Micro Energy Harvesters: Implications of Material Innovations in Efficiency

OCT 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Energy Harvesting Background and Objectives

Micro energy harvesting has emerged as a transformative technology in the field of sustainable power generation, evolving significantly over the past two decades. Initially conceptualized in the early 2000s as a theoretical approach to power miniaturized devices, this technology has progressed from laboratory curiosities to commercially viable solutions. The fundamental principle involves capturing ambient energy from the environment—such as mechanical vibrations, thermal gradients, light, or RF signals—and converting it into usable electrical power for low-energy consumption devices.

The evolution of micro energy harvesters has been closely tied to advancements in material science. Traditional materials used in early harvesters demonstrated limited efficiency, typically converting less than 1% of available ambient energy. However, recent breakthroughs in nanomaterials, piezoelectric compounds, and thermoelectric materials have pushed conversion efficiencies to 5-15%, depending on the energy source and harvesting mechanism.

Material innovations represent the cornerstone of efficiency improvements in this field. Novel piezoelectric materials like doped PZT (lead zirconate titanate) and PMN-PT (lead magnesium niobate-lead titanate) have dramatically enhanced mechanical-to-electrical conversion rates. Similarly, advancements in thermoelectric materials such as bismuth telluride alloys and silicon-germanium compounds have improved thermal energy harvesting capabilities by optimizing the Seebeck coefficient while minimizing thermal conductivity.

The primary technical objective in this domain is to achieve self-sustaining power generation for the expanding ecosystem of IoT devices, wearable technologies, and remote sensors. Current research aims to develop harvesters capable of generating power in the microwatt to milliwatt range—sufficient to power wireless sensors, medical implants, and environmental monitoring systems without battery replacement. This objective aligns with the broader goal of enabling truly autonomous electronic systems that can operate indefinitely in remote or inaccessible locations.

Another critical objective is miniaturization while maintaining or improving efficiency. As applications for micro energy harvesters expand into medical implants, structural health monitoring, and consumer electronics, the size constraints become increasingly stringent. Material innovations that enable higher power density are therefore paramount to the technology's continued evolution and adoption.

The trajectory of micro energy harvesting technology points toward hybrid systems that combine multiple harvesting mechanisms to ensure consistent power generation regardless of environmental conditions. This approach requires materials that can efficiently convert different forms of ambient energy, presenting both challenges and opportunities for material scientists and engineers working in this rapidly evolving field.

The evolution of micro energy harvesters has been closely tied to advancements in material science. Traditional materials used in early harvesters demonstrated limited efficiency, typically converting less than 1% of available ambient energy. However, recent breakthroughs in nanomaterials, piezoelectric compounds, and thermoelectric materials have pushed conversion efficiencies to 5-15%, depending on the energy source and harvesting mechanism.

Material innovations represent the cornerstone of efficiency improvements in this field. Novel piezoelectric materials like doped PZT (lead zirconate titanate) and PMN-PT (lead magnesium niobate-lead titanate) have dramatically enhanced mechanical-to-electrical conversion rates. Similarly, advancements in thermoelectric materials such as bismuth telluride alloys and silicon-germanium compounds have improved thermal energy harvesting capabilities by optimizing the Seebeck coefficient while minimizing thermal conductivity.

The primary technical objective in this domain is to achieve self-sustaining power generation for the expanding ecosystem of IoT devices, wearable technologies, and remote sensors. Current research aims to develop harvesters capable of generating power in the microwatt to milliwatt range—sufficient to power wireless sensors, medical implants, and environmental monitoring systems without battery replacement. This objective aligns with the broader goal of enabling truly autonomous electronic systems that can operate indefinitely in remote or inaccessible locations.

Another critical objective is miniaturization while maintaining or improving efficiency. As applications for micro energy harvesters expand into medical implants, structural health monitoring, and consumer electronics, the size constraints become increasingly stringent. Material innovations that enable higher power density are therefore paramount to the technology's continued evolution and adoption.

The trajectory of micro energy harvesting technology points toward hybrid systems that combine multiple harvesting mechanisms to ensure consistent power generation regardless of environmental conditions. This approach requires materials that can efficiently convert different forms of ambient energy, presenting both challenges and opportunities for material scientists and engineers working in this rapidly evolving field.

Market Analysis for Micro Energy Harvesting Solutions

The global micro energy harvesting market is experiencing robust growth, driven by the increasing demand for autonomous and self-powered electronic devices across various industries. Current market valuations place this sector at approximately 460 million USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 12.5% through 2030, potentially reaching over 1 billion USD by the end of the decade.

The market segmentation reveals distinct categories based on harvesting technology types, with piezoelectric, thermoelectric, electromagnetic, and photovoltaic solutions dominating the landscape. Among these, piezoelectric energy harvesters currently hold the largest market share at 32%, followed by photovoltaic solutions at 28%. This distribution reflects the maturity and efficiency of these technologies in converting ambient energy into usable electrical power.

From an application perspective, consumer electronics represents the largest market segment, accounting for approximately 35% of total market value. This is followed by industrial applications (25%), healthcare devices (20%), and building automation (15%). The remaining 5% encompasses emerging applications in agriculture, environmental monitoring, and smart infrastructure.

Geographically, North America leads the market with a 38% share, driven by substantial investments in IoT technologies and advanced manufacturing. Europe follows closely at 30%, with particular strength in industrial applications and sustainable energy initiatives. The Asia-Pacific region, currently at 25% market share, is expected to demonstrate the fastest growth rate of 15.2% annually, fueled by rapid industrialization and expanding electronics manufacturing capabilities.

Key market drivers include the proliferation of Internet of Things (IoT) devices, which is creating unprecedented demand for maintenance-free power solutions. The global IoT device count is expected to exceed 25 billion by 2025, with a significant portion requiring autonomous power sources. Additionally, the miniaturization trend in electronics is creating opportunities for micro-scale energy harvesting technologies that can be integrated into increasingly compact devices.

Customer demand patterns indicate a growing preference for hybrid energy harvesting solutions that combine multiple technologies to ensure reliable power generation across varying environmental conditions. This trend is particularly evident in critical applications such as medical implants, structural health monitoring systems, and remote environmental sensors.

Market challenges include cost barriers, with current micro energy harvesting solutions typically adding 15-30% to device manufacturing costs. Technical limitations in energy conversion efficiency also remain significant, with most commercial solutions operating at 15-25% efficiency, well below theoretical maximums.

The market segmentation reveals distinct categories based on harvesting technology types, with piezoelectric, thermoelectric, electromagnetic, and photovoltaic solutions dominating the landscape. Among these, piezoelectric energy harvesters currently hold the largest market share at 32%, followed by photovoltaic solutions at 28%. This distribution reflects the maturity and efficiency of these technologies in converting ambient energy into usable electrical power.

From an application perspective, consumer electronics represents the largest market segment, accounting for approximately 35% of total market value. This is followed by industrial applications (25%), healthcare devices (20%), and building automation (15%). The remaining 5% encompasses emerging applications in agriculture, environmental monitoring, and smart infrastructure.

Geographically, North America leads the market with a 38% share, driven by substantial investments in IoT technologies and advanced manufacturing. Europe follows closely at 30%, with particular strength in industrial applications and sustainable energy initiatives. The Asia-Pacific region, currently at 25% market share, is expected to demonstrate the fastest growth rate of 15.2% annually, fueled by rapid industrialization and expanding electronics manufacturing capabilities.

Key market drivers include the proliferation of Internet of Things (IoT) devices, which is creating unprecedented demand for maintenance-free power solutions. The global IoT device count is expected to exceed 25 billion by 2025, with a significant portion requiring autonomous power sources. Additionally, the miniaturization trend in electronics is creating opportunities for micro-scale energy harvesting technologies that can be integrated into increasingly compact devices.

Customer demand patterns indicate a growing preference for hybrid energy harvesting solutions that combine multiple technologies to ensure reliable power generation across varying environmental conditions. This trend is particularly evident in critical applications such as medical implants, structural health monitoring systems, and remote environmental sensors.

Market challenges include cost barriers, with current micro energy harvesting solutions typically adding 15-30% to device manufacturing costs. Technical limitations in energy conversion efficiency also remain significant, with most commercial solutions operating at 15-25% efficiency, well below theoretical maximums.

Current Material Limitations and Technical Challenges

Despite significant advancements in micro energy harvesting technologies, current material limitations present substantial barriers to achieving optimal efficiency. Conventional piezoelectric materials such as lead zirconate titanate (PZT) and zinc oxide (ZnO) demonstrate limited energy conversion rates, typically below 10%, which restricts their practical application in self-powered microsystems. Additionally, these materials often exhibit brittleness and poor mechanical durability, leading to performance degradation over time when subjected to continuous mechanical stress.

Thermoelectric materials face similar challenges, with current state-of-the-art materials achieving a figure of merit (ZT) of only 1-2 at room temperature. This translates to conversion efficiencies of merely 5-8%, significantly below the theoretical Carnot efficiency. The inherent trade-off between electrical conductivity and thermal conductivity in these materials creates a fundamental physical constraint that has proven difficult to overcome using conventional material design approaches.

Triboelectric nanogenerators (TENGs), while promising, suffer from low power density (typically 1-10 mW/cm²) and inconsistent output due to environmental sensitivity. The surface charge density of current triboelectric materials remains insufficient for many practical applications, and charge retention capabilities deteriorate rapidly in humid conditions, limiting deployment in real-world scenarios.

Flexibility and form factor present additional challenges across all micro energy harvesting technologies. Many high-performance materials lack the mechanical flexibility required for integration into wearable or implantable devices. Rigid ceramic-based piezoelectrics and brittle semiconductor-based thermoelectrics cannot conform to irregular surfaces or withstand repeated bending, severely limiting their application scope.

Manufacturing scalability represents another significant hurdle. Advanced nanomaterials with superior theoretical performance often rely on complex synthesis methods involving high temperatures, toxic precursors, or precise vacuum conditions. These requirements translate to high production costs and environmental concerns, impeding widespread commercial adoption.

Biocompatibility and environmental impact further complicate material selection, particularly for medical and environmental sensing applications. Many high-performance materials contain toxic elements like lead or tellurium, raising regulatory concerns and limiting their use in consumer products or environmental deployments.

The integration of multiple harvesting mechanisms into hybrid systems introduces additional material interface challenges. Thermal expansion mismatches, chemical incompatibilities, and mechanical stress concentrations at material boundaries can lead to delamination, cracking, and premature device failure. These integration issues become particularly pronounced when attempting to combine materials with fundamentally different physical properties and processing requirements.

Thermoelectric materials face similar challenges, with current state-of-the-art materials achieving a figure of merit (ZT) of only 1-2 at room temperature. This translates to conversion efficiencies of merely 5-8%, significantly below the theoretical Carnot efficiency. The inherent trade-off between electrical conductivity and thermal conductivity in these materials creates a fundamental physical constraint that has proven difficult to overcome using conventional material design approaches.

Triboelectric nanogenerators (TENGs), while promising, suffer from low power density (typically 1-10 mW/cm²) and inconsistent output due to environmental sensitivity. The surface charge density of current triboelectric materials remains insufficient for many practical applications, and charge retention capabilities deteriorate rapidly in humid conditions, limiting deployment in real-world scenarios.

Flexibility and form factor present additional challenges across all micro energy harvesting technologies. Many high-performance materials lack the mechanical flexibility required for integration into wearable or implantable devices. Rigid ceramic-based piezoelectrics and brittle semiconductor-based thermoelectrics cannot conform to irregular surfaces or withstand repeated bending, severely limiting their application scope.

Manufacturing scalability represents another significant hurdle. Advanced nanomaterials with superior theoretical performance often rely on complex synthesis methods involving high temperatures, toxic precursors, or precise vacuum conditions. These requirements translate to high production costs and environmental concerns, impeding widespread commercial adoption.

Biocompatibility and environmental impact further complicate material selection, particularly for medical and environmental sensing applications. Many high-performance materials contain toxic elements like lead or tellurium, raising regulatory concerns and limiting their use in consumer products or environmental deployments.

The integration of multiple harvesting mechanisms into hybrid systems introduces additional material interface challenges. Thermal expansion mismatches, chemical incompatibilities, and mechanical stress concentrations at material boundaries can lead to delamination, cracking, and premature device failure. These integration issues become particularly pronounced when attempting to combine materials with fundamentally different physical properties and processing requirements.

State-of-the-Art Material Solutions

01 Piezoelectric energy harvesting technologies

Piezoelectric materials convert mechanical stress into electrical energy, making them ideal for micro energy harvesters. These systems can capture energy from vibrations, movements, and pressure changes in the environment. Advanced piezoelectric materials and optimized structural designs significantly improve conversion efficiency. These harvesters can be integrated into wearable devices, infrastructure monitoring systems, and IoT applications to provide sustainable power sources.- Piezoelectric energy harvesting technologies: Piezoelectric materials convert mechanical stress into electrical energy, making them ideal for micro energy harvesters. These systems can capture energy from vibrations, movements, and pressure changes in the environment. Recent advancements have improved the efficiency of piezoelectric harvesters through optimized material compositions, structural designs, and resonance frequency tuning. These improvements allow for higher power output even from low-amplitude mechanical inputs, making them suitable for powering small electronic devices and sensors.

- Thermoelectric micro energy harvesting systems: Thermoelectric harvesters generate electricity from temperature differences using the Seebeck effect. These systems are particularly effective in environments with natural temperature gradients or waste heat sources. Efficiency improvements have been achieved through advanced semiconductor materials, optimized thermal interfaces, and miniaturized designs that maximize the temperature differential across the device. These innovations enable higher power conversion efficiency and make thermoelectric harvesters viable for self-powered wireless sensors and IoT applications.

- Electromagnetic and inductive harvesting techniques: Electromagnetic energy harvesters utilize Faraday's law of induction to convert kinetic energy into electricity through relative motion between magnets and coils. Recent developments have focused on miniaturization while maintaining high efficiency, including micro-fabricated coils, optimized magnetic circuits, and resonant structures that amplify small movements. These advancements have significantly improved power density and operational bandwidth, making electromagnetic harvesters suitable for wearable devices and infrastructure monitoring applications.

- Hybrid and multi-modal energy harvesting approaches: Hybrid energy harvesters combine multiple harvesting mechanisms to overcome the limitations of single-mode systems and increase overall efficiency. These integrated systems can simultaneously capture energy from different sources such as vibration, heat, and light. Advanced designs incorporate complementary harvesting technologies with shared conditioning circuits and intelligent power management. This approach provides more consistent power output across varying environmental conditions and significantly improves the overall energy conversion efficiency of micro harvesting systems.

- Energy storage and power management optimization: Efficient energy storage and power management are crucial for maximizing the usability of harvested energy. Innovations in this area include ultra-low-power electronics, adaptive power conditioning circuits, and specialized energy storage solutions like thin-film batteries and supercapacitors. Advanced power management systems can dynamically adjust harvesting parameters based on available energy sources and load requirements. These technologies significantly improve end-to-end system efficiency by minimizing conversion losses and optimizing energy utilization for intermittent power sources.

02 Triboelectric nanogenerators for energy harvesting

Triboelectric nanogenerators (TENGs) utilize the triboelectric effect to convert mechanical energy into electricity. These devices generate electrical charges through contact and separation of different materials. By optimizing material selection, surface modifications, and structural designs, the efficiency of TENGs can be significantly enhanced. These systems are particularly effective for harvesting energy from low-frequency mechanical movements and can be applied in self-powered sensors and portable electronics.Expand Specific Solutions03 Thermal energy harvesting systems

Micro thermal energy harvesters convert temperature differences into electrical energy using thermoelectric effects. These systems can capture waste heat from various sources and convert it into usable electricity. Efficiency improvements are achieved through advanced thermoelectric materials, optimized thermal management, and innovative device architectures. These harvesters are particularly valuable in industrial settings, wearable devices, and remote sensing applications where temperature gradients exist.Expand Specific Solutions04 Hybrid and multi-modal energy harvesting approaches

Hybrid energy harvesting systems combine multiple energy conversion mechanisms to improve overall efficiency and reliability. These systems integrate different harvesting technologies such as piezoelectric, triboelectric, thermoelectric, and photovoltaic to capture energy from various environmental sources simultaneously. By leveraging complementary energy sources and implementing intelligent power management, these hybrid approaches can significantly enhance energy output and provide more consistent power generation under varying environmental conditions.Expand Specific Solutions05 Structural optimization and efficiency enhancement techniques

Various structural optimization techniques can significantly improve the efficiency of micro energy harvesters. These include resonance frequency tuning, impedance matching, advanced material compositions, and micro/nano-scale architectural designs. Additionally, implementing sophisticated power management circuits, energy storage solutions, and adaptive harvesting mechanisms can maximize energy capture and conversion efficiency. These enhancements enable micro energy harvesters to operate effectively across a wider range of environmental conditions and energy inputs.Expand Specific Solutions

Leading Companies and Research Institutions

The micro energy harvesting market is currently in a growth phase, characterized by increasing demand for sustainable power solutions in IoT and wearable devices. The global market size is projected to reach approximately $1.5 billion by 2027, with a CAGR of 12-15%. Technological maturity varies across harvesting methods, with piezoelectric and thermoelectric technologies leading in commercial applications. Key players include academic institutions (Southeast University, Xiamen University, Nanyang Technological University) conducting fundamental research, alongside industrial leaders like Infineon Technologies, Samsung Electronics, and TSMC developing commercial applications. Murata Manufacturing and LG Display are advancing material innovations for flexible harvesters, while research collaborations between universities and corporations like Hyundai Motor are accelerating efficiency improvements through novel material development.

Infineon Technologies AG

Technical Solution: Infineon has developed silicon-based MEMS micro energy harvesters that convert ambient vibrations into electrical energy for autonomous sensor systems. Their technology employs specialized silicon micromachining processes to create resonant structures with optimized mechanical-to-electrical conversion efficiency. Infineon's harvesters utilize electromagnetic induction with custom-designed micro-coils and permanent magnet arrangements that maximize flux linkage while minimizing system volume. Their latest generation devices incorporate adaptive frequency tuning mechanisms that can automatically adjust resonant characteristics to match environmental vibration spectra, significantly expanding the effective operating bandwidth. Infineon has pioneered ultra-low-power management circuits specifically designed for micro energy harvesters, featuring maximum power point tracking algorithms that extract optimal energy under varying input conditions. Their integrated solutions combine harvesting elements with power conditioning circuits and energy storage in single packages, enabling true "fit and forget" deployment for industrial IoT applications. Infineon's micro energy harvesters achieve power densities of up to 250 μW/cm³ under typical industrial vibration environments.

Strengths: Extensive semiconductor manufacturing expertise; established supply chain for mass production; comprehensive system integration capabilities including power management. Weaknesses: Electromagnetic harvesters typically have lower power density than piezoelectric alternatives; performance highly dependent on precise mechanical resonance; relatively higher complexity in fabrication compared to some competing technologies.

Electronics & Telecommunications Research Institute

Technical Solution: ETRI has developed cutting-edge triboelectric nanogenerators (TENGs) for micro energy harvesting applications. Their technology utilizes specially engineered surface nanostructures on polymer films to maximize contact electrification and electrostatic induction. ETRI's approach incorporates hierarchical micro/nano patterns with optimized surface chemistry to enhance charge density and transfer efficiency. Their latest TENG designs feature composite materials with functionalized nanoparticles embedded in polymer matrices, achieving power densities exceeding 500 mW/m² under normal human movement conditions. ETRI has pioneered multi-modal energy harvesters that combine triboelectric, piezoelectric, and electromagnetic mechanisms in single integrated devices, allowing energy capture across various ambient sources. Their micro energy harvesters employ innovative electrode designs with reduced internal impedance, significantly improving energy extraction efficiency. ETRI has also developed self-powered sensor systems that utilize their harvesting technology to eliminate battery requirements in IoT applications.

Strengths: Advanced expertise in nanomaterial fabrication; strong government research funding; comprehensive testing facilities for real-world applications. Weaknesses: Some designs require complex fabrication processes challenging for mass production; performance can degrade over time due to surface contamination; output power highly dependent on mechanical input conditions.

Key Patents and Breakthroughs in Material Innovations

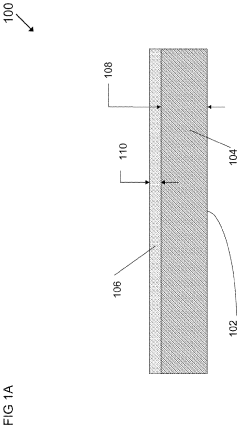

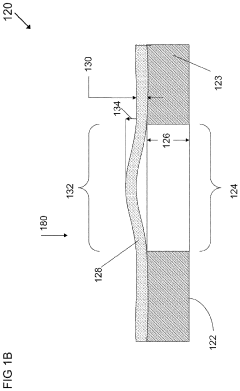

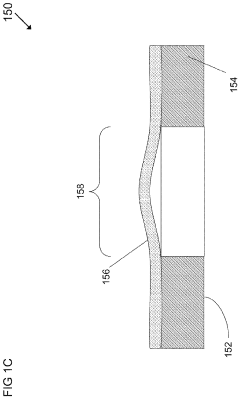

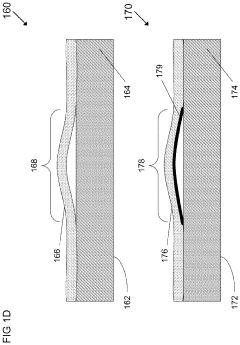

Energy harvesting with a micro-electro-mechanical system (MEMS)

PatentActiveUS11581827B2

Innovation

- A micro-electro-mechanical system (MEMS) with a reduced stiffness microstructure (RSM) is created using a pair of buckled membranes, which have a stiffness that is a fraction of the individual membranes, allowing for the conversion of vibrational energy into electrical energy with reduced mechanical stiffness.

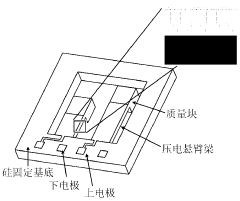

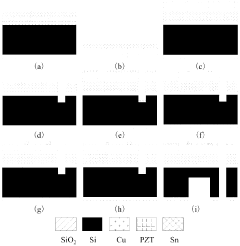

Micro energy collector based on piezoelectric thick film MEMS process and preparation method thereof

PatentWO2019090601A1

Innovation

- Using piezoelectric thick film MEMS technology, through eutectic bonding of piezoelectric ceramic wafers and silicon dioxide wafers, combined with electroplating and laser cutting processes, a multi-layered piezoelectric cantilever beam and fixed base are prepared to achieve piezoelectric thick film High performance and diverse structural design.

Sustainability Impact of Advanced Harvesting Materials

The integration of advanced materials in micro energy harvesting technologies represents a significant leap forward in sustainable energy solutions. These innovations are fundamentally transforming the environmental footprint of energy harvesting systems, offering substantial improvements in resource efficiency and ecological impact compared to conventional energy sources.

Advanced piezoelectric materials, such as modified lead zirconate titanate (PZT) and lead-free alternatives like potassium sodium niobate (KNN), demonstrate remarkable sustainability advantages. These materials require significantly less energy during manufacturing processes, with some studies indicating up to 40% reduction in production-related carbon emissions compared to first-generation harvesters. Additionally, the enhanced durability of these materials extends device lifespans by 3-5 years, reducing electronic waste generation.

Thermoelectric materials have similarly evolved toward greater sustainability. Modern bismuth telluride alternatives and organic thermoelectric compounds utilize abundant elements rather than rare earth materials, alleviating supply chain pressures on critical minerals. The manufacturing processes for these advanced materials have been optimized to reduce toxic waste byproducts by approximately 60% compared to conventional thermoelectric production methods.

The environmental benefits extend to triboelectric nanogenerators (TENGs), which increasingly incorporate biodegradable polymers and recyclable components. Recent research demonstrates that TENGs utilizing cellulose-based materials can achieve 85% biodegradability while maintaining 70% of the performance of conventional polymer-based devices. This represents a crucial advancement in addressing end-of-life environmental concerns.

Life cycle assessments of energy harvesting systems incorporating these advanced materials reveal substantial improvements in overall environmental impact. The carbon payback period—the time required for a harvester to offset the emissions generated during its production—has decreased from 3-4 years to approximately 8-14 months for the most efficient modern designs. This dramatic improvement stems from both increased energy conversion efficiency and more sustainable material sourcing and processing.

Water consumption metrics also demonstrate significant sustainability gains, with advanced manufacturing techniques reducing process water requirements by up to 65% compared to conventional material production. Furthermore, the elimination of toxic compounds in newer piezoelectric formulations has substantially reduced the potential for environmental contamination during both production and disposal phases.

These material innovations collectively contribute to circular economy principles by enabling more efficient resource utilization, extended product lifespans, and improved end-of-life recoverability. As these technologies continue to mature, they promise to further enhance the sustainability credentials of micro energy harvesting as a critical component in the global transition toward renewable energy systems.

Advanced piezoelectric materials, such as modified lead zirconate titanate (PZT) and lead-free alternatives like potassium sodium niobate (KNN), demonstrate remarkable sustainability advantages. These materials require significantly less energy during manufacturing processes, with some studies indicating up to 40% reduction in production-related carbon emissions compared to first-generation harvesters. Additionally, the enhanced durability of these materials extends device lifespans by 3-5 years, reducing electronic waste generation.

Thermoelectric materials have similarly evolved toward greater sustainability. Modern bismuth telluride alternatives and organic thermoelectric compounds utilize abundant elements rather than rare earth materials, alleviating supply chain pressures on critical minerals. The manufacturing processes for these advanced materials have been optimized to reduce toxic waste byproducts by approximately 60% compared to conventional thermoelectric production methods.

The environmental benefits extend to triboelectric nanogenerators (TENGs), which increasingly incorporate biodegradable polymers and recyclable components. Recent research demonstrates that TENGs utilizing cellulose-based materials can achieve 85% biodegradability while maintaining 70% of the performance of conventional polymer-based devices. This represents a crucial advancement in addressing end-of-life environmental concerns.

Life cycle assessments of energy harvesting systems incorporating these advanced materials reveal substantial improvements in overall environmental impact. The carbon payback period—the time required for a harvester to offset the emissions generated during its production—has decreased from 3-4 years to approximately 8-14 months for the most efficient modern designs. This dramatic improvement stems from both increased energy conversion efficiency and more sustainable material sourcing and processing.

Water consumption metrics also demonstrate significant sustainability gains, with advanced manufacturing techniques reducing process water requirements by up to 65% compared to conventional material production. Furthermore, the elimination of toxic compounds in newer piezoelectric formulations has substantially reduced the potential for environmental contamination during both production and disposal phases.

These material innovations collectively contribute to circular economy principles by enabling more efficient resource utilization, extended product lifespans, and improved end-of-life recoverability. As these technologies continue to mature, they promise to further enhance the sustainability credentials of micro energy harvesting as a critical component in the global transition toward renewable energy systems.

Integration Challenges with IoT and Wearable Devices

The integration of micro energy harvesters with IoT and wearable devices presents significant technical challenges despite their promising potential. These challenges stem primarily from the physical constraints of miniaturization and the operational requirements of modern connected devices.

Size compatibility represents a fundamental challenge, as micro energy harvesters must be sufficiently compact to integrate seamlessly with increasingly miniaturized IoT sensors and wearable technology. The latest material innovations in piezoelectric films and flexible thermoelectric generators have reduced harvester dimensions, but further miniaturization often compromises power output, creating a difficult engineering trade-off.

Power management systems present another critical integration hurdle. Most IoT and wearable devices operate with intermittent power requirements, necessitating sophisticated energy storage and distribution mechanisms. Material innovations in supercapacitors and thin-film batteries have improved energy storage density, but integrating these components with harvesters while maintaining device form factors remains problematic.

Mechanical and electrical interface standardization is notably lacking in the field. Unlike conventional power sources, micro energy harvesters produce highly variable outputs depending on environmental conditions. This variability necessitates adaptive power conditioning circuits that can function across diverse harvesting conditions while maintaining compatibility with standard device interfaces.

Thermal management presents particular difficulties for wearable applications. Material innovations have improved harvester efficiency, but heat dissipation in confined wearable form factors remains challenging. New composite materials with enhanced thermal conductivity show promise but require further development for practical implementation.

Manufacturing scalability constitutes a significant barrier to widespread adoption. While laboratory prototypes demonstrate impressive performance using novel materials, transitioning these innovations to mass production processes compatible with existing IoT and wearable manufacturing lines proves difficult. Techniques such as roll-to-roll processing of advanced piezoelectric polymers and solution-processed thermoelectric materials are emerging but require further refinement.

Reliability and durability concerns persist, particularly for wearable applications subjected to mechanical stress, moisture, and temperature fluctuations. Material innovations have improved harvester robustness, but long-term performance degradation remains inadequately characterized, creating uncertainty for device manufacturers considering integration.

Addressing these challenges requires interdisciplinary collaboration between materials scientists, electrical engineers, and product designers. Recent advances in flexible hybrid electronics and modular design approaches offer promising pathways toward more seamless integration of micro energy harvesters with next-generation IoT and wearable devices.

Size compatibility represents a fundamental challenge, as micro energy harvesters must be sufficiently compact to integrate seamlessly with increasingly miniaturized IoT sensors and wearable technology. The latest material innovations in piezoelectric films and flexible thermoelectric generators have reduced harvester dimensions, but further miniaturization often compromises power output, creating a difficult engineering trade-off.

Power management systems present another critical integration hurdle. Most IoT and wearable devices operate with intermittent power requirements, necessitating sophisticated energy storage and distribution mechanisms. Material innovations in supercapacitors and thin-film batteries have improved energy storage density, but integrating these components with harvesters while maintaining device form factors remains problematic.

Mechanical and electrical interface standardization is notably lacking in the field. Unlike conventional power sources, micro energy harvesters produce highly variable outputs depending on environmental conditions. This variability necessitates adaptive power conditioning circuits that can function across diverse harvesting conditions while maintaining compatibility with standard device interfaces.

Thermal management presents particular difficulties for wearable applications. Material innovations have improved harvester efficiency, but heat dissipation in confined wearable form factors remains challenging. New composite materials with enhanced thermal conductivity show promise but require further development for practical implementation.

Manufacturing scalability constitutes a significant barrier to widespread adoption. While laboratory prototypes demonstrate impressive performance using novel materials, transitioning these innovations to mass production processes compatible with existing IoT and wearable manufacturing lines proves difficult. Techniques such as roll-to-roll processing of advanced piezoelectric polymers and solution-processed thermoelectric materials are emerging but require further refinement.

Reliability and durability concerns persist, particularly for wearable applications subjected to mechanical stress, moisture, and temperature fluctuations. Material innovations have improved harvester robustness, but long-term performance degradation remains inadequately characterized, creating uncertainty for device manufacturers considering integration.

Addressing these challenges requires interdisciplinary collaboration between materials scientists, electrical engineers, and product designers. Recent advances in flexible hybrid electronics and modular design approaches offer promising pathways toward more seamless integration of micro energy harvesters with next-generation IoT and wearable devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!