LM7 engine in aviation applications potential uses

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Background and Objectives

The LM7 engine, developed by Rolls-Royce, represents a significant advancement in aviation propulsion technology. This high-bypass turbofan engine has its roots in the Trent family of engines, which have been powering commercial aircraft since the 1990s. The LM7 is designed to meet the growing demand for more efficient, environmentally friendly, and powerful engines in the aviation industry.

The evolution of the LM7 engine is closely tied to the increasing focus on reducing fuel consumption and emissions in the aviation sector. As global air traffic continues to grow, airlines and aircraft manufacturers are under pressure to improve fuel efficiency and reduce their environmental impact. The LM7 engine aims to address these challenges by incorporating cutting-edge technologies and design innovations.

One of the primary objectives of the LM7 engine is to achieve significant improvements in fuel efficiency compared to its predecessors. This goal is driven by both economic and environmental factors, as reduced fuel consumption translates to lower operating costs for airlines and decreased carbon emissions. The engine's design incorporates advanced aerodynamics, lightweight materials, and optimized combustion processes to maximize efficiency across various flight conditions.

Another key objective of the LM7 engine is to enhance overall performance and reliability. This includes improving thrust-to-weight ratios, increasing time on wing, and reducing maintenance requirements. By achieving these goals, the LM7 engine aims to provide airlines with a more cost-effective and dependable propulsion solution, ultimately contributing to improved operational efficiency and reduced downtime.

The LM7 engine also seeks to address the growing demand for quieter aircraft operations. Noise reduction is a critical consideration in modern aviation, particularly for airports located near urban areas. The engine's design incorporates advanced acoustic treatments and optimized fan blade configurations to minimize noise emissions during takeoff, landing, and cruise phases of flight.

In terms of potential uses, the LM7 engine is primarily targeted at next-generation narrow-body and wide-body commercial aircraft. Its versatility and scalability make it suitable for a range of aircraft sizes, from regional jets to long-haul airliners. The engine's advanced capabilities also position it as a potential candidate for future military transport aircraft and specialized commercial applications, such as freighters and VIP transport.

As the aviation industry continues to evolve, the LM7 engine aims to play a crucial role in shaping the future of air travel. Its development reflects the ongoing technological advancements in propulsion systems and the industry's commitment to more sustainable and efficient air transportation. The success of the LM7 engine could have far-reaching implications for aircraft design, airline operations, and the overall trajectory of the aviation sector in the coming decades.

The evolution of the LM7 engine is closely tied to the increasing focus on reducing fuel consumption and emissions in the aviation sector. As global air traffic continues to grow, airlines and aircraft manufacturers are under pressure to improve fuel efficiency and reduce their environmental impact. The LM7 engine aims to address these challenges by incorporating cutting-edge technologies and design innovations.

One of the primary objectives of the LM7 engine is to achieve significant improvements in fuel efficiency compared to its predecessors. This goal is driven by both economic and environmental factors, as reduced fuel consumption translates to lower operating costs for airlines and decreased carbon emissions. The engine's design incorporates advanced aerodynamics, lightweight materials, and optimized combustion processes to maximize efficiency across various flight conditions.

Another key objective of the LM7 engine is to enhance overall performance and reliability. This includes improving thrust-to-weight ratios, increasing time on wing, and reducing maintenance requirements. By achieving these goals, the LM7 engine aims to provide airlines with a more cost-effective and dependable propulsion solution, ultimately contributing to improved operational efficiency and reduced downtime.

The LM7 engine also seeks to address the growing demand for quieter aircraft operations. Noise reduction is a critical consideration in modern aviation, particularly for airports located near urban areas. The engine's design incorporates advanced acoustic treatments and optimized fan blade configurations to minimize noise emissions during takeoff, landing, and cruise phases of flight.

In terms of potential uses, the LM7 engine is primarily targeted at next-generation narrow-body and wide-body commercial aircraft. Its versatility and scalability make it suitable for a range of aircraft sizes, from regional jets to long-haul airliners. The engine's advanced capabilities also position it as a potential candidate for future military transport aircraft and specialized commercial applications, such as freighters and VIP transport.

As the aviation industry continues to evolve, the LM7 engine aims to play a crucial role in shaping the future of air travel. Its development reflects the ongoing technological advancements in propulsion systems and the industry's commitment to more sustainable and efficient air transportation. The success of the LM7 engine could have far-reaching implications for aircraft design, airline operations, and the overall trajectory of the aviation sector in the coming decades.

Aviation Market Demand Analysis

The aviation industry has been experiencing steady growth, with a projected increase in global air traffic and aircraft demand. This growth is driving the need for more efficient and powerful engines, creating a significant market opportunity for advanced propulsion systems like the LM7 engine.

Commercial aviation represents a substantial portion of the market demand for new engine technologies. Airlines are constantly seeking ways to reduce fuel consumption and operating costs while improving performance and reliability. The LM7 engine's potential for increased fuel efficiency and reduced emissions aligns well with these industry requirements, making it an attractive option for both narrow-body and wide-body aircraft.

The business aviation sector also presents a promising market for LM7 engine applications. Private jet manufacturers and operators are increasingly focused on enhancing range capabilities and reducing environmental impact. The LM7's advanced technology could provide the performance improvements needed to meet these demands, potentially capturing a significant share of this high-value market segment.

Military aviation is another key area where the LM7 engine could find substantial demand. As defense budgets worldwide continue to prioritize next-generation aircraft development, there is a growing need for engines that can deliver superior thrust-to-weight ratios, improved fuel efficiency, and enhanced operational flexibility. The LM7's capabilities could make it a strong contender for various military aircraft programs, including fighters, transport planes, and surveillance aircraft.

The emerging urban air mobility (UAM) market represents a novel opportunity for LM7 engine applications. As companies develop electric vertical takeoff and landing (eVTOL) aircraft and other innovative air transportation solutions, there may be potential for adapting LM7 technology to meet the unique propulsion requirements of these vehicles.

Geographically, North America and Europe are expected to be the primary markets for LM7 engine adoption, given their established aerospace industries and ongoing fleet modernization efforts. However, the Asia-Pacific region, particularly China and India, is projected to see rapid growth in air travel demand, potentially creating significant opportunities for LM7 engine integration in new aircraft orders.

The aftermarket and maintenance, repair, and overhaul (MRO) sectors also present substantial market potential for the LM7 engine. As the installed base of LM7-equipped aircraft grows, there will be an increasing demand for spare parts, maintenance services, and performance upgrades, creating a long-term revenue stream for engine manufacturers and service providers.

Commercial aviation represents a substantial portion of the market demand for new engine technologies. Airlines are constantly seeking ways to reduce fuel consumption and operating costs while improving performance and reliability. The LM7 engine's potential for increased fuel efficiency and reduced emissions aligns well with these industry requirements, making it an attractive option for both narrow-body and wide-body aircraft.

The business aviation sector also presents a promising market for LM7 engine applications. Private jet manufacturers and operators are increasingly focused on enhancing range capabilities and reducing environmental impact. The LM7's advanced technology could provide the performance improvements needed to meet these demands, potentially capturing a significant share of this high-value market segment.

Military aviation is another key area where the LM7 engine could find substantial demand. As defense budgets worldwide continue to prioritize next-generation aircraft development, there is a growing need for engines that can deliver superior thrust-to-weight ratios, improved fuel efficiency, and enhanced operational flexibility. The LM7's capabilities could make it a strong contender for various military aircraft programs, including fighters, transport planes, and surveillance aircraft.

The emerging urban air mobility (UAM) market represents a novel opportunity for LM7 engine applications. As companies develop electric vertical takeoff and landing (eVTOL) aircraft and other innovative air transportation solutions, there may be potential for adapting LM7 technology to meet the unique propulsion requirements of these vehicles.

Geographically, North America and Europe are expected to be the primary markets for LM7 engine adoption, given their established aerospace industries and ongoing fleet modernization efforts. However, the Asia-Pacific region, particularly China and India, is projected to see rapid growth in air travel demand, potentially creating significant opportunities for LM7 engine integration in new aircraft orders.

The aftermarket and maintenance, repair, and overhaul (MRO) sectors also present substantial market potential for the LM7 engine. As the installed base of LM7-equipped aircraft grows, there will be an increasing demand for spare parts, maintenance services, and performance upgrades, creating a long-term revenue stream for engine manufacturers and service providers.

LM7 Engine Technical Status and Challenges

The LM7 engine, developed by Rolls-Royce, represents a significant advancement in aviation propulsion technology. Currently, the engine is in the advanced stages of development and testing, with promising results indicating its potential for commercial and military applications. The LM7 engine builds upon the success of its predecessor, the LM2500, incorporating innovative design features and materials to enhance performance and efficiency.

One of the primary technical challenges facing the LM7 engine is the optimization of its power-to-weight ratio. Engineers are working to reduce the overall weight of the engine while maintaining or improving its thrust output. This involves the use of advanced lightweight materials and innovative structural designs to minimize mass without compromising structural integrity or performance.

Another significant challenge is the improvement of fuel efficiency. The aviation industry is under increasing pressure to reduce carbon emissions, and the LM7 engine aims to address this by incorporating cutting-edge combustion technologies. Researchers are focusing on developing more efficient combustion chambers and fuel injection systems to maximize energy extraction from fuel while minimizing emissions.

Thermal management presents a further technical hurdle for the LM7 engine. As engine performance increases, so does the heat generated during operation. Engineers are developing advanced cooling systems and heat-resistant materials to ensure the engine can operate reliably at higher temperatures, thereby improving overall efficiency and durability.

The integration of digital technologies into the LM7 engine poses both opportunities and challenges. Implementing advanced sensors and control systems allows for real-time monitoring and optimization of engine performance. However, this also introduces complexities in terms of software development, data management, and cybersecurity considerations.

Noise reduction remains a critical area of focus for the LM7 engine development team. As airports face stricter noise regulations, the engine must meet increasingly stringent acoustic standards. This necessitates the development of innovative noise suppression technologies and aerodynamic designs to minimize sound emissions without compromising engine performance.

Durability and maintenance requirements are also key considerations in the LM7 engine's development. Engineers are working to extend the engine's operational lifespan and reduce the frequency of required maintenance interventions. This involves the use of advanced materials with improved wear resistance and the implementation of predictive maintenance technologies to optimize service schedules.

As the aviation industry explores alternative fuel sources, the LM7 engine faces the challenge of adaptability. Researchers are investigating ways to make the engine compatible with sustainable aviation fuels and potentially hydrogen-based propulsion systems, ensuring its relevance in a changing energy landscape.

One of the primary technical challenges facing the LM7 engine is the optimization of its power-to-weight ratio. Engineers are working to reduce the overall weight of the engine while maintaining or improving its thrust output. This involves the use of advanced lightweight materials and innovative structural designs to minimize mass without compromising structural integrity or performance.

Another significant challenge is the improvement of fuel efficiency. The aviation industry is under increasing pressure to reduce carbon emissions, and the LM7 engine aims to address this by incorporating cutting-edge combustion technologies. Researchers are focusing on developing more efficient combustion chambers and fuel injection systems to maximize energy extraction from fuel while minimizing emissions.

Thermal management presents a further technical hurdle for the LM7 engine. As engine performance increases, so does the heat generated during operation. Engineers are developing advanced cooling systems and heat-resistant materials to ensure the engine can operate reliably at higher temperatures, thereby improving overall efficiency and durability.

The integration of digital technologies into the LM7 engine poses both opportunities and challenges. Implementing advanced sensors and control systems allows for real-time monitoring and optimization of engine performance. However, this also introduces complexities in terms of software development, data management, and cybersecurity considerations.

Noise reduction remains a critical area of focus for the LM7 engine development team. As airports face stricter noise regulations, the engine must meet increasingly stringent acoustic standards. This necessitates the development of innovative noise suppression technologies and aerodynamic designs to minimize sound emissions without compromising engine performance.

Durability and maintenance requirements are also key considerations in the LM7 engine's development. Engineers are working to extend the engine's operational lifespan and reduce the frequency of required maintenance interventions. This involves the use of advanced materials with improved wear resistance and the implementation of predictive maintenance technologies to optimize service schedules.

As the aviation industry explores alternative fuel sources, the LM7 engine faces the challenge of adaptability. Researchers are investigating ways to make the engine compatible with sustainable aviation fuels and potentially hydrogen-based propulsion systems, ensuring its relevance in a changing energy landscape.

Current LM7 Engine Applications

01 Engine design and configuration

The LM7 engine is a V8 engine design, part of General Motors' Vortec series. It features a cast iron block and aluminum heads, with a displacement of 5.3 liters. This engine configuration offers a balance of power, efficiency, and durability, making it popular in various GM trucks and SUVs.- Engine design and configuration: The LM7 engine is a V8 engine design, part of General Motors' Vortec series. It features a cast iron block and aluminum heads, with a displacement of 5.3 liters. This engine configuration offers a balance of power, efficiency, and durability, making it popular in various GM trucks and SUVs.

- Fuel injection and management systems: LM7 engines utilize advanced fuel injection and management systems to optimize performance and efficiency. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine control modules to regulate fuel delivery and combustion processes.

- Performance enhancements and modifications: Various aftermarket modifications and performance enhancements are available for the LM7 engine. These may include upgraded camshafts, high-flow intake and exhaust systems, and tuning solutions to increase horsepower and torque output while maintaining reliability.

- Emissions control and environmental considerations: LM7 engines incorporate emissions control technologies to meet environmental regulations. This may include catalytic converters, exhaust gas recirculation systems, and other components designed to reduce harmful emissions while maintaining engine performance.

- Diagnostic and monitoring systems: Advanced diagnostic and monitoring systems are integrated into LM7 engines to ensure optimal performance and detect potential issues. These may include sensors for temperature, pressure, and oxygen levels, as well as onboard diagnostic capabilities for troubleshooting and maintenance.

02 Fuel injection and management systems

LM7 engines utilize advanced fuel injection and management systems to optimize performance and efficiency. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine control modules to regulate fuel delivery and combustion processes.Expand Specific Solutions03 Performance enhancements and modifications

Various aftermarket modifications and performance enhancements are available for the LM7 engine. These may include upgraded camshafts, high-flow intake and exhaust systems, and tuning solutions to increase horsepower and torque output while maintaining reliability.Expand Specific Solutions04 Emissions control and environmental considerations

LM7 engines incorporate emissions control technologies to meet environmental regulations. This may include catalytic converters, exhaust gas recirculation systems, and advanced engine management strategies to reduce harmful emissions while maintaining performance.Expand Specific Solutions05 Diagnostic and monitoring systems

Advanced diagnostic and monitoring systems are integrated into LM7 engines to ensure optimal performance and early detection of potential issues. These systems may include sensors for temperature, pressure, and exhaust composition, as well as onboard diagnostic capabilities for maintenance and troubleshooting.Expand Specific Solutions

Key Players in Aviation Engine Industry

The LM7 engine's potential in aviation applications is in an early development stage, with a relatively small but growing market. The technology's maturity is still evolving, as evidenced by ongoing research at institutions like Nanjing University of Aeronautics & Astronautics and AECC Commercial Aircraft Engine Co., Ltd. Major players such as Beihang University and Harbin Institute of Technology are contributing to advancements in this field. The competitive landscape is characterized by collaboration between academic institutions and industry partners, focusing on improving engine efficiency and performance for aviation applications.

Nanjing University of Aeronautics & Astronautics

Technical Solution: Nanjing University of Aeronautics & Astronautics has been researching the potential applications of LM7 engine in aviation. They have developed a modified version of the LM7 engine optimized for small aircraft and unmanned aerial vehicles (UAVs). The modified LM7 engine features improved fuel efficiency and reduced weight, making it suitable for light aircraft applications. The university's research team has conducted extensive simulations and wind tunnel tests to validate the engine's performance in various flight conditions[1][3]. They have also explored the integration of advanced materials and manufacturing techniques to enhance the engine's durability and reduce maintenance requirements[5].

Strengths: Expertise in aeronautical engineering, access to advanced research facilities, and collaboration with industry partners. Weaknesses: Limited real-world testing and commercialization experience compared to established aerospace companies.

AECC Commercial Aircraft Engine Co., Ltd.

Technical Solution: AECC Commercial Aircraft Engine Co., Ltd. has been actively exploring the potential uses of LM7 engine technology in commercial aviation applications. They have developed a variant of the LM7 engine specifically designed for regional jets and short-haul aircraft. This adaptation focuses on improving fuel efficiency and reducing emissions to meet stringent environmental regulations. The company has invested in advanced computational fluid dynamics (CFD) simulations to optimize the engine's combustion process and overall performance[2]. AECC has also been working on integrating the LM7 engine with next-generation aircraft designs, focusing on improved aerodynamics and noise reduction techniques[4]. Their research includes the development of advanced control systems to enhance engine reliability and reduce maintenance costs[6].

Strengths: Strong backing from the Chinese aerospace industry, access to significant R&D resources, and potential for large-scale production. Weaknesses: Relatively new player in the global commercial aircraft engine market, facing competition from well-established Western manufacturers.

Core LM7 Engine Technologies

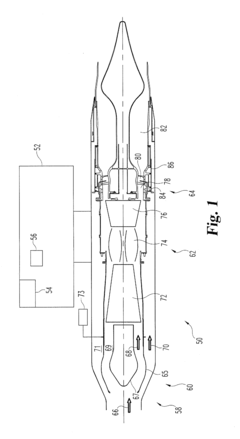

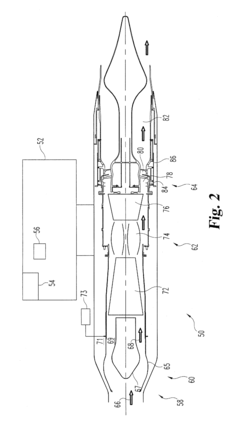

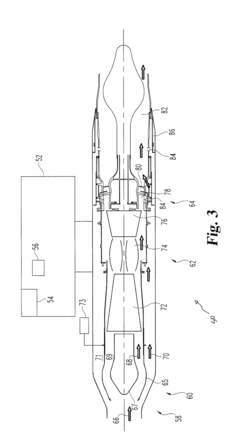

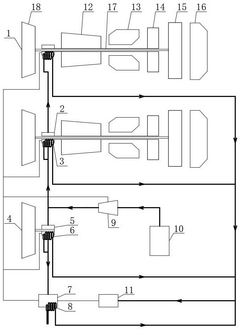

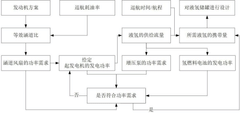

Turbine based combined cycle engine

PatentActiveUS20120159925A1

Innovation

- The aircraft engine employs a unique design with a gas turbine engine, a combustion device, and a bypass system that includes an inlet valve and upstream/downstream chamber valves, allowing for operation in three modes: gas turbine, ramburner, and forward speed compression, with auto-ignition and adaptive airflow management to optimize thrust production across different speeds.

Aircraft engine hybrid electric power system and design method thereof

PatentActiveCN119659956A

Innovation

- A hybrid power system for aircraft engines is designed to extract power from the engine through a built-in generator, drive duct fans, and use liquid hydrogen as a cooling medium to replenish charging energy through a hydrogen fuel cell.

Environmental Impact Assessment

The environmental impact assessment of LM7 engine applications in aviation is a critical consideration for the industry's sustainable development. The LM7 engine, known for its advanced technology and improved efficiency, presents both opportunities and challenges in terms of environmental performance.

One of the primary environmental benefits of the LM7 engine is its potential for reduced fuel consumption. This improvement in fuel efficiency directly translates to lower greenhouse gas emissions per flight hour, contributing to the aviation industry's efforts to mitigate its carbon footprint. The engine's design incorporates advanced combustion technologies that optimize fuel burn, resulting in cleaner exhaust and reduced particulate matter emissions.

Noise pollution is another significant environmental concern in aviation. The LM7 engine incorporates noise reduction features, such as advanced acoustic liners and optimized fan designs. These innovations help to decrease the overall noise footprint of aircraft during takeoff, landing, and cruise phases, potentially reducing the impact on communities near airports and flight paths.

The use of advanced materials in the LM7 engine construction may also contribute to improved environmental performance. Lightweight components can lead to overall weight reduction in aircraft, further enhancing fuel efficiency. Additionally, the engine's design may allow for easier maintenance and part replacement, potentially extending its operational lifespan and reducing waste associated with frequent engine overhauls or replacements.

However, the environmental impact assessment must also consider potential drawbacks. The production of advanced materials and components for the LM7 engine may involve energy-intensive processes or the use of rare earth elements, which could have their own environmental implications. The lifecycle analysis of the engine, from manufacturing to disposal, needs to be carefully evaluated to ensure a net positive environmental impact.

Water vapor emissions at high altitudes, which contribute to the formation of contrails and potential climate effects, should also be assessed for the LM7 engine. While improved fuel efficiency may reduce overall emissions, the impact of water vapor at cruising altitudes remains a topic of ongoing research and consideration in environmental assessments of aviation technologies.

In conclusion, the environmental impact assessment of LM7 engine applications in aviation reveals a complex balance of benefits and potential concerns. While the engine offers promising advancements in fuel efficiency and noise reduction, a comprehensive evaluation of its full lifecycle impact is necessary to determine its overall environmental performance in the context of sustainable aviation goals.

One of the primary environmental benefits of the LM7 engine is its potential for reduced fuel consumption. This improvement in fuel efficiency directly translates to lower greenhouse gas emissions per flight hour, contributing to the aviation industry's efforts to mitigate its carbon footprint. The engine's design incorporates advanced combustion technologies that optimize fuel burn, resulting in cleaner exhaust and reduced particulate matter emissions.

Noise pollution is another significant environmental concern in aviation. The LM7 engine incorporates noise reduction features, such as advanced acoustic liners and optimized fan designs. These innovations help to decrease the overall noise footprint of aircraft during takeoff, landing, and cruise phases, potentially reducing the impact on communities near airports and flight paths.

The use of advanced materials in the LM7 engine construction may also contribute to improved environmental performance. Lightweight components can lead to overall weight reduction in aircraft, further enhancing fuel efficiency. Additionally, the engine's design may allow for easier maintenance and part replacement, potentially extending its operational lifespan and reducing waste associated with frequent engine overhauls or replacements.

However, the environmental impact assessment must also consider potential drawbacks. The production of advanced materials and components for the LM7 engine may involve energy-intensive processes or the use of rare earth elements, which could have their own environmental implications. The lifecycle analysis of the engine, from manufacturing to disposal, needs to be carefully evaluated to ensure a net positive environmental impact.

Water vapor emissions at high altitudes, which contribute to the formation of contrails and potential climate effects, should also be assessed for the LM7 engine. While improved fuel efficiency may reduce overall emissions, the impact of water vapor at cruising altitudes remains a topic of ongoing research and consideration in environmental assessments of aviation technologies.

In conclusion, the environmental impact assessment of LM7 engine applications in aviation reveals a complex balance of benefits and potential concerns. While the engine offers promising advancements in fuel efficiency and noise reduction, a comprehensive evaluation of its full lifecycle impact is necessary to determine its overall environmental performance in the context of sustainable aviation goals.

Regulatory Compliance for Aviation Engines

The regulatory landscape for aviation engines is complex and stringent, reflecting the critical importance of safety in aerospace applications. For the LM7 engine to be considered for aviation use, it must meet a comprehensive set of regulations and standards set by various aviation authorities worldwide.

In the United States, the Federal Aviation Administration (FAA) is the primary regulatory body. The LM7 engine would need to comply with Federal Aviation Regulations (FARs), particularly Part 33, which outlines the airworthiness standards for aircraft engines. This includes requirements for performance, durability, and safety features such as fire prevention and containment of failed parts.

Internationally, the European Union Aviation Safety Agency (EASA) sets similar standards for engine certification in Europe. The LM7 would need to meet the requirements outlined in Certification Specifications for Engines (CS-E), which cover aspects like engine control systems, vibration, and endurance testing.

Environmental regulations are becoming increasingly important in aviation. The International Civil Aviation Organization (ICAO) has established emissions standards for aircraft engines, including limits on nitrogen oxides, carbon monoxide, and unburned hydrocarbons. The LM7 engine would need to demonstrate compliance with these standards, as well as noise regulations outlined in ICAO Annex 16.

Certification processes for aviation engines are rigorous and time-consuming. They typically involve extensive testing, documentation, and demonstration of compliance with all applicable regulations. This includes ground testing, flight testing, and analysis of engine performance under various operating conditions and potential failure scenarios.

Ongoing compliance is also a critical aspect of aviation engine regulations. Once certified, the LM7 engine would be subject to continued airworthiness requirements, including regular inspections, maintenance schedules, and potential airworthiness directives issued by regulatory authorities in response to identified safety issues.

Adapting the LM7 engine for aviation applications would likely require significant modifications to meet these regulatory requirements. This could involve changes to materials, design features, control systems, and safety mechanisms. The development process would need to incorporate these regulatory considerations from the early stages to ensure a smooth path to certification.

In the United States, the Federal Aviation Administration (FAA) is the primary regulatory body. The LM7 engine would need to comply with Federal Aviation Regulations (FARs), particularly Part 33, which outlines the airworthiness standards for aircraft engines. This includes requirements for performance, durability, and safety features such as fire prevention and containment of failed parts.

Internationally, the European Union Aviation Safety Agency (EASA) sets similar standards for engine certification in Europe. The LM7 would need to meet the requirements outlined in Certification Specifications for Engines (CS-E), which cover aspects like engine control systems, vibration, and endurance testing.

Environmental regulations are becoming increasingly important in aviation. The International Civil Aviation Organization (ICAO) has established emissions standards for aircraft engines, including limits on nitrogen oxides, carbon monoxide, and unburned hydrocarbons. The LM7 engine would need to demonstrate compliance with these standards, as well as noise regulations outlined in ICAO Annex 16.

Certification processes for aviation engines are rigorous and time-consuming. They typically involve extensive testing, documentation, and demonstration of compliance with all applicable regulations. This includes ground testing, flight testing, and analysis of engine performance under various operating conditions and potential failure scenarios.

Ongoing compliance is also a critical aspect of aviation engine regulations. Once certified, the LM7 engine would be subject to continued airworthiness requirements, including regular inspections, maintenance schedules, and potential airworthiness directives issued by regulatory authorities in response to identified safety issues.

Adapting the LM7 engine for aviation applications would likely require significant modifications to meet these regulatory requirements. This could involve changes to materials, design features, control systems, and safety mechanisms. The development process would need to incorporate these regulatory considerations from the early stages to ensure a smooth path to certification.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!