Impact of Hydroxyethylcellulose on Sustainable Manufacturing Practices

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC Background and Goals

Hydroxyethylcellulose (HEC) has emerged as a significant player in the realm of sustainable manufacturing practices, marking a pivotal shift in industrial processes towards more environmentally friendly approaches. This cellulose derivative, obtained from renewable plant sources, has a rich history dating back to the early 20th century when it was first synthesized. Over the decades, HEC has evolved from a niche product to a versatile material with wide-ranging applications across various industries.

The development trajectory of HEC technology has been characterized by continuous improvements in production methods, purification techniques, and tailoring of its properties to suit specific industrial needs. From its initial use as a thickening agent in the textile industry, HEC has expanded its footprint into sectors such as pharmaceuticals, personal care, construction, and oil drilling, among others. This expansion has been driven by the growing demand for sustainable alternatives to petroleum-based products and the increasing emphasis on eco-friendly manufacturing processes.

As global awareness of environmental issues has intensified, the focus on sustainable practices in manufacturing has become paramount. HEC aligns perfectly with this trend, offering a biodegradable and renewable alternative to many synthetic polymers. Its ability to modify viscosity, stabilize emulsions, and form films without leaving harmful residues has positioned it as a key component in the transition towards greener industrial processes.

The primary goal of exploring HEC in the context of sustainable manufacturing is to leverage its unique properties to reduce the environmental footprint of production processes across multiple industries. This involves optimizing HEC formulations to enhance performance while minimizing resource consumption and waste generation. Additionally, there is a concerted effort to develop more efficient and eco-friendly methods of producing HEC itself, further amplifying its positive impact on sustainability.

Another critical objective is to expand the application scope of HEC in sustainable manufacturing. This includes identifying novel uses that can replace less environmentally friendly materials and processes. Researchers and industry professionals are actively exploring ways to integrate HEC into advanced materials, such as biodegradable packaging, smart coatings, and eco-friendly adhesives, pushing the boundaries of its potential contributions to sustainability.

The technological evolution of HEC is closely intertwined with broader trends in green chemistry and circular economy principles. As such, a key goal is to establish HEC as a model compound for sustainable material development, showcasing how renewable resources can be effectively utilized to create high-performance products with minimal environmental impact. This ambition extends to inspiring innovation in related fields and catalyzing a broader shift towards bio-based materials in industrial applications.

The development trajectory of HEC technology has been characterized by continuous improvements in production methods, purification techniques, and tailoring of its properties to suit specific industrial needs. From its initial use as a thickening agent in the textile industry, HEC has expanded its footprint into sectors such as pharmaceuticals, personal care, construction, and oil drilling, among others. This expansion has been driven by the growing demand for sustainable alternatives to petroleum-based products and the increasing emphasis on eco-friendly manufacturing processes.

As global awareness of environmental issues has intensified, the focus on sustainable practices in manufacturing has become paramount. HEC aligns perfectly with this trend, offering a biodegradable and renewable alternative to many synthetic polymers. Its ability to modify viscosity, stabilize emulsions, and form films without leaving harmful residues has positioned it as a key component in the transition towards greener industrial processes.

The primary goal of exploring HEC in the context of sustainable manufacturing is to leverage its unique properties to reduce the environmental footprint of production processes across multiple industries. This involves optimizing HEC formulations to enhance performance while minimizing resource consumption and waste generation. Additionally, there is a concerted effort to develop more efficient and eco-friendly methods of producing HEC itself, further amplifying its positive impact on sustainability.

Another critical objective is to expand the application scope of HEC in sustainable manufacturing. This includes identifying novel uses that can replace less environmentally friendly materials and processes. Researchers and industry professionals are actively exploring ways to integrate HEC into advanced materials, such as biodegradable packaging, smart coatings, and eco-friendly adhesives, pushing the boundaries of its potential contributions to sustainability.

The technological evolution of HEC is closely intertwined with broader trends in green chemistry and circular economy principles. As such, a key goal is to establish HEC as a model compound for sustainable material development, showcasing how renewable resources can be effectively utilized to create high-performance products with minimal environmental impact. This ambition extends to inspiring innovation in related fields and catalyzing a broader shift towards bio-based materials in industrial applications.

Market Demand Analysis

The market demand for hydroxyethylcellulose (HEC) in sustainable manufacturing practices has been steadily increasing due to its versatile applications and eco-friendly properties. As industries worldwide shift towards more sustainable production methods, HEC has emerged as a key ingredient in various sectors, particularly in construction, personal care, and pharmaceuticals.

In the construction industry, HEC is widely used as a thickening agent and water retention aid in cement-based products. The growing emphasis on green building practices has led to a surge in demand for HEC-enhanced construction materials. These materials offer improved workability, reduced water consumption, and enhanced durability, aligning with sustainable construction goals.

The personal care and cosmetics sector has also witnessed a significant uptick in HEC usage. Consumers are increasingly seeking natural and sustainable products, driving manufacturers to incorporate plant-based ingredients like HEC into their formulations. HEC serves as an effective thickener, stabilizer, and film-former in various personal care products, replacing synthetic alternatives and contributing to the industry's sustainability efforts.

In the pharmaceutical industry, HEC plays a crucial role in drug delivery systems and controlled-release formulations. The increasing focus on environmentally friendly pharmaceutical manufacturing processes has boosted the demand for HEC as a sustainable excipient. Its biodegradability and non-toxic nature make it an attractive option for pharmaceutical companies aiming to reduce their environmental footprint.

The textile industry is another significant consumer of HEC, utilizing it in sizing agents and printing pastes. As the textile sector faces pressure to adopt more sustainable practices, the demand for HEC-based solutions has grown. These solutions offer improved fabric quality while reducing water consumption and chemical usage in textile processing.

Market analysis indicates that the global HEC market is expected to experience robust growth in the coming years, driven by the increasing adoption of sustainable manufacturing practices across industries. The Asia-Pacific region, in particular, is anticipated to witness substantial growth due to rapid industrialization and stringent environmental regulations.

However, the market demand for HEC is not without challenges. The availability of raw materials and potential price fluctuations of cellulose-based products may impact the supply chain. Additionally, the development of alternative sustainable materials could pose competition to HEC in certain applications.

Despite these challenges, the overall market outlook for HEC in sustainable manufacturing remains positive. The material's biodegradability, versatility, and performance characteristics position it as a key component in the transition towards more environmentally friendly production processes across multiple industries.

In the construction industry, HEC is widely used as a thickening agent and water retention aid in cement-based products. The growing emphasis on green building practices has led to a surge in demand for HEC-enhanced construction materials. These materials offer improved workability, reduced water consumption, and enhanced durability, aligning with sustainable construction goals.

The personal care and cosmetics sector has also witnessed a significant uptick in HEC usage. Consumers are increasingly seeking natural and sustainable products, driving manufacturers to incorporate plant-based ingredients like HEC into their formulations. HEC serves as an effective thickener, stabilizer, and film-former in various personal care products, replacing synthetic alternatives and contributing to the industry's sustainability efforts.

In the pharmaceutical industry, HEC plays a crucial role in drug delivery systems and controlled-release formulations. The increasing focus on environmentally friendly pharmaceutical manufacturing processes has boosted the demand for HEC as a sustainable excipient. Its biodegradability and non-toxic nature make it an attractive option for pharmaceutical companies aiming to reduce their environmental footprint.

The textile industry is another significant consumer of HEC, utilizing it in sizing agents and printing pastes. As the textile sector faces pressure to adopt more sustainable practices, the demand for HEC-based solutions has grown. These solutions offer improved fabric quality while reducing water consumption and chemical usage in textile processing.

Market analysis indicates that the global HEC market is expected to experience robust growth in the coming years, driven by the increasing adoption of sustainable manufacturing practices across industries. The Asia-Pacific region, in particular, is anticipated to witness substantial growth due to rapid industrialization and stringent environmental regulations.

However, the market demand for HEC is not without challenges. The availability of raw materials and potential price fluctuations of cellulose-based products may impact the supply chain. Additionally, the development of alternative sustainable materials could pose competition to HEC in certain applications.

Despite these challenges, the overall market outlook for HEC in sustainable manufacturing remains positive. The material's biodegradability, versatility, and performance characteristics position it as a key component in the transition towards more environmentally friendly production processes across multiple industries.

HEC Tech Challenges

Hydroxyethylcellulose (HEC) has emerged as a significant player in sustainable manufacturing practices, but its implementation faces several technical challenges. One of the primary obstacles is achieving consistent quality and performance across different batches of HEC. The molecular weight distribution and degree of substitution can vary, affecting the rheological properties and functionality of the final product. This variability poses difficulties in maintaining uniform product quality in industries such as personal care, pharmaceuticals, and construction materials.

Another significant challenge lies in the optimization of HEC production processes to enhance sustainability. While HEC is derived from renewable cellulose sources, the current manufacturing methods often involve energy-intensive steps and the use of potentially harmful chemicals. Developing more environmentally friendly synthesis routes that reduce energy consumption and minimize the use of hazardous substances remains a key technical hurdle. This includes finding alternatives to traditional etherification processes and exploring greener solvents and catalysts.

The integration of HEC into existing manufacturing systems also presents technical difficulties. Many industries are equipped with machinery and processes optimized for synthetic polymers, and the incorporation of HEC may require significant modifications to equipment and production lines. Engineers face the challenge of adapting or redesigning manufacturing processes to accommodate the unique properties of HEC without compromising efficiency or product quality.

Water management is another critical issue in HEC-based manufacturing. HEC's high water solubility and thickening properties can lead to increased water consumption in production processes. Developing effective water recycling and treatment systems specific to HEC-containing waste streams is essential for sustainable manufacturing but remains technically challenging. This includes addressing issues such as the removal of residual HEC from wastewater and the prevention of gel formation in recycling systems.

Furthermore, the biodegradability of HEC, while generally considered an advantage for sustainability, can pose challenges in certain applications. Ensuring long-term stability and shelf life of HEC-containing products, especially in aqueous formulations, requires innovative preservation techniques. Balancing biodegradability with product durability and performance is a complex technical problem that researchers continue to grapple with.

Lastly, the scaling up of HEC production to meet growing industrial demands while maintaining sustainability presents significant engineering challenges. Developing large-scale, efficient, and environmentally friendly production facilities requires overcoming issues related to heat transfer, mixing, and process control in viscous HEC solutions. Additionally, ensuring consistent product quality and minimizing waste generation at industrial scales remains a persistent technical challenge in the sustainable manufacturing of HEC.

Another significant challenge lies in the optimization of HEC production processes to enhance sustainability. While HEC is derived from renewable cellulose sources, the current manufacturing methods often involve energy-intensive steps and the use of potentially harmful chemicals. Developing more environmentally friendly synthesis routes that reduce energy consumption and minimize the use of hazardous substances remains a key technical hurdle. This includes finding alternatives to traditional etherification processes and exploring greener solvents and catalysts.

The integration of HEC into existing manufacturing systems also presents technical difficulties. Many industries are equipped with machinery and processes optimized for synthetic polymers, and the incorporation of HEC may require significant modifications to equipment and production lines. Engineers face the challenge of adapting or redesigning manufacturing processes to accommodate the unique properties of HEC without compromising efficiency or product quality.

Water management is another critical issue in HEC-based manufacturing. HEC's high water solubility and thickening properties can lead to increased water consumption in production processes. Developing effective water recycling and treatment systems specific to HEC-containing waste streams is essential for sustainable manufacturing but remains technically challenging. This includes addressing issues such as the removal of residual HEC from wastewater and the prevention of gel formation in recycling systems.

Furthermore, the biodegradability of HEC, while generally considered an advantage for sustainability, can pose challenges in certain applications. Ensuring long-term stability and shelf life of HEC-containing products, especially in aqueous formulations, requires innovative preservation techniques. Balancing biodegradability with product durability and performance is a complex technical problem that researchers continue to grapple with.

Lastly, the scaling up of HEC production to meet growing industrial demands while maintaining sustainability presents significant engineering challenges. Developing large-scale, efficient, and environmentally friendly production facilities requires overcoming issues related to heat transfer, mixing, and process control in viscous HEC solutions. Additionally, ensuring consistent product quality and minimizing waste generation at industrial scales remains a persistent technical challenge in the sustainable manufacturing of HEC.

Current HEC Solutions

01 Use as a thickening agent in various formulations

Hydroxyethylcellulose is widely used as a thickening agent in various formulations, including cosmetics, personal care products, and industrial applications. It helps to improve the viscosity and stability of liquid and semi-solid products, enhancing their texture and performance.- Use as a thickening agent in various industries: Hydroxyethylcellulose is widely used as a thickening agent in various industries, including cosmetics, pharmaceuticals, and oil drilling. It helps to increase the viscosity of solutions and provides stability to formulations.

- Application in personal care products: Hydroxyethylcellulose is commonly used in personal care products such as shampoos, lotions, and creams. It acts as a thickener, emulsifier, and stabilizer, improving the texture and consistency of these products.

- Use in oil and gas industry: Hydroxyethylcellulose is utilized in the oil and gas industry as a component in drilling fluids and fracturing fluids. It helps control fluid loss, improve viscosity, and enhance the overall performance of these fluids in well operations.

- Application in construction materials: Hydroxyethylcellulose is used in construction materials such as cement, mortar, and gypsum products. It acts as a water-retention agent, improves workability, and enhances the adhesion properties of these materials.

- Use in pharmaceutical formulations: Hydroxyethylcellulose is employed in pharmaceutical formulations as a binder, thickener, and stabilizer. It is used in various dosage forms, including tablets, capsules, and topical preparations, to improve drug delivery and product stability.

02 Application in oil and gas industry

Hydroxyethylcellulose is utilized in the oil and gas industry as a component in drilling fluids and fracturing fluids. It helps control fluid loss, improve rheological properties, and enhance the overall performance of these fluids in well operations.Expand Specific Solutions03 Use in pharmaceutical formulations

Hydroxyethylcellulose is employed in pharmaceutical formulations as a binder, film-forming agent, and controlled-release matrix. It helps in the development of various drug delivery systems, including tablets, capsules, and topical preparations.Expand Specific Solutions04 Application in personal care and cosmetic products

Hydroxyethylcellulose is used in personal care and cosmetic products as a stabilizer, emulsifier, and texture modifier. It helps improve the feel, consistency, and shelf-life of various products such as shampoos, lotions, and creams.Expand Specific Solutions05 Use in adhesive and coating formulations

Hydroxyethylcellulose is utilized in adhesive and coating formulations to improve their properties such as viscosity, water retention, and film-forming characteristics. It finds applications in various industries, including construction, textiles, and paper manufacturing.Expand Specific Solutions

Key HEC Manufacturers

The impact of Hydroxyethylcellulose on sustainable manufacturing practices is gaining traction in a maturing industry with significant market potential. The technology's maturity varies among key players, with established companies like Dow Global Technologies, LOTTE Fine Chemical, and Sumitomo Seika Chemicals leading the way. These firms have extensive experience in chemical manufacturing and are likely at the forefront of sustainable practices. Emerging players such as Hebei Jigao Chemical Fibre and Luzhou North Cellulose are also contributing to the field, potentially bringing innovative approaches. The involvement of academic institutions like Wuhan University and Beijing Institute of Technology suggests ongoing research and development, indicating room for further technological advancements and market growth in sustainable hydroxyethylcellulose production.

Dow Global Technologies LLC

Technical Solution: Dow has developed a sustainable manufacturing process for hydroxyethylcellulose (HEC) that reduces water consumption by up to 40% compared to traditional methods[1]. Their innovative approach involves using a closed-loop system that recycles process water and optimizes reaction conditions. This technology also incorporates green chemistry principles, utilizing bio-based raw materials and reducing the use of harmful solvents[2]. Dow's HEC production process integrates advanced process control systems and real-time monitoring to ensure consistent product quality while minimizing energy consumption[3].

Strengths: Significant reduction in water usage, improved sustainability profile, and consistent product quality. Weaknesses: Potential higher initial investment costs and the need for specialized equipment and training.

LOTTE Fine Chemical Co., Ltd.

Technical Solution: LOTTE Fine Chemical has implemented a novel continuous production method for HEC that enhances energy efficiency by approximately 25% compared to batch processes[4]. Their approach utilizes a series of specially designed reactors that allow for precise control of reaction parameters, resulting in improved product uniformity. The company has also incorporated renewable energy sources, such as solar panels, into their manufacturing facilities to further reduce the carbon footprint of HEC production[5]. Additionally, LOTTE has developed a proprietary purification technique that minimizes the use of organic solvents, contributing to a more environmentally friendly process[6].

Strengths: Improved energy efficiency, enhanced product consistency, and reduced reliance on fossil fuels. Weaknesses: Potentially higher complexity in process control and initial capital investment for continuous production setup.

HEC Innovations

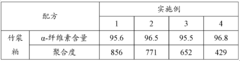

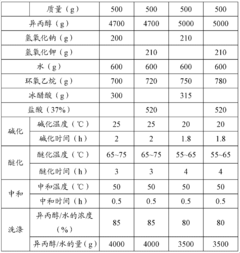

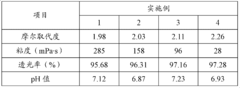

Hydroxyethyl cellulose and preparation method thereof

PatentActiveCN102060931B

Innovation

- By pulverizing the bamboo pulp and then performing an alkalization reaction in the reactor, adding ethylene oxide for etherification, and passing through nitrogen protection, then adding acid for neutralization and isopropyl alcohol aqueous solution washing, and finally controlling the moisture to obtain high quality of hydroxyethylcellulose.

Method of laundering coloured fabrics

PatentInactiveEP1563051B1

Innovation

- Incorporating low levels of hydroxy C2-C4 alkyl beta 1-4 polysaccharides, such as hydroxy ethyl cellulose, in the wash liquor to reduce fabric abrasion and dye pick-up, with a concentration of 0.1-0.005 g/L, in combination with detergent active surfactants, to maintain fabric integrity and appearance.

Environmental Impact

Hydroxyethylcellulose (HEC) has emerged as a significant player in sustainable manufacturing practices, with its environmental impact being a crucial aspect of consideration. As industries strive to reduce their ecological footprint, the use of HEC presents both opportunities and challenges in terms of environmental sustainability.

One of the primary environmental benefits of HEC is its biodegradability. Unlike many synthetic polymers, HEC can be broken down by natural processes, reducing long-term environmental accumulation. This characteristic makes it an attractive option for industries seeking to minimize their impact on ecosystems and align with circular economy principles.

The production of HEC also demonstrates potential for reduced environmental impact compared to some alternative materials. Derived from cellulose, a renewable resource, HEC production can be less resource-intensive than the manufacture of petroleum-based polymers. This contributes to a lower carbon footprint and decreased reliance on non-renewable resources.

However, the environmental impact of HEC is not without complexities. The sourcing of cellulose, typically from wood pulp, raises concerns about deforestation and habitat destruction if not managed sustainably. Responsible sourcing practices and certification schemes are crucial to mitigate these risks and ensure that HEC production does not contribute to environmental degradation.

Water usage in HEC production and application processes is another environmental consideration. While HEC itself is water-soluble and can reduce the need for harmful solvents in many applications, its production and use may still require significant water resources. Implementing water recycling systems and optimizing production processes can help address this concern.

The end-of-life management of HEC-containing products also plays a role in its overall environmental impact. While biodegradable, improper disposal or overuse of HEC can lead to water pollution and affect aquatic ecosystems. Developing effective waste management strategies and educating consumers on proper disposal methods are essential steps in minimizing these potential negative impacts.

In terms of energy consumption, the production of HEC generally requires less energy compared to many synthetic alternatives. This can translate to reduced greenhouse gas emissions associated with manufacturing processes. However, the specific energy profile can vary depending on production methods and scale, highlighting the need for ongoing optimization and innovation in manufacturing techniques.

As industries continue to adopt HEC in their sustainable manufacturing practices, ongoing research and development efforts are focused on further improving its environmental profile. This includes exploring more efficient production methods, enhancing its biodegradability properties, and investigating novel applications that can replace less sustainable materials across various sectors.

One of the primary environmental benefits of HEC is its biodegradability. Unlike many synthetic polymers, HEC can be broken down by natural processes, reducing long-term environmental accumulation. This characteristic makes it an attractive option for industries seeking to minimize their impact on ecosystems and align with circular economy principles.

The production of HEC also demonstrates potential for reduced environmental impact compared to some alternative materials. Derived from cellulose, a renewable resource, HEC production can be less resource-intensive than the manufacture of petroleum-based polymers. This contributes to a lower carbon footprint and decreased reliance on non-renewable resources.

However, the environmental impact of HEC is not without complexities. The sourcing of cellulose, typically from wood pulp, raises concerns about deforestation and habitat destruction if not managed sustainably. Responsible sourcing practices and certification schemes are crucial to mitigate these risks and ensure that HEC production does not contribute to environmental degradation.

Water usage in HEC production and application processes is another environmental consideration. While HEC itself is water-soluble and can reduce the need for harmful solvents in many applications, its production and use may still require significant water resources. Implementing water recycling systems and optimizing production processes can help address this concern.

The end-of-life management of HEC-containing products also plays a role in its overall environmental impact. While biodegradable, improper disposal or overuse of HEC can lead to water pollution and affect aquatic ecosystems. Developing effective waste management strategies and educating consumers on proper disposal methods are essential steps in minimizing these potential negative impacts.

In terms of energy consumption, the production of HEC generally requires less energy compared to many synthetic alternatives. This can translate to reduced greenhouse gas emissions associated with manufacturing processes. However, the specific energy profile can vary depending on production methods and scale, highlighting the need for ongoing optimization and innovation in manufacturing techniques.

As industries continue to adopt HEC in their sustainable manufacturing practices, ongoing research and development efforts are focused on further improving its environmental profile. This includes exploring more efficient production methods, enhancing its biodegradability properties, and investigating novel applications that can replace less sustainable materials across various sectors.

Regulatory Compliance

The regulatory landscape surrounding the use of hydroxyethylcellulose (HEC) in sustainable manufacturing practices is complex and multifaceted. Manufacturers must navigate a web of regulations at local, national, and international levels to ensure compliance while striving for sustainability.

At the forefront of regulatory considerations is the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union. REACH requires manufacturers and importers to register chemicals, including HEC, and provide safety data. This regulation aims to protect human health and the environment while promoting innovation and competitiveness in the chemical industry.

In the United States, the Environmental Protection Agency (EPA) oversees the regulation of chemicals under the Toxic Substances Control Act (TSCA). The TSCA inventory lists HEC, and manufacturers must comply with reporting requirements and any specific regulations related to its use. Additionally, the Food and Drug Administration (FDA) regulates HEC when used in food, drugs, or cosmetics, ensuring its safety for consumer products.

Globally, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Manufacturers using HEC must adhere to GHS guidelines for labeling and safety data sheets, promoting consistency in hazard communication across borders.

Sustainable manufacturing practices involving HEC must also consider waste management regulations. The European Waste Framework Directive and similar regulations in other regions set guidelines for waste reduction, recycling, and disposal. Manufacturers must ensure that their use of HEC aligns with these directives, implementing proper waste management strategies to minimize environmental impact.

Water quality regulations are another crucial aspect of compliance for HEC manufacturers. Given HEC's water-soluble nature, regulations such as the Clean Water Act in the United States and the Water Framework Directive in the EU set standards for water discharge and treatment. Manufacturers must implement appropriate wastewater treatment processes to meet these regulatory requirements.

Occupational health and safety regulations, such as those set by the Occupational Safety and Health Administration (OSHA) in the US, also play a significant role. These regulations ensure safe working conditions for employees handling HEC, requiring proper training, personal protective equipment, and exposure controls.

As sustainability becomes increasingly important, new regulations are emerging that focus on circular economy principles and life cycle assessments. Manufacturers using HEC in sustainable practices must stay informed about these evolving regulations and adapt their processes accordingly to maintain compliance and meet sustainability goals.

At the forefront of regulatory considerations is the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union. REACH requires manufacturers and importers to register chemicals, including HEC, and provide safety data. This regulation aims to protect human health and the environment while promoting innovation and competitiveness in the chemical industry.

In the United States, the Environmental Protection Agency (EPA) oversees the regulation of chemicals under the Toxic Substances Control Act (TSCA). The TSCA inventory lists HEC, and manufacturers must comply with reporting requirements and any specific regulations related to its use. Additionally, the Food and Drug Administration (FDA) regulates HEC when used in food, drugs, or cosmetics, ensuring its safety for consumer products.

Globally, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Manufacturers using HEC must adhere to GHS guidelines for labeling and safety data sheets, promoting consistency in hazard communication across borders.

Sustainable manufacturing practices involving HEC must also consider waste management regulations. The European Waste Framework Directive and similar regulations in other regions set guidelines for waste reduction, recycling, and disposal. Manufacturers must ensure that their use of HEC aligns with these directives, implementing proper waste management strategies to minimize environmental impact.

Water quality regulations are another crucial aspect of compliance for HEC manufacturers. Given HEC's water-soluble nature, regulations such as the Clean Water Act in the United States and the Water Framework Directive in the EU set standards for water discharge and treatment. Manufacturers must implement appropriate wastewater treatment processes to meet these regulatory requirements.

Occupational health and safety regulations, such as those set by the Occupational Safety and Health Administration (OSHA) in the US, also play a significant role. These regulations ensure safe working conditions for employees handling HEC, requiring proper training, personal protective equipment, and exposure controls.

As sustainability becomes increasingly important, new regulations are emerging that focus on circular economy principles and life cycle assessments. Manufacturers using HEC in sustainable practices must stay informed about these evolving regulations and adapt their processes accordingly to maintain compliance and meet sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!