ICP-MS vs EPMA: What Performs Better in Trace Element Detection?

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Trace Element Detection Technology Background and Objectives

Trace element detection has evolved significantly over the past several decades, transforming from rudimentary chemical analysis methods to sophisticated instrumental techniques capable of detecting elements at parts per billion (ppb) or even parts per trillion (ppt) levels. The journey began with colorimetric and gravimetric analyses in the early 20th century, progressing through atomic absorption spectroscopy (AAS) in the 1950s, to today's advanced technologies like Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Electron Probe Microanalysis (EPMA).

The development of trace element detection technologies has been driven by increasing demands across multiple industries including environmental monitoring, geological exploration, materials science, semiconductor manufacturing, and biomedical research. Each advancement has pushed the boundaries of detection limits, precision, accuracy, and spatial resolution, enabling scientists to answer increasingly complex questions about elemental composition and distribution.

ICP-MS, introduced commercially in the 1980s, revolutionized trace element analysis by combining the high-temperature ICP source with a mass spectrometer, allowing for multi-element detection with exceptional sensitivity. Meanwhile, EPMA, developed in the 1950s, has evolved to become a cornerstone technique for in-situ microanalysis, providing spatial resolution at the micrometer scale while maintaining quantitative accuracy.

The technological trajectory shows a clear trend toward lower detection limits, higher throughput, improved spatial resolution, and enhanced multi-element capabilities. Recent innovations have focused on reducing interferences, improving sample introduction systems, and developing more sophisticated data processing algorithms to extract meaningful information from complex samples.

The primary objective of modern trace element detection technology is to achieve the optimal balance between sensitivity, accuracy, precision, spatial resolution, and analytical throughput. This balance varies significantly depending on the application context, creating distinct technological niches where either ICP-MS or EPMA may excel.

Looking forward, the field is moving toward more integrated analytical approaches, combining complementary techniques to overcome individual limitations. Hybrid instruments and correlative microscopy approaches are emerging, allowing researchers to obtain comprehensive elemental information across multiple scales and concentration ranges.

The ultimate goal remains consistent: to develop analytical tools capable of accurately quantifying trace elements in increasingly complex matrices, with minimal sample preparation, maximum automation, and real-time data processing capabilities. This evolution continues to be driven by the growing recognition of trace elements' critical role in numerous scientific disciplines and industrial applications.

The development of trace element detection technologies has been driven by increasing demands across multiple industries including environmental monitoring, geological exploration, materials science, semiconductor manufacturing, and biomedical research. Each advancement has pushed the boundaries of detection limits, precision, accuracy, and spatial resolution, enabling scientists to answer increasingly complex questions about elemental composition and distribution.

ICP-MS, introduced commercially in the 1980s, revolutionized trace element analysis by combining the high-temperature ICP source with a mass spectrometer, allowing for multi-element detection with exceptional sensitivity. Meanwhile, EPMA, developed in the 1950s, has evolved to become a cornerstone technique for in-situ microanalysis, providing spatial resolution at the micrometer scale while maintaining quantitative accuracy.

The technological trajectory shows a clear trend toward lower detection limits, higher throughput, improved spatial resolution, and enhanced multi-element capabilities. Recent innovations have focused on reducing interferences, improving sample introduction systems, and developing more sophisticated data processing algorithms to extract meaningful information from complex samples.

The primary objective of modern trace element detection technology is to achieve the optimal balance between sensitivity, accuracy, precision, spatial resolution, and analytical throughput. This balance varies significantly depending on the application context, creating distinct technological niches where either ICP-MS or EPMA may excel.

Looking forward, the field is moving toward more integrated analytical approaches, combining complementary techniques to overcome individual limitations. Hybrid instruments and correlative microscopy approaches are emerging, allowing researchers to obtain comprehensive elemental information across multiple scales and concentration ranges.

The ultimate goal remains consistent: to develop analytical tools capable of accurately quantifying trace elements in increasingly complex matrices, with minimal sample preparation, maximum automation, and real-time data processing capabilities. This evolution continues to be driven by the growing recognition of trace elements' critical role in numerous scientific disciplines and industrial applications.

Market Applications and Analytical Demands

The trace element detection market is experiencing significant growth, driven by increasing demands across multiple industries for precise analytical capabilities. The global analytical instrumentation market, which includes trace element detection technologies, is projected to reach $85 billion by 2025, with a compound annual growth rate of approximately 6.7%. Within this expanding market, both ICP-MS and EPMA occupy critical niches, serving distinct but overlapping analytical needs.

In the semiconductor industry, trace element detection is essential for quality control and failure analysis. Manufacturers require detection limits in the parts-per-trillion range to identify contaminants that could compromise chip performance. ICP-MS has become the preferred method in this sector due to its superior detection limits and ability to analyze multiple elements simultaneously, enabling higher throughput in production environments.

The geological sciences represent another major market segment, where trace element analysis informs mineral exploration, ore characterization, and geochemical mapping. Here, both technologies find application, with EPMA preferred for spatial resolution in mineral phase identification and ICP-MS valued for bulk composition analysis with higher sensitivity for rare earth elements and precious metals.

Environmental monitoring constitutes a rapidly growing application area, particularly as regulatory frameworks worldwide impose stricter limits on pollutants. Water quality assessment, soil contamination studies, and atmospheric particulate analysis all require trace element detection capabilities. ICP-MS dominates this sector due to its lower detection limits and ability to handle liquid samples directly, though EPMA maintains relevance for particulate matter characterization.

The biomedical research and pharmaceutical sectors present unique analytical challenges, requiring detection of trace elements in biological tissues and drug formulations. ICP-MS has gained significant traction in these applications due to its compatibility with biological sample preparation methods and superior sensitivity for bioaccumulated metals and metalloproteins.

Advanced materials development represents an emerging market where both technologies are finding increased utilization. The characterization of novel alloys, composites, and nanomaterials demands both spatial resolution and high sensitivity. This application area often requires complementary use of both techniques, with EPMA providing microstructural context and ICP-MS delivering quantitative elemental profiles.

The analytical service provider market has responded to these diverse needs by increasingly offering both technologies as complementary services. Contract research organizations and testing laboratories have recognized that comprehensive trace element analysis often requires multiple methodological approaches tailored to specific client requirements.

In the semiconductor industry, trace element detection is essential for quality control and failure analysis. Manufacturers require detection limits in the parts-per-trillion range to identify contaminants that could compromise chip performance. ICP-MS has become the preferred method in this sector due to its superior detection limits and ability to analyze multiple elements simultaneously, enabling higher throughput in production environments.

The geological sciences represent another major market segment, where trace element analysis informs mineral exploration, ore characterization, and geochemical mapping. Here, both technologies find application, with EPMA preferred for spatial resolution in mineral phase identification and ICP-MS valued for bulk composition analysis with higher sensitivity for rare earth elements and precious metals.

Environmental monitoring constitutes a rapidly growing application area, particularly as regulatory frameworks worldwide impose stricter limits on pollutants. Water quality assessment, soil contamination studies, and atmospheric particulate analysis all require trace element detection capabilities. ICP-MS dominates this sector due to its lower detection limits and ability to handle liquid samples directly, though EPMA maintains relevance for particulate matter characterization.

The biomedical research and pharmaceutical sectors present unique analytical challenges, requiring detection of trace elements in biological tissues and drug formulations. ICP-MS has gained significant traction in these applications due to its compatibility with biological sample preparation methods and superior sensitivity for bioaccumulated metals and metalloproteins.

Advanced materials development represents an emerging market where both technologies are finding increased utilization. The characterization of novel alloys, composites, and nanomaterials demands both spatial resolution and high sensitivity. This application area often requires complementary use of both techniques, with EPMA providing microstructural context and ICP-MS delivering quantitative elemental profiles.

The analytical service provider market has responded to these diverse needs by increasingly offering both technologies as complementary services. Contract research organizations and testing laboratories have recognized that comprehensive trace element analysis often requires multiple methodological approaches tailored to specific client requirements.

ICP-MS and EPMA Technical Limitations and Challenges

Despite their widespread application in trace element detection, both ICP-MS and EPMA face significant technical limitations that impact their performance and applicability. ICP-MS encounters challenges with isobaric interferences, where different elements or molecular species with the same mass-to-charge ratio cannot be distinguished by conventional quadrupole mass analyzers. This becomes particularly problematic when analyzing complex matrices containing multiple elements with overlapping isotopes.

Sample preparation for ICP-MS presents another substantial challenge, as the technique requires complete dissolution of solid samples, which can be difficult for certain refractory minerals or alloys. Incomplete dissolution leads to biased results and underestimation of element concentrations. Additionally, the plasma-based ionization process in ICP-MS can suffer from matrix effects, where the presence of high concentrations of certain elements suppresses or enhances the ionization of other elements.

EPMA faces its own set of technical constraints, primarily related to detection limits. While ICP-MS can detect elements at parts per billion (ppb) levels, EPMA typically has detection limits in the parts per million (ppm) range, making it less suitable for ultra-trace element analysis. This limitation stems from the inherent background noise in X-ray detection systems and the relatively low efficiency of X-ray production compared to ion generation.

Spatial resolution presents another challenge for both techniques but in different ways. EPMA offers superior spatial resolution (typically 1-2 μm) compared to conventional solution-based ICP-MS, but this comes at the cost of sensitivity. Laser ablation ICP-MS has improved spatial capabilities but still cannot match EPMA's spatial precision for microanalysis applications.

Element-specific challenges also exist for both techniques. Light elements (Z<11) are difficult to analyze with EPMA due to low-energy X-rays being easily absorbed before detection. Conversely, ICP-MS struggles with certain elements like Si and S due to polyatomic interferences from plasma gases and sample matrices.

Instrument stability and drift represent ongoing challenges for both technologies. ICP-MS requires frequent recalibration due to signal drift over time, while EPMA faces issues with beam current stability and detector efficiency changes during long analytical sessions. These instabilities necessitate frequent standardization and quality control measures.

Cost considerations and technical expertise requirements further constrain the widespread application of both techniques. ICP-MS systems typically require specialized laboratory environments, high-purity reagents, and trained operators to manage complex interference correction procedures. EPMA demands expertise in both electron microscopy and X-ray microanalysis, with significant time investment needed for proper standardization and matrix correction procedures.

Sample preparation for ICP-MS presents another substantial challenge, as the technique requires complete dissolution of solid samples, which can be difficult for certain refractory minerals or alloys. Incomplete dissolution leads to biased results and underestimation of element concentrations. Additionally, the plasma-based ionization process in ICP-MS can suffer from matrix effects, where the presence of high concentrations of certain elements suppresses or enhances the ionization of other elements.

EPMA faces its own set of technical constraints, primarily related to detection limits. While ICP-MS can detect elements at parts per billion (ppb) levels, EPMA typically has detection limits in the parts per million (ppm) range, making it less suitable for ultra-trace element analysis. This limitation stems from the inherent background noise in X-ray detection systems and the relatively low efficiency of X-ray production compared to ion generation.

Spatial resolution presents another challenge for both techniques but in different ways. EPMA offers superior spatial resolution (typically 1-2 μm) compared to conventional solution-based ICP-MS, but this comes at the cost of sensitivity. Laser ablation ICP-MS has improved spatial capabilities but still cannot match EPMA's spatial precision for microanalysis applications.

Element-specific challenges also exist for both techniques. Light elements (Z<11) are difficult to analyze with EPMA due to low-energy X-rays being easily absorbed before detection. Conversely, ICP-MS struggles with certain elements like Si and S due to polyatomic interferences from plasma gases and sample matrices.

Instrument stability and drift represent ongoing challenges for both technologies. ICP-MS requires frequent recalibration due to signal drift over time, while EPMA faces issues with beam current stability and detector efficiency changes during long analytical sessions. These instabilities necessitate frequent standardization and quality control measures.

Cost considerations and technical expertise requirements further constrain the widespread application of both techniques. ICP-MS systems typically require specialized laboratory environments, high-purity reagents, and trained operators to manage complex interference correction procedures. EPMA demands expertise in both electron microscopy and X-ray microanalysis, with significant time investment needed for proper standardization and matrix correction procedures.

Comparative Analysis of ICP-MS and EPMA Methodologies

01 ICP-MS technology for trace element detection

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is a powerful analytical technique for detecting trace elements with high sensitivity and precision. This technology can detect elements at parts per billion (ppb) or even parts per trillion (ppt) levels. ICP-MS works by ionizing the sample with inductively coupled plasma and then using a mass spectrometer to separate and quantify the ions. This technique is particularly valuable for analyzing complex matrices and can detect multiple elements simultaneously.- ICP-MS technology for trace element detection: Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is a powerful analytical technique for detecting trace elements with high sensitivity and precision. It can detect elements at parts per billion (ppb) or even parts per trillion (ppt) levels. The technique involves ionizing the sample with inductively coupled plasma and then using mass spectrometry to separate and quantify the ions. ICP-MS is particularly valuable for multi-element analysis in complex matrices and has applications in environmental monitoring, geological studies, and materials science.

- EPMA technology for microanalysis and element mapping: Electron Probe Micro-Analysis (EPMA) is a non-destructive analytical technique used for determining the chemical composition of small volumes of solid materials. It works by bombarding a sample with an electron beam and analyzing the characteristic X-rays emitted. EPMA provides high spatial resolution for element mapping and can detect elements at concentrations down to approximately 100 ppm. This technique is particularly useful for analyzing the distribution of elements in heterogeneous samples and for characterizing microstructures in materials.

- Comparative performance of ICP-MS and EPMA for trace analysis: When comparing ICP-MS and EPMA for trace element detection, ICP-MS generally offers superior detection limits (often sub-ppb) and is better suited for ultra-trace analysis. EPMA provides better spatial resolution and is excellent for in-situ microanalysis but has higher detection limits (typically 10-100 ppm). ICP-MS requires sample dissolution, making it destructive, while EPMA is non-destructive and preserves spatial information. The choice between these techniques depends on the specific analytical requirements, including detection limits needed, sample size, preservation needs, and whether spatial distribution information is required.

- Sample preparation methods for enhanced trace element detection: Proper sample preparation is crucial for optimizing trace element detection performance in both ICP-MS and EPMA. For ICP-MS, this includes acid digestion, dilution protocols, and matrix matching to minimize interferences. For EPMA, sample preparation involves polishing to create flat surfaces, carbon coating to prevent charging, and careful selection of standards. Advanced preparation techniques such as pre-concentration, matrix separation, and specialized dissolution methods can significantly improve detection limits and analytical precision for challenging samples or ultra-trace elements.

- Innovations in instrumentation for improved detection performance: Recent technological innovations have significantly enhanced the trace element detection capabilities of both ICP-MS and EPMA. These advancements include collision/reaction cell technology in ICP-MS to reduce polyatomic interferences, high-sensitivity detectors, improved vacuum systems, and advanced software for data processing. For EPMA, developments include higher brightness electron sources, more efficient X-ray detectors, and improved wavelength-dispersive spectrometers. These innovations have pushed detection limits lower while improving precision, accuracy, and sample throughput for both techniques.

02 EPMA technology for microanalysis of materials

Electron Probe Micro-Analysis (EPMA) is a non-destructive analytical technique used for determining the chemical composition of small volumes of solid materials. EPMA uses a focused beam of electrons to excite characteristic X-rays within a sample, allowing for the identification and quantification of elements present. This technique provides high spatial resolution for microanalysis and is particularly useful for analyzing the distribution of elements in heterogeneous samples. EPMA can detect elements at concentrations down to approximately 100 ppm.Expand Specific Solutions03 Comparative performance of ICP-MS and EPMA for trace element analysis

When comparing ICP-MS and EPMA for trace element detection, ICP-MS generally offers superior detection limits, often 2-3 orders of magnitude better than EPMA. While ICP-MS excels at ultra-trace analysis with detection limits in the ppb to ppt range, EPMA provides better spatial resolution for microanalysis. ICP-MS requires sample dissolution, making it destructive, whereas EPMA is non-destructive and preserves spatial information. The choice between these techniques depends on whether priority is given to detection limits (ICP-MS) or spatial resolution and non-destructive analysis (EPMA).Expand Specific Solutions04 Sample preparation and handling for trace element analysis

Proper sample preparation is crucial for accurate trace element detection using both ICP-MS and EPMA. For ICP-MS, samples typically require digestion or dissolution to convert solid samples into liquid form, often using acids or other reagents. Contamination control is essential, as even minor contamination can significantly affect results at trace levels. For EPMA, samples must be polished and coated with a conductive material. The preparation methods significantly impact the detection limits, precision, and accuracy of the analytical results for both techniques.Expand Specific Solutions05 Advanced developments and applications in trace element detection

Recent advancements in ICP-MS and EPMA technologies have further enhanced trace element detection capabilities. These include the development of high-resolution ICP-MS systems, laser ablation ICP-MS for direct solid sampling, and field emission EPMA for improved spatial resolution. These technologies are being applied in various fields including environmental monitoring, geological studies, materials science, and semiconductor manufacturing. The integration of these analytical techniques with other methods and automated sample handling systems has expanded their applications and improved throughput for trace element analysis.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The ICP-MS vs EPMA trace element detection market is in a growth phase, with increasing demand across scientific research, environmental monitoring, and industrial applications. The global market size for analytical instruments is expanding, driven by stringent regulatory requirements and technological advancements. ICP-MS technology demonstrates higher maturity for trace element detection with superior sensitivity at parts-per-trillion levels, while EPMA offers better spatial resolution for microanalysis. Key players include established analytical instrument manufacturers like Revvity Health Sciences and SPECTRO Analytical, alongside specialized companies such as Kimia Analytics and Elemental Scientific focusing on ICP-MS innovations. Research institutions including CNRS, Swiss Federal Institute of Technology, and China University of Geosciences are advancing both technologies through collaborative research and applications development.

Micromass UK Ltd.

Technical Solution: Micromass UK Ltd. has developed advanced ICP-MS systems featuring collision/reaction cell technology that significantly reduces polyatomic interferences, a major limitation in trace element analysis. Their systems employ quadrupole and time-of-flight mass analyzers that achieve detection limits in the parts-per-trillion (ppt) range for most elements. The company's ICP-MS instruments incorporate unique sample introduction systems that improve ionization efficiency and reduce matrix effects, allowing for more accurate quantification of trace elements in complex samples. Micromass has also pioneered software solutions that automate calibration procedures and implement sophisticated interference correction algorithms, enhancing the reliability of multi-element analyses across diverse sample types. Their instruments are particularly noted for high-throughput capabilities, processing up to 60-80 samples per hour while maintaining analytical precision.

Strengths: Superior detection limits (ppt range) for most elements; excellent interference management through collision/reaction cell technology; high sample throughput. Weaknesses: Higher operational costs compared to EPMA; requires sample dissolution which may introduce contamination; more complex operation requiring specialized training.

Elemental Scientific, Inc.

Technical Solution: Elemental Scientific, Inc. specializes in sample introduction systems and accessories for ICP-MS that significantly enhance analytical performance. Their technology includes automated micro-flow nebulizers that reduce sample consumption to as little as 20 μL/min while improving sensitivity by up to 10 times compared to conventional systems. The company has developed integrated sample preparation platforms that combine automated dilution, internal standard addition, and calibration to minimize human error and contamination risks. Their prepFAST system enables online matrix removal and analyte preconcentration, improving detection limits for challenging environmental and biological samples. Elemental Scientific's apex-IR desolvation system removes solvent load to the plasma, reducing oxide formation and enhancing sensitivity for difficult elements like As, Se, and Hg. Their technologies are compatible with all major ICP-MS manufacturers, making them versatile solutions for laboratories seeking to optimize trace element detection capabilities.

Strengths: Significantly improves ICP-MS performance through specialized sample introduction; reduces sample consumption while enhancing sensitivity; compatible with multiple instrument platforms. Weaknesses: Adds additional cost to already expensive ICP-MS systems; requires technical expertise to optimize; primarily enhances ICP-MS rather than offering alternative analytical approaches.

Critical Performance Parameters and Detection Limits

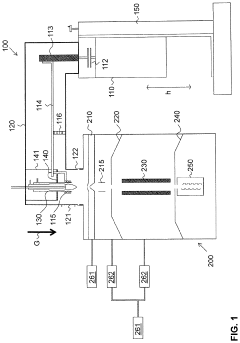

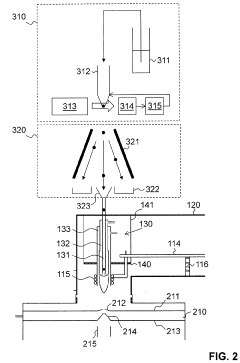

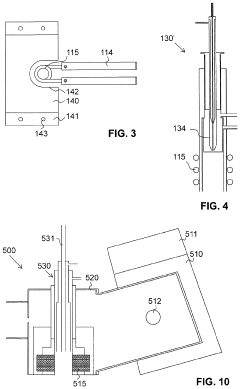

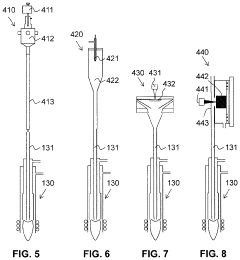

Ion source for inductively coupled plasma mass spectrometry

PatentActiveUS20220181135A1

Innovation

- An ICP source with a vertically oriented plasma torch and injector tube allows sample introduction along a downwards-pointing vertical direction, reducing reliance on carrier gas flow and enabling 100% transport efficiency by utilizing gravity, accommodating various sample sizes and types, and integrating with mass spectrometers for efficient ion extraction.

Sample Preparation Requirements and Considerations

Sample preparation represents a critical determinant in the analytical performance of both ICP-MS and EPMA techniques when detecting trace elements. The methodologies employed for sample preparation significantly influence detection limits, accuracy, precision, and overall reliability of the analytical results.

For ICP-MS analysis, samples typically require conversion to liquid form through acid digestion processes. Complete dissolution is essential, often necessitating combinations of strong acids such as HF, HNO3, HCl, and H2SO4 depending on the sample matrix. The digestion procedures may involve high-pressure vessels or microwave-assisted systems to enhance dissolution efficiency, particularly for refractory materials. Sample dilution factors must be carefully controlled to balance between minimizing matrix effects and maintaining adequate analyte concentrations above detection limits.

EPMA sample preparation focuses on creating flat, polished surfaces suitable for electron beam interaction. Samples are typically mounted in epoxy resin, ground with progressively finer abrasives, and polished to a mirror-like finish using diamond pastes or suspensions. The final surface must be free of relief, scratches, and contamination to ensure accurate quantification. Unlike ICP-MS, EPMA requires minimal chemical processing, reducing the risk of contamination but necessitating meticulous physical preparation.

Contamination control presents different challenges for each technique. ICP-MS is extremely sensitive to environmental contamination during sample processing, requiring ultra-clean laboratory conditions, high-purity reagents, and rigorous blank monitoring. EPMA faces contamination issues primarily during sample mounting and polishing, with carbon coating often applied to ensure conductivity for electron beam stability.

Sample homogeneity requirements also differ significantly. ICP-MS provides bulk analysis, requiring representative sampling and homogenization strategies for heterogeneous materials. In contrast, EPMA performs microanalysis at specific points, making it suitable for studying spatial variations but requiring multiple point analyses to characterize heterogeneous samples effectively.

Time considerations favor EPMA for rapid analysis of solid samples, as it requires minimal chemical processing. However, ICP-MS offers higher sample throughput once dissolution protocols are established, particularly for routine analyses of multiple elements across numerous samples.

The selection between these techniques must therefore consider not only analytical performance but also the practical aspects of sample preparation, including available expertise, equipment, time constraints, and the physical and chemical properties of the target materials.

For ICP-MS analysis, samples typically require conversion to liquid form through acid digestion processes. Complete dissolution is essential, often necessitating combinations of strong acids such as HF, HNO3, HCl, and H2SO4 depending on the sample matrix. The digestion procedures may involve high-pressure vessels or microwave-assisted systems to enhance dissolution efficiency, particularly for refractory materials. Sample dilution factors must be carefully controlled to balance between minimizing matrix effects and maintaining adequate analyte concentrations above detection limits.

EPMA sample preparation focuses on creating flat, polished surfaces suitable for electron beam interaction. Samples are typically mounted in epoxy resin, ground with progressively finer abrasives, and polished to a mirror-like finish using diamond pastes or suspensions. The final surface must be free of relief, scratches, and contamination to ensure accurate quantification. Unlike ICP-MS, EPMA requires minimal chemical processing, reducing the risk of contamination but necessitating meticulous physical preparation.

Contamination control presents different challenges for each technique. ICP-MS is extremely sensitive to environmental contamination during sample processing, requiring ultra-clean laboratory conditions, high-purity reagents, and rigorous blank monitoring. EPMA faces contamination issues primarily during sample mounting and polishing, with carbon coating often applied to ensure conductivity for electron beam stability.

Sample homogeneity requirements also differ significantly. ICP-MS provides bulk analysis, requiring representative sampling and homogenization strategies for heterogeneous materials. In contrast, EPMA performs microanalysis at specific points, making it suitable for studying spatial variations but requiring multiple point analyses to characterize heterogeneous samples effectively.

Time considerations favor EPMA for rapid analysis of solid samples, as it requires minimal chemical processing. However, ICP-MS offers higher sample throughput once dissolution protocols are established, particularly for routine analyses of multiple elements across numerous samples.

The selection between these techniques must therefore consider not only analytical performance but also the practical aspects of sample preparation, including available expertise, equipment, time constraints, and the physical and chemical properties of the target materials.

Cost-Benefit Analysis and Implementation Strategies

When evaluating ICP-MS and EPMA technologies for trace element detection, cost-benefit analysis reveals significant differences in initial investment and long-term operational expenses. ICP-MS systems typically range from $150,000 to $500,000, while EPMA instruments cost between $500,000 and $1.5 million. This substantial price difference makes ICP-MS more accessible for organizations with limited capital budgets.

Operational costs also favor ICP-MS, with annual maintenance expenses averaging $15,000-30,000 compared to EPMA's $30,000-60,000. ICP-MS consumes argon gas continuously, while EPMA requires less consumables but more specialized maintenance. Sample preparation costs for ICP-MS (dissolution and dilution) are generally lower than EPMA's requirements for polished, carbon-coated specimens.

Personnel considerations reveal that ICP-MS operation requires less specialized training, with technicians becoming proficient within 2-3 months. EPMA demands more extensive expertise, often requiring 6-12 months of training and advanced knowledge in electron optics and X-ray physics, translating to higher labor costs.

Implementation strategies should consider organizational needs and resources. For high-throughput environments analyzing multiple elements across numerous samples, ICP-MS offers superior efficiency with analysis times of 2-3 minutes per sample versus EPMA's 20-30 minutes. Laboratories focused on microanalysis and spatial distribution should prioritize EPMA despite higher costs.

A phased implementation approach often proves effective, beginning with ICP-MS for broad analytical capabilities, then adding EPMA when spatial resolution becomes critical. Alternatively, service-based models allow organizations to outsource analyses to specialized facilities, reducing capital expenditure while maintaining access to both technologies.

Cross-training staff on both platforms maximizes resource utilization and creates analytical redundancy. Implementing standardized workflows that direct samples to the appropriate technology based on detection limits, sample type, and required spatial resolution optimizes operational efficiency and cost-effectiveness.

Operational costs also favor ICP-MS, with annual maintenance expenses averaging $15,000-30,000 compared to EPMA's $30,000-60,000. ICP-MS consumes argon gas continuously, while EPMA requires less consumables but more specialized maintenance. Sample preparation costs for ICP-MS (dissolution and dilution) are generally lower than EPMA's requirements for polished, carbon-coated specimens.

Personnel considerations reveal that ICP-MS operation requires less specialized training, with technicians becoming proficient within 2-3 months. EPMA demands more extensive expertise, often requiring 6-12 months of training and advanced knowledge in electron optics and X-ray physics, translating to higher labor costs.

Implementation strategies should consider organizational needs and resources. For high-throughput environments analyzing multiple elements across numerous samples, ICP-MS offers superior efficiency with analysis times of 2-3 minutes per sample versus EPMA's 20-30 minutes. Laboratories focused on microanalysis and spatial distribution should prioritize EPMA despite higher costs.

A phased implementation approach often proves effective, beginning with ICP-MS for broad analytical capabilities, then adding EPMA when spatial resolution becomes critical. Alternatively, service-based models allow organizations to outsource analyses to specialized facilities, reducing capital expenditure while maintaining access to both technologies.

Cross-training staff on both platforms maximizes resource utilization and creates analytical redundancy. Implementing standardized workflows that direct samples to the appropriate technology based on detection limits, sample type, and required spatial resolution optimizes operational efficiency and cost-effectiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!