ICP-MS vs ICP-OES: Best for Metal Concentration in Steel

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Analysis Technology Background and Objectives

Metal concentration analysis in steel production has evolved significantly over the past several decades, transitioning from traditional wet chemical methods to sophisticated instrumental techniques. The development of spectroscopic methods has revolutionized the field, with Inductively Coupled Plasma (ICP) technology emerging as a cornerstone for precise elemental analysis in metallurgical applications since the 1970s.

ICP technology utilizes a high-temperature plasma source to excite atoms and ions, enabling detection and quantification of multiple elements simultaneously. This technological advancement has been crucial for the steel industry, where compositional control directly impacts mechanical properties, corrosion resistance, and overall quality of the final product.

The two primary ICP-based analytical techniques—Mass Spectrometry (ICP-MS) and Optical Emission Spectrometry (ICP-OES)—represent distinct evolutionary branches of this technology. ICP-MS, developed in the early 1980s, measures mass-to-charge ratios of ionized elements, while ICP-OES, which gained prominence in the 1970s, analyzes the characteristic wavelengths of light emitted by excited elements.

The historical trajectory of these technologies reflects the steel industry's increasing demand for more precise, rapid, and cost-effective analytical methods. Early adoption focused primarily on major element analysis, but contemporary applications extend to trace and ultra-trace element detection, which is critical for high-performance steel grades and specialized applications.

The technical objectives for metal concentration analysis in steel production center on achieving optimal balance between analytical performance parameters: sensitivity, precision, accuracy, dynamic range, sample throughput, and cost-effectiveness. Additionally, modern analytical systems aim to minimize matrix interference effects, reduce sample preparation requirements, and provide robust performance in industrial environments.

Current technological trends indicate a move toward more automated systems with enhanced data processing capabilities, integration with production control systems, and development of portable or at-line analyzers for real-time process monitoring. The evolution of these technologies continues to be driven by increasingly stringent quality control requirements in steel manufacturing, particularly for advanced high-strength steels, automotive-grade materials, and specialized alloys for critical applications.

The ultimate goal of metal concentration analysis technology development is to enable steel manufacturers to achieve precise compositional control throughout the production process, from raw material evaluation to final product verification, thereby ensuring consistent product quality while optimizing resource utilization and minimizing production costs.

ICP technology utilizes a high-temperature plasma source to excite atoms and ions, enabling detection and quantification of multiple elements simultaneously. This technological advancement has been crucial for the steel industry, where compositional control directly impacts mechanical properties, corrosion resistance, and overall quality of the final product.

The two primary ICP-based analytical techniques—Mass Spectrometry (ICP-MS) and Optical Emission Spectrometry (ICP-OES)—represent distinct evolutionary branches of this technology. ICP-MS, developed in the early 1980s, measures mass-to-charge ratios of ionized elements, while ICP-OES, which gained prominence in the 1970s, analyzes the characteristic wavelengths of light emitted by excited elements.

The historical trajectory of these technologies reflects the steel industry's increasing demand for more precise, rapid, and cost-effective analytical methods. Early adoption focused primarily on major element analysis, but contemporary applications extend to trace and ultra-trace element detection, which is critical for high-performance steel grades and specialized applications.

The technical objectives for metal concentration analysis in steel production center on achieving optimal balance between analytical performance parameters: sensitivity, precision, accuracy, dynamic range, sample throughput, and cost-effectiveness. Additionally, modern analytical systems aim to minimize matrix interference effects, reduce sample preparation requirements, and provide robust performance in industrial environments.

Current technological trends indicate a move toward more automated systems with enhanced data processing capabilities, integration with production control systems, and development of portable or at-line analyzers for real-time process monitoring. The evolution of these technologies continues to be driven by increasingly stringent quality control requirements in steel manufacturing, particularly for advanced high-strength steels, automotive-grade materials, and specialized alloys for critical applications.

The ultimate goal of metal concentration analysis technology development is to enable steel manufacturers to achieve precise compositional control throughout the production process, from raw material evaluation to final product verification, thereby ensuring consistent product quality while optimizing resource utilization and minimizing production costs.

Market Demand for Precise Steel Composition Analysis

The global steel industry has witnessed a significant shift towards precision manufacturing, driving an escalating demand for accurate compositional analysis. This trend is particularly evident in high-performance sectors such as aerospace, automotive, and medical device manufacturing, where even minor variations in metal concentrations can dramatically impact product performance and safety. Market research indicates that the global metal analysis equipment market, valued at approximately $10.3 billion in 2022, is projected to reach $15.7 billion by 2028, with analytical instruments for steel composition representing a substantial segment of this growth.

Steel manufacturers increasingly require comprehensive elemental analysis capabilities that can detect both major alloying elements and trace impurities at parts-per-billion levels. This demand stems from stringent quality control requirements and evolving international standards such as ASTM A751 and ISO 14284, which mandate precise verification of steel composition. The automotive industry, in particular, has intensified requirements for ultra-high-strength steels with tightly controlled compositions, driving a 23% increase in demand for advanced analytical instruments over the past five years.

Environmental regulations have emerged as another significant market driver. Restrictions on hazardous elements like lead, mercury, and cadmium in steel products have compelled manufacturers to implement more rigorous testing protocols. The European Union's RoHS and REACH regulations, along with similar frameworks in North America and Asia, have created substantial demand for analytical technologies capable of detecting regulated substances at increasingly lower concentrations.

Cost efficiency represents another crucial market factor. Steel producers seek analytical solutions that balance precision with operational economics. Industry surveys reveal that 78% of steel manufacturers prioritize instruments offering lower per-sample analysis costs and reduced maintenance requirements, while maintaining necessary accuracy levels. This has created a competitive landscape where both ICP-MS and ICP-OES technologies vie for market share based on their respective cost-performance profiles.

The geographical distribution of demand shows notable regional variations. While mature markets in North America and Europe focus on replacing aging equipment with more advanced systems, emerging economies in Asia-Pacific and Latin America are experiencing rapid growth in new installations. China, as the world's largest steel producer, has shown particularly strong demand growth, with analytical instrument imports increasing by 17% annually since 2019.

Digital integration capabilities have become increasingly important market requirements. Steel manufacturers seek analytical systems that seamlessly connect with manufacturing execution systems and quality management platforms, enabling real-time monitoring and automated documentation of compositional data. This trend aligns with broader Industry 4.0 initiatives and has become a key differentiator in purchasing decisions for approximately 65% of large steel producers.

Steel manufacturers increasingly require comprehensive elemental analysis capabilities that can detect both major alloying elements and trace impurities at parts-per-billion levels. This demand stems from stringent quality control requirements and evolving international standards such as ASTM A751 and ISO 14284, which mandate precise verification of steel composition. The automotive industry, in particular, has intensified requirements for ultra-high-strength steels with tightly controlled compositions, driving a 23% increase in demand for advanced analytical instruments over the past five years.

Environmental regulations have emerged as another significant market driver. Restrictions on hazardous elements like lead, mercury, and cadmium in steel products have compelled manufacturers to implement more rigorous testing protocols. The European Union's RoHS and REACH regulations, along with similar frameworks in North America and Asia, have created substantial demand for analytical technologies capable of detecting regulated substances at increasingly lower concentrations.

Cost efficiency represents another crucial market factor. Steel producers seek analytical solutions that balance precision with operational economics. Industry surveys reveal that 78% of steel manufacturers prioritize instruments offering lower per-sample analysis costs and reduced maintenance requirements, while maintaining necessary accuracy levels. This has created a competitive landscape where both ICP-MS and ICP-OES technologies vie for market share based on their respective cost-performance profiles.

The geographical distribution of demand shows notable regional variations. While mature markets in North America and Europe focus on replacing aging equipment with more advanced systems, emerging economies in Asia-Pacific and Latin America are experiencing rapid growth in new installations. China, as the world's largest steel producer, has shown particularly strong demand growth, with analytical instrument imports increasing by 17% annually since 2019.

Digital integration capabilities have become increasingly important market requirements. Steel manufacturers seek analytical systems that seamlessly connect with manufacturing execution systems and quality management platforms, enabling real-time monitoring and automated documentation of compositional data. This trend aligns with broader Industry 4.0 initiatives and has become a key differentiator in purchasing decisions for approximately 65% of large steel producers.

ICP-MS and ICP-OES Current Status and Challenges

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) represent two of the most advanced analytical techniques for metal concentration analysis globally. Both technologies have reached significant maturity, with ICP-MS first commercialized in the early 1980s and ICP-OES developed in the 1970s. The global market for these technologies continues to expand, with an estimated value exceeding $2.5 billion and growing at approximately 5-7% annually.

In the steel industry specifically, these technologies have become indispensable for quality control and research applications. Current ICP-MS systems offer detection limits in the parts-per-trillion (ppt) range, while ICP-OES typically achieves parts-per-billion (ppb) sensitivity. This difference represents one of the fundamental technical distinctions that influences application selection in steel analysis.

The geographical distribution of technological development shows concentration in North America, Europe, and East Asia. Leading manufacturers like Agilent, Thermo Fisher Scientific, and PerkinElmer continue to dominate the market with ongoing innovations. Japan and Germany have particularly strong positions in high-precision ICP-MS development, while China has rapidly expanded its manufacturing capabilities for more cost-effective systems.

Despite their maturity, both technologies face significant challenges. For ICP-MS, these include spectral interferences (particularly problematic for iron-rich matrices like steel), sample introduction limitations, and high operational costs. Modern collision/reaction cell technologies have partially addressed interference issues, but complete resolution remains elusive for complex steel matrices.

ICP-OES faces its own set of challenges, including lower sensitivity compared to ICP-MS, spectral line overlaps in multi-element analysis, and matrix effects that can significantly impact calibration. Recent advances in high-resolution detectors and sophisticated software algorithms have improved these limitations but have not eliminated them entirely.

Sample preparation represents a universal challenge for both technologies when analyzing steel. Dissolution procedures must be carefully optimized to ensure complete recovery of all elements while minimizing contamination. The high iron content in steel samples creates significant matrix effects that can suppress signals for trace elements.

Miniaturization and automation represent emerging trends for both technologies, with manufacturers working to reduce instrument footprint and increase sample throughput. However, these developments often come with trade-offs in analytical performance that must be carefully evaluated for steel industry applications.

Cost remains a significant barrier to wider adoption, particularly for ICP-MS systems which typically require investments of $150,000-300,000 plus ongoing operational expenses. This economic factor often drives technology selection decisions in industrial settings, sometimes favoring the more economical ICP-OES despite its technical limitations.

In the steel industry specifically, these technologies have become indispensable for quality control and research applications. Current ICP-MS systems offer detection limits in the parts-per-trillion (ppt) range, while ICP-OES typically achieves parts-per-billion (ppb) sensitivity. This difference represents one of the fundamental technical distinctions that influences application selection in steel analysis.

The geographical distribution of technological development shows concentration in North America, Europe, and East Asia. Leading manufacturers like Agilent, Thermo Fisher Scientific, and PerkinElmer continue to dominate the market with ongoing innovations. Japan and Germany have particularly strong positions in high-precision ICP-MS development, while China has rapidly expanded its manufacturing capabilities for more cost-effective systems.

Despite their maturity, both technologies face significant challenges. For ICP-MS, these include spectral interferences (particularly problematic for iron-rich matrices like steel), sample introduction limitations, and high operational costs. Modern collision/reaction cell technologies have partially addressed interference issues, but complete resolution remains elusive for complex steel matrices.

ICP-OES faces its own set of challenges, including lower sensitivity compared to ICP-MS, spectral line overlaps in multi-element analysis, and matrix effects that can significantly impact calibration. Recent advances in high-resolution detectors and sophisticated software algorithms have improved these limitations but have not eliminated them entirely.

Sample preparation represents a universal challenge for both technologies when analyzing steel. Dissolution procedures must be carefully optimized to ensure complete recovery of all elements while minimizing contamination. The high iron content in steel samples creates significant matrix effects that can suppress signals for trace elements.

Miniaturization and automation represent emerging trends for both technologies, with manufacturers working to reduce instrument footprint and increase sample throughput. However, these developments often come with trade-offs in analytical performance that must be carefully evaluated for steel industry applications.

Cost remains a significant barrier to wider adoption, particularly for ICP-MS systems which typically require investments of $150,000-300,000 plus ongoing operational expenses. This economic factor often drives technology selection decisions in industrial settings, sometimes favoring the more economical ICP-OES despite its technical limitations.

Comparative Analysis of ICP-MS and ICP-OES Methods

01 ICP-MS techniques for trace metal analysis

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is utilized for highly sensitive trace metal analysis, capable of detecting metals at parts per billion or trillion levels. This technique ionizes samples using plasma and separates ions based on their mass-to-charge ratio, enabling precise quantification of multiple elements simultaneously. ICP-MS is particularly valuable for environmental monitoring, quality control in manufacturing, and research applications requiring detection of ultra-low metal concentrations.- ICP-MS techniques for trace metal analysis: Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is utilized for highly sensitive trace metal analysis, capable of detecting metals at parts per billion or trillion levels. This technique ionizes samples using plasma and separates ions based on mass-to-charge ratios, enabling precise quantification of multiple elements simultaneously. ICP-MS is particularly valuable for environmental monitoring, quality control in manufacturing, and detecting metal contaminants in various matrices.

- ICP-OES methods for elemental composition determination: Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) measures the light emitted by excited atoms and ions in plasma to determine elemental composition. This technique offers excellent multi-element capabilities with good sensitivity and wide linear dynamic range. ICP-OES is widely applied in analyzing metals in geological samples, water quality assessment, and industrial quality control where moderate detection limits are sufficient.

- Sample preparation techniques for ICP analysis: Effective sample preparation is crucial for accurate metal concentration measurements using ICP techniques. Methods include acid digestion, microwave-assisted extraction, and dilution procedures to convert solid samples into solutions suitable for analysis. Proper preparation minimizes matrix effects and interferences while ensuring complete dissolution of target elements, leading to more reliable quantitative results in complex sample matrices.

- Calibration and quality control in ICP metal analysis: Precise calibration procedures and quality control measures are essential for accurate metal concentration measurements using ICP techniques. This includes the use of certified reference materials, internal standards, and matrix-matched calibration curves to compensate for instrumental drift and matrix effects. Regular system performance checks, blank measurements, and statistical validation methods ensure reliable analytical results across different sample types.

- Specialized ICP applications for challenging samples: Advanced ICP methodologies have been developed for analyzing challenging sample types and addressing specific analytical problems. These include coupling ICP with chromatographic separation techniques for speciation analysis, using collision/reaction cells to reduce interferences, and specialized sample introduction systems for volatile elements. These approaches enable accurate metal concentration measurements in complex matrices such as biological tissues, environmental samples with high dissolved solids, and industrial materials.

02 ICP-OES methods for metal concentration determination

Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) provides robust analysis of metal concentrations by measuring the characteristic wavelengths of light emitted by excited atoms in plasma. This technique offers excellent multi-element capabilities, wide linear dynamic range, and high sample throughput. ICP-OES is particularly suitable for samples with higher metal concentrations and is widely used in industrial quality control, environmental testing, and geological sample analysis.Expand Specific Solutions03 Sample preparation methods for ICP analysis

Effective sample preparation is crucial for accurate metal concentration measurements using ICP techniques. Methods include acid digestion, microwave-assisted extraction, and dilution protocols designed to solubilize metals while minimizing contamination and matrix effects. Proper sample preparation ensures complete recovery of target metals, reduces interferences, and improves measurement precision. Standardized preparation protocols are essential for consistent and reliable analytical results across different sample types.Expand Specific Solutions04 Calibration and quality control in ICP metal analysis

Accurate calibration and rigorous quality control procedures are essential for reliable metal concentration measurements using ICP techniques. This includes the use of certified reference materials, internal standards, and matrix-matched calibration curves to compensate for matrix effects and instrument drift. Quality control measures such as method validation, regular performance checks, and statistical process control ensure measurement accuracy and traceability to international standards.Expand Specific Solutions05 Specialized ICP applications for complex matrices

Advanced ICP-MS and ICP-OES methodologies have been developed for metal analysis in challenging sample matrices such as biological tissues, geological materials, and industrial waste. These specialized applications employ techniques like collision/reaction cells in ICP-MS to reduce polyatomic interferences, high-resolution optics in ICP-OES to resolve spectral overlaps, and specialized sample introduction systems. These innovations enable accurate metal concentration measurements even in complex matrices with high dissolved solids or organic content.Expand Specific Solutions

Key Industry Players in Analytical Instrumentation

The metal concentration analysis market in steel is currently in a mature growth phase, with ICP-MS and ICP-OES technologies competing for dominance. The global analytical instrumentation market for metal analysis exceeds $5 billion, with steady annual growth of 4-6%. ICP-MS offers superior detection limits and multi-element capabilities, making it preferred for trace analysis, while ICP-OES provides cost-effective solutions for routine testing. Companies like Bioyong Technology and Applied Spectra lead in ICP-MS innovation, while Jiangsu Skyray Instrument and DuPont have established strong positions in ICP-OES. Steel manufacturers including Baotou Iron & Steel and Xining Special Steel are driving demand through quality control requirements, while testing centers like NCS Testing Technology provide specialized analytical services to the industry.

China First Heavy Industries

Technical Solution: China First Heavy Industries has developed integrated analytical systems for steel quality control incorporating both ICP-MS and ICP-OES technologies. Their approach focuses on production-line integration, with automated sampling systems that feed directly into analytical instruments. The company has implemented specialized sample preparation protocols optimized for different steel grades, including high-temperature alloys and specialty steels. Their analytical framework incorporates real-time data processing algorithms that correlate elemental composition with mechanical properties, enabling predictive quality control. CFHI has also developed proprietary calibration standards specifically formulated for steel matrix analysis, addressing common interference issues encountered in high-iron samples.

Strengths: Vertical integration with steel production processes; practical implementation experience in high-volume manufacturing environments; specialized expertise in correlating analytical results with product quality parameters. Weaknesses: Technologies primarily optimized for internal use rather than commercial analytical platforms; less emphasis on detection limit optimization compared to dedicated instrument manufacturers.

Applied Spectra, Inc.

Technical Solution: Applied Spectra has developed advanced LIBS (Laser Induced Breakdown Spectroscopy) technology that complements traditional ICP-MS and ICP-OES methods for metal analysis in steel. Their J200 LIBS instrument incorporates proprietary software algorithms that enable rapid elemental mapping and quantification without sample preparation. The company has also pioneered the integration of LIBS with LA-ICP-MS (Laser Ablation ICP-MS) in their tandem LIBS/LA system, allowing simultaneous surface and depth profiling of steel samples with detection limits in the ppb range for trace elements and ppm range for major constituents. This dual-technology approach provides comprehensive elemental analysis capabilities that address limitations of standalone ICP techniques.

Strengths: Rapid analysis with minimal sample preparation; direct solid sampling capability; spatial resolution for heterogeneity assessment; complementary to traditional ICP methods. Weaknesses: Lower sensitivity than standalone ICP-MS for some trace elements; requires specialized expertise for operation and data interpretation.

Technical Innovations in Metal Concentration Detection

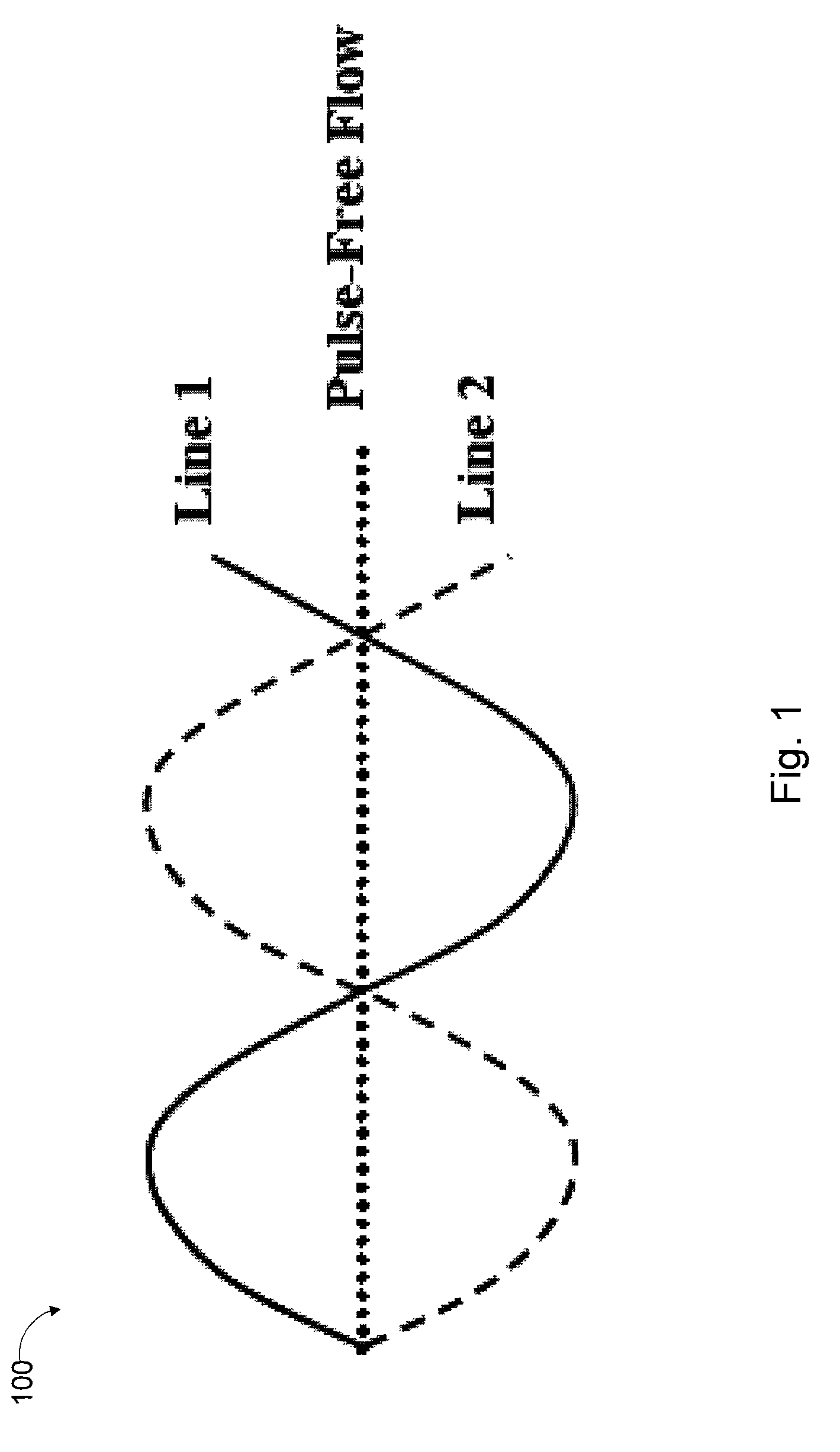

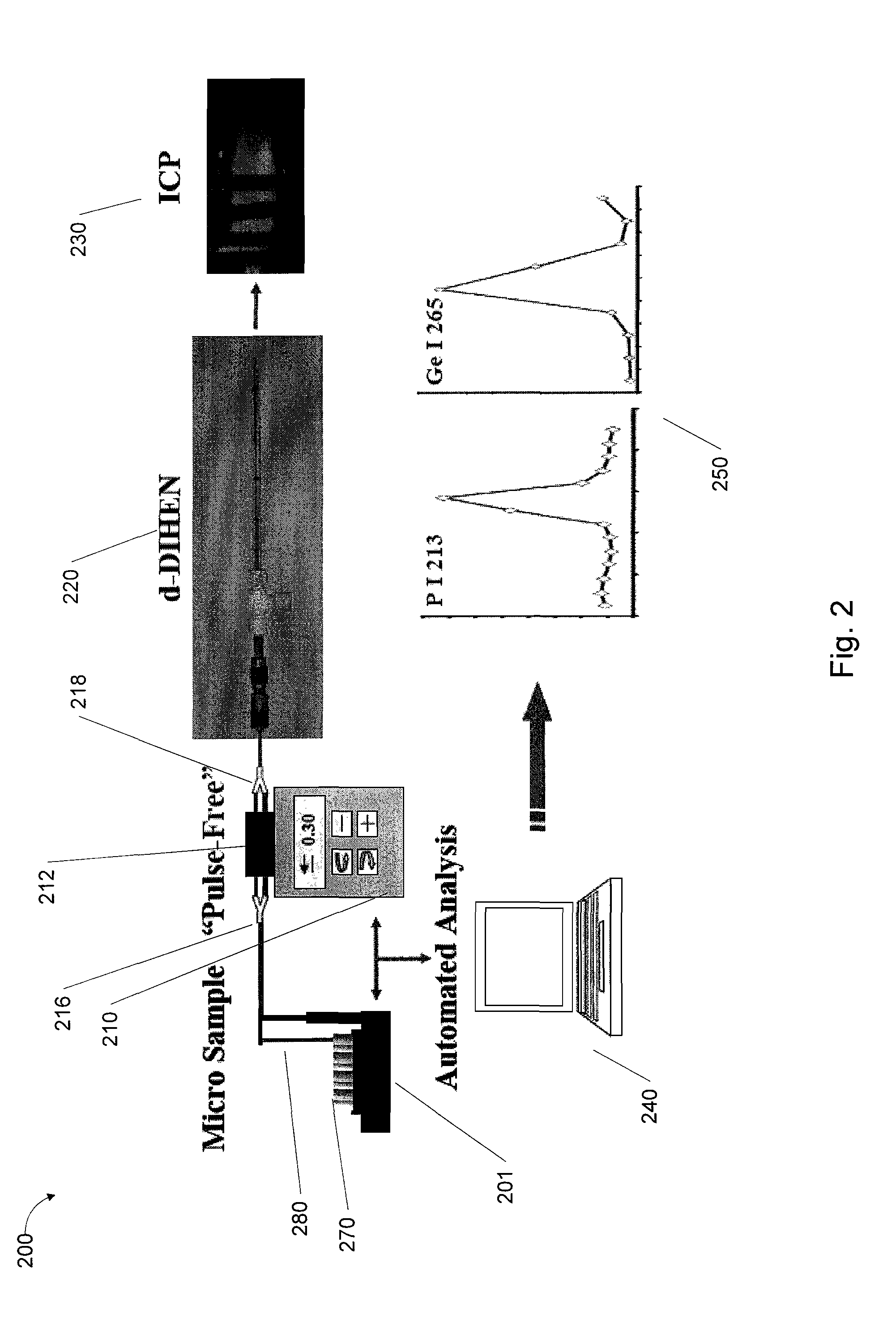

System and Method For Automated Sample Introduction

PatentInactiveUS20100229999A1

Innovation

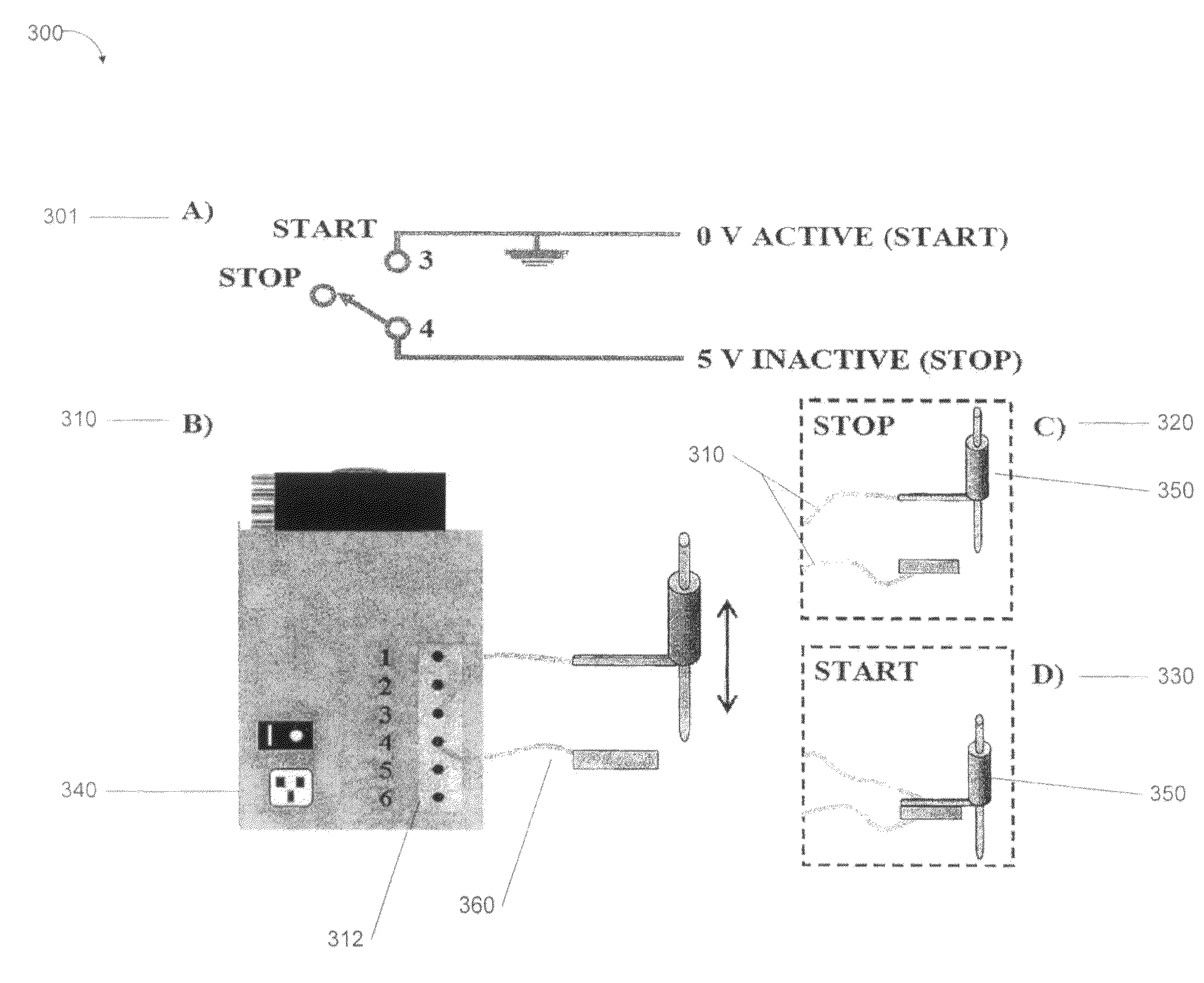

- A demountable direct injection high efficiency nebulizer (d-DIHEN) system is integrated with HP-ICP-OES, enabling pulse-free sample aspiration and automated sampling, reducing sample consumption and increasing sensitivity, allowing for precise phosphorus content measurement in acid-digested nucleotides and DNA.

Inductively coupled plasma mass spectrometry and emission analyzer

PatentInactiveJP2008064488A

Innovation

- Incorporation of oxygen- or air-permeable tubes or membranes in the gas supply lines, combined with a switching valve, allows controlled introduction of oxygen or air into the plasma to combat carbon deposition and spectral interference without additional equipment, using an automatic controller to synchronize oxygen introduction with organic solvent presence.

Cost-Benefit Analysis of Analytical Methods

When evaluating analytical methods for metal concentration analysis in steel production, cost-benefit analysis becomes a critical decision-making factor. ICP-MS (Inductively Coupled Plasma Mass Spectrometry) and ICP-OES (Inductively Coupled Plasma Optical Emission Spectrometry) represent significant investments that must be justified through comprehensive financial assessment.

Initial acquisition costs reveal substantial differences between these technologies. ICP-OES systems typically range from $60,000 to $150,000, while ICP-MS instruments command higher prices between $150,000 and $350,000. This price differential of approximately 2-3 times higher for ICP-MS represents a significant capital expenditure consideration for steel manufacturers.

Operational expenses further differentiate these technologies. ICP-OES demonstrates lower running costs with argon consumption at 15-20 L/min compared to ICP-MS's combined requirement of cooling and nebulizer gas totaling 16-20 L/min plus additional helium or hydrogen for collision/reaction cells. Maintenance requirements also favor ICP-OES, with annual service costs averaging $5,000-$10,000 versus $10,000-$20,000 for ICP-MS systems.

Sample throughput economics must be considered alongside detection capabilities. While ICP-OES processes samples more rapidly (20-30 samples per hour versus 15-25 for ICP-MS), the superior detection limits of ICP-MS (parts per trillion versus parts per billion for ICP-OES) may justify its higher costs when analyzing trace elements critical to steel quality.

Staff expertise requirements represent another significant cost factor. ICP-MS demands more specialized training and typically commands higher operator salaries ($65,000-$85,000 annually) compared to ICP-OES operators ($55,000-$70,000). Training investment is similarly higher for ICP-MS, requiring approximately 2-3 weeks versus 1-2 weeks for ICP-OES.

Return on investment calculations must incorporate regulatory compliance benefits. ICP-MS offers superior capability for meeting increasingly stringent international standards for trace element detection in steel products, potentially avoiding costly non-compliance penalties and product recalls that could exceed millions of dollars.

Long-term value assessment reveals that while ICP-MS requires higher initial investment, its superior analytical capabilities may deliver greater value over a 7-10 year instrument lifecycle, particularly for steel manufacturers producing high-specification products where trace element control directly impacts product performance and market value.

Initial acquisition costs reveal substantial differences between these technologies. ICP-OES systems typically range from $60,000 to $150,000, while ICP-MS instruments command higher prices between $150,000 and $350,000. This price differential of approximately 2-3 times higher for ICP-MS represents a significant capital expenditure consideration for steel manufacturers.

Operational expenses further differentiate these technologies. ICP-OES demonstrates lower running costs with argon consumption at 15-20 L/min compared to ICP-MS's combined requirement of cooling and nebulizer gas totaling 16-20 L/min plus additional helium or hydrogen for collision/reaction cells. Maintenance requirements also favor ICP-OES, with annual service costs averaging $5,000-$10,000 versus $10,000-$20,000 for ICP-MS systems.

Sample throughput economics must be considered alongside detection capabilities. While ICP-OES processes samples more rapidly (20-30 samples per hour versus 15-25 for ICP-MS), the superior detection limits of ICP-MS (parts per trillion versus parts per billion for ICP-OES) may justify its higher costs when analyzing trace elements critical to steel quality.

Staff expertise requirements represent another significant cost factor. ICP-MS demands more specialized training and typically commands higher operator salaries ($65,000-$85,000 annually) compared to ICP-OES operators ($55,000-$70,000). Training investment is similarly higher for ICP-MS, requiring approximately 2-3 weeks versus 1-2 weeks for ICP-OES.

Return on investment calculations must incorporate regulatory compliance benefits. ICP-MS offers superior capability for meeting increasingly stringent international standards for trace element detection in steel products, potentially avoiding costly non-compliance penalties and product recalls that could exceed millions of dollars.

Long-term value assessment reveals that while ICP-MS requires higher initial investment, its superior analytical capabilities may deliver greater value over a 7-10 year instrument lifecycle, particularly for steel manufacturers producing high-specification products where trace element control directly impacts product performance and market value.

Quality Control Standards and Compliance Requirements

Quality control in steel manufacturing requires adherence to stringent standards and compliance requirements, particularly when utilizing analytical techniques like ICP-MS and ICP-OES for metal concentration analysis. The steel industry operates under several international and regional regulatory frameworks that dictate acceptable limits for various elements and impurities.

ISO standards play a crucial role in this domain, with ISO 17025 establishing general requirements for the competence of testing laboratories. For steel analysis specifically, ISO 14284 outlines sampling procedures for determination of chemical composition, while ISO 22674 addresses requirements for metallic materials used in fixed and removable restorations and appliances.

ASTM International provides complementary standards, including ASTM E1086 for standard test methods for optical emission vacuum spectrometric analysis of stainless steel and ASTM E2465 for determination of trace elements in steel using ICP-MS. These standards often specify detection limits, precision requirements, and calibration procedures that directly impact the choice between ICP-MS and ICP-OES.

Regulatory bodies such as the European Union's Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation impose additional requirements on metal content analysis. These regulations establish maximum concentration values for certain hazardous substances in various products, including steel components.

Quality management systems like ISO 9001 further influence analytical method selection by emphasizing measurement traceability and uncertainty. When implementing either ICP-MS or ICP-OES, laboratories must demonstrate that their chosen technique meets the required detection limits and precision levels specified in these standards.

Industry-specific standards also exist, such as those from the Society of Automotive Engineers (SAE) for automotive-grade steel or American Petroleum Institute (API) specifications for oil and gas applications. These standards often include specific requirements for trace element analysis that may favor either ICP-MS or ICP-OES depending on the elements of interest and their concentration ranges.

Compliance documentation requirements represent another consideration when selecting between these analytical techniques. The chosen method must generate results that can be properly documented according to regulatory requirements, including calibration records, quality control samples, and measurement uncertainty calculations. ICP-MS typically offers advantages for documenting ultra-trace element compliance, while ICP-OES may be preferred for major and minor element documentation where higher concentrations are involved.

ISO standards play a crucial role in this domain, with ISO 17025 establishing general requirements for the competence of testing laboratories. For steel analysis specifically, ISO 14284 outlines sampling procedures for determination of chemical composition, while ISO 22674 addresses requirements for metallic materials used in fixed and removable restorations and appliances.

ASTM International provides complementary standards, including ASTM E1086 for standard test methods for optical emission vacuum spectrometric analysis of stainless steel and ASTM E2465 for determination of trace elements in steel using ICP-MS. These standards often specify detection limits, precision requirements, and calibration procedures that directly impact the choice between ICP-MS and ICP-OES.

Regulatory bodies such as the European Union's Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation impose additional requirements on metal content analysis. These regulations establish maximum concentration values for certain hazardous substances in various products, including steel components.

Quality management systems like ISO 9001 further influence analytical method selection by emphasizing measurement traceability and uncertainty. When implementing either ICP-MS or ICP-OES, laboratories must demonstrate that their chosen technique meets the required detection limits and precision levels specified in these standards.

Industry-specific standards also exist, such as those from the Society of Automotive Engineers (SAE) for automotive-grade steel or American Petroleum Institute (API) specifications for oil and gas applications. These standards often include specific requirements for trace element analysis that may favor either ICP-MS or ICP-OES depending on the elements of interest and their concentration ranges.

Compliance documentation requirements represent another consideration when selecting between these analytical techniques. The chosen method must generate results that can be properly documented according to regulatory requirements, including calibration records, quality control samples, and measurement uncertainty calculations. ICP-MS typically offers advantages for documenting ultra-trace element compliance, while ICP-OES may be preferred for major and minor element documentation where higher concentrations are involved.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!