurity testing following the implementation of ICH Q3D guidelines. These guidelines require comprehensive risk assessment and control of elemental impurities in drug products, creating sustained demand for advanced analytical capabilities.

Geographically, North America and Europe currently dominate the market with combined share of 58%, though Asia-Pacific is experiencing the fastest growth at 9.5% annually. This growth is primarily driven by China's strengthening environmental regulations, expansion of semiconductor manufacturing facilities across Taiwan, South Korea, and Japan, and increasing food safety concerns throughout the region.

The market demonstrates a clear trend toward technologies offering lower detection limits, higher throughput, and reduced sample preparation requirements. End-users increasingly demand solutions that can detect multiple elements simultaneously while maintaining precision at ultra-trace levels (parts per trillion), positioning advanced technologies like ICP-MS and TXRF favorably against traditional methods.

Current Status and Challenges of ICP-MS and TXRF

The global analytical instrumentation market has witnessed significant advancements in heavy metal detection technologies, with ICP-MS (Inductively Coupled Plasma Mass Spectrometry) and TXRF (Total Reflection X-ray Fluorescence) emerging as leading methodologies. Currently, ICP-MS dominates the market with approximately 65% share in heavy metal analysis applications, primarily due to its exceptional sensitivity reaching parts-per-trillion (ppt) levels.

ICP-MS technology has evolved substantially over the past decade, with modern systems featuring collision/reaction cells that effectively minimize polyatomic interferences. The latest generation instruments demonstrate improved matrix tolerance and enhanced sample throughput capabilities. However, ICP-MS systems still face challenges including high operational costs, complex sample preparation requirements, and significant expertise needed for operation and maintenance.

TXRF technology, while less prevalent than ICP-MS, has gained traction particularly in semiconductor manufacturing and environmental monitoring sectors. Current TXRF systems offer detection limits in the parts-per-billion (ppb) range, with newer models approaching sub-ppb sensitivity for certain elements. The technology benefits from minimal sample preparation requirements and substantially lower operational costs compared to ICP-MS.

A significant technical challenge for both technologies remains the accurate quantification of ultra-trace elements in complex matrices. For ICP-MS, polyatomic and isobaric interferences continue to complicate analysis despite advances in collision/reaction cell technology. TXRF faces limitations in quantitative accuracy due to matrix effects and challenges in standardization procedures.

Geographically, North America and Europe lead in ICP-MS adoption, accounting for approximately 60% of the global installed base. Asia-Pacific regions, particularly China and Japan, are experiencing the fastest growth rates in both technologies, driven by expanding semiconductor industries and stricter environmental regulations.

The miniaturization trend presents both opportunities and challenges. Portable ICP-MS systems have emerged but struggle with sensitivity compared to laboratory counterparts. TXRF has shown more promise in miniaturization efforts, with benchtop systems maintaining reasonable performance metrics.

Automation represents another frontier, with both technologies incorporating advanced sample handling systems and intelligent software for data interpretation. However, fully automated systems capable of continuous monitoring remain elusive, particularly for complex environmental samples requiring specialized preparation.

Regulatory pressures worldwide are driving demand for lower detection limits and higher precision, pushing both technologies toward their fundamental physical limitations. This has accelerated research into hybrid approaches and complementary techniques to overcome the inherent limitations of each method.

ICP-MS technology has evolved substantially over the past decade, with modern systems featuring collision/reaction cells that effectively minimize polyatomic interferences. The latest generation instruments demonstrate improved matrix tolerance and enhanced sample throughput capabilities. However, ICP-MS systems still face challenges including high operational costs, complex sample preparation requirements, and significant expertise needed for operation and maintenance.

TXRF technology, while less prevalent than ICP-MS, has gained traction particularly in semiconductor manufacturing and environmental monitoring sectors. Current TXRF systems offer detection limits in the parts-per-billion (ppb) range, with newer models approaching sub-ppb sensitivity for certain elements. The technology benefits from minimal sample preparation requirements and substantially lower operational costs compared to ICP-MS.

A significant technical challenge for both technologies remains the accurate quantification of ultra-trace elements in complex matrices. For ICP-MS, polyatomic and isobaric interferences continue to complicate analysis despite advances in collision/reaction cell technology. TXRF faces limitations in quantitative accuracy due to matrix effects and challenges in standardization procedures.

Geographically, North America and Europe lead in ICP-MS adoption, accounting for approximately 60% of the global installed base. Asia-Pacific regions, particularly China and Japan, are experiencing the fastest growth rates in both technologies, driven by expanding semiconductor industries and stricter environmental regulations.

The miniaturization trend presents both opportunities and challenges. Portable ICP-MS systems have emerged but struggle with sensitivity compared to laboratory counterparts. TXRF has shown more promise in miniaturization efforts, with benchtop systems maintaining reasonable performance metrics.

Automation represents another frontier, with both technologies incorporating advanced sample handling systems and intelligent software for data interpretation. However, fully automated systems capable of continuous monitoring remain elusive, particularly for complex environmental samples requiring specialized preparation.

Regulatory pressures worldwide are driving demand for lower detection limits and higher precision, pushing both technologies toward their fundamental physical limitations. This has accelerated research into hybrid approaches and complementary techniques to overcome the inherent limitations of each method.

Current Technical Solutions Comparison

01 Precision enhancement in ICP-MS technology

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) technology has been improved with various methods to enhance precision in elemental analysis. These improvements include optimized sample introduction systems, advanced ion optics, and calibration techniques that reduce interference and increase sensitivity. The technology allows for precise detection of trace elements at parts per billion or trillion levels, making it valuable for applications requiring high accuracy in elemental composition analysis.- Precision enhancement in ICP-MS technology: Inductively Coupled Plasma Mass Spectrometry (ICP-MS) technology has been improved to achieve higher precision in elemental analysis. These improvements include optimized sample introduction systems, enhanced ion focusing techniques, and advanced detector technologies. The precision of ICP-MS has been significantly enhanced through the development of collision/reaction cells that reduce interferences and improve signal-to-noise ratios, allowing for more accurate trace element detection at lower concentrations.

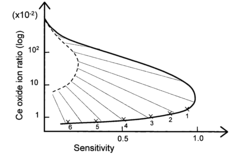

- TXRF technology advancements for precision measurement: Total Reflection X-ray Fluorescence (TXRF) technology has seen significant advancements to improve measurement precision. These include refined X-ray optics, improved sample preparation methods, and enhanced detection systems. TXRF offers advantages in surface analysis and trace element determination with minimal sample preparation. Recent developments have focused on increasing sensitivity and reducing background noise, resulting in more precise quantification of elements on various substrate materials.

- Comparative analysis of ICP-MS and TXRF precision capabilities: Studies comparing the precision capabilities of ICP-MS and TXRF technologies have revealed their complementary strengths in different analytical scenarios. ICP-MS generally offers superior detection limits and multi-element capabilities for bulk analysis, while TXRF excels in surface analysis with minimal sample consumption. The precision of both technologies depends on sample type, preparation methods, and specific analytical requirements. Understanding these differences allows researchers to select the appropriate technology based on their specific analytical needs.

- Calibration and standardization methods for precision improvement: Advanced calibration and standardization methods have been developed to improve the precision of both ICP-MS and TXRF technologies. These include internal standardization techniques, matrix-matched calibration approaches, and isotope dilution methods. Proper calibration procedures are essential for achieving high precision in elemental analysis. Recent innovations include automated calibration systems and reference materials specifically designed for these technologies, which significantly enhance measurement reproducibility and accuracy.

- Sample preparation techniques affecting measurement precision: Sample preparation techniques have a significant impact on the precision of both ICP-MS and TXRF measurements. Optimized digestion methods, contamination control procedures, and sample introduction systems have been developed to enhance precision. For ICP-MS, techniques such as microwave-assisted digestion and flow injection systems improve sample homogeneity. For TXRF, specialized sample carriers and deposition techniques ensure uniform sample distribution, which is critical for achieving high precision in trace element analysis.

02 TXRF technology advancements for precision measurement

Total Reflection X-ray Fluorescence (TXRF) technology has seen significant advancements to improve measurement precision. These include refined sample preparation methods, enhanced detector systems, and improved signal processing algorithms. TXRF offers advantages in surface contamination analysis and thin film characterization with minimal sample preparation requirements. The technology provides high sensitivity for trace element detection on surfaces with reduced background interference compared to conventional XRF techniques.Expand Specific Solutions03 Comparative analysis of ICP-MS and TXRF precision capabilities

Research has been conducted to compare the precision capabilities of ICP-MS and TXRF technologies across different applications. While ICP-MS generally offers higher sensitivity for bulk analysis and multi-element detection, TXRF provides advantages in surface analysis with minimal sample consumption. The selection between these technologies depends on specific application requirements, sample types, and the concentration ranges of target elements. Both technologies complement each other in comprehensive analytical workflows.Expand Specific Solutions04 Sample preparation techniques for improved analytical precision

Advanced sample preparation techniques have been developed to improve the precision of both ICP-MS and TXRF analyses. These include specialized digestion methods, matrix separation procedures, and preconcentration techniques that enhance detection limits and reduce matrix effects. Proper sample preparation is crucial for achieving high precision in trace element analysis, as it minimizes contamination risks and ensures representative sampling. Automated sample preparation systems have also been introduced to improve reproducibility and throughput.Expand Specific Solutions05 Calibration and quality control methods for precision assurance

Sophisticated calibration and quality control methods have been developed to ensure precision in ICP-MS and TXRF measurements. These include internal standardization, isotope dilution techniques, and certified reference materials for validation. Statistical approaches for uncertainty estimation and drift correction algorithms improve the reliability of analytical results. Regular performance verification protocols and interlaboratory comparison studies help maintain consistent precision levels across different instruments and laboratories.Expand Specific Solutions

Key Industry Players in Analytical Instrumentation

The heavy metal monitoring technology landscape is currently in a growth phase, with ICP-MS and TXRF competing for precision applications. The market is expanding due to increasing environmental regulations and industrial quality control needs. Thermo Fisher Scientific leads in ICP-MS technology with advanced spectrometry solutions, while Sigray is pioneering TXRF innovations with their high-resolution X-ray systems. SPECTRO Analytical Instruments and Shimadzu offer complementary analytical platforms, creating a competitive ecosystem. Academic institutions like Peking University and California Institute of Technology are advancing fundamental research, while semiconductor manufacturers (Samsung, SMIC) drive demand for ultra-trace contamination detection. The technology is maturing rapidly with integration of AI and automation features enhancing analytical capabilities.

Thermo Fisher Scientific (Bremen) GmbH

Technical Solution: Thermo Fisher Scientific has developed advanced ICP-MS systems like the iCAP RQ and iCAP TQ that utilize triple quadrupole technology for enhanced interference removal in heavy metal analysis. Their systems incorporate collision/reaction cell technology that effectively eliminates polyatomic interferences, allowing detection limits in the parts-per-trillion (ppt) range[1]. The company's instruments feature high-sensitivity ion optics and rapid scanning capabilities that enable multi-element analysis in a single run with minimal sample consumption. Their latest systems integrate intelligent software platforms that automate method development and quality control procedures, significantly reducing analysis time while maintaining precision[3]. Thermo Fisher's ICP-MS solutions also offer specialized sample introduction systems designed to handle complex matrices like environmental samples, biological tissues, and semiconductor materials with minimal matrix effects[5].

Strengths: Superior sensitivity (down to ppt levels) and wide dynamic range allowing analysis across multiple concentration levels. Advanced interference removal technology provides more accurate results in complex matrices. Weaknesses: Higher operational costs compared to TXRF, including maintenance expenses and consumables (gases, standards). Requires more extensive sample preparation and larger sample volumes than TXRF techniques.

Sigray, Inc.

Technical Solution: Sigray has developed advanced TXRF technology specifically optimized for semiconductor applications and heavy metal monitoring. Their systems utilize proprietary X-ray source technology that achieves significantly higher brightness than conventional sources, enabling detection limits in the low parts-per-trillion range for most heavy metals[5]. Sigray's TXRF instruments incorporate patented multi-target X-ray sources that can be optimized for specific elements of interest, enhancing sensitivity for challenging analytes. Their systems feature advanced silicon drift detectors with high count rate capabilities and exceptional energy resolution, minimizing spectral interferences in complex samples. Sigray has pioneered automated sample handling systems specifically designed for semiconductor wafer analysis, enabling high-throughput screening with minimal operator intervention[11]. Their analytical software includes advanced chemometric tools that can deconvolute overlapping spectral features, improving accuracy in multi-element determinations. Sigray's TXRF technology requires minimal sample preparation and consumes extremely small sample volumes (typically <10 μL), making it ideal for precious samples or high-throughput applications[12].

Strengths: Non-destructive analysis with minimal sample preparation requirements. Extremely low sample volume requirements make it ideal for precious samples or limited volume situations. Exceptional sensitivity for surface contamination analysis on semiconductor wafers. Weaknesses: More limited dynamic range compared to ICP-MS. Quantification can be challenging for some element combinations due to matrix effects and peak overlaps.

Core Technology Analysis of ICP-MS and TXRF

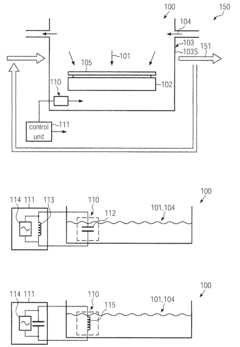

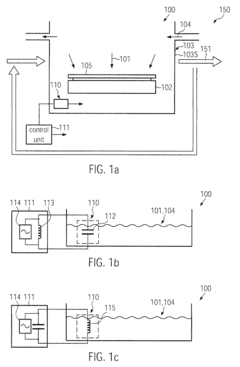

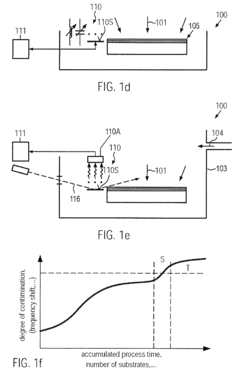

In situ monitoring of metal contamination during microstructure processing

PatentActiveUS20100077839A1

Innovation

- A tool internal sensor system is implemented to monitor metal contamination in situ by detecting variations in electromagnetic characteristics, such as capacitance or inductance, allowing for real-time monitoring of process liquids and ambients, reducing the need for complex sampling procedures and minimizing human resource effort.

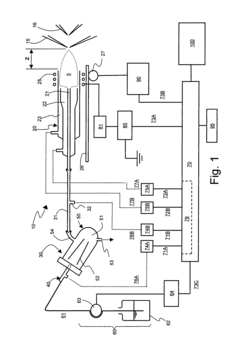

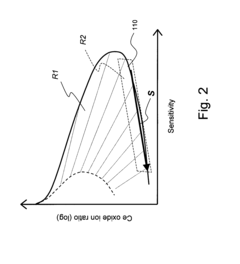

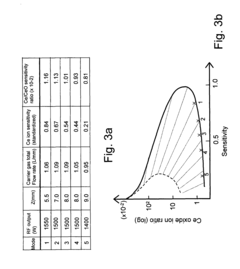

Inductively coupled plasma mass spectrometer

PatentActiveUS7671329B2

Innovation

- An ICP-MS system with a control device that adjusts the amount of liquid drops, carrier gas flow rate, RF power output, and plasma torch position to optimize ion sensitivity, allowing for continuous analysis of samples with varying concentrations without additional dilution equipment or lengthy procedures, thereby maintaining high sensitivity and precision.

Environmental Compliance and Regulatory Standards

Environmental monitoring and compliance frameworks worldwide have established increasingly stringent standards for heavy metal detection, creating a complex regulatory landscape that analytical technologies must navigate. The U.S. Environmental Protection Agency (EPA) has set specific Maximum Contaminant Levels (MCLs) for various heavy metals in drinking water, with lead limited to 15 ppb, arsenic to 10 ppb, and mercury to 2 ppb. These thresholds demand detection technologies capable of ultra-trace analysis with exceptional precision.

The European Union's Water Framework Directive and Drinking Water Directive similarly enforce strict heavy metal limits, often requiring detection capabilities in the sub-ppb range. The EU REACH regulation further mandates comprehensive chemical safety assessments, including detailed heavy metal analysis for industrial processes and consumer products.

In Asia, countries like China and Japan have implemented their own regulatory frameworks. China's Environmental Quality Standards for Surface Water (GB 3838-2002) and Japan's Water Pollution Control Law establish comparable limitations on heavy metal concentrations, though with some regional variations in specific thresholds and enforcement mechanisms.

The semiconductor industry faces particularly demanding compliance requirements through standards like SEMI F57, which governs trace metal contamination in high-purity chemicals. These standards often necessitate detection limits in the parts-per-trillion (ppt) range, pushing analytical technologies to their performance boundaries.

International standards organizations, including ISO and ASTM International, have developed standardized testing protocols that specify acceptable analytical methodologies. ISO 17294-2 specifically addresses ICP-MS applications for water analysis, while TXRF methodologies are referenced in various semiconductor industry standards.

Regulatory compliance drives technology selection between ICP-MS and TXRF systems. While both technologies can meet many regulatory requirements, ICP-MS typically offers lower detection limits necessary for the most stringent standards. However, TXRF provides advantages in sample preparation efficiency and direct surface analysis capabilities that may better serve certain compliance scenarios.

The trend toward lower detection limits in regulatory frameworks continues to evolve, with emerging concerns about ultra-trace contaminants and combination effects of multiple heavy metals at low concentrations. This regulatory progression demands ongoing refinement of analytical technologies and methodologies to ensure compliance with increasingly stringent environmental protection standards.

The European Union's Water Framework Directive and Drinking Water Directive similarly enforce strict heavy metal limits, often requiring detection capabilities in the sub-ppb range. The EU REACH regulation further mandates comprehensive chemical safety assessments, including detailed heavy metal analysis for industrial processes and consumer products.

In Asia, countries like China and Japan have implemented their own regulatory frameworks. China's Environmental Quality Standards for Surface Water (GB 3838-2002) and Japan's Water Pollution Control Law establish comparable limitations on heavy metal concentrations, though with some regional variations in specific thresholds and enforcement mechanisms.

The semiconductor industry faces particularly demanding compliance requirements through standards like SEMI F57, which governs trace metal contamination in high-purity chemicals. These standards often necessitate detection limits in the parts-per-trillion (ppt) range, pushing analytical technologies to their performance boundaries.

International standards organizations, including ISO and ASTM International, have developed standardized testing protocols that specify acceptable analytical methodologies. ISO 17294-2 specifically addresses ICP-MS applications for water analysis, while TXRF methodologies are referenced in various semiconductor industry standards.

Regulatory compliance drives technology selection between ICP-MS and TXRF systems. While both technologies can meet many regulatory requirements, ICP-MS typically offers lower detection limits necessary for the most stringent standards. However, TXRF provides advantages in sample preparation efficiency and direct surface analysis capabilities that may better serve certain compliance scenarios.

The trend toward lower detection limits in regulatory frameworks continues to evolve, with emerging concerns about ultra-trace contaminants and combination effects of multiple heavy metals at low concentrations. This regulatory progression demands ongoing refinement of analytical technologies and methodologies to ensure compliance with increasingly stringent environmental protection standards.

Cost-Benefit Analysis of Implementation

When evaluating the implementation of ICP-MS versus TXRF technologies for heavy metal monitoring, a comprehensive cost-benefit analysis reveals significant differences in financial implications across various operational dimensions.

Initial capital expenditure represents the most apparent distinction between these technologies. ICP-MS systems typically require investments ranging from $150,000 to $300,000, while TXRF instruments generally cost between $80,000 and $150,000. This substantial difference in acquisition costs can significantly impact budget planning, particularly for smaller laboratories or organizations with limited capital resources.

Operational expenses further differentiate these technologies. ICP-MS demands higher ongoing costs due to its consumption of high-purity argon gas, specialized maintenance requirements, and greater power consumption. Annual operational costs for ICP-MS typically range from $20,000 to $40,000, compared to TXRF's $8,000 to $15,000. Additionally, ICP-MS requires more extensive sample preparation, increasing labor costs and consumable expenses.

Throughput capacity and efficiency considerations can offset some cost differentials. ICP-MS offers superior sample throughput, processing 60-100 samples per day versus TXRF's 20-40 samples. For high-volume testing facilities, this efficiency may justify the higher implementation costs through greater productivity and revenue generation potential.

Return on investment timelines vary significantly between technologies. TXRF typically achieves ROI within 2-3 years for moderate-volume laboratories, while ICP-MS may require 3-5 years to reach break-even, depending on utilization rates and service offerings.

Staff training requirements represent another important cost consideration. ICP-MS operation demands more specialized expertise, with training costs averaging $5,000-$10,000 per technician. TXRF requires less intensive training, typically costing $2,000-$5,000 per operator, and can often be mastered more quickly.

Facility adaptation costs should not be overlooked. ICP-MS may require specialized laboratory modifications including enhanced ventilation systems, dedicated power supplies, and potentially reinforced flooring to accommodate its larger footprint and weight. TXRF generally integrates more easily into existing laboratory spaces with minimal modifications.

Long-term value assessment suggests that while ICP-MS represents a higher initial investment, its superior analytical capabilities, particularly for ultra-trace analysis and multi-element detection, may provide greater long-term scientific and commercial value for laboratories requiring these advanced capabilities.

Initial capital expenditure represents the most apparent distinction between these technologies. ICP-MS systems typically require investments ranging from $150,000 to $300,000, while TXRF instruments generally cost between $80,000 and $150,000. This substantial difference in acquisition costs can significantly impact budget planning, particularly for smaller laboratories or organizations with limited capital resources.

Operational expenses further differentiate these technologies. ICP-MS demands higher ongoing costs due to its consumption of high-purity argon gas, specialized maintenance requirements, and greater power consumption. Annual operational costs for ICP-MS typically range from $20,000 to $40,000, compared to TXRF's $8,000 to $15,000. Additionally, ICP-MS requires more extensive sample preparation, increasing labor costs and consumable expenses.

Throughput capacity and efficiency considerations can offset some cost differentials. ICP-MS offers superior sample throughput, processing 60-100 samples per day versus TXRF's 20-40 samples. For high-volume testing facilities, this efficiency may justify the higher implementation costs through greater productivity and revenue generation potential.

Return on investment timelines vary significantly between technologies. TXRF typically achieves ROI within 2-3 years for moderate-volume laboratories, while ICP-MS may require 3-5 years to reach break-even, depending on utilization rates and service offerings.

Staff training requirements represent another important cost consideration. ICP-MS operation demands more specialized expertise, with training costs averaging $5,000-$10,000 per technician. TXRF requires less intensive training, typically costing $2,000-$5,000 per operator, and can often be mastered more quickly.

Facility adaptation costs should not be overlooked. ICP-MS may require specialized laboratory modifications including enhanced ventilation systems, dedicated power supplies, and potentially reinforced flooring to accommodate its larger footprint and weight. TXRF generally integrates more easily into existing laboratory spaces with minimal modifications.

Long-term value assessment suggests that while ICP-MS represents a higher initial investment, its superior analytical capabilities, particularly for ultra-trace analysis and multi-element detection, may provide greater long-term scientific and commercial value for laboratories requiring these advanced capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!