Model Lithium Mine Ore Grade Distribution for Short-Term Mine Planning

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Mine Ore Grade Modeling Background and Objectives

Lithium has emerged as a critical mineral in the global transition to clean energy, primarily due to its essential role in rechargeable batteries for electric vehicles and energy storage systems. The historical development of lithium mining has evolved from traditional open-pit and underground mining methods to more sophisticated approaches incorporating advanced geological modeling techniques. This evolution reflects the growing demand for more efficient and sustainable extraction practices in the lithium mining industry.

The accurate modeling of ore grade distribution in lithium mines represents a significant technological advancement in mining operations. Early modeling techniques relied heavily on conventional geostatistical methods with limited data integration capabilities. However, recent years have witnessed a paradigm shift towards more comprehensive modeling approaches that incorporate multiple data sources and advanced computational methods.

The primary objective of lithium mine ore grade modeling for short-term planning is to optimize resource extraction by providing precise spatial distribution information of lithium concentrations within the deposit. This enables mining engineers to make informed decisions regarding blast patterns, excavation sequences, and material handling strategies. Additionally, accurate grade modeling facilitates effective waste management and minimizes environmental impact by reducing unnecessary processing of low-grade material.

Current technological trends in this domain include the integration of machine learning algorithms with traditional geostatistical methods, real-time data acquisition through IoT sensors, and the development of 3D visualization tools for enhanced interpretation of complex geological structures. These advancements are driving the industry towards more dynamic and adaptive short-term planning capabilities.

The expected technical outcomes from improved ore grade modeling include increased resource recovery rates, reduced dilution, optimized processing efficiency, and ultimately enhanced economic performance of lithium mining operations. Furthermore, precise grade modeling contributes to more sustainable mining practices by minimizing waste generation and reducing energy consumption in processing operations.

Looking forward, the trajectory of lithium ore grade modeling technology is moving towards fully integrated digital twin systems that provide real-time updates and predictive capabilities for short-term planning decisions. This represents a significant opportunity for mining companies to gain competitive advantages through technological innovation in an increasingly important mineral sector.

The accurate modeling of ore grade distribution in lithium mines represents a significant technological advancement in mining operations. Early modeling techniques relied heavily on conventional geostatistical methods with limited data integration capabilities. However, recent years have witnessed a paradigm shift towards more comprehensive modeling approaches that incorporate multiple data sources and advanced computational methods.

The primary objective of lithium mine ore grade modeling for short-term planning is to optimize resource extraction by providing precise spatial distribution information of lithium concentrations within the deposit. This enables mining engineers to make informed decisions regarding blast patterns, excavation sequences, and material handling strategies. Additionally, accurate grade modeling facilitates effective waste management and minimizes environmental impact by reducing unnecessary processing of low-grade material.

Current technological trends in this domain include the integration of machine learning algorithms with traditional geostatistical methods, real-time data acquisition through IoT sensors, and the development of 3D visualization tools for enhanced interpretation of complex geological structures. These advancements are driving the industry towards more dynamic and adaptive short-term planning capabilities.

The expected technical outcomes from improved ore grade modeling include increased resource recovery rates, reduced dilution, optimized processing efficiency, and ultimately enhanced economic performance of lithium mining operations. Furthermore, precise grade modeling contributes to more sustainable mining practices by minimizing waste generation and reducing energy consumption in processing operations.

Looking forward, the trajectory of lithium ore grade modeling technology is moving towards fully integrated digital twin systems that provide real-time updates and predictive capabilities for short-term planning decisions. This represents a significant opportunity for mining companies to gain competitive advantages through technological innovation in an increasingly important mineral sector.

Market Demand Analysis for High-Grade Lithium Resources

The global lithium market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and energy storage systems. High-grade lithium resources, containing concentrations typically above 1.5% Li2O, are becoming increasingly valuable assets in the mining industry. Market analysis indicates that demand for battery-grade lithium compounds is projected to grow at a CAGR of 18-20% through 2030, creating significant pressure on mining operations to optimize extraction of premium ore bodies.

The automotive sector represents the largest demand driver, accounting for approximately 80% of lithium consumption, with major manufacturers accelerating their EV production targets. Tesla, Volkswagen, and BYD have all announced plans to increase battery production capacity, directly impacting lithium demand forecasts. This surge has pushed lithium carbonate prices to record levels, reaching peaks of $80,000 per tonne in 2022, though with some stabilization occurring in 2023.

Geographic distribution of demand shows China leading consumption at 39%, followed by Europe (27%) and North America (21%). These regions have established battery manufacturing hubs that require consistent supply of high-grade lithium to maintain production efficiency and quality standards. The premium for high-grade lithium resources continues to widen as processing facilities seek to minimize energy consumption and environmental impact during refinement.

Short-term mine planning that accurately models ore grade distribution has become a critical competitive advantage in this market environment. Mining operations capable of selectively targeting high-grade zones can achieve 15-25% higher margins compared to traditional bulk mining approaches. This selective mining strategy requires sophisticated geological modeling capabilities that can accurately predict lithium concentration variations within deposits.

Market research indicates that mining companies implementing advanced ore grade distribution modeling can reduce production costs by 12-18% while increasing recovery rates by 8-10%. These efficiency gains translate directly to improved market position, especially during periods of price volatility. Investors are increasingly evaluating mining operations based on their technical capabilities to optimize high-grade resource extraction through precision modeling.

The supply-demand imbalance for high-grade lithium resources is expected to persist through 2028, with a projected supply deficit of 200,000-300,000 tonnes LCE (Lithium Carbonate Equivalent) annually. This market dynamic creates strong incentives for mining operations to invest in advanced modeling technologies that maximize the extraction value of existing deposits, particularly for short-term planning horizons where operational flexibility and grade control become paramount considerations.

The automotive sector represents the largest demand driver, accounting for approximately 80% of lithium consumption, with major manufacturers accelerating their EV production targets. Tesla, Volkswagen, and BYD have all announced plans to increase battery production capacity, directly impacting lithium demand forecasts. This surge has pushed lithium carbonate prices to record levels, reaching peaks of $80,000 per tonne in 2022, though with some stabilization occurring in 2023.

Geographic distribution of demand shows China leading consumption at 39%, followed by Europe (27%) and North America (21%). These regions have established battery manufacturing hubs that require consistent supply of high-grade lithium to maintain production efficiency and quality standards. The premium for high-grade lithium resources continues to widen as processing facilities seek to minimize energy consumption and environmental impact during refinement.

Short-term mine planning that accurately models ore grade distribution has become a critical competitive advantage in this market environment. Mining operations capable of selectively targeting high-grade zones can achieve 15-25% higher margins compared to traditional bulk mining approaches. This selective mining strategy requires sophisticated geological modeling capabilities that can accurately predict lithium concentration variations within deposits.

Market research indicates that mining companies implementing advanced ore grade distribution modeling can reduce production costs by 12-18% while increasing recovery rates by 8-10%. These efficiency gains translate directly to improved market position, especially during periods of price volatility. Investors are increasingly evaluating mining operations based on their technical capabilities to optimize high-grade resource extraction through precision modeling.

The supply-demand imbalance for high-grade lithium resources is expected to persist through 2028, with a projected supply deficit of 200,000-300,000 tonnes LCE (Lithium Carbonate Equivalent) annually. This market dynamic creates strong incentives for mining operations to invest in advanced modeling technologies that maximize the extraction value of existing deposits, particularly for short-term planning horizons where operational flexibility and grade control become paramount considerations.

Current Challenges in Lithium Ore Grade Distribution Modeling

Accurate modeling of lithium ore grade distribution presents significant challenges in the mining industry, particularly for short-term planning operations. The inherent geological complexity of lithium deposits creates fundamental difficulties in prediction and modeling. Unlike some other mineral deposits, lithium concentrations often exhibit high spatial variability within relatively short distances, making interpolation between sampling points problematic and reducing confidence in grade estimates.

Sampling limitations compound these challenges considerably. The cost and time constraints of drilling programs typically result in relatively sparse sampling grids compared to the scale of variability in lithium deposits. This sampling density inadequacy creates significant uncertainty in grade distribution models, especially in areas with complex geological structures or discontinuities.

Geostatistical methods currently employed for lithium grade estimation, such as kriging and conditional simulation, struggle to accurately capture the non-linear and non-stationary characteristics of lithium mineralization. These techniques often rely on assumptions of data stationarity that may not hold true across lithium deposits, leading to systematic errors in grade predictions.

The integration of multiple data sources presents another substantial challenge. Modern mining operations collect information from drill cores, blast holes, production samples, and geophysical surveys, each with different sampling support, precision, and bias characteristics. Developing models that effectively synthesize these heterogeneous data sources remains difficult, often resulting in inconsistent grade predictions.

Short-term planning requirements exacerbate these modeling challenges. While long-term models can average out some uncertainties, short-term planning demands higher precision to guide daily or weekly operational decisions. The need for rapid model updates as new information becomes available creates computational and methodological constraints that limit model sophistication.

Traditional deterministic modeling approaches fail to adequately quantify uncertainty in grade estimates. This limitation is particularly problematic for lithium mining, where processing decisions are highly sensitive to grade variations. Without proper uncertainty quantification, mining operations risk suboptimal material selection and processing strategies.

The dynamic nature of mining operations further complicates modeling efforts. As extraction progresses, the available data distribution changes, requiring continuous model updates and recalibration. Current modeling frameworks often lack the flexibility to efficiently incorporate new information without complete remodeling, creating practical implementation barriers for mining engineers.

Sampling limitations compound these challenges considerably. The cost and time constraints of drilling programs typically result in relatively sparse sampling grids compared to the scale of variability in lithium deposits. This sampling density inadequacy creates significant uncertainty in grade distribution models, especially in areas with complex geological structures or discontinuities.

Geostatistical methods currently employed for lithium grade estimation, such as kriging and conditional simulation, struggle to accurately capture the non-linear and non-stationary characteristics of lithium mineralization. These techniques often rely on assumptions of data stationarity that may not hold true across lithium deposits, leading to systematic errors in grade predictions.

The integration of multiple data sources presents another substantial challenge. Modern mining operations collect information from drill cores, blast holes, production samples, and geophysical surveys, each with different sampling support, precision, and bias characteristics. Developing models that effectively synthesize these heterogeneous data sources remains difficult, often resulting in inconsistent grade predictions.

Short-term planning requirements exacerbate these modeling challenges. While long-term models can average out some uncertainties, short-term planning demands higher precision to guide daily or weekly operational decisions. The need for rapid model updates as new information becomes available creates computational and methodological constraints that limit model sophistication.

Traditional deterministic modeling approaches fail to adequately quantify uncertainty in grade estimates. This limitation is particularly problematic for lithium mining, where processing decisions are highly sensitive to grade variations. Without proper uncertainty quantification, mining operations risk suboptimal material selection and processing strategies.

The dynamic nature of mining operations further complicates modeling efforts. As extraction progresses, the available data distribution changes, requiring continuous model updates and recalibration. Current modeling frameworks often lack the flexibility to efficiently incorporate new information without complete remodeling, creating practical implementation barriers for mining engineers.

Current Methodologies for Ore Grade Distribution Prediction

01 Lithium ore grade classification and distribution analysis

Methods and systems for classifying lithium ore grades and analyzing their distribution in deposits. These technologies enable mining companies to map ore grade variations across mining sites, helping to identify high-concentration zones and optimize extraction planning. The analysis typically involves geological surveys, sampling techniques, and statistical modeling to create comprehensive grade distribution maps.- Lithium ore grade classification and distribution analysis: Methods and systems for analyzing the grade distribution of lithium ore deposits, including techniques for classifying different grades of lithium-bearing minerals. These approaches help in understanding the spatial distribution of lithium concentrations within mining areas, enabling more efficient extraction planning and resource estimation. The analysis typically involves geological mapping, sampling, and statistical evaluation of ore bodies to determine economically viable mining zones.

- Advanced detection and measurement technologies for lithium ore grading: Innovative technologies and equipment designed specifically for detecting, measuring, and analyzing lithium content in ore samples. These technologies include spectroscopic methods, X-ray fluorescence, and other analytical techniques that provide rapid and accurate determination of lithium concentrations. Such advancements allow for real-time grade monitoring during mining operations and processing, improving quality control and extraction efficiency.

- Processing methods based on ore grade distribution: Specialized processing techniques that are optimized according to the grade distribution of lithium ores. These methods involve selective mining, beneficiation, and extraction processes tailored to different ore grades. By adapting processing parameters to specific grade characteristics, these approaches maximize lithium recovery while minimizing energy consumption and waste generation, ultimately improving the economic viability of lithium mining operations.

- Modeling and prediction of lithium ore grade distribution: Computational models and predictive algorithms designed to forecast lithium ore grade distributions across mining sites. These approaches utilize geological data, statistical analysis, and machine learning techniques to create three-dimensional models of ore bodies. Such predictive modeling helps in mine planning, resource estimation, and optimization of extraction sequences, reducing exploration costs and improving mining efficiency.

- Environmental and economic considerations in lithium grade exploitation: Methods addressing the environmental and economic aspects of exploiting different grades of lithium ore. These approaches focus on sustainable mining practices that consider the environmental impact of extracting various ore grades while maintaining economic viability. They include techniques for managing waste from low-grade ore processing, water conservation strategies, and cost-benefit analyses that balance extraction costs against market values for different lithium concentrations.

02 Advanced detection and measurement technologies for lithium content

Innovative technologies for detecting and measuring lithium content in ore samples with high precision. These include spectroscopic methods, X-ray fluorescence, and other analytical techniques that allow for rapid assessment of lithium concentrations. Such technologies enable real-time grade monitoring during mining operations and help maintain quality control in ore processing.Expand Specific Solutions03 Processing methods based on ore grade variations

Specialized processing methods designed to handle different grades of lithium ore efficiently. These techniques adapt extraction parameters based on the specific grade distribution of the ore being processed, maximizing lithium recovery rates. The methods include selective mining approaches, beneficiation techniques, and tailored leaching processes that account for mineralogical variations across different grade categories.Expand Specific Solutions04 Geological modeling and prediction of lithium ore grades

Computational methods and models for predicting lithium ore grade distributions based on geological data. These approaches use machine learning, geostatistical analysis, and 3D modeling to forecast grade variations in unexplored areas of lithium deposits. The models help in resource estimation, mine planning, and reducing exploration costs by identifying the most promising drilling targets.Expand Specific Solutions05 Equipment and systems for grade-based sorting and beneficiation

Specialized equipment and systems designed for sorting and beneficiating lithium ore based on grade distribution. These include sensor-based sorting technologies, density separation systems, and automated classification equipment that can separate different grades of ore for optimized processing. The equipment helps improve the economic viability of lithium mining operations by concentrating valuable material and reducing processing costs for lower-grade ores.Expand Specific Solutions

Key Players in Lithium Mining and Modeling Technology

The lithium mine ore grade distribution modeling market is in its growth phase, characterized by increasing demand for efficient short-term mine planning solutions. The market is expanding rapidly due to the global surge in lithium demand for electric vehicle batteries and energy storage systems. Technologically, the field combines traditional mining expertise with advanced computational modeling, with varying levels of maturity among key players. Companies like PetroChina and Anglo American Technical & Sustainability Services represent established resource extraction firms adapting these technologies, while specialized mining technology providers such as CiDRA Corporate Services and Changsha Dimai Digital Technology offer dedicated solutions. Academic institutions including China University of Mining & Technology and Commonwealth Scientific & Industrial Research Organisation are driving innovation through research partnerships with industry players.

Anglo American Technical & Sustainability Services Ltd.

Technical Solution: Anglo American has developed an advanced lithium mine ore grade distribution modeling system that integrates machine learning algorithms with traditional geostatistical methods. Their approach combines high-resolution geological data with real-time sensor information to create dynamic 3D models of ore grade distribution. The system employs ensemble learning techniques that combine multiple prediction models to improve accuracy in heterogeneous lithium deposits. Anglo American's solution incorporates automated drill core analysis using hyperspectral imaging and XRF scanning to rapidly assess lithium concentrations across the mine site. This data feeds into their proprietary GeoMine software platform, which uses sequential Gaussian simulation and neural networks to predict grade variability at different spatial scales. The system also features adaptive sampling strategies that optimize drilling patterns based on uncertainty quantification, allowing for more efficient resource allocation during exploration and production phases.

Strengths: Superior integration of multiple data sources and advanced AI algorithms provides more accurate grade predictions than traditional methods. The adaptive sampling approach reduces drilling costs while maintaining prediction accuracy. Weaknesses: The system requires significant computational resources and specialized expertise to implement and maintain. Performance may be limited in geologically complex deposits with unusual mineralization patterns.

China University of Mining & Technology

Technical Solution: China University of Mining & Technology has developed a comprehensive lithium ore grade distribution modeling framework specifically designed for short-term mine planning. Their approach integrates deep learning with traditional geostatistical methods to create high-resolution 3D models of lithium deposits. The system employs a multi-scale convolutional neural network architecture that can capture both local and regional patterns in ore grade distribution. A key innovation is their implementation of transfer learning techniques that allow models trained on well-characterized deposits to be adapted to new mining areas with limited sampling data. The university's research team has also developed specialized algorithms for uncertainty quantification, providing confidence intervals for grade estimates that directly inform risk assessment in short-term planning decisions. Their system incorporates real-time data from production drilling and in-pit sampling to continuously update and refine the grade models, enabling dynamic adjustment of mining sequences to maximize resource recovery and minimize dilution.

Strengths: The multi-scale approach effectively captures both fine and coarse spatial patterns in ore distribution, leading to more accurate grade predictions. The transfer learning capability significantly reduces the data requirements for new mining areas. Weaknesses: The complex modeling framework requires specialized expertise in both mining engineering and machine learning. Implementation costs can be high, potentially limiting adoption by smaller mining operations.

Advanced Geostatistical Techniques for Lithium Deposits

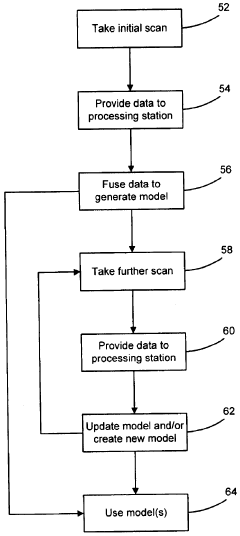

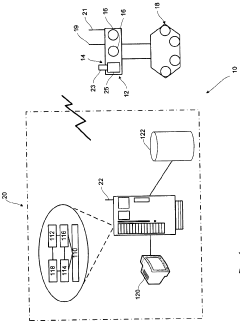

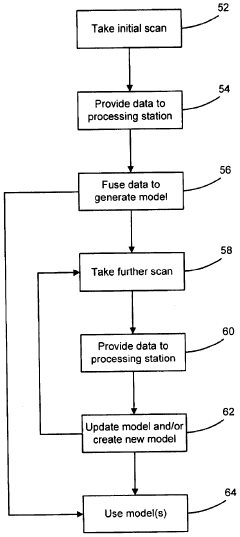

Scanning system for 3D mineralogy modelling

PatentActiveAU2009200859A1

Innovation

- A scanning system equipped with a hyperspectral imager and geometry scanner that generates and fuses geological and geometric information to create a 3D model of the mine bench face, enabling real-time ore grade assessments and informing drilling, blasting, and material processing decisions.

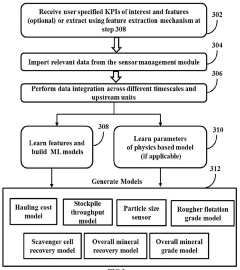

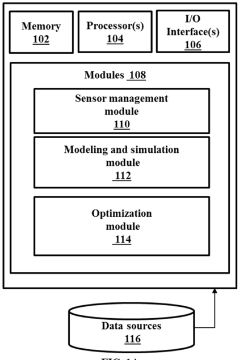

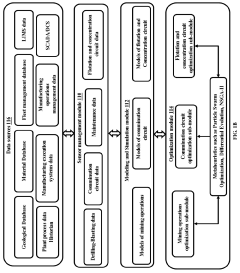

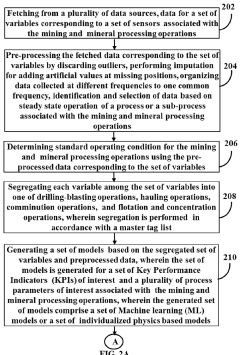

Method and system for online monitoring and optimization of mining and mineral processing operations

PatentActiveAU2021254666A1

Innovation

- A processor-implemented method and system for online monitoring and optimization that fetches data from various sources, preprocesses it, generates machine learning, physics-based, or hybrid models to simulate current operating conditions, and hierarchically optimizes KPIs across drilling, blasting, hauling, comminution, and flotation/concentration operations, while detecting sensor or equipment failures.

Environmental Impact Assessment of Lithium Mining Operations

The environmental impact assessment of lithium mining operations is a critical component when modeling ore grade distribution for short-term mine planning. Lithium extraction processes can significantly alter local ecosystems, with impacts varying based on the mining method employed and the specific geological characteristics of the deposit. Open-pit mining, the most common method for lithium extraction from hard rock deposits, creates substantial landscape disruption through vegetation clearing, topsoil removal, and waste rock accumulation.

Water consumption represents one of the most significant environmental concerns, particularly in brine extraction operations where extensive evaporation ponds can deplete local aquifers. In regions like the "Lithium Triangle" of South America, mining operations consume an estimated 65% of available water resources, creating competition with agricultural activities and threatening fragile desert ecosystems. The water footprint of producing one ton of lithium carbonate equivalent (LCE) ranges from 70,000 to 1.9 million liters, depending on the extraction method and local conditions.

Chemical contamination presents another substantial risk, as lithium processing typically involves acids, bases, and organic solvents that can contaminate soil and water systems if not properly managed. Monitoring data from established operations indicates that soil contamination can extend up to 3-5 kilometers from processing facilities, with elevated levels of lithium, sodium, and potassium affecting soil fertility and microbial activity.

Air quality impacts stem primarily from dust generation during blasting, crushing, and transportation activities. Particulate matter emissions can contain elevated concentrations of lithium, aluminum, and silica, potentially affecting worker health and nearby communities. Modern operations increasingly implement dust suppression systems and enclosed processing facilities to mitigate these impacts.

Energy consumption and associated carbon emissions represent a growing concern as the industry expands. Processing one ton of lithium requires approximately 5,300-15,000 kWh of energy, contributing to the carbon footprint of lithium production. This aspect is particularly relevant as lithium is marketed as a component of "green" technologies.

Biodiversity impacts vary significantly by location but can be severe in ecologically sensitive areas. The Atacama Desert, a major source of lithium, hosts numerous endemic species adapted to its unique conditions. Mining operations have been documented to affect flamingo populations and other specialized desert fauna through habitat modification and water table alterations.

Incorporating these environmental considerations into ore grade distribution models enables more sustainable short-term mine planning by optimizing extraction sequences to minimize ecological disruption while maintaining economic viability.

Water consumption represents one of the most significant environmental concerns, particularly in brine extraction operations where extensive evaporation ponds can deplete local aquifers. In regions like the "Lithium Triangle" of South America, mining operations consume an estimated 65% of available water resources, creating competition with agricultural activities and threatening fragile desert ecosystems. The water footprint of producing one ton of lithium carbonate equivalent (LCE) ranges from 70,000 to 1.9 million liters, depending on the extraction method and local conditions.

Chemical contamination presents another substantial risk, as lithium processing typically involves acids, bases, and organic solvents that can contaminate soil and water systems if not properly managed. Monitoring data from established operations indicates that soil contamination can extend up to 3-5 kilometers from processing facilities, with elevated levels of lithium, sodium, and potassium affecting soil fertility and microbial activity.

Air quality impacts stem primarily from dust generation during blasting, crushing, and transportation activities. Particulate matter emissions can contain elevated concentrations of lithium, aluminum, and silica, potentially affecting worker health and nearby communities. Modern operations increasingly implement dust suppression systems and enclosed processing facilities to mitigate these impacts.

Energy consumption and associated carbon emissions represent a growing concern as the industry expands. Processing one ton of lithium requires approximately 5,300-15,000 kWh of energy, contributing to the carbon footprint of lithium production. This aspect is particularly relevant as lithium is marketed as a component of "green" technologies.

Biodiversity impacts vary significantly by location but can be severe in ecologically sensitive areas. The Atacama Desert, a major source of lithium, hosts numerous endemic species adapted to its unique conditions. Mining operations have been documented to affect flamingo populations and other specialized desert fauna through habitat modification and water table alterations.

Incorporating these environmental considerations into ore grade distribution models enables more sustainable short-term mine planning by optimizing extraction sequences to minimize ecological disruption while maintaining economic viability.

Resource Estimation Uncertainty and Risk Management

Resource estimation in lithium mining operations inherently contains various levels of uncertainty that can significantly impact short-term mine planning decisions. These uncertainties stem from multiple sources including sampling errors, analytical inaccuracies, geological interpretation limitations, and the inherent variability of lithium deposits. When modeling ore grade distribution, companies must acknowledge that even the most sophisticated geostatistical methods cannot eliminate these uncertainties entirely.

Risk management frameworks specifically designed for lithium mining operations typically incorporate probabilistic approaches rather than deterministic ones. Monte Carlo simulations have proven particularly effective in quantifying grade distribution uncertainties by generating multiple equally probable realizations of the deposit. These simulations provide mining engineers with confidence intervals for expected ore grades rather than single-point estimates, enabling more robust planning decisions.

The financial implications of resource estimation uncertainty can be substantial. Studies across multiple lithium operations indicate that grade overestimation typically leads to a 15-25% shortfall in expected revenue during the first years of production. Conversely, grade underestimation may result in suboptimal capital allocation and missed market opportunities. Effective risk management requires transparent communication of these uncertainties to stakeholders and incorporation of contingency plans in short-term scheduling.

Conditional simulation techniques have emerged as best practice for managing grade uncertainty in lithium operations. Unlike kriging methods that provide smoothed estimates, conditional simulations preserve the variability of the deposit while honoring available sample data. Leading lithium producers increasingly employ multiple simulation scenarios to develop risk-adjusted production schedules that can adapt to various grade distribution outcomes.

Technological advancements in real-time grade control systems offer promising solutions for reducing uncertainty during operations. Hyperspectral imaging, laser-induced breakdown spectroscopy (LIBS), and portable XRF analyzers enable rapid ore characterization at the mining face, allowing for dynamic adjustments to short-term plans based on actual encountered conditions rather than pre-mining estimates. These technologies, when integrated with machine learning algorithms, can continuously refine grade distribution models as new data becomes available.

Risk management frameworks specifically designed for lithium mining operations typically incorporate probabilistic approaches rather than deterministic ones. Monte Carlo simulations have proven particularly effective in quantifying grade distribution uncertainties by generating multiple equally probable realizations of the deposit. These simulations provide mining engineers with confidence intervals for expected ore grades rather than single-point estimates, enabling more robust planning decisions.

The financial implications of resource estimation uncertainty can be substantial. Studies across multiple lithium operations indicate that grade overestimation typically leads to a 15-25% shortfall in expected revenue during the first years of production. Conversely, grade underestimation may result in suboptimal capital allocation and missed market opportunities. Effective risk management requires transparent communication of these uncertainties to stakeholders and incorporation of contingency plans in short-term scheduling.

Conditional simulation techniques have emerged as best practice for managing grade uncertainty in lithium operations. Unlike kriging methods that provide smoothed estimates, conditional simulations preserve the variability of the deposit while honoring available sample data. Leading lithium producers increasingly employ multiple simulation scenarios to develop risk-adjusted production schedules that can adapt to various grade distribution outcomes.

Technological advancements in real-time grade control systems offer promising solutions for reducing uncertainty during operations. Hyperspectral imaging, laser-induced breakdown spectroscopy (LIBS), and portable XRF analyzers enable rapid ore characterization at the mining face, allowing for dynamic adjustments to short-term plans based on actual encountered conditions rather than pre-mining estimates. These technologies, when integrated with machine learning algorithms, can continuously refine grade distribution models as new data becomes available.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!