ICP-MS vs ICP-OES for Rare Earth Element Quantification

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

REE Analysis Technology Background and Objectives

Rare Earth Elements (REEs) have emerged as critical materials in modern technology, playing essential roles in electronics, renewable energy systems, defense applications, and medical devices. The quantification of these elements has become increasingly important as global demand continues to rise, driven by technological advancements and geopolitical considerations. The analytical techniques for REE quantification have evolved significantly over the past decades, with Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) standing as the two predominant methodologies.

The historical development of REE analysis techniques began with traditional wet chemical methods in the early 20th century, progressing through flame photometry and atomic absorption spectroscopy in the mid-century. The introduction of ICP-OES in the 1970s and ICP-MS in the 1980s revolutionized trace element analysis, offering unprecedented sensitivity, multi-element capabilities, and analytical speed.

ICP-MS and ICP-OES operate on fundamentally different detection principles while sharing the same sample introduction and plasma ionization systems. ICP-MS measures mass-to-charge ratios of ionized elements, while ICP-OES detects the characteristic wavelengths of light emitted by excited atoms. This fundamental difference creates distinct performance profiles for REE quantification.

The technological trajectory in this field is moving toward enhanced sensitivity, improved interference management, and greater automation. Recent innovations include triple quadrupole ICP-MS systems, high-resolution sector field instruments, and advanced sample introduction techniques designed to minimize matrix effects and enhance detection limits.

The primary objective of this technical research is to comprehensively compare ICP-MS and ICP-OES methodologies specifically for REE quantification. This includes evaluating their respective detection limits, precision, accuracy, sample throughput, interference management capabilities, and cost-effectiveness across various sample matrices relevant to geological, environmental, and industrial applications.

Additionally, this research aims to identify optimal analytical protocols for different REE quantification scenarios, considering factors such as required detection limits, sample complexity, available resources, and specific application requirements. The ultimate goal is to provide evidence-based guidance for selecting the most appropriate analytical technique based on specific analytical needs and constraints.

Understanding the comparative advantages and limitations of these technologies is crucial for laboratories and industries involved in REE exploration, processing, recycling, and quality control, particularly as global competition for these strategic resources intensifies and regulatory requirements for their monitoring become more stringent.

The historical development of REE analysis techniques began with traditional wet chemical methods in the early 20th century, progressing through flame photometry and atomic absorption spectroscopy in the mid-century. The introduction of ICP-OES in the 1970s and ICP-MS in the 1980s revolutionized trace element analysis, offering unprecedented sensitivity, multi-element capabilities, and analytical speed.

ICP-MS and ICP-OES operate on fundamentally different detection principles while sharing the same sample introduction and plasma ionization systems. ICP-MS measures mass-to-charge ratios of ionized elements, while ICP-OES detects the characteristic wavelengths of light emitted by excited atoms. This fundamental difference creates distinct performance profiles for REE quantification.

The technological trajectory in this field is moving toward enhanced sensitivity, improved interference management, and greater automation. Recent innovations include triple quadrupole ICP-MS systems, high-resolution sector field instruments, and advanced sample introduction techniques designed to minimize matrix effects and enhance detection limits.

The primary objective of this technical research is to comprehensively compare ICP-MS and ICP-OES methodologies specifically for REE quantification. This includes evaluating their respective detection limits, precision, accuracy, sample throughput, interference management capabilities, and cost-effectiveness across various sample matrices relevant to geological, environmental, and industrial applications.

Additionally, this research aims to identify optimal analytical protocols for different REE quantification scenarios, considering factors such as required detection limits, sample complexity, available resources, and specific application requirements. The ultimate goal is to provide evidence-based guidance for selecting the most appropriate analytical technique based on specific analytical needs and constraints.

Understanding the comparative advantages and limitations of these technologies is crucial for laboratories and industries involved in REE exploration, processing, recycling, and quality control, particularly as global competition for these strategic resources intensifies and regulatory requirements for their monitoring become more stringent.

Market Demand for Rare Earth Element Quantification

The global market for rare earth element (REE) quantification technologies has experienced significant growth over the past decade, driven primarily by increasing industrial applications across multiple sectors. The demand for precise analytical methods like ICP-MS (Inductively Coupled Plasma Mass Spectrometry) and ICP-OES (Inductively Coupled Plasma Optical Emission Spectrometry) has risen in parallel with the expanding utilization of rare earth elements in high-tech manufacturing.

The electronics industry represents the largest market segment requiring accurate REE quantification, with estimated annual growth of 7-8% through 2025. This growth is fueled by the essential role of rare earth elements in smartphones, computers, and other consumer electronics. Manufacturers require increasingly sensitive detection methods to ensure product quality and regulatory compliance, creating sustained demand for advanced analytical technologies.

Renewable energy applications constitute the fastest-growing market segment for REE quantification. The wind turbine industry alone has seen a 12% compound annual growth rate in REE usage, primarily neodymium and dysprosium for permanent magnets. This trend has directly translated to increased demand for precise quantification methods capable of detecting these specific elements at varying concentration levels.

The automotive sector, particularly electric vehicles, represents another significant market driver. With projections indicating electric vehicles will comprise 30% of global vehicle sales by 2030, the demand for rare earth elements in battery and motor components continues to accelerate. This has created substantial market opportunities for analytical instrument manufacturers specializing in REE detection technologies.

Geographically, Asia-Pacific dominates the market demand for REE quantification technologies, accounting for approximately 45% of global market share. China, as both the primary producer and consumer of rare earth elements, represents the largest single country market. North America and Europe follow with growing demand driven by reshoring initiatives and strategic mineral security concerns.

Environmental monitoring and remediation efforts have emerged as an important secondary market. Regulatory agencies worldwide have implemented stricter guidelines for REE contamination monitoring, creating demand for field-deployable quantification technologies with lower detection limits and higher accuracy.

The mining and resource extraction industry continues to be a traditional but stable market segment. Exploration companies require precise analytical methods to evaluate potential deposits, while processing facilities need ongoing monitoring capabilities to optimize extraction efficiency and ensure product quality.

The electronics industry represents the largest market segment requiring accurate REE quantification, with estimated annual growth of 7-8% through 2025. This growth is fueled by the essential role of rare earth elements in smartphones, computers, and other consumer electronics. Manufacturers require increasingly sensitive detection methods to ensure product quality and regulatory compliance, creating sustained demand for advanced analytical technologies.

Renewable energy applications constitute the fastest-growing market segment for REE quantification. The wind turbine industry alone has seen a 12% compound annual growth rate in REE usage, primarily neodymium and dysprosium for permanent magnets. This trend has directly translated to increased demand for precise quantification methods capable of detecting these specific elements at varying concentration levels.

The automotive sector, particularly electric vehicles, represents another significant market driver. With projections indicating electric vehicles will comprise 30% of global vehicle sales by 2030, the demand for rare earth elements in battery and motor components continues to accelerate. This has created substantial market opportunities for analytical instrument manufacturers specializing in REE detection technologies.

Geographically, Asia-Pacific dominates the market demand for REE quantification technologies, accounting for approximately 45% of global market share. China, as both the primary producer and consumer of rare earth elements, represents the largest single country market. North America and Europe follow with growing demand driven by reshoring initiatives and strategic mineral security concerns.

Environmental monitoring and remediation efforts have emerged as an important secondary market. Regulatory agencies worldwide have implemented stricter guidelines for REE contamination monitoring, creating demand for field-deployable quantification technologies with lower detection limits and higher accuracy.

The mining and resource extraction industry continues to be a traditional but stable market segment. Exploration companies require precise analytical methods to evaluate potential deposits, while processing facilities need ongoing monitoring capabilities to optimize extraction efficiency and ensure product quality.

ICP-MS and ICP-OES Current Status and Challenges

The global analytical instrumentation market has witnessed significant advancements in spectroscopic techniques for rare earth element (REE) quantification. Currently, Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) represent the two dominant technologies in this field, each with distinct capabilities and limitations that influence their application scope.

ICP-MS technology has reached a high level of sophistication, with modern systems achieving detection limits in the parts per trillion (ppt) range for most rare earth elements. This exceptional sensitivity has positioned ICP-MS as the preferred method for ultra-trace analysis in environmental monitoring, geological surveys, and advanced materials research. The latest generation of ICP-MS instruments incorporates collision/reaction cell technology that effectively addresses polyatomic interferences, a historical challenge in REE analysis.

Conversely, ICP-OES systems have evolved to offer detection limits in the parts per billion (ppb) range, with significant improvements in spectral resolution that mitigate the spectral overlap issues previously limiting REE analysis. The technology has benefited from advances in detector technology, particularly charge-coupled devices (CCDs) and complementary metal-oxide-semiconductor (CMOS) detectors, enabling simultaneous multi-element analysis with enhanced speed and precision.

Geographically, North America and Europe lead in the development and adoption of advanced ICP-MS technologies, while Asia-Pacific regions, particularly China and Japan, have made substantial investments in both technologies due to their strategic importance in REE processing and manufacturing. China's dominance in rare earth element production has catalyzed significant research into analytical methodologies, resulting in novel applications of both techniques.

Despite these advancements, several technical challenges persist. For ICP-MS, matrix effects remain problematic when analyzing complex geological samples, requiring sophisticated sample preparation protocols. Additionally, isobaric interferences between certain REEs (e.g., 153Eu and 153Gd) continue to challenge accurate quantification in some applications, necessitating high-resolution instruments or mathematical correction models.

ICP-OES faces its own set of challenges, primarily related to sensitivity limitations when analyzing low-abundance REEs in environmental samples. The technique also struggles with spectral complexity in REE-rich samples, where numerous emission lines can lead to overlapping spectra that complicate accurate identification and quantification.

Both technologies confront common challenges in sample preparation, particularly for solid samples requiring dissolution. The refractory nature of some rare earth minerals necessitates aggressive digestion procedures that can introduce contamination or result in incomplete recovery, affecting analytical accuracy. Furthermore, the high cost of instrumentation and maintenance represents a significant barrier to widespread adoption, particularly in developing regions where REE resources may be abundant but analytical infrastructure is limited.

ICP-MS technology has reached a high level of sophistication, with modern systems achieving detection limits in the parts per trillion (ppt) range for most rare earth elements. This exceptional sensitivity has positioned ICP-MS as the preferred method for ultra-trace analysis in environmental monitoring, geological surveys, and advanced materials research. The latest generation of ICP-MS instruments incorporates collision/reaction cell technology that effectively addresses polyatomic interferences, a historical challenge in REE analysis.

Conversely, ICP-OES systems have evolved to offer detection limits in the parts per billion (ppb) range, with significant improvements in spectral resolution that mitigate the spectral overlap issues previously limiting REE analysis. The technology has benefited from advances in detector technology, particularly charge-coupled devices (CCDs) and complementary metal-oxide-semiconductor (CMOS) detectors, enabling simultaneous multi-element analysis with enhanced speed and precision.

Geographically, North America and Europe lead in the development and adoption of advanced ICP-MS technologies, while Asia-Pacific regions, particularly China and Japan, have made substantial investments in both technologies due to their strategic importance in REE processing and manufacturing. China's dominance in rare earth element production has catalyzed significant research into analytical methodologies, resulting in novel applications of both techniques.

Despite these advancements, several technical challenges persist. For ICP-MS, matrix effects remain problematic when analyzing complex geological samples, requiring sophisticated sample preparation protocols. Additionally, isobaric interferences between certain REEs (e.g., 153Eu and 153Gd) continue to challenge accurate quantification in some applications, necessitating high-resolution instruments or mathematical correction models.

ICP-OES faces its own set of challenges, primarily related to sensitivity limitations when analyzing low-abundance REEs in environmental samples. The technique also struggles with spectral complexity in REE-rich samples, where numerous emission lines can lead to overlapping spectra that complicate accurate identification and quantification.

Both technologies confront common challenges in sample preparation, particularly for solid samples requiring dissolution. The refractory nature of some rare earth minerals necessitates aggressive digestion procedures that can introduce contamination or result in incomplete recovery, affecting analytical accuracy. Furthermore, the high cost of instrumentation and maintenance represents a significant barrier to widespread adoption, particularly in developing regions where REE resources may be abundant but analytical infrastructure is limited.

Current Technical Solutions for REE Quantification

01 Comparison of ICP-MS and ICP-OES for quantitative analysis

Both ICP-MS (Inductively Coupled Plasma Mass Spectrometry) and ICP-OES (Inductively Coupled Plasma Optical Emission Spectrometry) are powerful analytical techniques for elemental analysis, but they differ in detection limits, accuracy, and application scope. ICP-MS generally offers lower detection limits and higher sensitivity for trace element analysis, while ICP-OES provides good quantification accuracy for higher concentration samples with less matrix interference. The choice between these techniques depends on the specific analytical requirements, sample matrix complexity, and concentration range of target elements.- Accuracy enhancement in ICP-MS/OES quantification: Various methods have been developed to enhance the accuracy of quantification in ICP-MS and ICP-OES analytical techniques. These include optimizing sample preparation protocols, implementing internal standardization, and using matrix-matched calibration standards. Advanced data processing algorithms can also be employed to correct for spectral interferences and matrix effects, thereby improving the overall quantification accuracy of trace elements and isotopes in complex samples.

- Interference reduction techniques for ICP analysis: Interference reduction is critical for accurate quantification in ICP-MS and ICP-OES. Techniques include collision/reaction cell technology in ICP-MS to eliminate polyatomic interferences, high-resolution spectral analysis to separate overlapping emission lines in ICP-OES, and mathematical correction models. Sample preparation methods such as matrix separation and pre-concentration can also minimize interferences, leading to improved detection limits and quantification accuracy.

- Calibration strategies for quantitative analysis: Effective calibration strategies are essential for accurate quantification in ICP-MS and ICP-OES. These include multi-point calibration curves, standard addition methods, and isotope dilution techniques for ICP-MS. The use of certified reference materials ensures traceability and validation of analytical results. Dynamic calibration approaches that account for instrument drift over time can further enhance quantification accuracy across a wide concentration range of analytes.

- Sample preparation optimization for accurate quantification: Optimized sample preparation protocols significantly impact quantification accuracy in ICP-MS and ICP-OES analyses. Techniques include microwave-assisted digestion, acid dissolution methods tailored to specific sample matrices, and clean room procedures to minimize contamination. Standardized sample introduction systems and aerosol generation methods ensure consistent analyte transport to the plasma, while pre-concentration techniques can improve detection of trace elements in complex matrices.

- Instrumental advancements for improved quantification: Recent instrumental advancements have significantly improved quantification accuracy in ICP-MS and ICP-OES. These include high-resolution mass spectrometers, triple quadrupole ICP-MS systems for enhanced interference removal, and dual-view ICP-OES instruments that optimize sensitivity across different concentration ranges. Advanced detector technologies with improved dynamic range and stability, coupled with automated quality control procedures, ensure consistent and reliable quantitative results even for challenging sample types.

02 Calibration methods for improving quantification accuracy

Various calibration strategies can significantly improve the quantification accuracy of ICP-MS and ICP-OES analyses. These include external calibration with matrix-matched standards, standard addition methods, internal standardization, and isotope dilution techniques (for ICP-MS). Proper calibration accounts for matrix effects, instrument drift, and potential interferences, ensuring more accurate and reliable quantitative results. Multi-point calibration curves with appropriate concentration ranges and regular verification using certified reference materials are essential practices for achieving high quantification accuracy.Expand Specific Solutions03 Sample preparation techniques affecting quantification accuracy

Sample preparation plays a crucial role in determining the quantification accuracy of ICP-MS and ICP-OES analyses. Proper digestion methods (acid digestion, microwave-assisted digestion, fusion techniques) ensure complete dissolution of samples, while filtration and dilution steps help minimize matrix effects and prevent instrument contamination. Contamination control during sample handling and preparation is essential for trace element analysis. The choice of sample preparation method must be tailored to the sample type and target elements to achieve optimal quantification accuracy.Expand Specific Solutions04 Interference management for accurate quantification

Both ICP-MS and ICP-OES face various interferences that can compromise quantification accuracy. In ICP-MS, these include isobaric, polyatomic, and doubly-charged ion interferences, while ICP-OES deals primarily with spectral overlaps. Advanced interference management techniques include collision/reaction cells in ICP-MS, high-resolution optics in ICP-OES, mathematical correction models, and careful selection of analytical wavelengths or isotopes. Effective interference management is critical for achieving accurate quantification, especially in complex sample matrices.Expand Specific Solutions05 Method validation and quality control for ensuring quantification accuracy

Rigorous method validation and quality control procedures are essential for ensuring the accuracy of quantitative results in ICP-MS and ICP-OES analyses. These include determining method detection limits, quantification limits, linearity ranges, precision (repeatability and reproducibility), and trueness. Regular analysis of certified reference materials, blank samples, spiked samples, and participation in proficiency testing programs help verify method performance and identify potential issues. Implementing appropriate quality control measures throughout the analytical process ensures reliable and defensible quantitative data.Expand Specific Solutions

Major Players in REE Analysis Instrumentation

The rare earth element quantification market is currently in a growth phase, with ICP-MS and ICP-OES technologies competing for dominance. The global market is expanding rapidly due to increasing applications in electronics, renewable energy, and advanced materials, estimated at approximately $2.5 billion with a CAGR of 8-10%. Technologically, ICP-MS has gained an edge for ultra-trace analysis, with Thermo Fisher Scientific, Agilent Technologies, and SPECTRO Analytical Instruments leading innovation. Regional players like Bioyong Technology and Kimia Analytics are emerging with specialized solutions. Academic institutions including China University of Geosciences and KRISS are advancing fundamental research, while industry-specific applications are being developed by Chugai Pharmaceutical and Sinopec for pharmaceutical and petrochemical sectors respectively, indicating technology maturation across diverse applications.

Thermo Fisher Scientific (Bremen) GmbH

Technical Solution: Thermo Fisher Scientific has pioneered advanced ICP-MS technology for rare earth element quantification through their iCAP RQ and iCAP TQ ICP-MS systems. These platforms incorporate their patented QCell collision/reaction cell technology with selectable gas modes (helium, hydrogen, oxygen) to effectively eliminate polyatomic interferences that commonly affect REE analysis. Their triple quadrupole technology enables MS/MS mode operation, providing unprecedented selectivity for challenging REE determinations in complex matrices. Thermo Fisher's high-sensitivity interface design achieves detection limits in the sub-ppt range for most REEs, while their proprietary kinetic energy discrimination (KED) technology effectively removes matrix-based interferences. For high-throughput applications, they've developed the PrepFAST automated sample introduction system that reduces sample preparation time by up to 70% while maintaining analytical precision. Their Qtegra software platform includes specialized REE analysis templates with pre-configured interference corrections and internal standardization protocols specifically optimized for geological, environmental, and industrial samples.

Strengths: Exceptional sensitivity and selectivity through triple quadrupole technology; comprehensive interference management system; intuitive software with specialized REE workflows; high sample throughput with automation options. Weaknesses: Premium pricing compared to ICP-OES solutions; requires specialized operator expertise; higher operational costs including gas consumption; more complex maintenance requirements than optical emission systems.

China University of Geosciences

Technical Solution: China University of Geosciences has developed comprehensive analytical protocols for rare earth element quantification in geological materials using both ICP-MS and ICP-OES techniques. Their research has focused on optimizing sample preparation methods for challenging geological matrices, including refractory minerals and high-silica rocks that traditionally present difficulties in REE extraction. They've pioneered modified fusion techniques using lithium metaborate/tetraborate fluxes followed by acid dissolution, achieving near-complete recovery of REEs from resistant minerals. For ICP-MS applications, they've established matrix-matched calibration strategies using geological reference materials that significantly improve measurement accuracy. Their research has demonstrated that optimized collision cell parameters with mixed gas modes (helium/hydrogen) effectively eliminate polyatomic interferences affecting REE determination. For ICP-OES applications, they've developed wavelength selection protocols that identify optimal emission lines for each REE based on sample composition, minimizing spectral interferences. Their comparative studies between ICP-MS and ICP-OES have established decision frameworks for selecting the appropriate technique based on sample characteristics, required detection limits, and analytical throughput considerations.

Strengths: Specialized expertise in geological sample preparation; comprehensive understanding of matrix effects in REE analysis; practical decision frameworks for technique selection; extensive experience with challenging geological matrices. Weaknesses: Research focus may emphasize geological applications over other sample types; methodologies may require adaptation for industrial settings; techniques optimized for accuracy may have lower sample throughput than commercial solutions.

Key Innovations in ICP-MS and ICP-OES Technologies

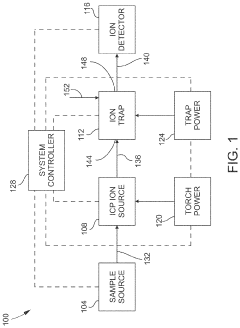

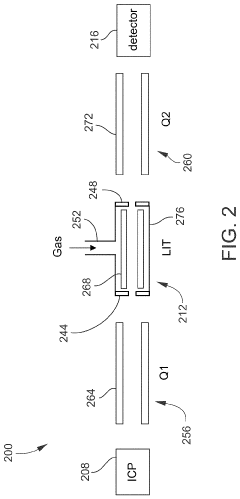

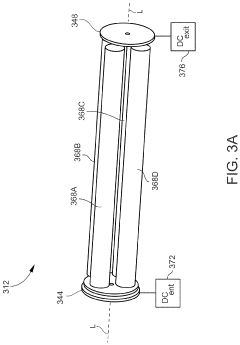

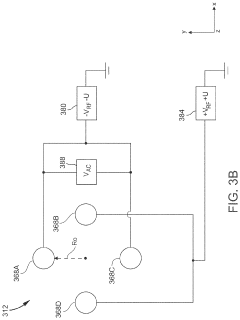

Inductively coupled plasma mass spectrometry (ICP-MS) with ion trapping

PatentActiveUS11443933B1

Innovation

- Incorporating an ion trap, such as a linear ion trap, into the ICP-MS system to confine and mass-selectively eject ions, allowing for the simultaneous analysis of multiple elements from transient signals by preventing ion exit and entry during a confinement period and transmitting selected ions to a detector for measurement.

Sample Preparation Methods for REE Analysis

Sample preparation is a critical step in the analytical workflow for rare earth element (REE) quantification, directly impacting the accuracy, precision, and detection limits of both ICP-MS and ICP-OES techniques. The preparation process typically begins with sample digestion, where solid samples are converted into solution form suitable for instrumental analysis.

Acid digestion represents the most common approach for REE sample preparation, with different acid combinations employed depending on sample matrix. For silicate-based materials, a mixture of hydrofluoric acid (HF) with nitric acid (HNO₃) and perchloric acid (HClO₄) is frequently utilized. Carbonate samples generally require simpler preparation using dilute nitric acid, while organic-rich samples may necessitate hydrogen peroxide (H₂O₂) treatment prior to acid digestion.

Microwave-assisted digestion has emerged as a preferred method for REE sample preparation, offering advantages of shorter digestion times, reduced contamination risk, and improved safety compared to conventional hotplate digestion. This technique enables complete dissolution of most geological materials within 20-40 minutes under controlled temperature and pressure conditions.

Fusion methods represent an alternative approach particularly valuable for refractory minerals resistant to acid digestion. Lithium metaborate (LiBO₂) or sodium peroxide (Na₂O₂) fusion techniques can effectively decompose zircon, monazite, and other minerals containing high REE concentrations. However, fusion methods typically introduce higher total dissolved solids, potentially causing matrix effects in subsequent instrumental analysis.

Pre-concentration techniques are often necessary when analyzing samples with low REE concentrations. Ion exchange chromatography, solid-phase extraction, and co-precipitation methods can effectively separate and concentrate REEs from complex matrices. These techniques are particularly important for ICP-OES analysis, which generally exhibits higher detection limits compared to ICP-MS.

Matrix matching between calibration standards and samples is essential for accurate quantification. The preparation of matrix-matched standards or the use of internal standardization helps compensate for matrix effects that can influence ionization efficiency in the plasma. For ICP-MS analysis, particular attention must be paid to potential polyatomic interferences, which may require additional sample preparation steps such as chemical separation or mathematical correction models.

Acid digestion represents the most common approach for REE sample preparation, with different acid combinations employed depending on sample matrix. For silicate-based materials, a mixture of hydrofluoric acid (HF) with nitric acid (HNO₃) and perchloric acid (HClO₄) is frequently utilized. Carbonate samples generally require simpler preparation using dilute nitric acid, while organic-rich samples may necessitate hydrogen peroxide (H₂O₂) treatment prior to acid digestion.

Microwave-assisted digestion has emerged as a preferred method for REE sample preparation, offering advantages of shorter digestion times, reduced contamination risk, and improved safety compared to conventional hotplate digestion. This technique enables complete dissolution of most geological materials within 20-40 minutes under controlled temperature and pressure conditions.

Fusion methods represent an alternative approach particularly valuable for refractory minerals resistant to acid digestion. Lithium metaborate (LiBO₂) or sodium peroxide (Na₂O₂) fusion techniques can effectively decompose zircon, monazite, and other minerals containing high REE concentrations. However, fusion methods typically introduce higher total dissolved solids, potentially causing matrix effects in subsequent instrumental analysis.

Pre-concentration techniques are often necessary when analyzing samples with low REE concentrations. Ion exchange chromatography, solid-phase extraction, and co-precipitation methods can effectively separate and concentrate REEs from complex matrices. These techniques are particularly important for ICP-OES analysis, which generally exhibits higher detection limits compared to ICP-MS.

Matrix matching between calibration standards and samples is essential for accurate quantification. The preparation of matrix-matched standards or the use of internal standardization helps compensate for matrix effects that can influence ionization efficiency in the plasma. For ICP-MS analysis, particular attention must be paid to potential polyatomic interferences, which may require additional sample preparation steps such as chemical separation or mathematical correction models.

Environmental Impact of REE Analysis Technologies

The environmental footprint of Rare Earth Element (REE) analytical technologies represents a critical consideration in their application and development. ICP-MS and ICP-OES systems both generate significant environmental impacts through their operational requirements and waste streams, though with notable differences in magnitude and type.

ICP-MS technology typically consumes higher quantities of argon gas—approximately 15-20 L/min compared to ICP-OES's 12-15 L/min—resulting in greater resource depletion and carbon emissions associated with gas production and transportation. Additionally, ICP-MS systems generally require more sophisticated laboratory infrastructure, including enhanced clean room facilities and specialized ventilation systems, increasing their embodied carbon footprint.

Waste management presents substantial environmental challenges for both technologies. ICP-MS generates more hazardous waste per sample due to its use of concentrated acids for sample preparation and its requirement for calibration standards containing multiple elements. The disposal of these materials necessitates specialized handling protocols to prevent environmental contamination.

Energy consumption patterns differ significantly between the technologies. ICP-MS systems typically consume 20-30% more electricity than comparable ICP-OES setups, primarily due to the additional power requirements of the mass spectrometry components. This translates to higher greenhouse gas emissions throughout the operational lifespan of the equipment.

Water usage represents another environmental consideration, with both technologies requiring ultra-pure water for sample preparation and system maintenance. ICP-MS generally demands higher water purity standards, resulting in greater resource consumption and wastewater generation through purification processes.

Recent technological advancements have begun addressing these environmental concerns. Newer ICP-MS models incorporate eco-friendly features such as sleep modes that reduce argon consumption during idle periods and more efficient sample introduction systems that minimize waste generation. Similarly, modern ICP-OES systems have implemented lower-flow plasma torches and recycling systems for cooling water.

The environmental impact assessment must also consider the full lifecycle of these analytical systems, including manufacturing, transportation, operational lifespan, and end-of-life disposal. While ICP-MS systems generally have higher environmental costs per unit, their superior sensitivity may reduce the need for sample concentration procedures, potentially offsetting some environmental impacts through reduced chemical usage in sample preparation.

ICP-MS technology typically consumes higher quantities of argon gas—approximately 15-20 L/min compared to ICP-OES's 12-15 L/min—resulting in greater resource depletion and carbon emissions associated with gas production and transportation. Additionally, ICP-MS systems generally require more sophisticated laboratory infrastructure, including enhanced clean room facilities and specialized ventilation systems, increasing their embodied carbon footprint.

Waste management presents substantial environmental challenges for both technologies. ICP-MS generates more hazardous waste per sample due to its use of concentrated acids for sample preparation and its requirement for calibration standards containing multiple elements. The disposal of these materials necessitates specialized handling protocols to prevent environmental contamination.

Energy consumption patterns differ significantly between the technologies. ICP-MS systems typically consume 20-30% more electricity than comparable ICP-OES setups, primarily due to the additional power requirements of the mass spectrometry components. This translates to higher greenhouse gas emissions throughout the operational lifespan of the equipment.

Water usage represents another environmental consideration, with both technologies requiring ultra-pure water for sample preparation and system maintenance. ICP-MS generally demands higher water purity standards, resulting in greater resource consumption and wastewater generation through purification processes.

Recent technological advancements have begun addressing these environmental concerns. Newer ICP-MS models incorporate eco-friendly features such as sleep modes that reduce argon consumption during idle periods and more efficient sample introduction systems that minimize waste generation. Similarly, modern ICP-OES systems have implemented lower-flow plasma torches and recycling systems for cooling water.

The environmental impact assessment must also consider the full lifecycle of these analytical systems, including manufacturing, transportation, operational lifespan, and end-of-life disposal. While ICP-MS systems generally have higher environmental costs per unit, their superior sensitivity may reduce the need for sample concentration procedures, potentially offsetting some environmental impacts through reduced chemical usage in sample preparation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!