ICP-MS Calibration Drift: Causes and Solutions

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ICP-MS Technology Evolution and Objectives

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) has evolved significantly since its commercial introduction in the early 1980s. This analytical technique combines a high-temperature ICP source with a mass spectrometer to detect and quantify trace elements at concentrations as low as one part per trillion. The evolution of ICP-MS technology has been driven by the increasing demand for more accurate, sensitive, and reliable elemental analysis across various industries including environmental monitoring, pharmaceuticals, semiconductor manufacturing, and geological sciences.

The initial ICP-MS systems faced significant challenges with calibration stability, often requiring frequent recalibration due to signal drift. Throughout the 1990s, advancements in sample introduction systems, plasma generation technology, and interface design substantially improved instrument stability. The introduction of collision/reaction cell technology in the late 1990s represented a major breakthrough, addressing polyatomic interferences that previously limited analytical accuracy.

In the 2000s, the development of high-resolution ICP-MS systems further enhanced the technology's capabilities, allowing for better separation of analytes from interferences. Concurrently, improvements in detector technology and electronics led to wider dynamic ranges and lower detection limits. The integration of automated sample handling systems and sophisticated software algorithms for drift correction marked another significant advancement in the field.

Recent technological innovations have focused on addressing calibration drift issues through hardware improvements and advanced software solutions. Modern ICP-MS instruments incorporate internal standardization methods, automated quality control procedures, and real-time drift correction algorithms. The miniaturization of components and development of more energy-efficient systems have also contributed to greater stability and reduced maintenance requirements.

The primary objective in ICP-MS technology development today is achieving long-term calibration stability without sacrificing sensitivity or accuracy. This includes minimizing the effects of matrix interferences, reducing memory effects, and developing more robust plasma conditions that can withstand complex sample matrices. Additionally, there is a growing emphasis on developing sustainable solutions that reduce argon consumption and overall operational costs.

Looking forward, the integration of artificial intelligence and machine learning algorithms for predictive maintenance and automated optimization represents the next frontier in ICP-MS technology. These advancements aim to further minimize calibration drift by anticipating system fluctuations before they impact analytical results, ultimately moving toward "calibration-free" ICP-MS systems that maintain accuracy over extended analytical runs.

The initial ICP-MS systems faced significant challenges with calibration stability, often requiring frequent recalibration due to signal drift. Throughout the 1990s, advancements in sample introduction systems, plasma generation technology, and interface design substantially improved instrument stability. The introduction of collision/reaction cell technology in the late 1990s represented a major breakthrough, addressing polyatomic interferences that previously limited analytical accuracy.

In the 2000s, the development of high-resolution ICP-MS systems further enhanced the technology's capabilities, allowing for better separation of analytes from interferences. Concurrently, improvements in detector technology and electronics led to wider dynamic ranges and lower detection limits. The integration of automated sample handling systems and sophisticated software algorithms for drift correction marked another significant advancement in the field.

Recent technological innovations have focused on addressing calibration drift issues through hardware improvements and advanced software solutions. Modern ICP-MS instruments incorporate internal standardization methods, automated quality control procedures, and real-time drift correction algorithms. The miniaturization of components and development of more energy-efficient systems have also contributed to greater stability and reduced maintenance requirements.

The primary objective in ICP-MS technology development today is achieving long-term calibration stability without sacrificing sensitivity or accuracy. This includes minimizing the effects of matrix interferences, reducing memory effects, and developing more robust plasma conditions that can withstand complex sample matrices. Additionally, there is a growing emphasis on developing sustainable solutions that reduce argon consumption and overall operational costs.

Looking forward, the integration of artificial intelligence and machine learning algorithms for predictive maintenance and automated optimization represents the next frontier in ICP-MS technology. These advancements aim to further minimize calibration drift by anticipating system fluctuations before they impact analytical results, ultimately moving toward "calibration-free" ICP-MS systems that maintain accuracy over extended analytical runs.

Market Demand Analysis for Precise Elemental Analysis

The global market for precise elemental analysis continues to experience robust growth, driven primarily by increasing demands across multiple industries for accurate trace element detection and quantification. ICP-MS (Inductively Coupled Plasma Mass Spectrometry) technology has emerged as the gold standard for these applications due to its exceptional sensitivity, multi-element capabilities, and wide dynamic range.

The pharmaceutical sector represents one of the largest market segments, with stringent regulatory requirements necessitating precise elemental impurity testing in drug products. Recent implementation of ICH Q3D guidelines and USP <232>/<233> standards has significantly expanded the need for reliable ICP-MS instrumentation that can maintain calibration stability throughout extended analytical runs.

Environmental monitoring constitutes another substantial market driver, with government agencies and private laboratories requiring increasingly sensitive detection of heavy metals and other contaminants in water, soil, and air samples. The growing public awareness of environmental contamination has led to more comprehensive testing protocols that demand instruments with minimal calibration drift to ensure data integrity across large sample batches.

The food and beverage industry has similarly witnessed escalating demand for elemental analysis, particularly for detecting contaminants and verifying nutritional content. As global supply chains become more complex, the need for reliable testing methods that can maintain calibration across diverse sample matrices has become paramount for ensuring consumer safety and regulatory compliance.

Clinical diagnostics represents an emerging high-growth segment, with ICP-MS increasingly utilized for biomonitoring of essential and toxic elements in biological samples. The clinical environment demands particularly stable instrumentation due to the critical nature of patient diagnostics and the high throughput requirements of modern healthcare facilities.

Market research indicates that laboratories across these sectors consistently identify calibration drift as a significant pain point affecting productivity and data quality. A recent survey of analytical laboratories revealed that technicians spend approximately 15-20% of their operational time addressing calibration-related issues, representing a substantial efficiency loss and operational cost.

The economic impact of calibration drift extends beyond direct labor costs, encompassing sample reanalysis expenses, increased calibration standard consumption, and potential regulatory compliance issues. Consequently, there exists a clear market opportunity for technological solutions that can effectively mitigate ICP-MS calibration drift, with potential customers demonstrating willingness to invest in premium instrumentation that offers enhanced stability and reduced maintenance requirements.

The pharmaceutical sector represents one of the largest market segments, with stringent regulatory requirements necessitating precise elemental impurity testing in drug products. Recent implementation of ICH Q3D guidelines and USP <232>/<233> standards has significantly expanded the need for reliable ICP-MS instrumentation that can maintain calibration stability throughout extended analytical runs.

Environmental monitoring constitutes another substantial market driver, with government agencies and private laboratories requiring increasingly sensitive detection of heavy metals and other contaminants in water, soil, and air samples. The growing public awareness of environmental contamination has led to more comprehensive testing protocols that demand instruments with minimal calibration drift to ensure data integrity across large sample batches.

The food and beverage industry has similarly witnessed escalating demand for elemental analysis, particularly for detecting contaminants and verifying nutritional content. As global supply chains become more complex, the need for reliable testing methods that can maintain calibration across diverse sample matrices has become paramount for ensuring consumer safety and regulatory compliance.

Clinical diagnostics represents an emerging high-growth segment, with ICP-MS increasingly utilized for biomonitoring of essential and toxic elements in biological samples. The clinical environment demands particularly stable instrumentation due to the critical nature of patient diagnostics and the high throughput requirements of modern healthcare facilities.

Market research indicates that laboratories across these sectors consistently identify calibration drift as a significant pain point affecting productivity and data quality. A recent survey of analytical laboratories revealed that technicians spend approximately 15-20% of their operational time addressing calibration-related issues, representing a substantial efficiency loss and operational cost.

The economic impact of calibration drift extends beyond direct labor costs, encompassing sample reanalysis expenses, increased calibration standard consumption, and potential regulatory compliance issues. Consequently, there exists a clear market opportunity for technological solutions that can effectively mitigate ICP-MS calibration drift, with potential customers demonstrating willingness to invest in premium instrumentation that offers enhanced stability and reduced maintenance requirements.

Current Challenges in ICP-MS Calibration Stability

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) has become an indispensable analytical technique for trace element analysis across various industries. However, calibration drift remains one of the most persistent challenges affecting measurement accuracy and reliability. This issue manifests as a gradual deviation in instrument response over time, even when analyzing identical samples or standards, leading to compromised data quality and increased analytical uncertainty.

The primary causes of calibration drift in ICP-MS systems can be categorized into several key areas. Sample introduction system instabilities represent a significant contributor, where nebulizer clogging, peristaltic pump tubing degradation, and spray chamber temperature fluctuations lead to inconsistent sample delivery. These components are particularly susceptible to matrix effects from high-salt or organic-rich samples, exacerbating drift issues during extended analytical runs.

Plasma instabilities constitute another major source of calibration drift. Fluctuations in RF power, argon gas flow rates, and torch positioning can alter ionization efficiency and ion transmission, particularly affecting elements with high ionization potentials. Additionally, ambient laboratory conditions including temperature, humidity, and barometric pressure variations can induce subtle yet significant changes in plasma characteristics over time.

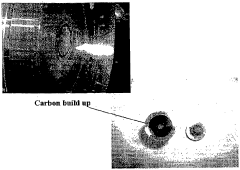

Interface region complications further contribute to drift phenomena. The sampling and skimmer cones experience progressive deposition of matrix components and analytes during operation, altering the ion beam profile and extraction efficiency. This cone degradation is especially problematic when analyzing samples with complex matrices, as the deposition rate accelerates and creates increasingly variable analytical conditions.

Ion optics and mass analyzer components also experience performance changes during extended operation. Charge build-up on ion lenses, quadrupole contamination, and detector fatigue all contribute to signal attenuation that varies by element and concentration, complicating correction attempts. Modern instruments incorporate electron multiplier detectors that, while highly sensitive, exhibit gain degradation over time that differs across the mass range.

Software-based drift correction approaches have shown limited success in addressing these multifaceted issues. Internal standardization remains the most common mitigation strategy, but selecting appropriate internal standards that behave identically to analytes across diverse sample types presents significant challenges. More sophisticated approaches like multivariate statistical corrections show promise but require extensive validation across different sample matrices.

The economic impact of calibration drift extends beyond data quality concerns, manifesting in increased quality control sample requirements, repeated calibrations, reduced sample throughput, and higher labor costs for method development and validation. These challenges collectively represent a significant barrier to wider ICP-MS adoption in routine analytical environments where operational efficiency is paramount.

The primary causes of calibration drift in ICP-MS systems can be categorized into several key areas. Sample introduction system instabilities represent a significant contributor, where nebulizer clogging, peristaltic pump tubing degradation, and spray chamber temperature fluctuations lead to inconsistent sample delivery. These components are particularly susceptible to matrix effects from high-salt or organic-rich samples, exacerbating drift issues during extended analytical runs.

Plasma instabilities constitute another major source of calibration drift. Fluctuations in RF power, argon gas flow rates, and torch positioning can alter ionization efficiency and ion transmission, particularly affecting elements with high ionization potentials. Additionally, ambient laboratory conditions including temperature, humidity, and barometric pressure variations can induce subtle yet significant changes in plasma characteristics over time.

Interface region complications further contribute to drift phenomena. The sampling and skimmer cones experience progressive deposition of matrix components and analytes during operation, altering the ion beam profile and extraction efficiency. This cone degradation is especially problematic when analyzing samples with complex matrices, as the deposition rate accelerates and creates increasingly variable analytical conditions.

Ion optics and mass analyzer components also experience performance changes during extended operation. Charge build-up on ion lenses, quadrupole contamination, and detector fatigue all contribute to signal attenuation that varies by element and concentration, complicating correction attempts. Modern instruments incorporate electron multiplier detectors that, while highly sensitive, exhibit gain degradation over time that differs across the mass range.

Software-based drift correction approaches have shown limited success in addressing these multifaceted issues. Internal standardization remains the most common mitigation strategy, but selecting appropriate internal standards that behave identically to analytes across diverse sample types presents significant challenges. More sophisticated approaches like multivariate statistical corrections show promise but require extensive validation across different sample matrices.

The economic impact of calibration drift extends beyond data quality concerns, manifesting in increased quality control sample requirements, repeated calibrations, reduced sample throughput, and higher labor costs for method development and validation. These challenges collectively represent a significant barrier to wider ICP-MS adoption in routine analytical environments where operational efficiency is paramount.

Current Drift Compensation Techniques and Approaches

01 Internal standard methods for drift correction

Internal standard methods involve adding known concentrations of elements not present in the sample to correct for calibration drift in ICP-MS. These standards are measured alongside the analytes and used to normalize the signal, compensating for sensitivity changes over time. This approach helps maintain measurement accuracy during long analytical runs by providing continuous drift correction based on the ratio of analyte signal to internal standard signal.- Internal standard methods for drift correction: Internal standard methods involve adding known concentrations of elements not present in the sample to correct for calibration drift in ICP-MS. These standards are measured alongside the sample and used to normalize the signal, compensating for variations in instrument sensitivity over time. This approach helps maintain measurement accuracy during long analytical runs by providing continuous drift correction.

- Automated calibration systems: Automated calibration systems for ICP-MS incorporate hardware and software solutions that periodically introduce calibration standards during analysis. These systems can detect drift in real-time and apply corrections automatically, reducing manual intervention. Some implementations include intelligent algorithms that predict drift patterns and adjust measurement parameters accordingly, ensuring consistent analytical performance over extended periods.

- Multi-point calibration techniques: Multi-point calibration techniques involve using multiple concentration levels of calibration standards to establish a robust calibration curve for ICP-MS analysis. This approach improves the accuracy of measurements across a wide concentration range and provides better resistance to drift effects. By periodically verifying against these multiple calibration points, analysts can detect and correct for instrument drift more effectively.

- Signal processing algorithms for drift compensation: Advanced signal processing algorithms can be applied to ICP-MS data to mathematically correct for calibration drift. These computational methods analyze signal patterns over time to identify and compensate for systematic variations in instrument response. Some approaches include machine learning techniques that adapt to specific instrument characteristics and can distinguish between different types of drift, applying appropriate corrections to maintain measurement accuracy.

- Hardware modifications for stability improvement: Hardware modifications to ICP-MS systems can significantly reduce calibration drift. These include temperature-controlled spray chambers, improved plasma torch designs, and stabilized power supplies that minimize fluctuations in operating conditions. Some innovations focus on sample introduction systems that provide more consistent aerosol generation, while others implement electronic feedback mechanisms that continuously adjust instrument parameters to maintain optimal performance.

02 Automated calibration systems for ICP-MS

Automated calibration systems for ICP-MS incorporate hardware and software solutions that periodically introduce calibration standards during analysis. These systems can detect drift in real-time and apply corrections automatically, reducing manual intervention. Some implementations include automated sample introduction systems that periodically inject calibration standards, while others utilize feedback mechanisms that adjust instrument parameters based on measured drift to maintain consistent performance.Expand Specific Solutions03 Mathematical correction algorithms for signal drift

Mathematical correction algorithms process raw ICP-MS data to compensate for calibration drift. These algorithms can include linear interpolation between calibration points, polynomial regression models, or more complex statistical approaches. Some methods apply time-dependent correction factors based on periodic measurements of quality control samples, while others use predictive models to estimate drift patterns and apply appropriate corrections to maintain measurement accuracy throughout analytical sessions.Expand Specific Solutions04 Hardware modifications to reduce calibration drift

Hardware modifications to ICP-MS systems can significantly reduce calibration drift at its source. These include temperature-controlled spray chambers, improved plasma torch designs, and stabilized power supplies. Some innovations focus on optimizing sample introduction systems to ensure consistent aerosol generation, while others implement electronic stabilization circuits for the mass analyzer components. These physical improvements help maintain stable operating conditions and reduce the need for frequent recalibration.Expand Specific Solutions05 Quality control protocols for monitoring and managing drift

Quality control protocols for ICP-MS establish systematic approaches to monitor and manage calibration drift during analytical sessions. These protocols include regular measurement of check standards, blank solutions, and certified reference materials at defined intervals. Some methods implement statistical process control techniques to identify when drift exceeds acceptable limits, triggering recalibration. Comprehensive protocols also include documentation procedures to track instrument performance over time and validate the reliability of analytical results.Expand Specific Solutions

Leading Manufacturers and Research Institutions in ICP-MS

The ICP-MS calibration drift market is in a growth phase, with increasing demand driven by expanding applications in environmental monitoring, pharmaceuticals, and research. The market size is projected to reach significant value due to the critical role of accurate calibration in analytical chemistry. Technologically, solutions range from basic to advanced, with companies like Agilent Technologies, PerkinElmer (Revvity Health Sciences), and Thermo Fisher leading innovation. Established players such as Applied Materials, Analog Devices, and Siemens AG contribute sophisticated electronic and measurement technologies, while academic institutions like Chongqing University and Beijing Technology & Business University provide research support. The competitive landscape features both specialized analytical instrument manufacturers and diversified technology corporations developing integrated calibration solutions.

Renishaw Plc

Technical Solution: Renishaw has developed specialized ICP-MS calibration solutions focused on laser ablation ICP-MS applications. Their technology centers on high-precision sample introduction systems that maintain consistent sample delivery to the plasma, significantly reducing drift caused by sample transport variations. Renishaw's calibration approach incorporates reference materials with matrix-matched standards that minimize differential matrix effects during extended analytical sessions. Their systems feature automated calibration verification routines that monitor drift patterns and alert operators when recalibration is necessary. Renishaw has pioneered the use of solid internal standards for laser ablation applications, providing continuous drift correction throughout sample analysis. Their software implements sophisticated drift correction algorithms that can distinguish between different drift mechanisms and apply appropriate mathematical corrections. Additionally, Renishaw's instruments incorporate plasma monitoring systems that detect changes in plasma conditions and automatically adjust operating parameters to maintain stable ionization efficiency[7][8].

Strengths: Specialized expertise in laser ablation ICP-MS applications; innovative solid-state calibration standards that provide superior long-term stability. Weaknesses: Solutions primarily focused on specialized applications rather than routine liquid sample analysis; higher technical expertise required for optimal implementation.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has applied their expertise in process control systems to develop advanced solutions for ICP-MS calibration drift management. Their approach focuses on environmental control systems that maintain stable laboratory conditions, minimizing drift caused by temperature and humidity fluctuations. Honeywell's technology includes precision gas delivery systems that ensure consistent argon flow to the plasma, addressing drift related to plasma instability. Their automated sample handling systems incorporate weight-based dilution verification to ensure consistent sample preparation, eliminating a major source of apparent calibration drift. Honeywell has developed specialized sensors that monitor critical ICP-MS operating parameters in real-time, enabling proactive intervention before drift becomes significant. Their control systems implement predictive maintenance algorithms that identify components approaching failure conditions that could contribute to calibration instability. Additionally, Honeywell's data management software applies statistical process control techniques to distinguish between random measurement variation and systematic calibration drift, optimizing recalibration frequency[9][10].

Strengths: Comprehensive environmental and process control approach that addresses root causes of drift; integration with laboratory information management systems for enhanced quality control. Weaknesses: Solutions often require significant laboratory infrastructure modifications; higher implementation complexity compared to instrument-specific approaches.

Key Innovations in Calibration Stability Research

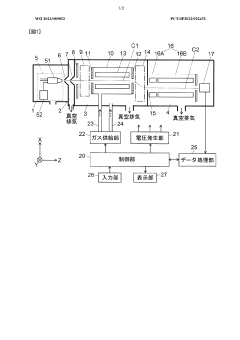

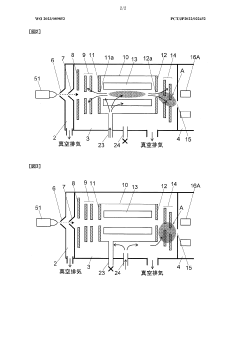

Inductively coupled plasma mass spectrometer

PatentWO2023089852A1

Innovation

- The ICP-MS system maintains a predetermined gas presence in the vacuum chamber during both measurement modes, reducing collisions of plasma gas particles with ion optical elements by introducing a gas outside the collision cell, thereby minimizing charge-up and signal drift.

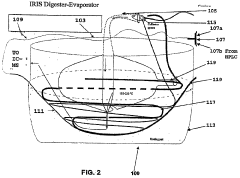

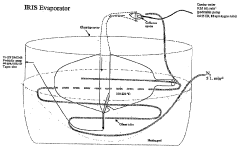

Iris digester-evaporator interface

PatentWO2010076580A1

Innovation

- The IRIS Digester-Evaporator interface device processes HPLC effluent by digesting samples with nitric acid and evaporating excess solvent on-line, eliminating organic solvents and optimizing conditions for improved analyte transport and ionization in ICP-MS systems, featuring a PEEK tee for acid mixing and a preheated quartz coil for digestion, and a nitrogen flow for solvent evaporation.

Environmental Factors Affecting ICP-MS Performance

Environmental factors play a crucial role in the stability and reliability of ICP-MS (Inductively Coupled Plasma Mass Spectrometry) systems. Laboratory conditions directly impact calibration stability and measurement accuracy, making environmental control essential for minimizing calibration drift.

Temperature fluctuations represent one of the most significant environmental challenges affecting ICP-MS performance. Even minor variations of ±2°C can cause substantial signal drift by altering sample viscosity, nebulization efficiency, and plasma characteristics. Research indicates that temperature changes in the spray chamber particularly affect element-specific responses, with a documented 0.5-1.5% signal change per degree Celsius for many elements.

Humidity variations similarly compromise instrument stability by affecting aerosol formation and transport processes. High humidity environments (>60% RH) can lead to condensation within sample introduction systems, altering effective analyte transport to the plasma. Conversely, extremely low humidity may generate static electricity that interferes with ion transmission and detection systems.

Barometric pressure changes, though often overlooked, significantly impact plasma stability and ionization efficiency. Studies have demonstrated that a 1% change in atmospheric pressure can result in a 0.3-0.8% shift in analyte sensitivity for many elements. This effect becomes particularly pronounced during weather front passages or in laboratories at varying elevations.

Airborne particulates and chemical contaminants represent another critical environmental factor. Dust particles containing metals can introduce sporadic contamination, while volatile organic compounds from laboratory solvents may alter plasma conditions or contribute to polyatomic interferences. Modern laboratories implement HEPA filtration systems that remove 99.97% of particles ≥0.3μm, significantly reducing these contamination risks.

Electrical supply stability directly affects ICP-MS performance, with voltage fluctuations as small as 5% potentially disrupting RF power delivery to the plasma. Such disruptions manifest as signal instability and calibration drift. Uninterruptible power supplies (UPS) with power conditioning capabilities have become standard equipment in high-precision analytical laboratories.

Vibration sources, including HVAC systems, centrifuges, and nearby construction activities, can physically disturb sample introduction components and ion optics. Studies have shown that vibrations above 0.1g acceleration can induce measurable signal fluctuations, particularly affecting high-resolution measurements and isotope ratio determinations.

Electromagnetic interference (EMI) from nearby equipment can disrupt the sensitive electronics in mass spectrometers. Modern ICP-MS instruments incorporate EMI shielding, but proximity to MRI facilities, NMR spectrometers, or high-current electrical systems may still introduce measurement artifacts that contribute to calibration instability.

Temperature fluctuations represent one of the most significant environmental challenges affecting ICP-MS performance. Even minor variations of ±2°C can cause substantial signal drift by altering sample viscosity, nebulization efficiency, and plasma characteristics. Research indicates that temperature changes in the spray chamber particularly affect element-specific responses, with a documented 0.5-1.5% signal change per degree Celsius for many elements.

Humidity variations similarly compromise instrument stability by affecting aerosol formation and transport processes. High humidity environments (>60% RH) can lead to condensation within sample introduction systems, altering effective analyte transport to the plasma. Conversely, extremely low humidity may generate static electricity that interferes with ion transmission and detection systems.

Barometric pressure changes, though often overlooked, significantly impact plasma stability and ionization efficiency. Studies have demonstrated that a 1% change in atmospheric pressure can result in a 0.3-0.8% shift in analyte sensitivity for many elements. This effect becomes particularly pronounced during weather front passages or in laboratories at varying elevations.

Airborne particulates and chemical contaminants represent another critical environmental factor. Dust particles containing metals can introduce sporadic contamination, while volatile organic compounds from laboratory solvents may alter plasma conditions or contribute to polyatomic interferences. Modern laboratories implement HEPA filtration systems that remove 99.97% of particles ≥0.3μm, significantly reducing these contamination risks.

Electrical supply stability directly affects ICP-MS performance, with voltage fluctuations as small as 5% potentially disrupting RF power delivery to the plasma. Such disruptions manifest as signal instability and calibration drift. Uninterruptible power supplies (UPS) with power conditioning capabilities have become standard equipment in high-precision analytical laboratories.

Vibration sources, including HVAC systems, centrifuges, and nearby construction activities, can physically disturb sample introduction components and ion optics. Studies have shown that vibrations above 0.1g acceleration can induce measurable signal fluctuations, particularly affecting high-resolution measurements and isotope ratio determinations.

Electromagnetic interference (EMI) from nearby equipment can disrupt the sensitive electronics in mass spectrometers. Modern ICP-MS instruments incorporate EMI shielding, but proximity to MRI facilities, NMR spectrometers, or high-current electrical systems may still introduce measurement artifacts that contribute to calibration instability.

Quality Control Standards and Compliance Requirements

In the realm of ICP-MS analysis, adherence to quality control standards and compliance requirements is paramount for ensuring reliable analytical results. Laboratories utilizing ICP-MS technology must comply with various international and national standards, including ISO/IEC 17025 for testing and calibration laboratories, which specifically addresses technical competence and quality management systems. This standard requires laboratories to implement procedures for monitoring calibration drift and taking corrective actions when necessary.

The United States Environmental Protection Agency (EPA) has established Method 6020 for ICP-MS analysis, which outlines specific quality control requirements including calibration verification frequency, acceptable drift limits, and corrective actions. According to EPA guidelines, continuing calibration verification (CCV) standards must be analyzed every 10 samples, with acceptance criteria typically set at ±10% of the true value. When calibration drift exceeds these limits, laboratories must take immediate corrective action and potentially reanalyze samples.

Similarly, the United States Pharmacopeia (USP) Chapter <233> provides guidelines for elemental impurities analysis using ICP-MS, specifying calibration requirements and system suitability tests. For pharmaceutical applications, calibration drift must be monitored throughout analytical runs to ensure compliance with stringent quality requirements for drug products.

European regulatory bodies, including the European Medicines Agency (EMA), have established comparable guidelines through ICH Q3D for elemental impurities. These guidelines mandate regular system suitability tests and calibration checks to monitor and control instrument drift during analysis.

Clinical laboratories performing ICP-MS analysis must adhere to Clinical Laboratory Improvement Amendments (CLIA) regulations in the United States, which require comprehensive quality control procedures including calibration verification at defined intervals. CLIA regulations specify that laboratories must establish protocols for identifying and addressing calibration drift to maintain analytical accuracy.

Industry-specific standards also exist, such as those from ASTM International for environmental and materials testing. ASTM D5673 specifically addresses ICP-MS analysis of water samples and includes requirements for calibration frequency and drift monitoring.

To maintain compliance with these various regulatory frameworks, laboratories must implement robust quality management systems that include standard operating procedures (SOPs) for calibration, regular performance verification, and comprehensive documentation of all calibration activities and drift corrections. Internal quality control samples, certified reference materials, and participation in proficiency testing programs are essential components of a compliant ICP-MS laboratory operation.

The United States Environmental Protection Agency (EPA) has established Method 6020 for ICP-MS analysis, which outlines specific quality control requirements including calibration verification frequency, acceptable drift limits, and corrective actions. According to EPA guidelines, continuing calibration verification (CCV) standards must be analyzed every 10 samples, with acceptance criteria typically set at ±10% of the true value. When calibration drift exceeds these limits, laboratories must take immediate corrective action and potentially reanalyze samples.

Similarly, the United States Pharmacopeia (USP) Chapter <233> provides guidelines for elemental impurities analysis using ICP-MS, specifying calibration requirements and system suitability tests. For pharmaceutical applications, calibration drift must be monitored throughout analytical runs to ensure compliance with stringent quality requirements for drug products.

European regulatory bodies, including the European Medicines Agency (EMA), have established comparable guidelines through ICH Q3D for elemental impurities. These guidelines mandate regular system suitability tests and calibration checks to monitor and control instrument drift during analysis.

Clinical laboratories performing ICP-MS analysis must adhere to Clinical Laboratory Improvement Amendments (CLIA) regulations in the United States, which require comprehensive quality control procedures including calibration verification at defined intervals. CLIA regulations specify that laboratories must establish protocols for identifying and addressing calibration drift to maintain analytical accuracy.

Industry-specific standards also exist, such as those from ASTM International for environmental and materials testing. ASTM D5673 specifically addresses ICP-MS analysis of water samples and includes requirements for calibration frequency and drift monitoring.

To maintain compliance with these various regulatory frameworks, laboratories must implement robust quality management systems that include standard operating procedures (SOPs) for calibration, regular performance verification, and comprehensive documentation of all calibration activities and drift corrections. Internal quality control samples, certified reference materials, and participation in proficiency testing programs are essential components of a compliant ICP-MS laboratory operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!