Micro Energy Harvesters for Low-Power Communication Devices

OCT 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Energy Harvesting Technology Background and Objectives

Micro energy harvesting technology has evolved significantly over the past two decades, transforming from theoretical concepts into practical applications. This evolution has been driven by the increasing demand for autonomous, self-powered electronic devices, particularly in the Internet of Things (IoT) ecosystem. The fundamental principle behind micro energy harvesting involves capturing small amounts of energy from ambient sources such as light, vibration, thermal gradients, and radio frequency signals, then converting this energy into usable electrical power for low-power communication devices.

The historical trajectory of micro energy harvesting began in the early 2000s with rudimentary piezoelectric and thermoelectric generators. By 2010, significant advancements in materials science and microfabrication techniques enabled the development of more efficient and compact harvesters. The period between 2015 and 2020 witnessed the integration of these technologies into commercial applications, albeit with limited efficiency and power output capabilities.

Current technological trends indicate a shift toward hybrid energy harvesting systems that can simultaneously capture energy from multiple ambient sources, thereby increasing reliability and power output. Additionally, there is growing interest in developing harvesters specifically optimized for the unique requirements of low-power communication protocols such as BLE (Bluetooth Low Energy), LoRa, and Zigbee, which operate with minimal power consumption.

The primary objective of micro energy harvesting technology for low-power communication devices is to achieve complete energy autonomy, eliminating the need for battery replacement or external charging. This goal encompasses several specific technical targets: increasing energy conversion efficiency to exceed 30% for most harvesting mechanisms; reducing form factors to below 1 cm³ while maintaining adequate power output; enhancing power management circuits to operate efficiently at sub-microwatt levels; and developing intelligent energy storage solutions that balance immediate power needs with long-term energy storage.

Another critical objective is to ensure consistent power delivery despite the inherently intermittent nature of ambient energy sources. This requires sophisticated power management strategies and potentially hybrid storage solutions combining supercapacitors for rapid energy capture with thin-film batteries for long-term storage.

The ultimate vision for this technology is to enable a new generation of perpetually powered communication devices that can operate indefinitely in remote or inaccessible locations, supporting applications ranging from environmental monitoring and structural health assessment to medical implants and distributed sensing networks. Achieving this vision would represent a paradigm shift in how we design and deploy wireless communication systems, potentially eliminating billions of disposable batteries from the waste stream annually.

The historical trajectory of micro energy harvesting began in the early 2000s with rudimentary piezoelectric and thermoelectric generators. By 2010, significant advancements in materials science and microfabrication techniques enabled the development of more efficient and compact harvesters. The period between 2015 and 2020 witnessed the integration of these technologies into commercial applications, albeit with limited efficiency and power output capabilities.

Current technological trends indicate a shift toward hybrid energy harvesting systems that can simultaneously capture energy from multiple ambient sources, thereby increasing reliability and power output. Additionally, there is growing interest in developing harvesters specifically optimized for the unique requirements of low-power communication protocols such as BLE (Bluetooth Low Energy), LoRa, and Zigbee, which operate with minimal power consumption.

The primary objective of micro energy harvesting technology for low-power communication devices is to achieve complete energy autonomy, eliminating the need for battery replacement or external charging. This goal encompasses several specific technical targets: increasing energy conversion efficiency to exceed 30% for most harvesting mechanisms; reducing form factors to below 1 cm³ while maintaining adequate power output; enhancing power management circuits to operate efficiently at sub-microwatt levels; and developing intelligent energy storage solutions that balance immediate power needs with long-term energy storage.

Another critical objective is to ensure consistent power delivery despite the inherently intermittent nature of ambient energy sources. This requires sophisticated power management strategies and potentially hybrid storage solutions combining supercapacitors for rapid energy capture with thin-film batteries for long-term storage.

The ultimate vision for this technology is to enable a new generation of perpetually powered communication devices that can operate indefinitely in remote or inaccessible locations, supporting applications ranging from environmental monitoring and structural health assessment to medical implants and distributed sensing networks. Achieving this vision would represent a paradigm shift in how we design and deploy wireless communication systems, potentially eliminating billions of disposable batteries from the waste stream annually.

Market Analysis for Self-Powered IoT Communication Devices

The self-powered IoT communication devices market is experiencing unprecedented growth, driven by the increasing deployment of IoT sensors across various industries. The global market for energy harvesting systems was valued at approximately $440 million in 2022 and is projected to reach $1.3 billion by 2028, growing at a CAGR of 19.2%. This growth is particularly significant for micro energy harvesters designed for low-power communication devices, which represent about 35% of this market.

The demand for self-powered IoT devices stems from several key factors. First, the operational cost reduction achieved by eliminating battery replacement in remote or hard-to-access locations provides substantial long-term savings. Studies indicate that maintenance costs for battery replacement can account for up to 80% of the total cost of ownership for IoT sensor networks over their lifetime.

Second, environmental sustainability concerns are driving adoption, as self-powered devices significantly reduce electronic waste from disposed batteries. An estimated 3 billion batteries are discarded annually from IoT devices alone, creating a strong market pull for sustainable alternatives.

Industry-specific demand varies considerably. Smart buildings and industrial automation lead adoption with approximately 28% market share, followed by consumer electronics (22%), healthcare monitoring (17%), agricultural applications (15%), and infrastructure monitoring (12%). The remaining 6% encompasses emerging applications like wearable technology and environmental monitoring.

Regional market analysis reveals North America currently holds the largest market share at 38%, followed by Europe (29%), Asia-Pacific (26%), and the rest of the world (7%). However, the Asia-Pacific region is expected to witness the highest growth rate of 23.5% through 2028, primarily due to rapid industrial IoT adoption in China, Japan, and South Korea.

Key market drivers include the proliferation of IoT deployments, with connected devices projected to exceed 75 billion by 2025. The decreasing power requirements of modern communication protocols like BLE 5.0, Zigbee, and LoRaWAN have made energy harvesting increasingly viable. Additionally, the push toward edge computing is creating demand for autonomous power solutions at the network edge.

Market challenges include price sensitivity, as self-powered solutions currently command a 30-40% premium over battery-powered alternatives. Technical limitations in energy harvesting efficiency and power output consistency also remain barriers to wider adoption in applications requiring higher or more consistent power.

The market is expected to reach an inflection point around 2025-2026 when improvements in harvesting efficiency and decreasing component costs will likely drive accelerated adoption across multiple sectors, particularly in industrial IoT and smart infrastructure applications.

The demand for self-powered IoT devices stems from several key factors. First, the operational cost reduction achieved by eliminating battery replacement in remote or hard-to-access locations provides substantial long-term savings. Studies indicate that maintenance costs for battery replacement can account for up to 80% of the total cost of ownership for IoT sensor networks over their lifetime.

Second, environmental sustainability concerns are driving adoption, as self-powered devices significantly reduce electronic waste from disposed batteries. An estimated 3 billion batteries are discarded annually from IoT devices alone, creating a strong market pull for sustainable alternatives.

Industry-specific demand varies considerably. Smart buildings and industrial automation lead adoption with approximately 28% market share, followed by consumer electronics (22%), healthcare monitoring (17%), agricultural applications (15%), and infrastructure monitoring (12%). The remaining 6% encompasses emerging applications like wearable technology and environmental monitoring.

Regional market analysis reveals North America currently holds the largest market share at 38%, followed by Europe (29%), Asia-Pacific (26%), and the rest of the world (7%). However, the Asia-Pacific region is expected to witness the highest growth rate of 23.5% through 2028, primarily due to rapid industrial IoT adoption in China, Japan, and South Korea.

Key market drivers include the proliferation of IoT deployments, with connected devices projected to exceed 75 billion by 2025. The decreasing power requirements of modern communication protocols like BLE 5.0, Zigbee, and LoRaWAN have made energy harvesting increasingly viable. Additionally, the push toward edge computing is creating demand for autonomous power solutions at the network edge.

Market challenges include price sensitivity, as self-powered solutions currently command a 30-40% premium over battery-powered alternatives. Technical limitations in energy harvesting efficiency and power output consistency also remain barriers to wider adoption in applications requiring higher or more consistent power.

The market is expected to reach an inflection point around 2025-2026 when improvements in harvesting efficiency and decreasing component costs will likely drive accelerated adoption across multiple sectors, particularly in industrial IoT and smart infrastructure applications.

Current Challenges in Micro-Scale Energy Harvesting Technologies

Despite significant advancements in micro-scale energy harvesting technologies, several critical challenges continue to impede widespread adoption and optimal performance for low-power communication devices. The miniaturization of energy harvesters presents fundamental physical limitations that affect energy conversion efficiency. As dimensions decrease to the micro-scale, surface-to-volume ratios increase dramatically, leading to dominant surface effects that can negatively impact energy generation mechanisms. This scaling challenge is particularly evident in piezoelectric and electromagnetic harvesters, where reduced dimensions directly correlate with diminished power output.

Material limitations constitute another significant barrier. Current piezoelectric materials exhibit efficiency constraints, with even high-performance materials like PZT and PMN-PT converting only 5-10% of mechanical energy into electrical energy. Similarly, thermoelectric materials struggle with low figure-of-merit (ZT) values, typically below 2 at room temperature, limiting thermal-to-electrical conversion efficiency to under 10% in practical applications.

Power density remains inadequate for many applications, with most micro-harvesters generating only 10-100 μW/cm², falling short of the requirements for continuous operation of wireless communication modules that may require periodic bursts of 1-10 mW. This power gap necessitates complex power management systems that add to overall device complexity and cost.

Environmental dependency presents another substantial challenge. Vibration-based harvesters operate optimally at specific resonant frequencies, making them ineffective when environmental vibrations deviate from these frequencies. Similarly, thermoelectric generators require consistent temperature gradients, while photovoltaic micro-harvesters depend on reliable light sources, limiting their deployment versatility.

Integration complexity with existing microelectronic fabrication processes poses significant manufacturing hurdles. Many harvesting technologies require specialized materials and processes that are incompatible with standard CMOS fabrication techniques, creating barriers to cost-effective mass production and seamless integration with communication circuits.

Storage limitations further complicate system design, as micro-batteries and supercapacitors at this scale suffer from limited energy density, high self-discharge rates, and reduced cycle life. These storage constraints often become the bottleneck in creating truly autonomous micro-systems.

Cross-domain optimization represents perhaps the most complex challenge, requiring simultaneous expertise in mechanical engineering, materials science, electrical engineering, and manufacturing processes. The interdisciplinary nature of these systems makes holistic optimization exceptionally difficult, often resulting in sub-optimal compromises between competing design requirements.

Material limitations constitute another significant barrier. Current piezoelectric materials exhibit efficiency constraints, with even high-performance materials like PZT and PMN-PT converting only 5-10% of mechanical energy into electrical energy. Similarly, thermoelectric materials struggle with low figure-of-merit (ZT) values, typically below 2 at room temperature, limiting thermal-to-electrical conversion efficiency to under 10% in practical applications.

Power density remains inadequate for many applications, with most micro-harvesters generating only 10-100 μW/cm², falling short of the requirements for continuous operation of wireless communication modules that may require periodic bursts of 1-10 mW. This power gap necessitates complex power management systems that add to overall device complexity and cost.

Environmental dependency presents another substantial challenge. Vibration-based harvesters operate optimally at specific resonant frequencies, making them ineffective when environmental vibrations deviate from these frequencies. Similarly, thermoelectric generators require consistent temperature gradients, while photovoltaic micro-harvesters depend on reliable light sources, limiting their deployment versatility.

Integration complexity with existing microelectronic fabrication processes poses significant manufacturing hurdles. Many harvesting technologies require specialized materials and processes that are incompatible with standard CMOS fabrication techniques, creating barriers to cost-effective mass production and seamless integration with communication circuits.

Storage limitations further complicate system design, as micro-batteries and supercapacitors at this scale suffer from limited energy density, high self-discharge rates, and reduced cycle life. These storage constraints often become the bottleneck in creating truly autonomous micro-systems.

Cross-domain optimization represents perhaps the most complex challenge, requiring simultaneous expertise in mechanical engineering, materials science, electrical engineering, and manufacturing processes. The interdisciplinary nature of these systems makes holistic optimization exceptionally difficult, often resulting in sub-optimal compromises between competing design requirements.

Current Technical Solutions for Low-Power Energy Harvesting

01 Piezoelectric micro energy harvesters

Piezoelectric materials convert mechanical energy into electrical energy through the piezoelectric effect. These micro energy harvesters can capture energy from vibrations, movements, and mechanical stresses in the environment. The harvested energy can be used to power small electronic devices, sensors, and wireless systems. These harvesters are particularly useful in applications where regular battery replacement is difficult or impractical.- Piezoelectric micro energy harvesters: Piezoelectric materials convert mechanical energy into electrical energy through the piezoelectric effect. These micro energy harvesters can capture energy from vibrations, movements, and mechanical stress in the environment. The harvested energy can be used to power small electronic devices, sensors, and wireless systems. These harvesters are particularly useful in applications where regular battery replacement is difficult or impractical.

- Triboelectric micro energy harvesters: Triboelectric energy harvesters generate electricity through contact electrification and electrostatic induction when two different materials come into contact and separate. These harvesters can convert various mechanical energies such as friction, vibration, and human motion into electrical energy. They are characterized by their simple structure, high efficiency, and low cost, making them suitable for self-powered systems and wearable electronics.

- Electromagnetic micro energy harvesters: Electromagnetic micro energy harvesters utilize Faraday's law of electromagnetic induction to convert mechanical energy into electrical energy. These systems typically consist of magnets and coils, where relative movement between them generates electrical current. They are effective for harvesting energy from low-frequency vibrations and can be designed in various configurations to optimize power output for specific applications such as structural health monitoring and IoT devices.

- Thermal micro energy harvesters: Thermal energy harvesters convert temperature differences into electrical energy using thermoelectric effects. These devices can harvest waste heat from industrial processes, body heat, or environmental temperature gradients. The efficiency of thermal energy harvesters depends on the temperature difference and the thermoelectric materials used. Recent advancements focus on improving the efficiency and reducing the size of these harvesters for integration into microelectronic systems.

- Hybrid and integrated micro energy harvesting systems: Hybrid micro energy harvesters combine multiple harvesting mechanisms to increase energy output and reliability. These systems may integrate piezoelectric, triboelectric, electromagnetic, and/or thermal harvesting technologies into a single device. Such integration allows for energy capture from various environmental sources simultaneously, enhancing overall efficiency and providing more consistent power output. These hybrid systems often include energy storage components and power management circuits to optimize energy utilization.

02 Triboelectric micro energy harvesters

Triboelectric energy harvesters generate electricity through contact electrification and electrostatic induction when two different materials come into contact and separate. These harvesters can effectively convert mechanical energy from human motion, wind, water waves, and other environmental sources into electrical energy. The technology offers advantages such as simple structure, low cost, high efficiency, and diverse material selection for various applications.Expand Specific Solutions03 Thermal micro energy harvesters

Thermal energy harvesters convert temperature differences into electrical energy using thermoelectric effects. These devices can harvest energy from waste heat, body heat, or environmental temperature gradients. The technology utilizes materials with high Seebeck coefficients to maximize energy conversion efficiency. Applications include powering wearable devices, remote sensors, and IoT devices in environments where temperature differences exist.Expand Specific Solutions04 RF and electromagnetic micro energy harvesters

Radio frequency (RF) and electromagnetic energy harvesters capture ambient electromagnetic energy from sources such as radio waves, Wi-Fi signals, and cellular networks. These harvesters typically use antennas to collect electromagnetic waves and rectifier circuits to convert them into usable DC power. The technology is particularly valuable for powering wireless sensor networks, IoT devices, and other low-power electronics in urban environments with abundant RF signals.Expand Specific Solutions05 Hybrid and integrated micro energy harvesting systems

Hybrid energy harvesting systems combine multiple energy harvesting technologies to improve overall efficiency and reliability. These systems may integrate piezoelectric, triboelectric, thermal, and electromagnetic harvesting methods to capture energy from various environmental sources simultaneously. Advanced designs include energy management circuits, storage components, and power conditioning systems to provide stable power output for practical applications. This approach addresses the limitations of individual harvesting methods and enhances energy availability.Expand Specific Solutions

Key Industry Players in Micro Energy Harvesting Ecosystem

Micro Energy Harvesters for Low-Power Communication Devices market is in its growth phase, with increasing demand driven by IoT proliferation. The market is projected to expand significantly as energy-efficient communication becomes critical across industries. Technologically, the field shows varying maturity levels, with established players like Texas Instruments, Qualcomm, and Samsung Electronics leading commercial applications through advanced semiconductor solutions. Research institutions including University of Florida, Indian Institute of Science, and National University of Singapore are advancing fundamental breakthroughs. Companies like Nordic Semiconductor and Robert Bosch are developing specialized applications, while emerging players from China such as Shenzhen Cooperation Technology are rapidly gaining ground with cost-effective solutions. The ecosystem demonstrates a healthy balance between academic innovation and industrial commercialization.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed an integrated micro energy harvesting solution specifically designed for low-power communication devices. Their technology centers around the BQ25570 ultra-low-power harvester power management IC, which can extract microwatts to milliwatts from various energy sources including solar, thermal, and vibration with over 90% efficiency. The system features a programmable maximum power point tracking (MPPT) capability that dynamically adjusts to optimize energy extraction across varying environmental conditions. TI's solution incorporates a boost converter that can start operation with input voltages as low as 330mV, enabling energy capture from previously unusable low-voltage sources. Their integrated power management system includes intelligent battery management with temperature-compensated charging and protection features, extending the operational life of energy storage components. The technology is complemented by TI's ultra-low-power MSP430 microcontrollers and CC series wireless transceivers, creating a complete ecosystem for self-powered IoT applications.

Strengths: Highly integrated solution with industry-leading power conversion efficiency; comprehensive ecosystem approach including processing and communication components; extensive design support tools and reference designs. Weaknesses: Higher implementation complexity compared to simpler solutions; requires careful system design to maximize benefits; optimal performance depends on proper configuration of multiple parameters.

Robert Bosch GmbH

Technical Solution: Bosch has developed an industrial-grade micro energy harvesting platform specifically engineered for low-power communication devices in harsh environments. Their technology focuses on vibration and thermal energy harvesting, utilizing electromagnetic and thermoelectric generators optimized for industrial machinery applications. Bosch's solution features ruggedized mechanical designs capable of withstanding extreme temperatures (-40°C to 125°C) and high vibration environments while maintaining reliable energy generation. Their proprietary energy management system incorporates ultra-efficient DC-DC conversion with adaptive maximum power point tracking, achieving over 85% conversion efficiency across varying input conditions. The platform integrates seamlessly with Bosch's industrial sensor networks and low-power wireless protocols, enabling self-powered condition monitoring and predictive maintenance applications. Their system includes specialized energy storage solutions using supercapacitors and thin-film batteries optimized for high-cycle applications, ensuring reliable operation for over 10 years without maintenance. Bosch has implemented this technology in industrial IoT deployments, demonstrating reliable operation in environments where traditional battery-powered devices would fail.

Strengths: Exceptional reliability and durability in harsh industrial environments; comprehensive integration with industrial automation systems; proven field performance in demanding applications. Weaknesses: Solutions tend to be application-specific rather than general-purpose; higher initial cost compared to simpler energy harvesting systems; optimization required for specific deployment environments.

Critical Patents and Innovations in Micro Energy Harvesting

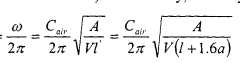

Energy harvesting device and method of harvesting energy

PatentWO2014204410A1

Innovation

- The proposed energy harvesting device incorporates a microchannel and a bluff body to generate a vortex fluid street, with a piezoelectric micro-belt interacting with the vortex to convert mechanical energy into electrical energy, utilizing frequency up-conversion to enhance efficiency and reduce device size.

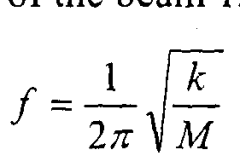

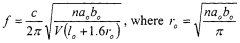

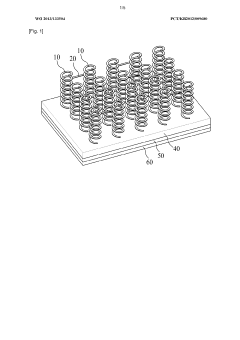

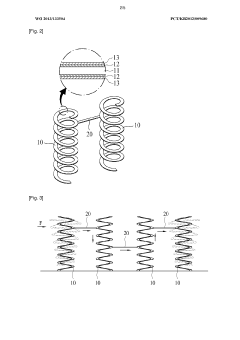

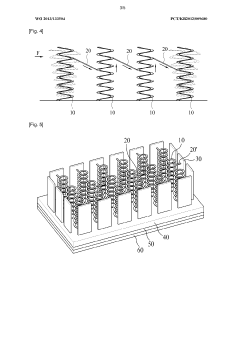

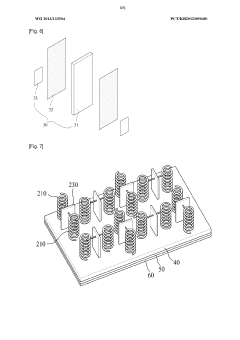

Energy-harvesting apparatus comprising coil spring-type microscale piezoelectric resonator

PatentWO2013133504A1

Innovation

- The energy harvesting device employs a plurality of micro-piezoelectric vibrators in the form of coil springs and plate-type piezoelectric vibrators connected through various connection units on a printed circuit board, allowing for efficient power generation from external forces and heat, with the ability to transmit and collect energy through diverse paths.

Sustainability Impact and Environmental Benefits

Micro energy harvesting technologies represent a significant advancement in sustainable energy solutions for low-power communication devices. These technologies directly contribute to reducing the environmental footprint of the rapidly expanding Internet of Things (IoT) ecosystem by eliminating or reducing the need for conventional batteries. The environmental benefits are multifaceted, beginning with the substantial reduction in battery waste. Conventional batteries contain toxic materials including heavy metals such as lead, mercury, and cadmium that pose serious environmental hazards when improperly disposed of, contaminating soil and water resources.

By extending device operational lifetimes through ambient energy harvesting, these technologies significantly reduce the frequency of battery replacements and disposals. This translates to fewer resources being consumed in battery manufacturing processes, which typically involve energy-intensive extraction of raw materials, processing, and transportation. The reduction in manufacturing demand consequently leads to decreased carbon emissions associated with these industrial processes.

The sustainability impact extends beyond waste reduction to include operational efficiency improvements. Self-powered devices eliminate the energy losses associated with battery charging cycles and reduce the need for maintenance visits to remote installations. For large-scale IoT deployments in smart cities, agricultural monitoring, or environmental sensing networks, this represents substantial energy savings and reduced carbon emissions from maintenance-related transportation.

From a circular economy perspective, micro energy harvesters promote more sustainable product lifecycles. Many harvesting technologies utilize materials that can be more readily recycled or have lower environmental impact compared to battery components. Additionally, the design philosophy behind energy harvesting often emphasizes longevity and durability, further reducing the environmental burden of electronic waste.

In developing regions with limited access to power infrastructure, these technologies enable the deployment of communication networks and sensing systems without requiring extensive electrical grid expansion. This leapfrogging effect allows communities to benefit from modern communication technologies while minimizing environmental disruption and resource consumption.

The quantifiable environmental benefits include potential reduction in global battery waste, estimated at billions of units annually, decreased carbon emissions from manufacturing and transportation, and conservation of finite natural resources used in battery production. As these technologies mature and achieve wider adoption, their cumulative positive environmental impact will continue to grow, contributing significantly to global sustainability goals and circular economy initiatives.

By extending device operational lifetimes through ambient energy harvesting, these technologies significantly reduce the frequency of battery replacements and disposals. This translates to fewer resources being consumed in battery manufacturing processes, which typically involve energy-intensive extraction of raw materials, processing, and transportation. The reduction in manufacturing demand consequently leads to decreased carbon emissions associated with these industrial processes.

The sustainability impact extends beyond waste reduction to include operational efficiency improvements. Self-powered devices eliminate the energy losses associated with battery charging cycles and reduce the need for maintenance visits to remote installations. For large-scale IoT deployments in smart cities, agricultural monitoring, or environmental sensing networks, this represents substantial energy savings and reduced carbon emissions from maintenance-related transportation.

From a circular economy perspective, micro energy harvesters promote more sustainable product lifecycles. Many harvesting technologies utilize materials that can be more readily recycled or have lower environmental impact compared to battery components. Additionally, the design philosophy behind energy harvesting often emphasizes longevity and durability, further reducing the environmental burden of electronic waste.

In developing regions with limited access to power infrastructure, these technologies enable the deployment of communication networks and sensing systems without requiring extensive electrical grid expansion. This leapfrogging effect allows communities to benefit from modern communication technologies while minimizing environmental disruption and resource consumption.

The quantifiable environmental benefits include potential reduction in global battery waste, estimated at billions of units annually, decreased carbon emissions from manufacturing and transportation, and conservation of finite natural resources used in battery production. As these technologies mature and achieve wider adoption, their cumulative positive environmental impact will continue to grow, contributing significantly to global sustainability goals and circular economy initiatives.

Integration Strategies with Existing Communication Protocols

The integration of micro energy harvesters with existing communication protocols represents a critical challenge in developing truly autonomous low-power communication devices. Current communication standards were primarily designed for devices with stable power supplies, not considering the intermittent and variable nature of harvested energy. Successful integration requires careful protocol adaptation and energy-aware communication strategies.

Bluetooth Low Energy (BLE) offers promising compatibility with energy harvesting systems due to its inherently low power consumption characteristics. By implementing adaptive duty cycling that synchronizes transmission intervals with energy availability, BLE-enabled devices can operate effectively even with inconsistent power generation. Recent advancements have demonstrated BLE devices functioning on as little as 10μW of harvested power through optimized protocol implementations.

LoRaWAN and other LPWAN (Low Power Wide Area Network) protocols present viable integration paths for energy harvesting systems deployed in remote monitoring applications. These protocols' inherent design for minimal power consumption aligns well with harvested energy constraints. Modified implementations featuring extended sleep modes and compressed data packets have shown 30-40% improvement in energy efficiency while maintaining communication reliability.

IEEE 802.15.4-based protocols (including ZigBee and Thread) have been successfully adapted for energy harvesting applications through specialized MAC layer modifications. These modifications include priority-based transmission scheduling and dynamic packet sizing based on available energy. Research indicates that implementing energy-aware routing algorithms within these protocols can extend network lifetime by up to 65% when powered by micro energy harvesters.

Wake-up radio technology represents a particularly promising integration strategy, allowing the main radio to remain in sleep mode until activated by an ultra-low-power secondary receiver. This approach has demonstrated power reductions of up to 95% in certain applications while maintaining responsiveness. Several commercial implementations now combine wake-up radios with vibration or RF energy harvesters to create maintenance-free sensor nodes.

Cross-layer optimization techniques that enable communication stacks to adapt based on real-time energy availability show significant promise. These approaches modify traditional protocol boundaries, allowing energy information to influence decisions at multiple network layers simultaneously. Experimental implementations have demonstrated up to 70% improvement in message delivery reliability under variable energy harvesting conditions compared to conventional protocol implementations.

The emergence of specialized communication protocols specifically designed for energy harvesting systems, such as ECOLINK and Intermittent Network Stack (INS), represents a significant advancement. These protocols incorporate energy-awareness at their core, featuring adaptive modulation schemes, opportunistic transmission windows, and graceful performance degradation when energy is scarce.

Bluetooth Low Energy (BLE) offers promising compatibility with energy harvesting systems due to its inherently low power consumption characteristics. By implementing adaptive duty cycling that synchronizes transmission intervals with energy availability, BLE-enabled devices can operate effectively even with inconsistent power generation. Recent advancements have demonstrated BLE devices functioning on as little as 10μW of harvested power through optimized protocol implementations.

LoRaWAN and other LPWAN (Low Power Wide Area Network) protocols present viable integration paths for energy harvesting systems deployed in remote monitoring applications. These protocols' inherent design for minimal power consumption aligns well with harvested energy constraints. Modified implementations featuring extended sleep modes and compressed data packets have shown 30-40% improvement in energy efficiency while maintaining communication reliability.

IEEE 802.15.4-based protocols (including ZigBee and Thread) have been successfully adapted for energy harvesting applications through specialized MAC layer modifications. These modifications include priority-based transmission scheduling and dynamic packet sizing based on available energy. Research indicates that implementing energy-aware routing algorithms within these protocols can extend network lifetime by up to 65% when powered by micro energy harvesters.

Wake-up radio technology represents a particularly promising integration strategy, allowing the main radio to remain in sleep mode until activated by an ultra-low-power secondary receiver. This approach has demonstrated power reductions of up to 95% in certain applications while maintaining responsiveness. Several commercial implementations now combine wake-up radios with vibration or RF energy harvesters to create maintenance-free sensor nodes.

Cross-layer optimization techniques that enable communication stacks to adapt based on real-time energy availability show significant promise. These approaches modify traditional protocol boundaries, allowing energy information to influence decisions at multiple network layers simultaneously. Experimental implementations have demonstrated up to 70% improvement in message delivery reliability under variable energy harvesting conditions compared to conventional protocol implementations.

The emergence of specialized communication protocols specifically designed for energy harvesting systems, such as ECOLINK and Intermittent Network Stack (INS), represents a significant advancement. These protocols incorporate energy-awareness at their core, featuring adaptive modulation schemes, opportunistic transmission windows, and graceful performance degradation when energy is scarce.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!