L92 engine retrofit feasibility in electrified vehicles

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Background

The L92 engine, developed by General Motors, is a powerful and efficient V8 engine that has been widely used in various high-performance vehicles. Introduced in 2006, the L92 is part of the GM Gen IV small-block engine family, known for its advanced design and impressive output. This 6.2-liter engine features an aluminum block and cylinder heads, which contribute to its relatively lightweight construction compared to its predecessors.

One of the key innovations in the L92 engine is the implementation of variable valve timing (VVT) technology. This system allows for optimized engine performance across different operating conditions, improving both power output and fuel efficiency. The L92 also incorporates a high-flow cylinder head design and a revised camshaft profile, which further enhance its performance characteristics.

Initially, the L92 engine was primarily used in GM's full-size SUVs and trucks, such as the Chevrolet Tahoe, GMC Yukon, and Cadillac Escalade. Its robust design and impressive power output made it an ideal choice for these larger vehicles, providing ample towing capacity and acceleration. Over time, variations of the L92 engine found their way into performance-oriented cars like the Chevrolet Camaro and Pontiac G8.

The L92 engine's output typically ranges from 403 to 430 horsepower, depending on the specific application and tuning. This power is delivered smoothly across a wide RPM range, thanks to its advanced design features. The engine's torque output is equally impressive, usually peaking around 415 to 425 lb-ft, providing strong low-end and mid-range performance.

From an engineering perspective, the L92 engine represents a significant step forward in V8 engine design. Its use of advanced materials and manufacturing techniques allowed for tighter tolerances and improved reliability compared to earlier V8 engines. The incorporation of electronic throttle control and sophisticated engine management systems further enhanced its overall performance and efficiency.

As automotive technology has progressed, particularly in the direction of electrification, the role of high-performance internal combustion engines like the L92 has come under scrutiny. However, the engine's robust design and adaptability have made it a candidate for potential retrofitting in hybrid or electrified vehicle applications. This consideration stems from its proven reliability, compact size for its output, and the potential for further optimization when integrated with electric powertrains.

One of the key innovations in the L92 engine is the implementation of variable valve timing (VVT) technology. This system allows for optimized engine performance across different operating conditions, improving both power output and fuel efficiency. The L92 also incorporates a high-flow cylinder head design and a revised camshaft profile, which further enhance its performance characteristics.

Initially, the L92 engine was primarily used in GM's full-size SUVs and trucks, such as the Chevrolet Tahoe, GMC Yukon, and Cadillac Escalade. Its robust design and impressive power output made it an ideal choice for these larger vehicles, providing ample towing capacity and acceleration. Over time, variations of the L92 engine found their way into performance-oriented cars like the Chevrolet Camaro and Pontiac G8.

The L92 engine's output typically ranges from 403 to 430 horsepower, depending on the specific application and tuning. This power is delivered smoothly across a wide RPM range, thanks to its advanced design features. The engine's torque output is equally impressive, usually peaking around 415 to 425 lb-ft, providing strong low-end and mid-range performance.

From an engineering perspective, the L92 engine represents a significant step forward in V8 engine design. Its use of advanced materials and manufacturing techniques allowed for tighter tolerances and improved reliability compared to earlier V8 engines. The incorporation of electronic throttle control and sophisticated engine management systems further enhanced its overall performance and efficiency.

As automotive technology has progressed, particularly in the direction of electrification, the role of high-performance internal combustion engines like the L92 has come under scrutiny. However, the engine's robust design and adaptability have made it a candidate for potential retrofitting in hybrid or electrified vehicle applications. This consideration stems from its proven reliability, compact size for its output, and the potential for further optimization when integrated with electric powertrains.

EV Market Analysis

The electric vehicle (EV) market has experienced significant growth in recent years, driven by increasing environmental concerns, government incentives, and technological advancements. This growth trend is expected to continue, with the global EV market projected to reach substantial market value by 2030. The market expansion is particularly notable in regions such as China, Europe, and North America, where supportive policies and consumer awareness have accelerated EV adoption.

Within this rapidly evolving landscape, the concept of retrofitting conventional internal combustion engines, such as the L92 engine, for use in electrified vehicles presents an intriguing opportunity. This approach could potentially bridge the gap between traditional automotive technologies and the emerging EV sector, offering a transitional solution for manufacturers and consumers alike.

The market demand for such retrofit solutions is influenced by several factors. Firstly, there is a growing consumer segment interested in maintaining the familiarity and performance characteristics of traditional engines while benefiting from electrification. This group includes automotive enthusiasts and those who appreciate the heritage of iconic engine designs like the L92.

Secondly, the retrofit market could address the needs of fleet operators and businesses looking to extend the lifespan of their existing vehicles while meeting increasingly stringent emissions regulations. This approach could offer a cost-effective alternative to full vehicle replacement, particularly for specialized or heavy-duty vehicles.

The potential market size for L92 engine retrofits in electrified vehicles is closely tied to the broader hybrid electric vehicle (HEV) and plug-in hybrid electric vehicle (PHEV) markets. These segments have shown steady growth, with PHEVs often seen as a stepping stone between conventional vehicles and full EVs. The retrofit solution could capture a portion of this market, especially in regions where the transition to full electrification faces infrastructure or consumer acceptance challenges.

However, the market potential for engine retrofits must be considered alongside the rapid advancement of battery technology and the decreasing costs of full electric powertrains. As these technologies improve, the long-term viability of retrofit solutions may be impacted. Additionally, regulatory environments in various markets play a crucial role in shaping demand, with some regions pushing for a faster transition to zero-emission vehicles.

In conclusion, while the overall EV market shows strong growth potential, the specific market for L92 engine retrofits in electrified vehicles represents a niche segment. Its success will depend on factors such as cost-effectiveness, performance benefits, and regulatory alignment. As the automotive industry continues its transition towards electrification, innovative solutions like engine retrofits may find their place in serving specific market needs and facilitating a smoother transition to electric mobility.

Within this rapidly evolving landscape, the concept of retrofitting conventional internal combustion engines, such as the L92 engine, for use in electrified vehicles presents an intriguing opportunity. This approach could potentially bridge the gap between traditional automotive technologies and the emerging EV sector, offering a transitional solution for manufacturers and consumers alike.

The market demand for such retrofit solutions is influenced by several factors. Firstly, there is a growing consumer segment interested in maintaining the familiarity and performance characteristics of traditional engines while benefiting from electrification. This group includes automotive enthusiasts and those who appreciate the heritage of iconic engine designs like the L92.

Secondly, the retrofit market could address the needs of fleet operators and businesses looking to extend the lifespan of their existing vehicles while meeting increasingly stringent emissions regulations. This approach could offer a cost-effective alternative to full vehicle replacement, particularly for specialized or heavy-duty vehicles.

The potential market size for L92 engine retrofits in electrified vehicles is closely tied to the broader hybrid electric vehicle (HEV) and plug-in hybrid electric vehicle (PHEV) markets. These segments have shown steady growth, with PHEVs often seen as a stepping stone between conventional vehicles and full EVs. The retrofit solution could capture a portion of this market, especially in regions where the transition to full electrification faces infrastructure or consumer acceptance challenges.

However, the market potential for engine retrofits must be considered alongside the rapid advancement of battery technology and the decreasing costs of full electric powertrains. As these technologies improve, the long-term viability of retrofit solutions may be impacted. Additionally, regulatory environments in various markets play a crucial role in shaping demand, with some regions pushing for a faster transition to zero-emission vehicles.

In conclusion, while the overall EV market shows strong growth potential, the specific market for L92 engine retrofits in electrified vehicles represents a niche segment. Its success will depend on factors such as cost-effectiveness, performance benefits, and regulatory alignment. As the automotive industry continues its transition towards electrification, innovative solutions like engine retrofits may find their place in serving specific market needs and facilitating a smoother transition to electric mobility.

Retrofit Challenges

Retrofitting L92 engines into electrified vehicles presents several significant challenges that must be carefully considered. The primary obstacle lies in integrating a large, high-performance internal combustion engine into a vehicle architecture designed for electric propulsion. This requires extensive modifications to the vehicle's powertrain, cooling systems, and electronic control units.

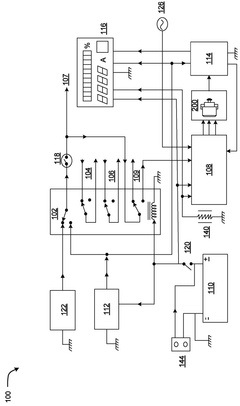

One of the most pressing issues is the need for a complete redesign of the vehicle's power management system. The L92 engine, known for its high output, requires a robust electrical system to support its operation alongside electric motors. This necessitates the development of a sophisticated hybrid control unit capable of managing power distribution between the combustion engine and electric components efficiently.

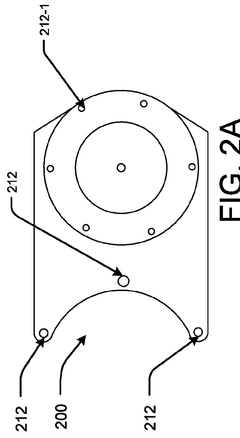

Space constraints pose another major challenge. The L92 engine's substantial size and weight may require significant alterations to the vehicle's chassis and body structure. This could potentially compromise the vehicle's original design intent, affecting aerodynamics, weight distribution, and overall performance characteristics. Engineers must find innovative ways to package the engine, electric motors, and battery systems without sacrificing interior space or vehicle dynamics.

Thermal management becomes increasingly complex in a retrofit scenario. The L92 engine generates considerable heat, which must be effectively dissipated alongside the thermal output from electric components. This requires a redesign of the cooling system to handle the combined thermal load, potentially necessitating larger radiators, additional cooling circuits, and advanced heat exchangers.

Emissions compliance presents a formidable hurdle. Integrating a high-performance V8 engine into an electrified vehicle may compromise the vehicle's overall emissions profile. Meeting stringent environmental regulations could require extensive modifications to the engine's fuel and exhaust systems, potentially including advanced catalytic converters and particulate filters.

The vehicle's transmission system may also require significant modifications or complete replacement to accommodate the torque characteristics of both the L92 engine and electric motors. Developing a transmission that can seamlessly handle power inputs from multiple sources while maintaining efficiency and drivability is a complex engineering task.

Software integration poses a substantial challenge. The vehicle's existing electronic systems must be reprogrammed to accommodate the L92 engine, ensuring seamless operation with the electric powertrain components. This involves developing new control algorithms for engine management, power distribution, and regenerative braking systems.

Lastly, the retrofit process must address safety concerns associated with combining high-voltage electrical systems with a powerful combustion engine. This includes implementing robust isolation measures, redesigning crumple zones, and ensuring that all components meet stringent safety standards for hybrid and electric vehicles.

One of the most pressing issues is the need for a complete redesign of the vehicle's power management system. The L92 engine, known for its high output, requires a robust electrical system to support its operation alongside electric motors. This necessitates the development of a sophisticated hybrid control unit capable of managing power distribution between the combustion engine and electric components efficiently.

Space constraints pose another major challenge. The L92 engine's substantial size and weight may require significant alterations to the vehicle's chassis and body structure. This could potentially compromise the vehicle's original design intent, affecting aerodynamics, weight distribution, and overall performance characteristics. Engineers must find innovative ways to package the engine, electric motors, and battery systems without sacrificing interior space or vehicle dynamics.

Thermal management becomes increasingly complex in a retrofit scenario. The L92 engine generates considerable heat, which must be effectively dissipated alongside the thermal output from electric components. This requires a redesign of the cooling system to handle the combined thermal load, potentially necessitating larger radiators, additional cooling circuits, and advanced heat exchangers.

Emissions compliance presents a formidable hurdle. Integrating a high-performance V8 engine into an electrified vehicle may compromise the vehicle's overall emissions profile. Meeting stringent environmental regulations could require extensive modifications to the engine's fuel and exhaust systems, potentially including advanced catalytic converters and particulate filters.

The vehicle's transmission system may also require significant modifications or complete replacement to accommodate the torque characteristics of both the L92 engine and electric motors. Developing a transmission that can seamlessly handle power inputs from multiple sources while maintaining efficiency and drivability is a complex engineering task.

Software integration poses a substantial challenge. The vehicle's existing electronic systems must be reprogrammed to accommodate the L92 engine, ensuring seamless operation with the electric powertrain components. This involves developing new control algorithms for engine management, power distribution, and regenerative braking systems.

Lastly, the retrofit process must address safety concerns associated with combining high-voltage electrical systems with a powerful combustion engine. This includes implementing robust isolation measures, redesigning crumple zones, and ensuring that all components meet stringent safety standards for hybrid and electric vehicles.

Current Retrofit Solutions

01 Engine design and configuration

The L92 engine is a V8 engine design with specific configurations for improved performance and efficiency. It features advanced technologies such as variable valve timing and direct fuel injection. The engine's design focuses on optimizing power output, fuel economy, and emissions control.- Engine design and configuration: The L92 engine is a V8 engine design with specific configurations for improved performance and efficiency. It features advanced technologies in its cylinder head design, valve train, and combustion chamber layout to optimize power output and fuel economy.

- Fuel injection system: The L92 engine incorporates a sophisticated fuel injection system to enhance fuel delivery and combustion efficiency. This system may include direct injection technology or other advanced fuel delivery methods to improve engine performance and reduce emissions.

- Variable valve timing: The L92 engine may feature variable valve timing technology to optimize engine performance across different operating conditions. This system allows for improved power output, fuel efficiency, and reduced emissions by adjusting valve timing based on engine speed and load.

- Engine management system: An advanced engine management system is utilized in the L92 engine to control various aspects of engine operation. This system may include electronic control units, sensors, and actuators to optimize performance, fuel efficiency, and emissions control.

- Exhaust system design: The L92 engine incorporates a specially designed exhaust system to enhance engine performance and reduce emissions. This may include features such as exhaust gas recirculation, catalytic converters, and tuned exhaust manifolds to optimize engine breathing and reduce environmental impact.

02 Fuel injection system

The L92 engine incorporates a sophisticated fuel injection system, likely featuring direct injection technology. This system is designed to improve fuel atomization, combustion efficiency, and overall engine performance. It may include high-pressure fuel pumps and precision injectors for optimal fuel delivery.Expand Specific Solutions03 Valve train and timing mechanisms

Advanced valve train components and timing mechanisms are utilized in the L92 engine to enhance performance and efficiency. This may include variable valve timing systems, roller rocker arms, and hydraulic lifters. These components work together to optimize engine breathing and combustion across various operating conditions.Expand Specific Solutions04 Engine control and management systems

The L92 engine likely employs sophisticated engine control and management systems. These systems may include advanced sensors, electronic control units, and software algorithms to optimize engine performance, fuel efficiency, and emissions control. They can adjust various engine parameters in real-time based on operating conditions.Expand Specific Solutions05 Emissions control technologies

To meet stringent emissions regulations, the L92 engine incorporates various emissions control technologies. These may include exhaust gas recirculation systems, catalytic converters, and advanced air intake designs. The engine's overall design and control strategies are likely optimized to minimize harmful emissions while maintaining performance.Expand Specific Solutions

Key Industry Players

The L92 engine retrofit feasibility in electrified vehicles presents a competitive landscape in the early stages of development. The market size is relatively small but growing, driven by the increasing demand for electrification solutions in the automotive industry. The technology's maturity is still evolving, with key players like Robert Bosch GmbH, Ford Global Technologies LLC, and Volkswagen AG leading research and development efforts. Other companies such as BYD Co., Ltd. and Volvo Personvagnar AB are also contributing to advancements in this field. The competition is intensifying as automotive manufacturers and suppliers race to develop cost-effective and efficient retrofit solutions for existing internal combustion engines in the transition towards electrified powertrains.

Robert Bosch GmbH

Technical Solution: Bosch has developed a versatile hybrid retrofit system applicable to various engine types, including the L92. Their solution centers around a 48V mild hybrid system that can be easily integrated into existing powertrains. The Bosch system includes a compact 48V electric motor-generator, a 48V lithium-ion battery, and a DC-DC converter for powering the 12V electrical system[9]. Bosch's retrofit kit also features an intelligent boost recuperation system that optimizes energy recovery during deceleration and provides electric boost during acceleration. The company has developed sophisticated control software that seamlessly manages the interaction between the combustion engine and electric components, ensuring smooth operation and maximizing efficiency gains[10].

Strengths: Highly adaptable system suitable for various vehicle types and engine configurations. Relatively simple integration process with minimal modifications to existing powertrains. Weaknesses: Limited electric-only operation due to the mild hybrid nature of the system.

Ford Global Technologies LLC

Technical Solution: Ford has developed a hybrid retrofit system for the L92 engine, focusing on integrating electric components with the existing V8 architecture. The system includes a high-voltage battery pack, electric motor, and power electronics unit designed to work seamlessly with the L92's fuel injection and valve timing systems. Ford's approach utilizes a P2 hybrid configuration, placing the electric motor between the engine and transmission for optimal power blending[1]. The retrofit kit is designed for easy installation, minimizing modifications to the vehicle's existing powertrain structure. Ford has also implemented advanced control algorithms to manage power distribution between the combustion engine and electric motor, optimizing fuel efficiency and performance[3].

Strengths: Leverages existing L92 engine infrastructure, potentially reducing costs. Offers improved fuel efficiency and performance. Weaknesses: May face challenges in packaging due to the large size of the L92 engine, potentially limiting application in smaller vehicles.

L92 Adaptation Innovations

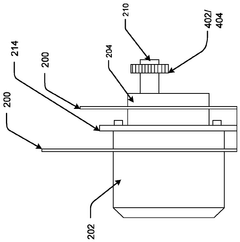

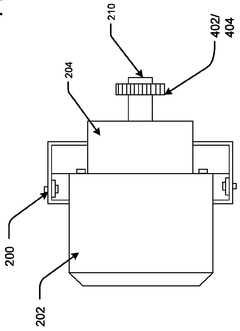

Dual powered retrofit kit for a two-wheeler vehicle

PatentWO2025046317A1

Innovation

- A dual-powered retrofit kit for two-wheeler vehicles that enables IC engine vehicles to switch between fuel-powered and electric modes, featuring a brushless direct current (BLDC) mid drive motor, automatic gearbox, and a switch for mode selection, allowing seamless integration without altering the original engine and drive system.

Retrofit technology for converting non-electric and internal combustion car into the electric car

PatentActiveIN201821002357A

Innovation

- The Electric Car Retrofit Module (ECRM) replaces the IC engine and related accessories with energy storage technology, a main electric motor, auxiliary motor, and an Intelligent Motor Control Unit, converting the vehicle into a full electric vehicle with zero emissions, while maintaining the original chassis and enhancing performance and comfort.

Emissions Regulations

Emissions regulations play a crucial role in shaping the automotive industry's approach to engine design and vehicle electrification. The feasibility of retrofitting L92 engines in electrified vehicles is significantly influenced by these regulations, which are becoming increasingly stringent worldwide.

In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) set the standards for vehicle emissions. The EPA's Tier 3 standards, implemented in 2017, require a fleet-wide average of 30 mg/mile of non-methane organic gases (NMOG) plus nitrogen oxides (NOx) by 2025. These standards pose a significant challenge for conventional internal combustion engines, including the L92.

The European Union has implemented Euro 6 standards, with Euro 7 on the horizon. These regulations set limits on various pollutants, including carbon monoxide (CO), hydrocarbons (HC), nitrogen oxides (NOx), and particulate matter (PM). The Euro 7 standards, expected to be implemented in the coming years, will further tighten these limits, potentially making it more challenging for retrofitted L92 engines to comply.

China, the world's largest automotive market, has adopted the China 6 emissions standards, which are comparable to Euro 6 in terms of stringency. These regulations have accelerated the adoption of electrified vehicles in the country and may impact the viability of L92 engine retrofits.

The global trend towards zero-emission vehicles (ZEVs) is also reflected in emissions regulations. Many countries and regions have announced plans to phase out internal combustion engines in favor of electric vehicles. For instance, the United Kingdom plans to ban the sale of new petrol and diesel cars by 2030, while California aims to achieve 100% ZEV sales by 2035.

These regulatory trends present significant challenges for the L92 engine retrofit in electrified vehicles. To meet emissions standards, extensive modifications may be required, including advanced aftertreatment systems, improved engine management, and integration with hybrid powertrains. The cost and complexity of these modifications could potentially outweigh the benefits of retrofitting.

However, some opportunities exist within the regulatory framework. Many regions offer incentives for low-emission vehicles, which could potentially apply to well-designed L92 retrofit solutions. Additionally, some regulations allow for transitional periods or exemptions for certain vehicle categories, which could provide a window of opportunity for retrofit projects.

In conclusion, while emissions regulations pose significant challenges to L92 engine retrofits in electrified vehicles, they also drive innovation in powertrain technology. The feasibility of such retrofits will depend on the ability to meet increasingly stringent standards while remaining cost-effective and competitive with purpose-built electrified powertrains.

In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) set the standards for vehicle emissions. The EPA's Tier 3 standards, implemented in 2017, require a fleet-wide average of 30 mg/mile of non-methane organic gases (NMOG) plus nitrogen oxides (NOx) by 2025. These standards pose a significant challenge for conventional internal combustion engines, including the L92.

The European Union has implemented Euro 6 standards, with Euro 7 on the horizon. These regulations set limits on various pollutants, including carbon monoxide (CO), hydrocarbons (HC), nitrogen oxides (NOx), and particulate matter (PM). The Euro 7 standards, expected to be implemented in the coming years, will further tighten these limits, potentially making it more challenging for retrofitted L92 engines to comply.

China, the world's largest automotive market, has adopted the China 6 emissions standards, which are comparable to Euro 6 in terms of stringency. These regulations have accelerated the adoption of electrified vehicles in the country and may impact the viability of L92 engine retrofits.

The global trend towards zero-emission vehicles (ZEVs) is also reflected in emissions regulations. Many countries and regions have announced plans to phase out internal combustion engines in favor of electric vehicles. For instance, the United Kingdom plans to ban the sale of new petrol and diesel cars by 2030, while California aims to achieve 100% ZEV sales by 2035.

These regulatory trends present significant challenges for the L92 engine retrofit in electrified vehicles. To meet emissions standards, extensive modifications may be required, including advanced aftertreatment systems, improved engine management, and integration with hybrid powertrains. The cost and complexity of these modifications could potentially outweigh the benefits of retrofitting.

However, some opportunities exist within the regulatory framework. Many regions offer incentives for low-emission vehicles, which could potentially apply to well-designed L92 retrofit solutions. Additionally, some regulations allow for transitional periods or exemptions for certain vehicle categories, which could provide a window of opportunity for retrofit projects.

In conclusion, while emissions regulations pose significant challenges to L92 engine retrofits in electrified vehicles, they also drive innovation in powertrain technology. The feasibility of such retrofits will depend on the ability to meet increasingly stringent standards while remaining cost-effective and competitive with purpose-built electrified powertrains.

Cost-Benefit Analysis

The cost-benefit analysis of retrofitting L92 engines in electrified vehicles requires a comprehensive evaluation of financial implications, performance improvements, and environmental impacts. Initial investment costs for the retrofit process are substantial, including expenses for engine procurement, modification of existing vehicle systems, and labor for installation. These upfront costs can range from $5,000 to $15,000 per vehicle, depending on the complexity of the integration and the scale of implementation.

However, the long-term benefits of L92 engine retrofits may outweigh the initial expenditure. Improved fuel efficiency is a primary advantage, with potential fuel savings of 15-25% compared to older engine models. This translates to significant operational cost reductions over the vehicle's lifetime, especially for fleet operators with high mileage vehicles. The enhanced performance characteristics of the L92 engine, such as increased horsepower and torque, can also contribute to improved vehicle capabilities and potentially extended service life.

Environmental benefits must be factored into the analysis. The L92 engine's advanced combustion technology and improved emissions control systems can lead to a reduction in greenhouse gas emissions by up to 20% compared to older engine models. This environmental improvement may result in tangible benefits such as compliance with stricter emissions regulations and potential tax incentives or carbon credits in certain jurisdictions.

Maintenance costs should also be considered. While the L92 engine may require specialized maintenance procedures, its reliability and durability can potentially reduce overall maintenance frequency and costs. The availability of parts and service expertise for L92 engines in the aftermarket should be evaluated to ensure long-term supportability of the retrofitted vehicles.

The return on investment (ROI) timeline is a critical factor in the cost-benefit analysis. Depending on vehicle usage patterns and fuel prices, the payback period for the retrofit investment can range from 2 to 5 years. Fleet operators with high-mileage vehicles are likely to see faster ROI due to accelerated fuel savings and performance benefits.

Lastly, the analysis should consider the potential impact on vehicle resale value. While the initial depreciation may be higher due to the retrofit cost, the improved performance and efficiency of the L92 engine could potentially increase the vehicle's value in the secondary market, particularly as environmental regulations become more stringent.

However, the long-term benefits of L92 engine retrofits may outweigh the initial expenditure. Improved fuel efficiency is a primary advantage, with potential fuel savings of 15-25% compared to older engine models. This translates to significant operational cost reductions over the vehicle's lifetime, especially for fleet operators with high mileage vehicles. The enhanced performance characteristics of the L92 engine, such as increased horsepower and torque, can also contribute to improved vehicle capabilities and potentially extended service life.

Environmental benefits must be factored into the analysis. The L92 engine's advanced combustion technology and improved emissions control systems can lead to a reduction in greenhouse gas emissions by up to 20% compared to older engine models. This environmental improvement may result in tangible benefits such as compliance with stricter emissions regulations and potential tax incentives or carbon credits in certain jurisdictions.

Maintenance costs should also be considered. While the L92 engine may require specialized maintenance procedures, its reliability and durability can potentially reduce overall maintenance frequency and costs. The availability of parts and service expertise for L92 engines in the aftermarket should be evaluated to ensure long-term supportability of the retrofitted vehicles.

The return on investment (ROI) timeline is a critical factor in the cost-benefit analysis. Depending on vehicle usage patterns and fuel prices, the payback period for the retrofit investment can range from 2 to 5 years. Fleet operators with high-mileage vehicles are likely to see faster ROI due to accelerated fuel savings and performance benefits.

Lastly, the analysis should consider the potential impact on vehicle resale value. While the initial depreciation may be higher due to the retrofit cost, the improved performance and efficiency of the L92 engine could potentially increase the vehicle's value in the secondary market, particularly as environmental regulations become more stringent.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!