Integrated Processes Using Propyne for Waste Valorization

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne Valorization Background and Objectives

Propyne valorization has emerged as a promising field in waste management and sustainable chemistry, addressing the growing need for efficient resource utilization and environmental protection. The background of this technology stems from the increasing global focus on circular economy principles and the imperative to reduce industrial waste. Propyne, also known as methylacetylene, is a byproduct of various industrial processes, particularly in the petrochemical sector. Historically, it has been considered a low-value waste product, often flared or used as fuel gas.

The evolution of propyne valorization technology can be traced back to the early 2000s when researchers began exploring its potential as a valuable chemical feedstock. Initial studies focused on its use in organic synthesis, particularly in the production of specialty chemicals. As environmental regulations tightened and sustainability became a key industrial focus, the interest in propyne valorization intensified, leading to more comprehensive research into its applications.

The primary objective of propyne valorization is to transform this waste product into high-value chemicals and materials, thereby reducing environmental impact and improving resource efficiency. This aligns with broader industrial goals of minimizing waste, reducing carbon footprint, and enhancing process economics. Specific technical objectives include developing efficient catalytic systems for propyne conversion, optimizing reaction conditions for selective product formation, and integrating valorization processes into existing industrial setups.

Recent technological advancements have expanded the scope of propyne valorization. Researchers are now exploring its potential in the production of polymers, fine chemicals, and even as a precursor for carbon nanomaterials. The integration of propyne valorization with other waste management technologies is also being investigated, aiming to create more comprehensive and efficient waste treatment systems.

The current technological landscape is characterized by a growing interest in green chemistry approaches. This has led to the development of novel catalysts and reaction systems that operate under milder conditions, consume less energy, and produce fewer byproducts. Additionally, there is a trend towards process intensification, where propyne valorization is combined with other chemical transformations in one-pot reactions or continuous flow systems.

Looking ahead, the field of propyne valorization is expected to continue evolving, driven by advancements in catalysis, process engineering, and materials science. Future objectives include scaling up laboratory successes to industrial levels, improving the selectivity and yield of desired products, and expanding the range of valuable chemicals that can be derived from propyne. There is also a growing emphasis on developing bio-based catalysts and environmentally benign solvents to further enhance the sustainability of these processes.

The evolution of propyne valorization technology can be traced back to the early 2000s when researchers began exploring its potential as a valuable chemical feedstock. Initial studies focused on its use in organic synthesis, particularly in the production of specialty chemicals. As environmental regulations tightened and sustainability became a key industrial focus, the interest in propyne valorization intensified, leading to more comprehensive research into its applications.

The primary objective of propyne valorization is to transform this waste product into high-value chemicals and materials, thereby reducing environmental impact and improving resource efficiency. This aligns with broader industrial goals of minimizing waste, reducing carbon footprint, and enhancing process economics. Specific technical objectives include developing efficient catalytic systems for propyne conversion, optimizing reaction conditions for selective product formation, and integrating valorization processes into existing industrial setups.

Recent technological advancements have expanded the scope of propyne valorization. Researchers are now exploring its potential in the production of polymers, fine chemicals, and even as a precursor for carbon nanomaterials. The integration of propyne valorization with other waste management technologies is also being investigated, aiming to create more comprehensive and efficient waste treatment systems.

The current technological landscape is characterized by a growing interest in green chemistry approaches. This has led to the development of novel catalysts and reaction systems that operate under milder conditions, consume less energy, and produce fewer byproducts. Additionally, there is a trend towards process intensification, where propyne valorization is combined with other chemical transformations in one-pot reactions or continuous flow systems.

Looking ahead, the field of propyne valorization is expected to continue evolving, driven by advancements in catalysis, process engineering, and materials science. Future objectives include scaling up laboratory successes to industrial levels, improving the selectivity and yield of desired products, and expanding the range of valuable chemicals that can be derived from propyne. There is also a growing emphasis on developing bio-based catalysts and environmentally benign solvents to further enhance the sustainability of these processes.

Market Analysis for Propyne-Based Waste Valorization

The market for propyne-based waste valorization is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable industrial practices. This innovative approach to waste management offers a promising solution for converting waste materials into valuable products, thereby addressing both economic and ecological challenges.

The global waste management market, which encompasses waste valorization technologies, was valued at approximately $400 billion in 2020 and is projected to reach over $600 billion by 2025, with a compound annual growth rate (CAGR) of around 7%. Within this broader market, the segment for advanced waste treatment and valorization technologies is growing at an even faster rate, estimated at 10-12% annually.

Propyne-based waste valorization specifically targets the conversion of organic waste streams into high-value chemicals and materials. This technology is particularly attractive in regions with stringent environmental regulations and high waste management costs, such as Europe, North America, and parts of Asia. The market potential is further enhanced by the increasing demand for sustainable and bio-based products across various industries.

Key industries driving the demand for propyne-based waste valorization include chemicals, plastics, pharmaceuticals, and agriculture. The chemical industry, in particular, shows strong interest in this technology as it aligns with the principles of circular economy and offers a pathway to reduce dependence on fossil-based feedstocks. The market for bio-based chemicals, which can be produced through propyne-based waste valorization, is expected to grow from $9.5 billion in 2020 to $15 billion by 2025.

The adoption of propyne-based waste valorization is also influenced by regulatory frameworks promoting sustainable waste management practices. For instance, the European Union's Circular Economy Action Plan and similar initiatives in other regions are creating a favorable environment for the development and implementation of advanced waste valorization technologies.

However, the market faces certain challenges, including high initial investment costs, technological complexities, and competition from established waste treatment methods. Despite these hurdles, the long-term economic and environmental benefits of propyne-based waste valorization are expected to drive market growth.

In terms of regional distribution, North America and Europe currently lead the market for advanced waste valorization technologies, including propyne-based processes. However, rapid industrialization and urbanization in Asia-Pacific countries are creating new opportunities for market expansion in this region.

The market landscape is characterized by a mix of established waste management companies, chemical manufacturers, and innovative startups. Collaborations between industry players and research institutions are becoming increasingly common, accelerating technological advancements and market adoption.

The global waste management market, which encompasses waste valorization technologies, was valued at approximately $400 billion in 2020 and is projected to reach over $600 billion by 2025, with a compound annual growth rate (CAGR) of around 7%. Within this broader market, the segment for advanced waste treatment and valorization technologies is growing at an even faster rate, estimated at 10-12% annually.

Propyne-based waste valorization specifically targets the conversion of organic waste streams into high-value chemicals and materials. This technology is particularly attractive in regions with stringent environmental regulations and high waste management costs, such as Europe, North America, and parts of Asia. The market potential is further enhanced by the increasing demand for sustainable and bio-based products across various industries.

Key industries driving the demand for propyne-based waste valorization include chemicals, plastics, pharmaceuticals, and agriculture. The chemical industry, in particular, shows strong interest in this technology as it aligns with the principles of circular economy and offers a pathway to reduce dependence on fossil-based feedstocks. The market for bio-based chemicals, which can be produced through propyne-based waste valorization, is expected to grow from $9.5 billion in 2020 to $15 billion by 2025.

The adoption of propyne-based waste valorization is also influenced by regulatory frameworks promoting sustainable waste management practices. For instance, the European Union's Circular Economy Action Plan and similar initiatives in other regions are creating a favorable environment for the development and implementation of advanced waste valorization technologies.

However, the market faces certain challenges, including high initial investment costs, technological complexities, and competition from established waste treatment methods. Despite these hurdles, the long-term economic and environmental benefits of propyne-based waste valorization are expected to drive market growth.

In terms of regional distribution, North America and Europe currently lead the market for advanced waste valorization technologies, including propyne-based processes. However, rapid industrialization and urbanization in Asia-Pacific countries are creating new opportunities for market expansion in this region.

The market landscape is characterized by a mix of established waste management companies, chemical manufacturers, and innovative startups. Collaborations between industry players and research institutions are becoming increasingly common, accelerating technological advancements and market adoption.

Technical Challenges in Propyne Integration

The integration of propyne into waste valorization processes presents several significant technical challenges that need to be addressed for successful implementation. One of the primary obstacles is the efficient and selective conversion of propyne to value-added products. Propyne's high reactivity can lead to undesired side reactions and product mixtures, necessitating the development of highly selective catalysts and reaction conditions.

Another major challenge lies in the separation and purification of propyne from complex waste streams. Propyne often exists in low concentrations within these streams, making its isolation technically demanding and potentially energy-intensive. Advanced separation technologies, such as membrane-based systems or novel adsorption materials, need to be developed to efficiently extract propyne from diverse waste sources.

The stability and safety concerns associated with propyne handling also pose significant technical hurdles. Propyne is highly flammable and can form explosive mixtures with air, requiring robust safety measures and specialized equipment for its storage, transportation, and processing. This necessitates the development of inherently safer process designs and advanced monitoring systems to ensure operational safety.

Process integration and optimization present another set of challenges. Incorporating propyne-based valorization into existing waste treatment facilities requires careful consideration of heat integration, mass balance, and overall process efficiency. The development of flexible and modular process designs that can adapt to varying waste compositions and scales is crucial for widespread adoption.

Energy efficiency is a critical factor in propyne integration. The high reactivity of propyne often requires precise temperature control and energy management. Developing energy-efficient reactor designs and heat recovery systems is essential to make the process economically viable and environmentally sustainable.

Catalyst development remains a key technical challenge. Designing catalysts that can selectively activate propyne while tolerating impurities present in waste streams is crucial. This involves research into novel catalyst materials, support structures, and reaction mechanisms to enhance activity, selectivity, and longevity under real-world conditions.

Lastly, the scale-up of laboratory-proven technologies to industrial-scale operations presents significant engineering challenges. Issues such as heat and mass transfer limitations, catalyst deactivation, and process control become more pronounced at larger scales. Overcoming these challenges requires innovative reactor designs, advanced process control strategies, and pilot-scale demonstrations to validate the technology's feasibility and performance at commercial scales.

Another major challenge lies in the separation and purification of propyne from complex waste streams. Propyne often exists in low concentrations within these streams, making its isolation technically demanding and potentially energy-intensive. Advanced separation technologies, such as membrane-based systems or novel adsorption materials, need to be developed to efficiently extract propyne from diverse waste sources.

The stability and safety concerns associated with propyne handling also pose significant technical hurdles. Propyne is highly flammable and can form explosive mixtures with air, requiring robust safety measures and specialized equipment for its storage, transportation, and processing. This necessitates the development of inherently safer process designs and advanced monitoring systems to ensure operational safety.

Process integration and optimization present another set of challenges. Incorporating propyne-based valorization into existing waste treatment facilities requires careful consideration of heat integration, mass balance, and overall process efficiency. The development of flexible and modular process designs that can adapt to varying waste compositions and scales is crucial for widespread adoption.

Energy efficiency is a critical factor in propyne integration. The high reactivity of propyne often requires precise temperature control and energy management. Developing energy-efficient reactor designs and heat recovery systems is essential to make the process economically viable and environmentally sustainable.

Catalyst development remains a key technical challenge. Designing catalysts that can selectively activate propyne while tolerating impurities present in waste streams is crucial. This involves research into novel catalyst materials, support structures, and reaction mechanisms to enhance activity, selectivity, and longevity under real-world conditions.

Lastly, the scale-up of laboratory-proven technologies to industrial-scale operations presents significant engineering challenges. Issues such as heat and mass transfer limitations, catalyst deactivation, and process control become more pronounced at larger scales. Overcoming these challenges requires innovative reactor designs, advanced process control strategies, and pilot-scale demonstrations to validate the technology's feasibility and performance at commercial scales.

Current Propyne Integration Solutions

01 Synthesis and production of propyne

Various methods for synthesizing and producing propyne are described. These include catalytic processes, thermal cracking, and other chemical reactions to obtain propyne from different starting materials. The processes aim to improve yield, efficiency, and purity of the propyne product.- Synthesis and production of propyne: Various methods and processes for synthesizing and producing propyne are described. These include catalytic processes, thermal cracking, and other chemical reactions to obtain propyne from different precursors.

- Purification and separation of propyne: Techniques for purifying and separating propyne from mixtures or other compounds are outlined. These may involve distillation, adsorption, or membrane separation processes to obtain high-purity propyne.

- Applications of propyne in chemical synthesis: Propyne is used as a starting material or intermediate in various chemical syntheses. It can be employed in the production of polymers, pharmaceuticals, and other valuable chemical compounds.

- Propyne in fuel compositions: The use of propyne in fuel compositions is explored. It may be incorporated into fuel blends to improve combustion properties or as an additive to enhance fuel performance.

- Safety and handling of propyne: Methods and systems for the safe handling, storage, and transportation of propyne are described. This includes specialized equipment, safety protocols, and risk mitigation strategies due to the flammable nature of propyne.

02 Propyne as a raw material in chemical processes

Propyne serves as an important raw material in various chemical processes. It is used in the production of other chemicals, polymers, and materials. The applications include the synthesis of specialty chemicals, pharmaceuticals, and industrial products.Expand Specific Solutions03 Purification and separation of propyne

Techniques for purifying and separating propyne from mixtures are discussed. These methods involve distillation, adsorption, membrane separation, and other physical or chemical processes to obtain high-purity propyne for industrial use.Expand Specific Solutions04 Propyne in fuel compositions

The use of propyne in fuel compositions is explored. It can be incorporated into various fuel blends to enhance combustion properties, improve engine performance, or reduce emissions. Research focuses on optimizing propyne content in fuel mixtures for different applications.Expand Specific Solutions05 Safety and handling of propyne

Safety measures and handling procedures for propyne are outlined. Due to its flammable and potentially explosive nature, specific precautions are necessary for storage, transportation, and use of propyne in industrial settings. Guidelines for risk assessment and mitigation are provided.Expand Specific Solutions

Key Players in Propyne Valorization Industry

The integrated processes using propyne for waste valorization represent an emerging field in the chemical industry, currently in its early development stage. The market size is relatively small but growing, driven by increasing focus on sustainability and circular economy principles. Technologically, the field is still evolving, with varying levels of maturity across different applications. Key players like China Petroleum & Chemical Corp., BASF Corp., and The Dow Chemical Co. are investing in research and development to advance propyne-based waste valorization technologies. Smaller specialized firms and research institutions are also contributing to innovation in this area. As the technology matures, we can expect increased commercialization efforts and potential market expansion in the coming years.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an integrated process for waste valorization using propyne. Their approach involves catalytic dehydrogenation of propane to produce propyne, followed by selective hydrogenation to propylene[1]. The process utilizes a novel catalyst system that enhances propyne yield and selectivity. Sinopec has also implemented a closed-loop system that recycles unreacted propane and byproducts, improving overall efficiency[2]. The company has integrated this technology into their existing petrochemical infrastructure, allowing for seamless adoption and scale-up[3].

Strengths: Efficient catalyst system, integrated with existing infrastructure, closed-loop recycling. Weaknesses: High energy requirements, potential catalyst deactivation over time.

BASF Corp.

Technical Solution: BASF Corp. has developed a multi-step process for waste valorization using propyne as a key intermediate. Their approach begins with the conversion of waste plastics into a mixture of hydrocarbons, including propane[1]. The propane is then selectively dehydrogenated to propyne using a proprietary catalyst[2]. BASF's process incorporates a novel purification step that removes impurities from the propyne stream, ensuring high-quality feedstock for downstream processes[3]. The purified propyne is then used in the production of various high-value chemicals, such as acrylonitrile and methyl methacrylate[4]. BASF has also implemented advanced process control systems to optimize the overall efficiency and reduce energy consumption[5].

Strengths: Versatile waste-to-chemicals approach, high-purity propyne production, integration with downstream processes. Weaknesses: Complex multi-step process, potential high capital costs for implementation.

Innovative Propyne Valorization Techniques

Method and system for material valorization of waste for the co-production of hydrogen and hydrocarbons or alcohols

PatentPendingEP4509582A1

Innovation

- A method and system for thermal treatment of waste that integrates pyrolysis and cracking processes to co-produce hydrogen and hydrocarbons or alcohols, enhancing hydrogen production efficiency through process stream integration and catalyst usage.

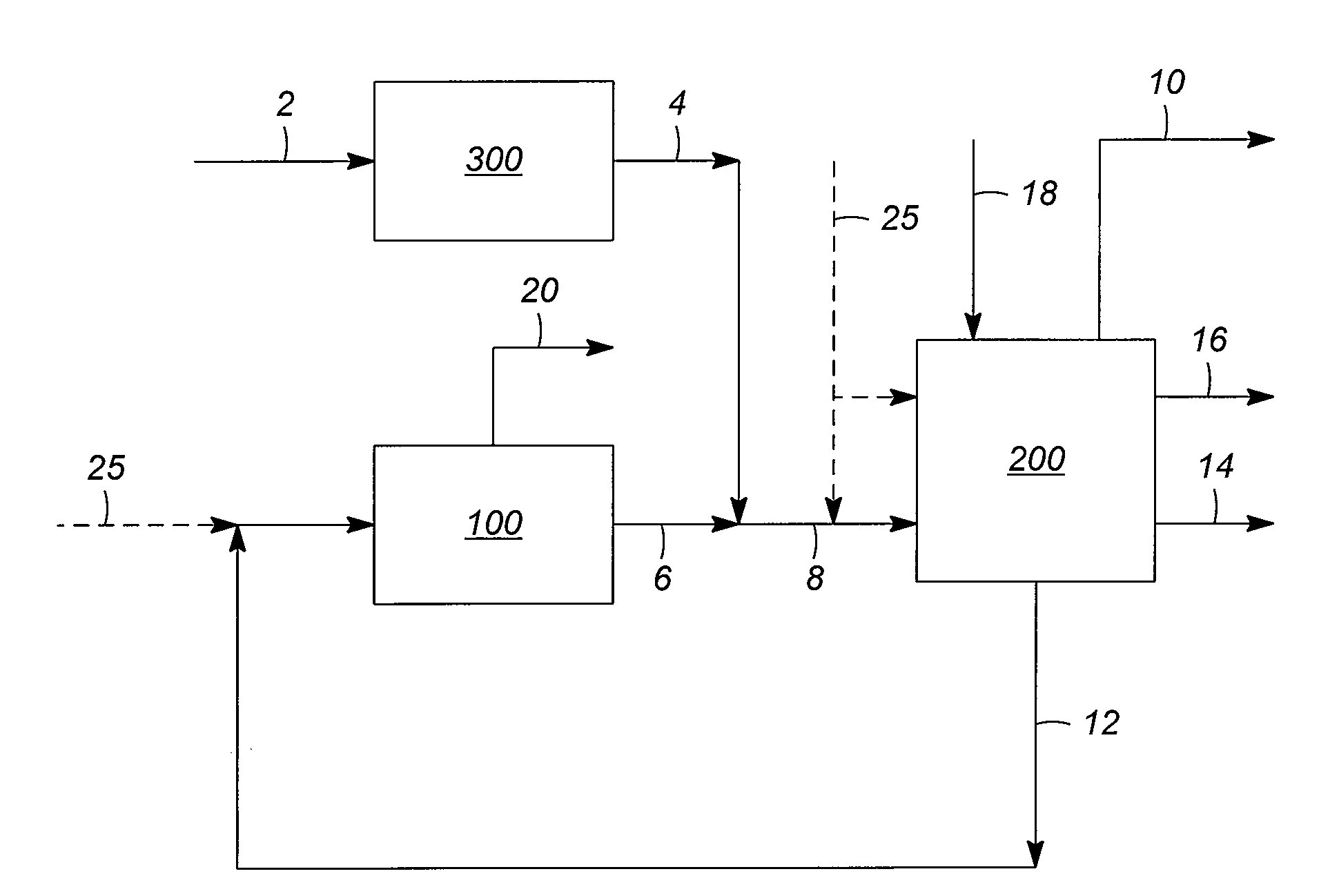

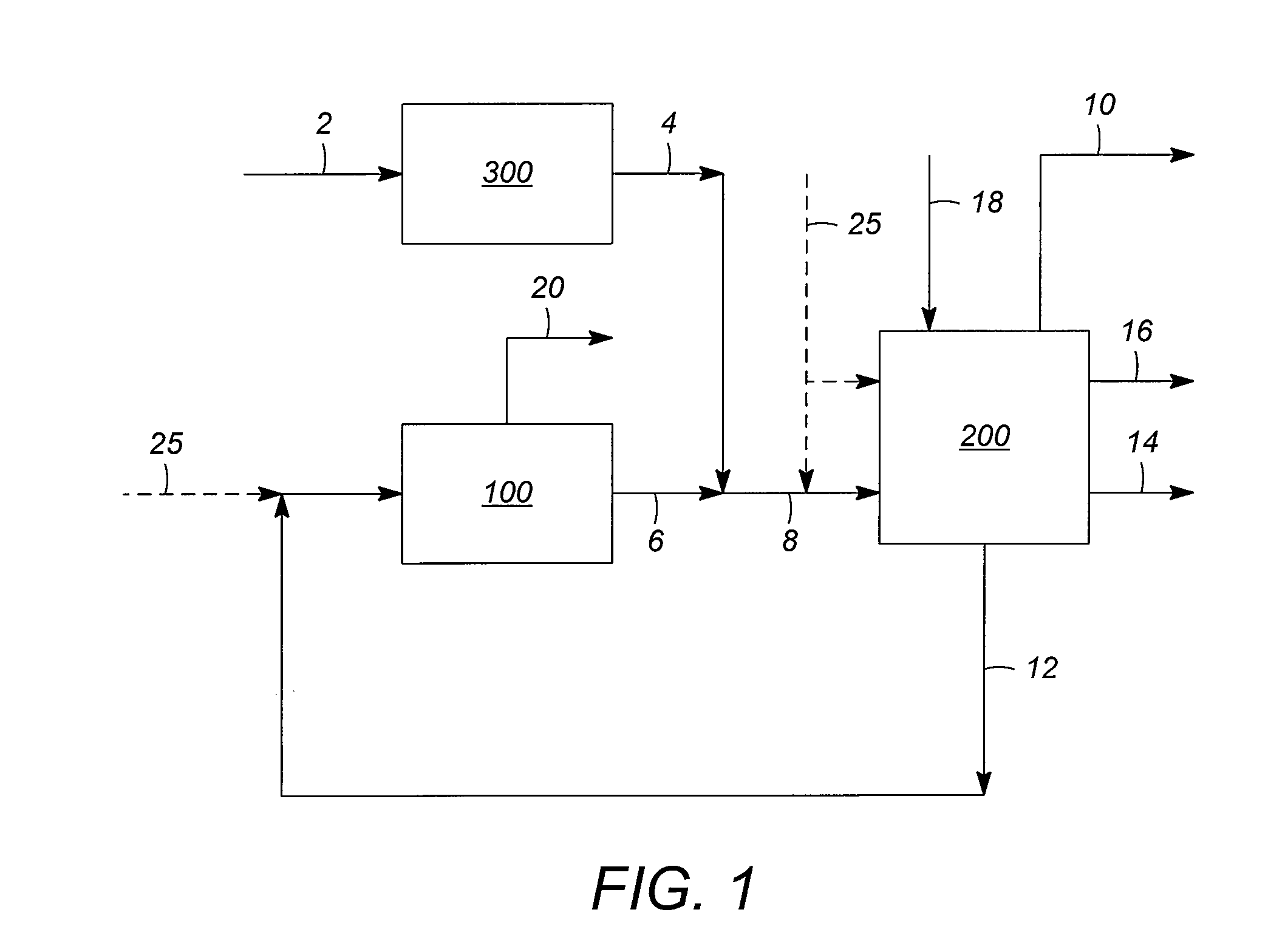

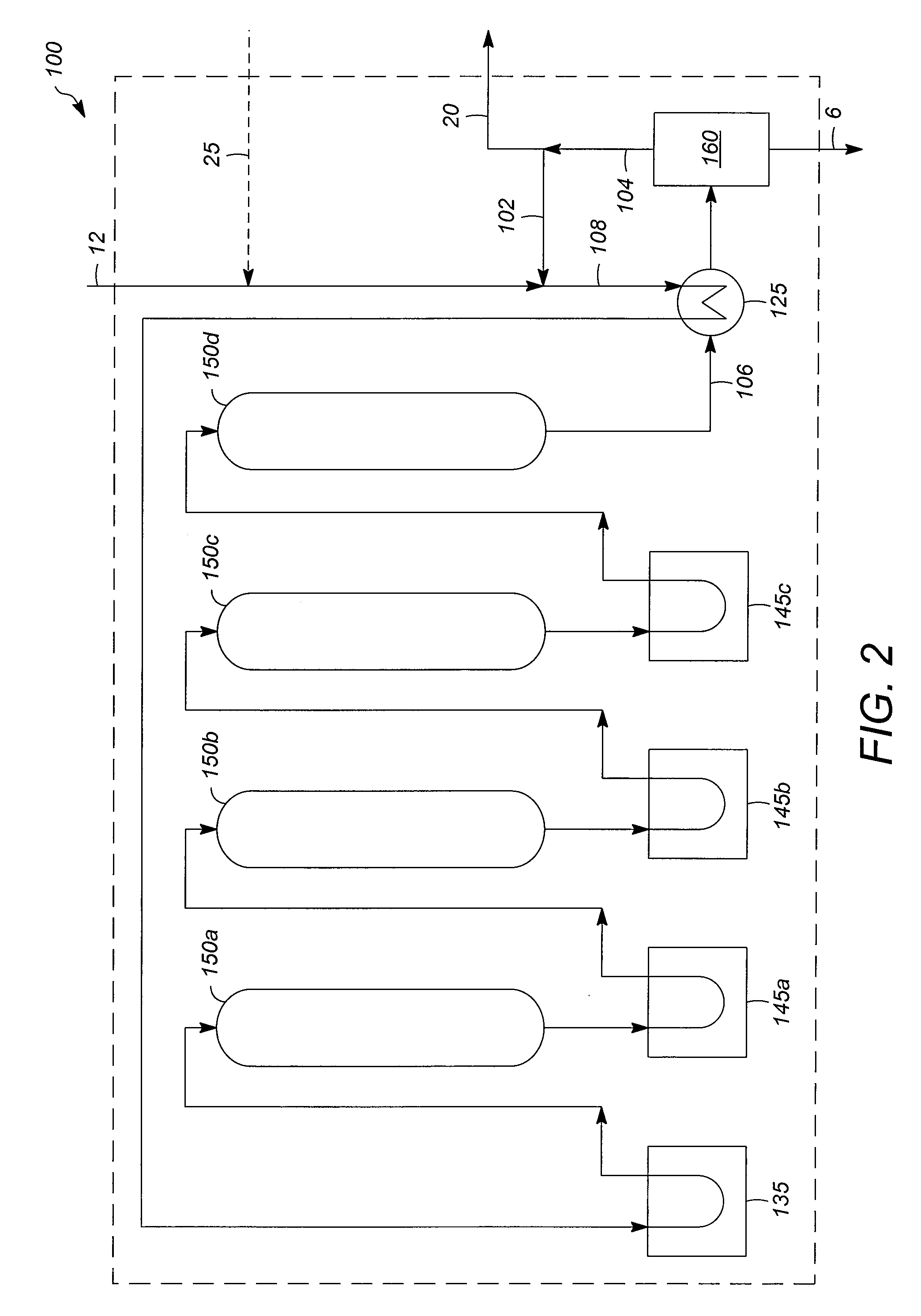

Integrated processes for propylene production and recovery

PatentActiveUS20100331589A1

Innovation

- An integrated process that combines propylene recovery and catalytic dehydrogenation, eliminating the need for conventional fractionation sections by sharing separation equipment, allowing for complete or near-complete conversion of propane to propylene, and achieving significant capital and energy savings.

Environmental Impact Assessment

The environmental impact assessment of integrated processes using propyne for waste valorization is a critical aspect that requires thorough examination. These processes, while offering potential benefits in waste management and resource recovery, also present environmental challenges that must be carefully evaluated and mitigated.

One of the primary environmental concerns is the potential for air pollution. Propyne, being a highly reactive hydrocarbon, can contribute to the formation of ground-level ozone and smog if released into the atmosphere. The combustion of propyne and its derivatives may also result in the emission of carbon dioxide, contributing to greenhouse gas levels. To address these issues, stringent emission control measures must be implemented, including the use of advanced scrubbing technologies and catalytic converters.

Water pollution is another significant consideration. The waste valorization processes may generate wastewater containing organic compounds, heavy metals, and other contaminants. Proper treatment and disposal of this wastewater are essential to prevent contamination of local water bodies and groundwater resources. Advanced water treatment technologies, such as membrane filtration and advanced oxidation processes, should be integrated into the overall system design.

The energy consumption of these integrated processes is a crucial factor in their environmental impact. While waste valorization can potentially recover energy from waste materials, the processes themselves may require substantial energy inputs. Conducting a comprehensive life cycle assessment is necessary to determine the net energy balance and associated carbon footprint of the entire system.

Land use and biodiversity impacts must also be considered. The construction and operation of facilities for these integrated processes may require significant land area, potentially leading to habitat disruption or loss. Careful site selection and implementation of biodiversity conservation measures are essential to minimize these impacts.

Noise pollution and odor emissions are additional environmental concerns that need to be addressed. The operation of machinery and chemical processes can generate significant noise levels, while the handling and processing of waste materials may produce unpleasant odors. Implementing noise reduction technologies and odor control systems is crucial for maintaining the quality of life in surrounding communities.

Lastly, the potential for accidental releases and spills must be carefully evaluated. Propyne and its derivatives are flammable and potentially explosive, posing risks to both the environment and human safety. Robust safety protocols, containment systems, and emergency response plans must be developed and rigorously implemented to minimize these risks.

One of the primary environmental concerns is the potential for air pollution. Propyne, being a highly reactive hydrocarbon, can contribute to the formation of ground-level ozone and smog if released into the atmosphere. The combustion of propyne and its derivatives may also result in the emission of carbon dioxide, contributing to greenhouse gas levels. To address these issues, stringent emission control measures must be implemented, including the use of advanced scrubbing technologies and catalytic converters.

Water pollution is another significant consideration. The waste valorization processes may generate wastewater containing organic compounds, heavy metals, and other contaminants. Proper treatment and disposal of this wastewater are essential to prevent contamination of local water bodies and groundwater resources. Advanced water treatment technologies, such as membrane filtration and advanced oxidation processes, should be integrated into the overall system design.

The energy consumption of these integrated processes is a crucial factor in their environmental impact. While waste valorization can potentially recover energy from waste materials, the processes themselves may require substantial energy inputs. Conducting a comprehensive life cycle assessment is necessary to determine the net energy balance and associated carbon footprint of the entire system.

Land use and biodiversity impacts must also be considered. The construction and operation of facilities for these integrated processes may require significant land area, potentially leading to habitat disruption or loss. Careful site selection and implementation of biodiversity conservation measures are essential to minimize these impacts.

Noise pollution and odor emissions are additional environmental concerns that need to be addressed. The operation of machinery and chemical processes can generate significant noise levels, while the handling and processing of waste materials may produce unpleasant odors. Implementing noise reduction technologies and odor control systems is crucial for maintaining the quality of life in surrounding communities.

Lastly, the potential for accidental releases and spills must be carefully evaluated. Propyne and its derivatives are flammable and potentially explosive, posing risks to both the environment and human safety. Robust safety protocols, containment systems, and emergency response plans must be developed and rigorously implemented to minimize these risks.

Economic Feasibility Analysis

The economic feasibility analysis of integrated processes using propyne for waste valorization requires a comprehensive evaluation of costs, revenues, and potential market impact. Initial capital expenditure for such processes is substantial, encompassing specialized equipment for propyne handling, reaction vessels, and separation units. Operational costs include raw materials, energy consumption, and maintenance, which can be offset by the value of products generated from waste streams.

A key economic driver is the potential for revenue diversification. Propyne-based processes can yield a range of valuable products, including polymers, fine chemicals, and fuel additives. This versatility allows for adaptability to market fluctuations and reduces dependency on single product streams. The ability to valorize waste materials also presents an opportunity for cost savings in waste disposal and potential regulatory compliance benefits.

Market analysis indicates growing demand for sustainable chemical processes, particularly those that can upcycle waste. This trend aligns favorably with propyne-based waste valorization, potentially commanding premium pricing for "green" products. However, market penetration may face challenges due to established incumbent technologies and the need for customer education on new product offerings.

Scalability is a critical factor in economic viability. Initial pilot-scale operations may face higher per-unit costs, but economies of scale can be achieved as production volumes increase. This scalability potential enhances the long-term economic prospects of propyne-based waste valorization processes.

Risk assessment reveals that propyne price volatility and supply chain reliability are significant economic factors. Strategies to mitigate these risks, such as long-term supply contracts or development of alternative feedstock sources, should be considered in feasibility calculations. Additionally, the regulatory landscape surrounding waste processing and chemical manufacturing can impact operational costs and market access, necessitating a thorough understanding of compliance requirements in target markets.

Return on investment (ROI) projections for propyne-based waste valorization processes vary depending on scale, product mix, and market conditions. Initial estimates suggest potential payback periods of 3-5 years for well-optimized operations, with ROI improving as processes mature and market acceptance grows. However, these projections are sensitive to factors such as feedstock costs, energy prices, and product market dynamics.

In conclusion, while integrated processes using propyne for waste valorization present promising economic potential, careful consideration of capital requirements, operational costs, market dynamics, and risk factors is essential for accurate feasibility assessment. The technology's alignment with sustainability trends and its potential for value-added product creation offer compelling economic incentives, but successful implementation will require strategic planning and potentially phased deployment to manage financial risks effectively.

A key economic driver is the potential for revenue diversification. Propyne-based processes can yield a range of valuable products, including polymers, fine chemicals, and fuel additives. This versatility allows for adaptability to market fluctuations and reduces dependency on single product streams. The ability to valorize waste materials also presents an opportunity for cost savings in waste disposal and potential regulatory compliance benefits.

Market analysis indicates growing demand for sustainable chemical processes, particularly those that can upcycle waste. This trend aligns favorably with propyne-based waste valorization, potentially commanding premium pricing for "green" products. However, market penetration may face challenges due to established incumbent technologies and the need for customer education on new product offerings.

Scalability is a critical factor in economic viability. Initial pilot-scale operations may face higher per-unit costs, but economies of scale can be achieved as production volumes increase. This scalability potential enhances the long-term economic prospects of propyne-based waste valorization processes.

Risk assessment reveals that propyne price volatility and supply chain reliability are significant economic factors. Strategies to mitigate these risks, such as long-term supply contracts or development of alternative feedstock sources, should be considered in feasibility calculations. Additionally, the regulatory landscape surrounding waste processing and chemical manufacturing can impact operational costs and market access, necessitating a thorough understanding of compliance requirements in target markets.

Return on investment (ROI) projections for propyne-based waste valorization processes vary depending on scale, product mix, and market conditions. Initial estimates suggest potential payback periods of 3-5 years for well-optimized operations, with ROI improving as processes mature and market acceptance grows. However, these projections are sensitive to factors such as feedstock costs, energy prices, and product market dynamics.

In conclusion, while integrated processes using propyne for waste valorization present promising economic potential, careful consideration of capital requirements, operational costs, market dynamics, and risk factors is essential for accurate feasibility assessment. The technology's alignment with sustainability trends and its potential for value-added product creation offer compelling economic incentives, but successful implementation will require strategic planning and potentially phased deployment to manage financial risks effectively.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!