Magnetron Sputtering Effects on Nitinol Coating Properties

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Sputtering Nitinol Coating Overview

Magnetron sputtering is a widely used physical vapor deposition technique for applying thin films of various materials onto substrates. In the context of Nitinol coatings, this process has gained significant attention due to its ability to produce high-quality, uniform coatings with excellent adhesion and controlled composition.

Nitinol, an equiatomic alloy of nickel and titanium, is renowned for its unique shape memory and superelastic properties. These characteristics make it highly desirable for numerous applications, particularly in the medical device industry. The application of Nitinol coatings through magnetron sputtering offers the potential to enhance surface properties and functionality of various substrates.

The magnetron sputtering process for Nitinol coatings typically involves the use of a Nitinol target in a vacuum chamber. Argon gas is introduced and ionized to form a plasma. The positively charged argon ions are accelerated towards the negatively charged Nitinol target, causing atoms to be ejected from the target surface. These sputtered atoms then condense on the substrate, forming a thin film coating.

One of the key advantages of magnetron sputtering for Nitinol coatings is the ability to precisely control the composition and thickness of the deposited film. This level of control is crucial for maintaining the desired properties of Nitinol, such as its transformation temperatures and mechanical behavior. Additionally, the process allows for the deposition of Nitinol coatings at relatively low temperatures, which is beneficial for temperature-sensitive substrates.

The properties of magnetron sputtered Nitinol coatings can be influenced by various process parameters. These include sputtering power, working pressure, substrate temperature, and target-to-substrate distance. By optimizing these parameters, researchers and engineers can tailor the microstructure, composition, and functional properties of the Nitinol coatings to meet specific application requirements.

Recent advancements in magnetron sputtering technology have led to the development of high-power impulse magnetron sputtering (HiPIMS) and reactive sputtering techniques. These innovations offer new possibilities for further enhancing the quality and performance of Nitinol coatings, such as improved density, adhesion, and control over stoichiometry.

The effects of magnetron sputtering on Nitinol coating properties are multifaceted and can significantly impact the overall performance of the coated components. Understanding and optimizing these effects is crucial for advancing the application of Nitinol coatings in various fields, from biomedical implants to aerospace components.

Nitinol, an equiatomic alloy of nickel and titanium, is renowned for its unique shape memory and superelastic properties. These characteristics make it highly desirable for numerous applications, particularly in the medical device industry. The application of Nitinol coatings through magnetron sputtering offers the potential to enhance surface properties and functionality of various substrates.

The magnetron sputtering process for Nitinol coatings typically involves the use of a Nitinol target in a vacuum chamber. Argon gas is introduced and ionized to form a plasma. The positively charged argon ions are accelerated towards the negatively charged Nitinol target, causing atoms to be ejected from the target surface. These sputtered atoms then condense on the substrate, forming a thin film coating.

One of the key advantages of magnetron sputtering for Nitinol coatings is the ability to precisely control the composition and thickness of the deposited film. This level of control is crucial for maintaining the desired properties of Nitinol, such as its transformation temperatures and mechanical behavior. Additionally, the process allows for the deposition of Nitinol coatings at relatively low temperatures, which is beneficial for temperature-sensitive substrates.

The properties of magnetron sputtered Nitinol coatings can be influenced by various process parameters. These include sputtering power, working pressure, substrate temperature, and target-to-substrate distance. By optimizing these parameters, researchers and engineers can tailor the microstructure, composition, and functional properties of the Nitinol coatings to meet specific application requirements.

Recent advancements in magnetron sputtering technology have led to the development of high-power impulse magnetron sputtering (HiPIMS) and reactive sputtering techniques. These innovations offer new possibilities for further enhancing the quality and performance of Nitinol coatings, such as improved density, adhesion, and control over stoichiometry.

The effects of magnetron sputtering on Nitinol coating properties are multifaceted and can significantly impact the overall performance of the coated components. Understanding and optimizing these effects is crucial for advancing the application of Nitinol coatings in various fields, from biomedical implants to aerospace components.

Market Demand Analysis

The market demand for Nitinol coatings enhanced by magnetron sputtering has been steadily growing across various industries, driven by the unique properties of Nitinol and the advantages offered by the magnetron sputtering process. Nitinol, a nickel-titanium alloy known for its shape memory and superelastic properties, has found widespread applications in medical devices, aerospace, automotive, and consumer electronics sectors.

In the medical device industry, Nitinol coatings are particularly sought after for their biocompatibility and corrosion resistance. The use of magnetron sputtering to deposit Nitinol coatings on medical implants, such as stents, guidewires, and orthopedic devices, has led to improved performance and longevity. This has resulted in a significant market demand, with the global medical Nitinol market expected to experience substantial growth in the coming years.

The aerospace and automotive industries have also shown increasing interest in Nitinol coatings applied through magnetron sputtering. These coatings offer enhanced wear resistance, thermal management, and shape memory properties, which are crucial for components subjected to extreme conditions. The growing emphasis on lightweight materials and fuel efficiency in these sectors has further boosted the demand for Nitinol-coated parts.

Consumer electronics manufacturers have begun exploring Nitinol coatings for their potential in creating durable and flexible devices. The ability to deposit thin, uniform layers of Nitinol through magnetron sputtering has opened up new possibilities for designing innovative products with improved durability and functionality.

The market demand is also influenced by the ongoing research and development efforts aimed at optimizing the magnetron sputtering process for Nitinol coatings. Advancements in this area are expected to lead to coatings with enhanced properties, further expanding their potential applications and market reach.

Geographically, North America and Europe currently dominate the market for Nitinol coatings, primarily due to their advanced healthcare sectors and strong presence in aerospace and automotive industries. However, the Asia-Pacific region is emerging as a significant market, driven by rapid industrialization, increasing healthcare expenditure, and growing adoption of advanced technologies.

As industries continue to seek materials with superior properties and performance, the demand for Nitinol coatings produced through magnetron sputtering is expected to rise. This trend is likely to be further accelerated by ongoing technological advancements and the expansion of application areas, positioning Nitinol coatings as a key material in various high-tech industries for the foreseeable future.

In the medical device industry, Nitinol coatings are particularly sought after for their biocompatibility and corrosion resistance. The use of magnetron sputtering to deposit Nitinol coatings on medical implants, such as stents, guidewires, and orthopedic devices, has led to improved performance and longevity. This has resulted in a significant market demand, with the global medical Nitinol market expected to experience substantial growth in the coming years.

The aerospace and automotive industries have also shown increasing interest in Nitinol coatings applied through magnetron sputtering. These coatings offer enhanced wear resistance, thermal management, and shape memory properties, which are crucial for components subjected to extreme conditions. The growing emphasis on lightweight materials and fuel efficiency in these sectors has further boosted the demand for Nitinol-coated parts.

Consumer electronics manufacturers have begun exploring Nitinol coatings for their potential in creating durable and flexible devices. The ability to deposit thin, uniform layers of Nitinol through magnetron sputtering has opened up new possibilities for designing innovative products with improved durability and functionality.

The market demand is also influenced by the ongoing research and development efforts aimed at optimizing the magnetron sputtering process for Nitinol coatings. Advancements in this area are expected to lead to coatings with enhanced properties, further expanding their potential applications and market reach.

Geographically, North America and Europe currently dominate the market for Nitinol coatings, primarily due to their advanced healthcare sectors and strong presence in aerospace and automotive industries. However, the Asia-Pacific region is emerging as a significant market, driven by rapid industrialization, increasing healthcare expenditure, and growing adoption of advanced technologies.

As industries continue to seek materials with superior properties and performance, the demand for Nitinol coatings produced through magnetron sputtering is expected to rise. This trend is likely to be further accelerated by ongoing technological advancements and the expansion of application areas, positioning Nitinol coatings as a key material in various high-tech industries for the foreseeable future.

Current Challenges in Nitinol Coating

Despite the numerous advantages of Nitinol coatings, several challenges persist in their development and application through magnetron sputtering. One of the primary issues is achieving uniform coating thickness and composition across complex geometries. The non-planar surfaces of medical devices and implants often lead to inconsistent deposition rates, resulting in variations in coating properties.

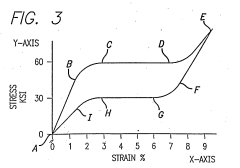

Another significant challenge lies in controlling the phase transformation temperatures of the Nitinol coating. The martensitic to austenitic transformation, crucial for the shape memory effect, can be altered during the sputtering process. Factors such as substrate temperature, deposition rate, and post-deposition heat treatment significantly influence these transformation temperatures, making precise control a complex task.

Adhesion of the Nitinol coating to various substrate materials remains a persistent issue. The substantial difference in thermal expansion coefficients between Nitinol and common substrate materials can lead to delamination or cracking of the coating, especially under cyclic loading conditions typical in medical applications.

The stoichiometry of the Nitinol coating presents another challenge. Maintaining the precise 50:50 atomic ratio of nickel to titanium is critical for optimal shape memory and superelastic properties. However, preferential sputtering of one element over the other can occur, leading to deviations from the desired composition.

Contamination during the sputtering process is a significant concern. Oxygen incorporation, in particular, can lead to the formation of titanium oxides, degrading the performance of the Nitinol coating. Achieving and maintaining high vacuum conditions and using high-purity targets are essential but challenging aspects of the process.

The crystallization of the Nitinol coating poses another hurdle. As-deposited coatings are often amorphous or nanocrystalline, requiring post-deposition heat treatment to achieve the desired crystalline structure. However, this heat treatment can lead to interdiffusion between the coating and substrate, potentially altering the properties of both.

Lastly, the scalability of the magnetron sputtering process for Nitinol coatings presents challenges in industrial applications. Achieving consistent coating properties across large batches or on complex three-dimensional structures remains a significant technological and economic challenge for widespread adoption in medical device manufacturing.

Another significant challenge lies in controlling the phase transformation temperatures of the Nitinol coating. The martensitic to austenitic transformation, crucial for the shape memory effect, can be altered during the sputtering process. Factors such as substrate temperature, deposition rate, and post-deposition heat treatment significantly influence these transformation temperatures, making precise control a complex task.

Adhesion of the Nitinol coating to various substrate materials remains a persistent issue. The substantial difference in thermal expansion coefficients between Nitinol and common substrate materials can lead to delamination or cracking of the coating, especially under cyclic loading conditions typical in medical applications.

The stoichiometry of the Nitinol coating presents another challenge. Maintaining the precise 50:50 atomic ratio of nickel to titanium is critical for optimal shape memory and superelastic properties. However, preferential sputtering of one element over the other can occur, leading to deviations from the desired composition.

Contamination during the sputtering process is a significant concern. Oxygen incorporation, in particular, can lead to the formation of titanium oxides, degrading the performance of the Nitinol coating. Achieving and maintaining high vacuum conditions and using high-purity targets are essential but challenging aspects of the process.

The crystallization of the Nitinol coating poses another hurdle. As-deposited coatings are often amorphous or nanocrystalline, requiring post-deposition heat treatment to achieve the desired crystalline structure. However, this heat treatment can lead to interdiffusion between the coating and substrate, potentially altering the properties of both.

Lastly, the scalability of the magnetron sputtering process for Nitinol coatings presents challenges in industrial applications. Achieving consistent coating properties across large batches or on complex three-dimensional structures remains a significant technological and economic challenge for widespread adoption in medical device manufacturing.

Existing Coating Solutions

01 Nitinol coating properties and applications

Nitinol coatings exhibit unique properties such as shape memory and superelasticity, making them suitable for various applications. These coatings can be applied to different substrates to enhance their performance and durability. The properties of Nitinol coatings can be tailored through composition control and heat treatment processes.- Nitinol coating properties and applications: Nitinol coatings exhibit unique properties such as shape memory and superelasticity, making them suitable for various applications. These coatings can be applied to different substrates to enhance their performance and durability. The properties of Nitinol coatings can be tailored through composition and processing techniques to meet specific requirements in industries such as medical devices, aerospace, and automotive.

- Coating methods for Nitinol: Various coating methods can be employed to apply Nitinol coatings, including physical vapor deposition, chemical vapor deposition, and electrodeposition. Each method offers different advantages in terms of coating thickness, uniformity, and adhesion. The choice of coating method depends on the specific application requirements and the desired properties of the final coated product.

- Surface treatment and modification of Nitinol coatings: Surface treatments and modifications can be applied to Nitinol coatings to enhance their properties and performance. These treatments may include chemical etching, plasma treatment, or the application of additional layers. Such modifications can improve biocompatibility, corrosion resistance, and wear resistance of the Nitinol coatings, making them suitable for a wider range of applications.

- Characterization and testing of Nitinol coatings: Various techniques are used to characterize and test Nitinol coatings, including microscopy, spectroscopy, and mechanical testing. These methods help evaluate the coating's thickness, composition, adhesion, and performance under different conditions. Proper characterization and testing are essential for ensuring the quality and reliability of Nitinol coatings in their intended applications.

- Thermal and mechanical properties of Nitinol coatings: Nitinol coatings exhibit unique thermal and mechanical properties, including shape memory effect and superelasticity. These properties are influenced by factors such as composition, heat treatment, and processing conditions. Understanding and controlling these properties are crucial for optimizing the performance of Nitinol coatings in various applications, particularly in temperature-sensitive or high-stress environments.

02 Coating methods for Nitinol

Various coating methods can be employed to apply Nitinol coatings, including physical vapor deposition, sputtering, and electroplating. Each method offers specific advantages in terms of coating thickness, adhesion, and uniformity. The choice of coating method depends on the desired properties and the substrate material.Expand Specific Solutions03 Surface treatment and adhesion improvement

Surface treatment techniques can be used to enhance the adhesion of Nitinol coatings to substrates. These treatments may include chemical etching, plasma cleaning, or the application of intermediate layers. Improved adhesion leads to better durability and performance of the coated components.Expand Specific Solutions04 Characterization of Nitinol coating properties

Various analytical techniques are employed to characterize the properties of Nitinol coatings, including X-ray diffraction, scanning electron microscopy, and nanoindentation. These methods help in assessing the coating's microstructure, composition, and mechanical properties, which are crucial for optimizing coating performance.Expand Specific Solutions05 Applications of Nitinol coatings in medical devices

Nitinol coatings find extensive applications in medical devices due to their biocompatibility and unique properties. They are used in stents, guidewires, and other implantable devices. The coatings can improve the device's functionality, reduce friction, and enhance corrosion resistance in physiological environments.Expand Specific Solutions

Key Industry Players

The magnetron sputtering effects on Nitinol coating properties market is in a growth phase, driven by increasing demand for advanced materials in various industries. The global market size for thin film coatings, including Nitinol, is projected to reach several billion dollars by 2025. Technologically, the field is advancing rapidly, with companies like Applied Materials, Inc. and Oerlikon Surface Solutions AG leading innovation. These firms, along with others such as Hon Hai Precision Industry Co., Ltd. and SCHOTT AG, are investing heavily in R&D to improve coating properties and process efficiency. The competitive landscape is characterized by a mix of established players and emerging specialists, with a focus on developing proprietary technologies and expanding application areas.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced magnetron sputtering techniques for Nitinol coating deposition. Their process utilizes a rotating magnetron system with optimized target-to-substrate distance, allowing for uniform and dense Nitinol films[1]. The company employs a multi-cathode sputtering system that enables precise control over the Ni-Ti composition ratio, crucial for achieving desired shape memory and superelastic properties[2]. They have also implemented a substrate bias technique during deposition, which enhances film adhesion and reduces internal stresses[3]. Additionally, Applied Materials has developed a post-deposition heat treatment process that fine-tunes the crystalline structure of the Nitinol coating, optimizing its functional properties for various applications[4].

Strengths: Precise composition control, uniform coating deposition, and enhanced film adhesion. Weaknesses: Potentially higher equipment costs and complexity in process control.

Oerlikon Surface Solutions AG

Technical Solution: Oerlikon has pioneered a high-power impulse magnetron sputtering (HiPIMS) technique for Nitinol coatings. This method utilizes short pulses of high-power density to create a highly ionized plasma, resulting in denser and more adherent Nitinol films[5]. Their process incorporates a unique target design that minimizes arcing and enhances target utilization efficiency[6]. Oerlikon has also developed a reactive sputtering approach, introducing controlled amounts of nitrogen during deposition to create Nitinol-based nitride coatings with enhanced hardness and wear resistance[7]. Furthermore, they have implemented an in-situ heating system that allows for real-time control of substrate temperature during deposition, enabling better crystallization and phase formation of the Nitinol coating[8].

Strengths: High-density films, improved adhesion, and versatility in coating properties. Weaknesses: Higher energy consumption and potential for increased target wear.

Core Innovations in Sputtering

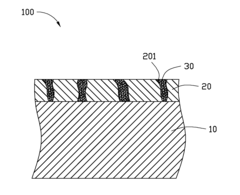

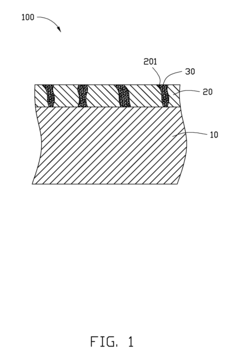

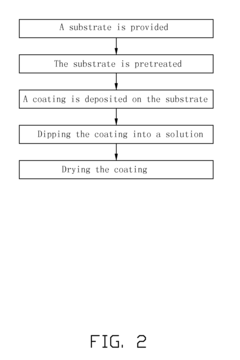

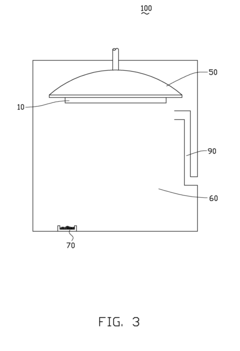

Coated article and method for manufacturing same

PatentInactiveUS20120028030A1

Innovation

- A method involving magnetron sputtering to deposit an aluminum titanium nitride coating on substrates, followed by sealing micropores with a specific solution containing NaCOOCH3, HCOOCH3, NH3.H2O, NaSO4, HNO3, and NaTi, which prevents penetration and corrosion.

Nitinol alloy for with good mechanical stability and a good superelastic operating window

PatentWO2006081011A2

Innovation

- A nickel-titanium alloy with a ternary element such as platinum or palladium is used to enhance radiopacity while maintaining superelastic properties, allowing for a thinner strut design that maintains flexibility and mechanical stability.

Material Characterization Methods

Material characterization methods play a crucial role in understanding the effects of magnetron sputtering on Nitinol coating properties. These techniques provide essential insights into the structural, chemical, and physical attributes of the coatings, enabling researchers and engineers to optimize the sputtering process and enhance the performance of Nitinol-based devices.

X-ray diffraction (XRD) is a fundamental technique used to analyze the crystalline structure of Nitinol coatings. It reveals information about phase composition, crystal orientation, and lattice parameters. By comparing XRD patterns before and after sputtering, researchers can assess how the deposition process affects the material's crystallinity and phase transformations.

Scanning electron microscopy (SEM) is employed to examine the surface morphology and microstructure of Nitinol coatings. High-resolution SEM images provide valuable information about coating uniformity, grain size, and potential defects such as pinholes or cracks. Energy-dispersive X-ray spectroscopy (EDS), often integrated with SEM, allows for elemental analysis of the coating composition.

Transmission electron microscopy (TEM) offers atomic-scale resolution for investigating the internal structure of Nitinol coatings. TEM analysis can reveal details about grain boundaries, dislocations, and interfacial characteristics between the coating and substrate. This technique is particularly useful for studying the formation of intermetallic phases during the sputtering process.

Atomic force microscopy (AFM) is utilized to measure surface roughness and topography at the nanoscale. AFM data can provide quantitative information about coating smoothness and homogeneity, which are critical factors affecting the material's biocompatibility and corrosion resistance in medical applications.

X-ray photoelectron spectroscopy (XPS) is employed to analyze the chemical composition and bonding states of elements in the Nitinol coating surface. This technique is particularly valuable for investigating the formation of oxide layers and assessing the stoichiometry of the deposited material.

Nanoindentation tests are conducted to evaluate the mechanical properties of Nitinol coatings, including hardness and elastic modulus. These measurements help researchers understand how magnetron sputtering parameters influence the coating's mechanical behavior and wear resistance.

Fourier transform infrared spectroscopy (FTIR) is used to identify chemical bonds and functional groups present in the coating. This technique can detect the presence of impurities or unwanted compounds formed during the sputtering process, providing insights into the coating's chemical purity.

By employing these advanced characterization methods, researchers can comprehensively assess the impact of magnetron sputtering on Nitinol coating properties. The data obtained from these techniques guide the optimization of deposition parameters, enabling the development of high-quality Nitinol coatings with tailored properties for specific applications in medical devices, aerospace, and other industries.

X-ray diffraction (XRD) is a fundamental technique used to analyze the crystalline structure of Nitinol coatings. It reveals information about phase composition, crystal orientation, and lattice parameters. By comparing XRD patterns before and after sputtering, researchers can assess how the deposition process affects the material's crystallinity and phase transformations.

Scanning electron microscopy (SEM) is employed to examine the surface morphology and microstructure of Nitinol coatings. High-resolution SEM images provide valuable information about coating uniformity, grain size, and potential defects such as pinholes or cracks. Energy-dispersive X-ray spectroscopy (EDS), often integrated with SEM, allows for elemental analysis of the coating composition.

Transmission electron microscopy (TEM) offers atomic-scale resolution for investigating the internal structure of Nitinol coatings. TEM analysis can reveal details about grain boundaries, dislocations, and interfacial characteristics between the coating and substrate. This technique is particularly useful for studying the formation of intermetallic phases during the sputtering process.

Atomic force microscopy (AFM) is utilized to measure surface roughness and topography at the nanoscale. AFM data can provide quantitative information about coating smoothness and homogeneity, which are critical factors affecting the material's biocompatibility and corrosion resistance in medical applications.

X-ray photoelectron spectroscopy (XPS) is employed to analyze the chemical composition and bonding states of elements in the Nitinol coating surface. This technique is particularly valuable for investigating the formation of oxide layers and assessing the stoichiometry of the deposited material.

Nanoindentation tests are conducted to evaluate the mechanical properties of Nitinol coatings, including hardness and elastic modulus. These measurements help researchers understand how magnetron sputtering parameters influence the coating's mechanical behavior and wear resistance.

Fourier transform infrared spectroscopy (FTIR) is used to identify chemical bonds and functional groups present in the coating. This technique can detect the presence of impurities or unwanted compounds formed during the sputtering process, providing insights into the coating's chemical purity.

By employing these advanced characterization methods, researchers can comprehensively assess the impact of magnetron sputtering on Nitinol coating properties. The data obtained from these techniques guide the optimization of deposition parameters, enabling the development of high-quality Nitinol coatings with tailored properties for specific applications in medical devices, aerospace, and other industries.

Biocompatibility Considerations

Biocompatibility is a critical consideration when evaluating the effects of magnetron sputtering on Nitinol coating properties. The interaction between the coated Nitinol surface and biological systems plays a crucial role in determining the success of medical implants and devices.

One of the primary concerns in biocompatibility is the potential release of nickel ions from the Nitinol substrate. Magnetron sputtering can significantly influence the surface composition and structure of the coating, which in turn affects the rate of nickel ion release. Properly optimized sputtering parameters can create a dense, uniform coating that acts as an effective barrier against nickel leaching, thereby reducing the risk of allergic reactions and other adverse biological responses.

The surface topography of the sputtered coating also impacts cell adhesion and proliferation. Magnetron sputtering allows for precise control over the surface roughness and morphology, which can be tailored to promote or inhibit cell attachment depending on the specific application. For instance, a slightly roughened surface may enhance osseointegration in orthopedic implants, while a smoother surface might be preferred for cardiovascular stents to minimize platelet adhesion and thrombosis risk.

Another important aspect of biocompatibility is the coating's resistance to corrosion and wear in physiological environments. The high-energy nature of magnetron sputtering can produce coatings with excellent adhesion to the Nitinol substrate and enhanced corrosion resistance. This is particularly important for long-term implants that are exposed to the aggressive ionic environment of body fluids.

The choice of coating material deposited via magnetron sputtering also plays a significant role in biocompatibility. Materials such as titanium nitride (TiN) or diamond-like carbon (DLC) are often used due to their excellent biocompatibility and mechanical properties. These coatings can further improve the overall performance of Nitinol devices by combining the shape memory and superelastic properties of Nitinol with enhanced surface characteristics.

Magnetron sputtering also offers the possibility of creating multi-layered or gradient coatings, which can provide a combination of desirable properties. For example, a titanium interlayer can improve adhesion between the Nitinol substrate and a biocompatible top layer, while a gradual transition in composition can minimize internal stresses and enhance coating stability.

The sterilization compatibility of sputtered coatings is another crucial biocompatibility consideration. Magnetron sputtered coatings must maintain their integrity and properties after exposure to common sterilization methods such as ethylene oxide treatment, gamma irradiation, or autoclaving. The high-density nature of sputtered coatings often provides good resistance to these sterilization processes, but this must be verified for each specific coating system.

One of the primary concerns in biocompatibility is the potential release of nickel ions from the Nitinol substrate. Magnetron sputtering can significantly influence the surface composition and structure of the coating, which in turn affects the rate of nickel ion release. Properly optimized sputtering parameters can create a dense, uniform coating that acts as an effective barrier against nickel leaching, thereby reducing the risk of allergic reactions and other adverse biological responses.

The surface topography of the sputtered coating also impacts cell adhesion and proliferation. Magnetron sputtering allows for precise control over the surface roughness and morphology, which can be tailored to promote or inhibit cell attachment depending on the specific application. For instance, a slightly roughened surface may enhance osseointegration in orthopedic implants, while a smoother surface might be preferred for cardiovascular stents to minimize platelet adhesion and thrombosis risk.

Another important aspect of biocompatibility is the coating's resistance to corrosion and wear in physiological environments. The high-energy nature of magnetron sputtering can produce coatings with excellent adhesion to the Nitinol substrate and enhanced corrosion resistance. This is particularly important for long-term implants that are exposed to the aggressive ionic environment of body fluids.

The choice of coating material deposited via magnetron sputtering also plays a significant role in biocompatibility. Materials such as titanium nitride (TiN) or diamond-like carbon (DLC) are often used due to their excellent biocompatibility and mechanical properties. These coatings can further improve the overall performance of Nitinol devices by combining the shape memory and superelastic properties of Nitinol with enhanced surface characteristics.

Magnetron sputtering also offers the possibility of creating multi-layered or gradient coatings, which can provide a combination of desirable properties. For example, a titanium interlayer can improve adhesion between the Nitinol substrate and a biocompatible top layer, while a gradual transition in composition can minimize internal stresses and enhance coating stability.

The sterilization compatibility of sputtered coatings is another crucial biocompatibility consideration. Magnetron sputtered coatings must maintain their integrity and properties after exposure to common sterilization methods such as ethylene oxide treatment, gamma irradiation, or autoclaving. The high-density nature of sputtered coatings often provides good resistance to these sterilization processes, but this must be verified for each specific coating system.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!