Immobilization Strategies for Propyne-Derived Catalysts

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne Catalyst Evolution

The evolution of propyne-derived catalysts has been marked by significant advancements in immobilization strategies over the past few decades. Initially, these catalysts were primarily used in homogeneous systems, which limited their industrial applicability due to difficulties in separation and recycling. The first major breakthrough came with the development of heterogeneous catalysts, where propyne-derived complexes were immobilized on solid supports such as silica, alumina, and zeolites.

As research progressed, more sophisticated immobilization techniques emerged. The use of polymer-supported catalysts gained traction, offering improved stability and easier handling. This approach allowed for better control over the catalyst's microenvironment, leading to enhanced selectivity and activity. Concurrently, the development of sol-gel methods provided a new avenue for catalyst immobilization, enabling the creation of highly porous materials with well-dispersed active sites.

The advent of nanotechnology brought about a paradigm shift in propyne catalyst evolution. Researchers began exploring the potential of nanoparticles and nanostructured materials as supports for propyne-derived catalysts. This led to the creation of catalysts with exceptionally high surface areas and improved mass transfer properties, resulting in significantly enhanced catalytic performance.

In recent years, the focus has shifted towards more sustainable and environmentally friendly immobilization strategies. The use of bio-based supports, such as cellulose and chitosan, has gained attention due to their renewable nature and biodegradability. These materials offer unique properties that can be tailored to optimize catalyst performance while reducing environmental impact.

Another notable trend in propyne catalyst evolution has been the development of magnetic supports. These materials allow for easy separation of the catalyst from reaction mixtures using external magnetic fields, greatly simplifying the recovery and recycling process. This innovation has addressed one of the longstanding challenges in heterogeneous catalysis, making propyne-derived catalysts more attractive for industrial applications.

The most recent advancements in this field involve the integration of multiple functionalities into a single catalyst system. This approach, often referred to as multifunctional or hierarchical catalysts, combines different catalytic sites or immobilization strategies to achieve synergistic effects. For instance, propyne-derived catalysts have been immobilized on supports that also contain acid or base sites, enabling cascade reactions to be carried out in a single step.

Looking ahead, the evolution of propyne-derived catalysts is likely to continue in the direction of more sophisticated, tailored, and sustainable immobilization strategies. The integration of artificial intelligence and machine learning in catalyst design and optimization is expected to accelerate this process, potentially leading to breakthroughs in catalyst efficiency and selectivity.

As research progressed, more sophisticated immobilization techniques emerged. The use of polymer-supported catalysts gained traction, offering improved stability and easier handling. This approach allowed for better control over the catalyst's microenvironment, leading to enhanced selectivity and activity. Concurrently, the development of sol-gel methods provided a new avenue for catalyst immobilization, enabling the creation of highly porous materials with well-dispersed active sites.

The advent of nanotechnology brought about a paradigm shift in propyne catalyst evolution. Researchers began exploring the potential of nanoparticles and nanostructured materials as supports for propyne-derived catalysts. This led to the creation of catalysts with exceptionally high surface areas and improved mass transfer properties, resulting in significantly enhanced catalytic performance.

In recent years, the focus has shifted towards more sustainable and environmentally friendly immobilization strategies. The use of bio-based supports, such as cellulose and chitosan, has gained attention due to their renewable nature and biodegradability. These materials offer unique properties that can be tailored to optimize catalyst performance while reducing environmental impact.

Another notable trend in propyne catalyst evolution has been the development of magnetic supports. These materials allow for easy separation of the catalyst from reaction mixtures using external magnetic fields, greatly simplifying the recovery and recycling process. This innovation has addressed one of the longstanding challenges in heterogeneous catalysis, making propyne-derived catalysts more attractive for industrial applications.

The most recent advancements in this field involve the integration of multiple functionalities into a single catalyst system. This approach, often referred to as multifunctional or hierarchical catalysts, combines different catalytic sites or immobilization strategies to achieve synergistic effects. For instance, propyne-derived catalysts have been immobilized on supports that also contain acid or base sites, enabling cascade reactions to be carried out in a single step.

Looking ahead, the evolution of propyne-derived catalysts is likely to continue in the direction of more sophisticated, tailored, and sustainable immobilization strategies. The integration of artificial intelligence and machine learning in catalyst design and optimization is expected to accelerate this process, potentially leading to breakthroughs in catalyst efficiency and selectivity.

Industrial Applications

Propyne-derived catalysts have found significant applications across various industrial sectors, leveraging their unique properties and versatility. In the petrochemical industry, these catalysts play a crucial role in the production of high-value chemicals and polymers. They are particularly effective in selective hydrogenation processes, enabling the conversion of propyne to propene, a key feedstock for polypropylene production. This application has revolutionized the efficiency of propylene manufacturing, reducing costs and improving product quality.

The pharmaceutical industry has also benefited from immobilized propyne-derived catalysts. These catalysts are employed in the synthesis of complex drug molecules, facilitating selective transformations and enabling the production of pharmaceutical intermediates with high purity and yield. Their use has streamlined drug manufacturing processes, contributing to more cost-effective and environmentally friendly production methods.

In the fine chemicals sector, immobilized propyne-derived catalysts have proven invaluable for the synthesis of specialty chemicals, fragrances, and flavors. Their selectivity and efficiency in catalyzing carbon-carbon bond formation reactions have opened up new pathways for the production of complex organic compounds. This has led to the development of novel products and improved existing processes, enhancing the competitiveness of companies in this sector.

The polymer industry has embraced these catalysts for the production of advanced materials. They are utilized in the synthesis of functionalized polymers, enabling the incorporation of specific properties into materials. This has resulted in the creation of high-performance plastics with enhanced thermal stability, mechanical strength, and chemical resistance, meeting the demands of various end-use applications in automotive, aerospace, and electronics industries.

Environmental applications of immobilized propyne-derived catalysts have gained traction in recent years. These catalysts are employed in air and water purification systems, effectively removing pollutants and contaminants. Their ability to catalyze oxidation reactions has made them valuable in the treatment of industrial effluents and the remediation of contaminated sites, contributing to sustainable environmental management practices.

In the energy sector, these catalysts have found applications in fuel cell technology and hydrogen production. They facilitate the efficient conversion of hydrocarbons to hydrogen, supporting the development of clean energy solutions. Additionally, their use in the upgrading of biofuels has improved the quality and performance of renewable energy sources, aligning with global efforts to reduce carbon emissions and promote sustainable energy alternatives.

The pharmaceutical industry has also benefited from immobilized propyne-derived catalysts. These catalysts are employed in the synthesis of complex drug molecules, facilitating selective transformations and enabling the production of pharmaceutical intermediates with high purity and yield. Their use has streamlined drug manufacturing processes, contributing to more cost-effective and environmentally friendly production methods.

In the fine chemicals sector, immobilized propyne-derived catalysts have proven invaluable for the synthesis of specialty chemicals, fragrances, and flavors. Their selectivity and efficiency in catalyzing carbon-carbon bond formation reactions have opened up new pathways for the production of complex organic compounds. This has led to the development of novel products and improved existing processes, enhancing the competitiveness of companies in this sector.

The polymer industry has embraced these catalysts for the production of advanced materials. They are utilized in the synthesis of functionalized polymers, enabling the incorporation of specific properties into materials. This has resulted in the creation of high-performance plastics with enhanced thermal stability, mechanical strength, and chemical resistance, meeting the demands of various end-use applications in automotive, aerospace, and electronics industries.

Environmental applications of immobilized propyne-derived catalysts have gained traction in recent years. These catalysts are employed in air and water purification systems, effectively removing pollutants and contaminants. Their ability to catalyze oxidation reactions has made them valuable in the treatment of industrial effluents and the remediation of contaminated sites, contributing to sustainable environmental management practices.

In the energy sector, these catalysts have found applications in fuel cell technology and hydrogen production. They facilitate the efficient conversion of hydrocarbons to hydrogen, supporting the development of clean energy solutions. Additionally, their use in the upgrading of biofuels has improved the quality and performance of renewable energy sources, aligning with global efforts to reduce carbon emissions and promote sustainable energy alternatives.

Immobilization Challenges

The immobilization of propyne-derived catalysts presents several significant challenges that researchers and industry professionals must address. One of the primary obstacles is maintaining catalyst activity and selectivity after immobilization. The process of attaching the catalyst to a support material can often lead to changes in its electronic and steric properties, potentially altering its catalytic performance. This is particularly critical for propyne-derived catalysts, which rely on specific molecular configurations for their effectiveness.

Another major challenge lies in selecting an appropriate support material that provides optimal surface area and porosity while ensuring compatibility with the catalyst and reaction conditions. The support must not only facilitate the immobilization process but also allow for efficient mass transfer of reactants and products. For propyne-derived catalysts, which are often used in gas-phase reactions, the support material must withstand high temperatures and pressures without degrading or interfering with the catalytic process.

Leaching of the immobilized catalyst during reaction conditions poses a significant problem, potentially leading to loss of catalytic activity and contamination of the product stream. Developing robust immobilization strategies that can withstand the harsh conditions often associated with propyne-based reactions is crucial. This includes creating strong covalent bonds or employing advanced encapsulation techniques to ensure the catalyst remains firmly attached to the support material throughout multiple reaction cycles.

The heterogeneity of the immobilized catalyst system can also present challenges in terms of characterization and performance evaluation. Unlike homogeneous catalysts, immobilized systems may exhibit non-uniform distribution of active sites, leading to diffusion limitations and reduced overall efficiency. Developing accurate methods to assess the distribution and accessibility of catalytic sites on the support surface is essential for optimizing catalyst performance.

Scalability and cost-effectiveness of immobilization strategies represent significant hurdles in industrial applications. While laboratory-scale immobilization techniques may prove successful, translating these methods to large-scale production can be problematic. Factors such as reproducibility, uniformity of catalyst loading, and economic viability must be carefully considered when developing immobilization strategies for commercial use.

Lastly, the potential for catalyst deactivation due to coke formation or poisoning by reaction byproducts is a persistent challenge in propyne-derived catalyst systems. Immobilization strategies must not only focus on securing the catalyst but also on designing supports that can mitigate these deactivation mechanisms, potentially through the incorporation of promoters or the development of regeneration protocols compatible with the immobilized system.

Another major challenge lies in selecting an appropriate support material that provides optimal surface area and porosity while ensuring compatibility with the catalyst and reaction conditions. The support must not only facilitate the immobilization process but also allow for efficient mass transfer of reactants and products. For propyne-derived catalysts, which are often used in gas-phase reactions, the support material must withstand high temperatures and pressures without degrading or interfering with the catalytic process.

Leaching of the immobilized catalyst during reaction conditions poses a significant problem, potentially leading to loss of catalytic activity and contamination of the product stream. Developing robust immobilization strategies that can withstand the harsh conditions often associated with propyne-based reactions is crucial. This includes creating strong covalent bonds or employing advanced encapsulation techniques to ensure the catalyst remains firmly attached to the support material throughout multiple reaction cycles.

The heterogeneity of the immobilized catalyst system can also present challenges in terms of characterization and performance evaluation. Unlike homogeneous catalysts, immobilized systems may exhibit non-uniform distribution of active sites, leading to diffusion limitations and reduced overall efficiency. Developing accurate methods to assess the distribution and accessibility of catalytic sites on the support surface is essential for optimizing catalyst performance.

Scalability and cost-effectiveness of immobilization strategies represent significant hurdles in industrial applications. While laboratory-scale immobilization techniques may prove successful, translating these methods to large-scale production can be problematic. Factors such as reproducibility, uniformity of catalyst loading, and economic viability must be carefully considered when developing immobilization strategies for commercial use.

Lastly, the potential for catalyst deactivation due to coke formation or poisoning by reaction byproducts is a persistent challenge in propyne-derived catalyst systems. Immobilization strategies must not only focus on securing the catalyst but also on designing supports that can mitigate these deactivation mechanisms, potentially through the incorporation of promoters or the development of regeneration protocols compatible with the immobilized system.

Current Immobilization Methods

01 Immobilization of propyne-derived catalysts on solid supports

Propyne-derived catalysts can be immobilized on various solid supports such as silica, alumina, or polymeric materials. This immobilization process enhances catalyst stability, allows for easy separation and recycling, and can improve catalytic performance in certain reactions.- Immobilization of propyne-derived catalysts on solid supports: Propyne-derived catalysts can be immobilized on various solid supports such as silica, alumina, or polymeric materials. This immobilization process enhances catalyst stability, allows for easy separation and recycling, and can improve overall catalytic performance in reactions involving propyne derivatives.

- Synthesis of propyne-derived metal complexes for catalysis: Novel metal complexes derived from propyne can be synthesized and used as catalysts. These complexes often involve transition metals and can be designed with specific ligands to enhance their catalytic activity and selectivity in various organic transformations.

- Application of immobilized propyne-derived catalysts in organic synthesis: Immobilized propyne-derived catalysts find applications in various organic synthesis reactions, such as alkyne functionalization, cycloadditions, and coupling reactions. The immobilization strategy allows for the development of heterogeneous catalytic systems with improved efficiency and reusability.

- Development of propyne-derived catalysts for polymerization reactions: Propyne-derived catalysts can be developed and immobilized for use in polymerization reactions. These catalysts may offer advantages in controlling polymer properties, such as molecular weight distribution and stereochemistry, and can be particularly useful in the synthesis of specialty polymers.

- Characterization and optimization of immobilized propyne-derived catalysts: Various analytical techniques and optimization strategies can be employed to characterize and improve the performance of immobilized propyne-derived catalysts. This includes studying the catalyst structure, surface properties, and reaction kinetics to enhance catalytic activity, selectivity, and longevity.

02 Synthesis of propyne-derived metal complexes for catalysis

Novel propyne-derived metal complexes are synthesized for use as catalysts in various organic transformations. These complexes often involve transition metals and can be designed with specific ligands to tune their catalytic properties.Expand Specific Solutions03 Application of immobilized propyne-derived catalysts in organic synthesis

Immobilized propyne-derived catalysts find applications in various organic synthesis reactions, including alkyne functionalization, cycloadditions, and coupling reactions. The immobilization strategy allows for heterogeneous catalysis, facilitating product separation and catalyst reuse.Expand Specific Solutions04 Development of propyne-derived catalysts for polymerization reactions

Propyne-derived catalysts are developed and immobilized for use in polymerization reactions. These catalysts can control polymer properties such as molecular weight, tacticity, and composition, making them valuable in the production of specialized polymeric materials.Expand Specific Solutions05 Characterization and optimization of immobilized propyne-derived catalysts

Various analytical techniques are employed to characterize immobilized propyne-derived catalysts, including spectroscopic methods, microscopy, and catalytic activity assays. These studies aim to optimize catalyst performance, understand structure-activity relationships, and improve immobilization strategies.Expand Specific Solutions

Key Industry Players

The immobilization strategies for propyne-derived catalysts market is in a growth phase, driven by increasing demand for efficient and sustainable catalytic processes. The global market size is estimated to be in the hundreds of millions of dollars, with steady expansion projected. Technologically, the field is advancing rapidly, with key players like China Petroleum & Chemical Corp., ExxonMobil Chemical Patents, Inc., and Saudi Basic Industries Corp. leading innovation. These companies are developing novel immobilization techniques to enhance catalyst stability, recyclability, and performance. While established petrochemical giants dominate, emerging players and research institutions are also contributing to technological advancements, indicating a competitive and dynamic landscape.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced immobilization strategies for propyne-derived catalysts, focusing on heterogeneous catalysis. Their approach involves the use of mesoporous silica supports with tailored pore structures to immobilize propyne-derived metal complexes. This method enhances catalyst stability and reusability while maintaining high catalytic activity. Sinopec has implemented a novel grafting technique that allows for precise control over the distribution and density of catalytic sites on the support surface[1]. Additionally, they have explored the use of organic-inorganic hybrid materials as supports, which provide a synergistic effect between the organic ligands and inorganic framework, leading to improved catalyst performance in various petrochemical processes[3].

Strengths: Enhanced catalyst stability and reusability, precise control over catalytic site distribution, and improved performance in petrochemical processes. Weaknesses: Potential mass transfer limitations in some reactions and possible leaching of metal species over extended use.

Nippon Shokubai Co., Ltd.

Technical Solution: Nippon Shokubai Co., Ltd. has pioneered an innovative immobilization strategy for propyne-derived catalysts using metal-organic frameworks (MOFs) as supports. Their approach involves the in-situ synthesis of propyne-derived metal complexes within the pores of carefully selected MOFs, creating a highly dispersed and stable catalytic system. The company has developed a series of MOFs with tunable pore sizes and functionalities, allowing for precise control over the catalyst environment[5]. This strategy has shown remarkable success in selective hydrogenation reactions, where the confined space within the MOF pores enhances product selectivity. Additionally, Nippon Shokubai has explored post-synthetic modification techniques to further optimize the catalytic performance and stability of these immobilized systems[6].

Strengths: Highly dispersed and stable catalytic system, enhanced product selectivity, and tunable catalyst environment. Weaknesses: Potential limitations in scalability and possible sensitivity to moisture in some applications.

Innovative Anchoring Techniques

Catalysts for ring-closing metathesis

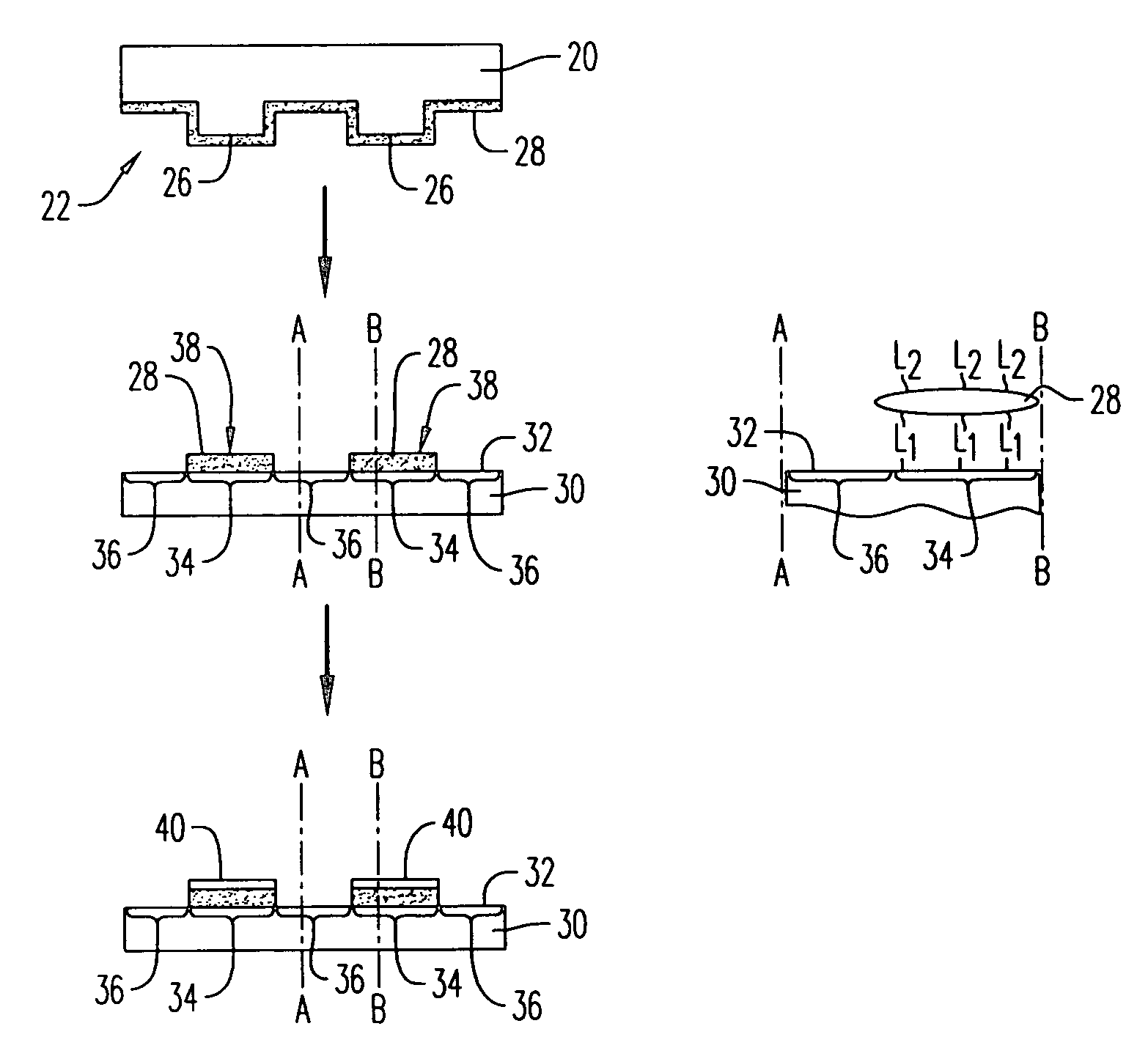

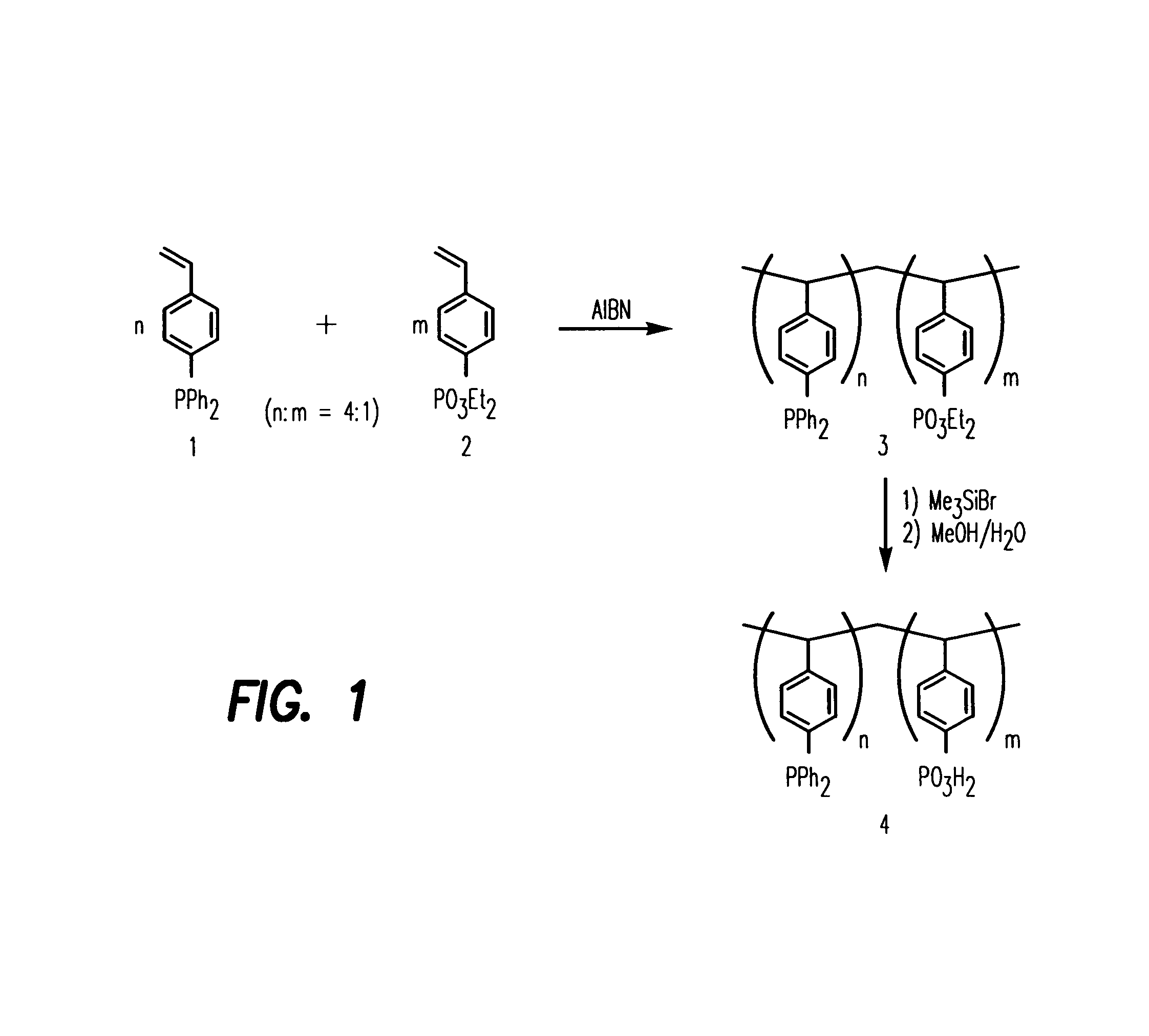

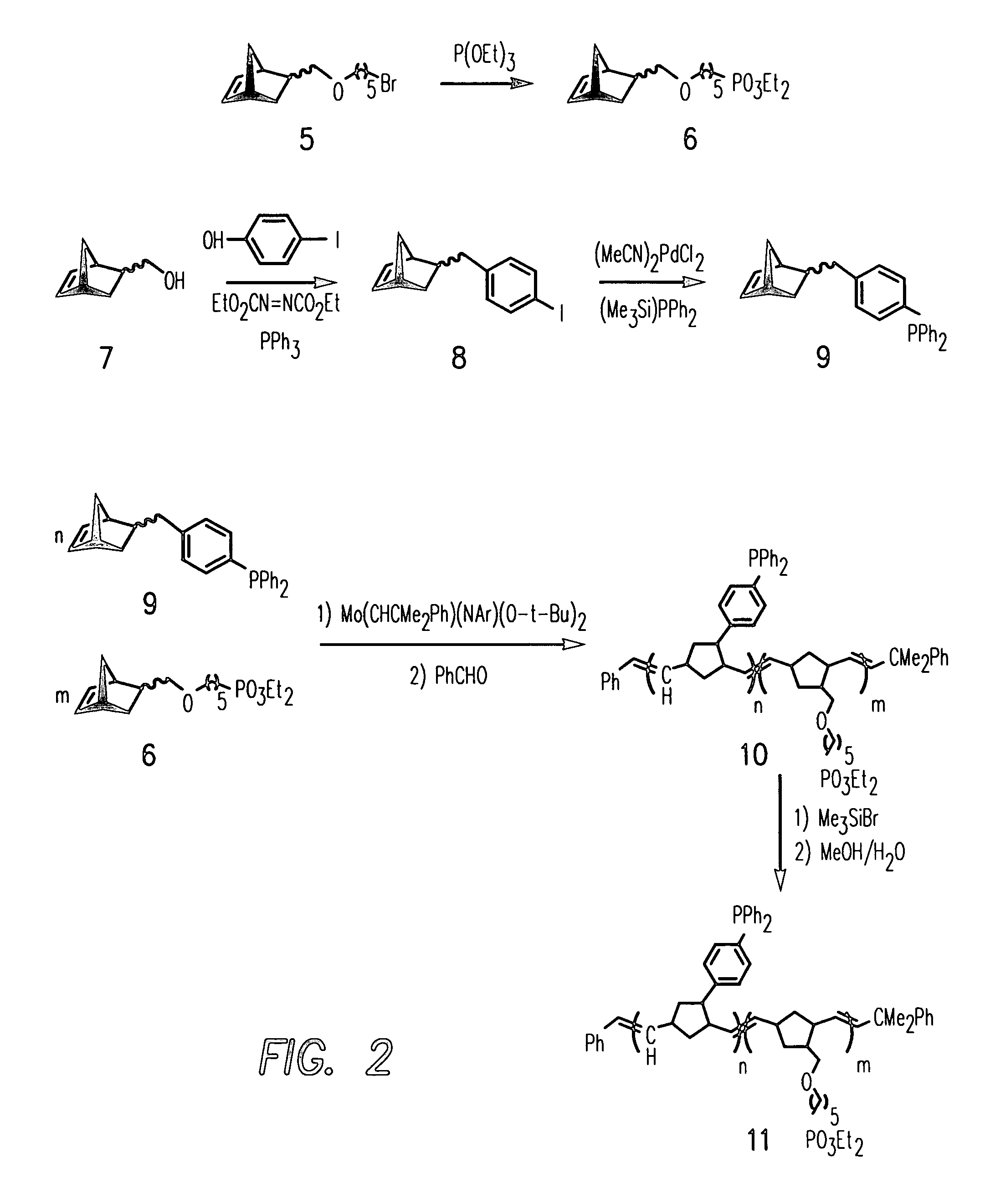

PatentInactiveUS20130131353A1

Innovation

- A catalyst composition is developed by immobilizing ruthenium-based Grubbs or Hoveyda-Grubbs catalysts on siliceous mesocellular foam supports using linking groups like carbamates or silyl groups, allowing for efficient reuse in RCM reactions with improved activity and stability.

Materials and methods for immobilization of catalysts on surfaces and for selective electroless metallization

PatentInactiveUS7087267B2

Innovation

- Development of ligating copolymers capable of binding to substrates and ligating with metal catalysts, allowing for the immobilization of catalysts on surfaces and selective electroless metallization using a simplified process compatible with microcontact printing solvents, reducing the number of steps and reactions needed.

Environmental Impact Assessment

The environmental impact assessment of immobilization strategies for propyne-derived catalysts is a crucial aspect of their development and implementation. These catalysts play a significant role in various industrial processes, particularly in the production of fine chemicals and pharmaceuticals. However, their potential environmental effects must be carefully evaluated to ensure sustainable and responsible use.

One of the primary environmental concerns associated with propyne-derived catalysts is the potential release of toxic or harmful substances during their production, use, or disposal. The immobilization process itself may involve the use of solvents or other chemicals that could pose environmental risks if not properly managed. Additionally, the support materials used for immobilization, such as polymers or inorganic substrates, may have their own environmental implications in terms of production and disposal.

The leaching of catalytic species from the immobilized system is another important consideration. While immobilization strategies aim to enhance catalyst stability and reusability, there is always a risk of gradual release of metal ions or organic ligands into the reaction medium. This leaching can lead to contamination of products and waste streams, potentially impacting aquatic ecosystems if not adequately treated.

Energy consumption and greenhouse gas emissions associated with the production and use of immobilized propyne-derived catalysts must also be assessed. The immobilization process may require additional energy inputs compared to homogeneous catalysts, and the overall life cycle energy balance should be evaluated. Furthermore, the potential for these catalysts to enable more efficient chemical processes that reduce overall energy consumption and emissions should be considered as a positive environmental impact.

The recyclability and longevity of immobilized catalysts offer significant environmental benefits by reducing the need for frequent catalyst replacement and minimizing waste generation. However, the end-of-life management of spent catalysts remains a critical issue. Proper disposal or recycling methods must be developed to prevent the release of potentially harmful components into the environment.

Water usage and wastewater generation in processes utilizing immobilized propyne-derived catalysts should also be carefully examined. While heterogeneous catalysts often allow for easier separation from reaction mixtures, the washing and regeneration steps may still consume significant amounts of water and generate wastewater that requires treatment.

In conclusion, a comprehensive environmental impact assessment of immobilization strategies for propyne-derived catalysts must consider the entire life cycle of the catalyst system, from raw material extraction to final disposal. This holistic approach will help identify potential environmental risks and opportunities for improvement, guiding the development of more sustainable catalytic processes.

One of the primary environmental concerns associated with propyne-derived catalysts is the potential release of toxic or harmful substances during their production, use, or disposal. The immobilization process itself may involve the use of solvents or other chemicals that could pose environmental risks if not properly managed. Additionally, the support materials used for immobilization, such as polymers or inorganic substrates, may have their own environmental implications in terms of production and disposal.

The leaching of catalytic species from the immobilized system is another important consideration. While immobilization strategies aim to enhance catalyst stability and reusability, there is always a risk of gradual release of metal ions or organic ligands into the reaction medium. This leaching can lead to contamination of products and waste streams, potentially impacting aquatic ecosystems if not adequately treated.

Energy consumption and greenhouse gas emissions associated with the production and use of immobilized propyne-derived catalysts must also be assessed. The immobilization process may require additional energy inputs compared to homogeneous catalysts, and the overall life cycle energy balance should be evaluated. Furthermore, the potential for these catalysts to enable more efficient chemical processes that reduce overall energy consumption and emissions should be considered as a positive environmental impact.

The recyclability and longevity of immobilized catalysts offer significant environmental benefits by reducing the need for frequent catalyst replacement and minimizing waste generation. However, the end-of-life management of spent catalysts remains a critical issue. Proper disposal or recycling methods must be developed to prevent the release of potentially harmful components into the environment.

Water usage and wastewater generation in processes utilizing immobilized propyne-derived catalysts should also be carefully examined. While heterogeneous catalysts often allow for easier separation from reaction mixtures, the washing and regeneration steps may still consume significant amounts of water and generate wastewater that requires treatment.

In conclusion, a comprehensive environmental impact assessment of immobilization strategies for propyne-derived catalysts must consider the entire life cycle of the catalyst system, from raw material extraction to final disposal. This holistic approach will help identify potential environmental risks and opportunities for improvement, guiding the development of more sustainable catalytic processes.

Scalability and Cost Analysis

The scalability and cost analysis of immobilization strategies for propyne-derived catalysts is crucial for their industrial application and commercial viability. The primary challenge lies in maintaining catalyst performance while increasing production scale and minimizing costs.

Scaling up the immobilization process requires careful consideration of several factors. Firstly, the choice of support material significantly impacts scalability. Inorganic supports like silica or alumina offer advantages in terms of availability and cost-effectiveness at large scales. However, organic polymer supports may provide better control over catalyst distribution and accessibility. The trade-off between these options must be evaluated based on specific application requirements and production volumes.

The immobilization method itself also plays a critical role in scalability. Covalent attachment methods, while offering strong catalyst binding, may face challenges in maintaining uniform coverage across large surface areas. Physical adsorption techniques, on the other hand, can be more easily scaled but may suffer from catalyst leaching issues. Encapsulation methods present a middle ground, potentially offering both scalability and stability, but require careful optimization of pore sizes and distributions.

From a cost perspective, the choice of catalyst precursors and ligands significantly impacts overall expenses. While high-performance catalysts often rely on precious metals and sophisticated ligands, their cost may be prohibitive for large-scale applications. Developing immobilization strategies that allow for reduced catalyst loading without compromising activity could lead to substantial cost savings. Additionally, the use of earth-abundant metals as alternatives to precious metal catalysts is an active area of research that could dramatically reduce costs if successfully implemented.

The recyclability of immobilized catalysts is another crucial factor in cost analysis. Effective immobilization strategies that prevent catalyst leaching and maintain activity over multiple cycles can significantly reduce operational costs. However, this must be balanced against the potentially higher initial costs of more robust immobilization techniques.

Process integration and optimization also play vital roles in improving scalability and reducing costs. Continuous flow systems, for instance, can offer advantages in terms of efficiency and product quality compared to batch processes. However, they may require specialized equipment and expertise, potentially increasing initial capital costs.

Lastly, regulatory compliance and environmental considerations must be factored into the scalability and cost analysis. Sustainable immobilization strategies that minimize waste generation and use environmentally benign materials may incur higher upfront costs but could prove more economical in the long term, especially considering increasingly stringent environmental regulations.

In conclusion, the successful scale-up and cost-effective implementation of immobilization strategies for propyne-derived catalysts require a holistic approach. This approach must balance catalyst performance, production efficiency, material costs, and environmental impact to achieve a commercially viable solution.

Scaling up the immobilization process requires careful consideration of several factors. Firstly, the choice of support material significantly impacts scalability. Inorganic supports like silica or alumina offer advantages in terms of availability and cost-effectiveness at large scales. However, organic polymer supports may provide better control over catalyst distribution and accessibility. The trade-off between these options must be evaluated based on specific application requirements and production volumes.

The immobilization method itself also plays a critical role in scalability. Covalent attachment methods, while offering strong catalyst binding, may face challenges in maintaining uniform coverage across large surface areas. Physical adsorption techniques, on the other hand, can be more easily scaled but may suffer from catalyst leaching issues. Encapsulation methods present a middle ground, potentially offering both scalability and stability, but require careful optimization of pore sizes and distributions.

From a cost perspective, the choice of catalyst precursors and ligands significantly impacts overall expenses. While high-performance catalysts often rely on precious metals and sophisticated ligands, their cost may be prohibitive for large-scale applications. Developing immobilization strategies that allow for reduced catalyst loading without compromising activity could lead to substantial cost savings. Additionally, the use of earth-abundant metals as alternatives to precious metal catalysts is an active area of research that could dramatically reduce costs if successfully implemented.

The recyclability of immobilized catalysts is another crucial factor in cost analysis. Effective immobilization strategies that prevent catalyst leaching and maintain activity over multiple cycles can significantly reduce operational costs. However, this must be balanced against the potentially higher initial costs of more robust immobilization techniques.

Process integration and optimization also play vital roles in improving scalability and reducing costs. Continuous flow systems, for instance, can offer advantages in terms of efficiency and product quality compared to batch processes. However, they may require specialized equipment and expertise, potentially increasing initial capital costs.

Lastly, regulatory compliance and environmental considerations must be factored into the scalability and cost analysis. Sustainable immobilization strategies that minimize waste generation and use environmentally benign materials may incur higher upfront costs but could prove more economical in the long term, especially considering increasingly stringent environmental regulations.

In conclusion, the successful scale-up and cost-effective implementation of immobilization strategies for propyne-derived catalysts require a holistic approach. This approach must balance catalyst performance, production efficiency, material costs, and environmental impact to achieve a commercially viable solution.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!