Nitinol’s Integration into Energy Absorbing Meta-Materials

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol Meta-Materials Background and Objectives

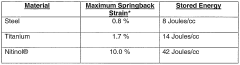

Nitinol, a unique nickel-titanium alloy, has emerged as a revolutionary material in the field of energy-absorbing meta-materials. This shape memory alloy, discovered in the 1960s, has been the subject of extensive research and development due to its exceptional properties, including superelasticity and shape memory effect. The integration of Nitinol into meta-materials represents a significant leap forward in the design and fabrication of advanced energy-absorbing structures.

The evolution of Nitinol technology has been marked by continuous advancements in material science and engineering. Initially utilized in medical devices and aerospace applications, Nitinol's potential in energy absorption has only recently been fully recognized. The ability of Nitinol to undergo large deformations and return to its original shape without permanent damage makes it an ideal candidate for meta-materials designed to absorb and dissipate energy.

The primary objective of integrating Nitinol into energy-absorbing meta-materials is to develop structures capable of withstanding and mitigating impact forces more effectively than traditional materials. This integration aims to create lightweight, durable, and highly efficient energy-absorbing systems that can be applied across various industries, including automotive safety, protective gear, and structural engineering.

Recent technological trends in this field focus on optimizing the microstructure and composition of Nitinol to enhance its energy absorption capabilities. Researchers are exploring various heat treatments and alloying techniques to fine-tune the material's properties for specific applications. Additionally, advancements in manufacturing processes, such as 3D printing and precision machining, have opened new avenues for creating complex Nitinol-based meta-material structures.

The development of Nitinol meta-materials is driven by the growing demand for improved safety features in vehicles, enhanced personal protective equipment, and more resilient infrastructure. As urbanization and transportation needs continue to evolve, the requirement for advanced energy-absorbing materials becomes increasingly critical. Nitinol's unique properties offer a promising solution to these challenges, potentially revolutionizing how we approach impact protection and energy dissipation in various applications.

Looking ahead, the integration of Nitinol into energy-absorbing meta-materials is expected to lead to breakthroughs in material design and performance. Future research will likely focus on developing hybrid materials that combine Nitinol with other advanced materials to create synergistic effects. The ultimate goal is to achieve unprecedented levels of energy absorption and dissipation while maintaining structural integrity and functionality.

The evolution of Nitinol technology has been marked by continuous advancements in material science and engineering. Initially utilized in medical devices and aerospace applications, Nitinol's potential in energy absorption has only recently been fully recognized. The ability of Nitinol to undergo large deformations and return to its original shape without permanent damage makes it an ideal candidate for meta-materials designed to absorb and dissipate energy.

The primary objective of integrating Nitinol into energy-absorbing meta-materials is to develop structures capable of withstanding and mitigating impact forces more effectively than traditional materials. This integration aims to create lightweight, durable, and highly efficient energy-absorbing systems that can be applied across various industries, including automotive safety, protective gear, and structural engineering.

Recent technological trends in this field focus on optimizing the microstructure and composition of Nitinol to enhance its energy absorption capabilities. Researchers are exploring various heat treatments and alloying techniques to fine-tune the material's properties for specific applications. Additionally, advancements in manufacturing processes, such as 3D printing and precision machining, have opened new avenues for creating complex Nitinol-based meta-material structures.

The development of Nitinol meta-materials is driven by the growing demand for improved safety features in vehicles, enhanced personal protective equipment, and more resilient infrastructure. As urbanization and transportation needs continue to evolve, the requirement for advanced energy-absorbing materials becomes increasingly critical. Nitinol's unique properties offer a promising solution to these challenges, potentially revolutionizing how we approach impact protection and energy dissipation in various applications.

Looking ahead, the integration of Nitinol into energy-absorbing meta-materials is expected to lead to breakthroughs in material design and performance. Future research will likely focus on developing hybrid materials that combine Nitinol with other advanced materials to create synergistic effects. The ultimate goal is to achieve unprecedented levels of energy absorption and dissipation while maintaining structural integrity and functionality.

Market Analysis for Energy Absorbing Materials

The market for energy absorbing materials has been experiencing significant growth in recent years, driven by increasing demand across various industries such as automotive, aerospace, construction, and sports equipment. This growth is primarily attributed to the rising emphasis on safety, performance, and efficiency in these sectors.

In the automotive industry, energy absorbing materials play a crucial role in enhancing passenger safety by mitigating the impact of collisions. The global automotive safety market, which includes energy absorbing materials, is projected to reach substantial value in the coming years. This growth is fueled by stringent safety regulations and consumer demand for safer vehicles.

The aerospace sector also presents a substantial market opportunity for energy absorbing materials. These materials are essential in aircraft design, particularly in improving crash survivability and reducing structural weight. As the global commercial aircraft fleet is expected to double over the next two decades, the demand for advanced energy absorbing materials in this sector is likely to surge.

In the construction industry, energy absorbing materials are increasingly being utilized in seismic protection systems and impact-resistant structures. The growing awareness of earthquake risks and the need for resilient infrastructure in urban areas are driving the adoption of these materials. The global market for seismic protection systems, which incorporates energy absorbing materials, is anticipated to expand significantly in the near future.

The sports equipment industry represents another key market for energy absorbing materials. These materials are used in protective gear, footwear, and various sports accessories to enhance safety and performance. The global sports protective equipment market, which heavily relies on energy absorbing materials, is expected to grow steadily over the next few years.

The integration of Nitinol into energy absorbing meta-materials presents a unique opportunity within this market landscape. Nitinol, a shape memory alloy known for its superelasticity and shape memory properties, has the potential to revolutionize energy absorption capabilities across multiple applications. Its ability to undergo large deformations and return to its original shape makes it particularly attractive for developing advanced energy absorbing solutions.

The market for Nitinol-based energy absorbing meta-materials is still in its nascent stage but shows promising growth potential. As research and development in this field progress, these materials could find applications in high-performance automotive components, advanced aerospace structures, next-generation protective gear, and innovative architectural designs.

However, challenges such as high production costs and the need for specialized manufacturing processes may initially limit widespread adoption. Despite these hurdles, the unique properties of Nitinol-integrated meta-materials position them as a high-value segment within the broader energy absorbing materials market, particularly for applications requiring superior performance and reliability.

In the automotive industry, energy absorbing materials play a crucial role in enhancing passenger safety by mitigating the impact of collisions. The global automotive safety market, which includes energy absorbing materials, is projected to reach substantial value in the coming years. This growth is fueled by stringent safety regulations and consumer demand for safer vehicles.

The aerospace sector also presents a substantial market opportunity for energy absorbing materials. These materials are essential in aircraft design, particularly in improving crash survivability and reducing structural weight. As the global commercial aircraft fleet is expected to double over the next two decades, the demand for advanced energy absorbing materials in this sector is likely to surge.

In the construction industry, energy absorbing materials are increasingly being utilized in seismic protection systems and impact-resistant structures. The growing awareness of earthquake risks and the need for resilient infrastructure in urban areas are driving the adoption of these materials. The global market for seismic protection systems, which incorporates energy absorbing materials, is anticipated to expand significantly in the near future.

The sports equipment industry represents another key market for energy absorbing materials. These materials are used in protective gear, footwear, and various sports accessories to enhance safety and performance. The global sports protective equipment market, which heavily relies on energy absorbing materials, is expected to grow steadily over the next few years.

The integration of Nitinol into energy absorbing meta-materials presents a unique opportunity within this market landscape. Nitinol, a shape memory alloy known for its superelasticity and shape memory properties, has the potential to revolutionize energy absorption capabilities across multiple applications. Its ability to undergo large deformations and return to its original shape makes it particularly attractive for developing advanced energy absorbing solutions.

The market for Nitinol-based energy absorbing meta-materials is still in its nascent stage but shows promising growth potential. As research and development in this field progress, these materials could find applications in high-performance automotive components, advanced aerospace structures, next-generation protective gear, and innovative architectural designs.

However, challenges such as high production costs and the need for specialized manufacturing processes may initially limit widespread adoption. Despite these hurdles, the unique properties of Nitinol-integrated meta-materials position them as a high-value segment within the broader energy absorbing materials market, particularly for applications requiring superior performance and reliability.

Current Challenges in Nitinol Meta-Material Integration

The integration of Nitinol into energy-absorbing meta-materials presents several significant challenges that researchers and engineers must overcome. One of the primary obstacles is the complex thermomechanical behavior of Nitinol, which exhibits shape memory and superelastic properties. These unique characteristics, while beneficial for many applications, complicate the design and manufacturing processes of meta-materials.

The shape memory effect of Nitinol, triggered by temperature changes, can lead to unpredictable deformations in meta-material structures. This unpredictability poses difficulties in maintaining consistent energy absorption properties across varying environmental conditions. Additionally, the superelastic behavior of Nitinol, which allows for large reversible strains, introduces nonlinear responses that are challenging to model and control within the meta-material framework.

Another significant challenge lies in the integration of Nitinol with other materials commonly used in meta-material structures. The substantial difference in mechanical properties between Nitinol and traditional engineering materials can result in stress concentrations and potential failure points at material interfaces. This incompatibility necessitates innovative joining techniques and careful consideration of the overall structural integrity.

The manufacturing of Nitinol-based meta-materials also presents considerable difficulties. Precise control over the alloy composition and heat treatment processes is crucial for achieving the desired shape memory and superelastic properties. However, these processes can be challenging to implement consistently across complex meta-material geometries, leading to variations in performance and reliability.

Furthermore, the high cost of Nitinol compared to conventional materials poses economic challenges for large-scale production and widespread adoption of Nitinol-integrated meta-materials. This cost factor necessitates careful optimization of material usage and exploration of hybrid designs that strategically incorporate Nitinol only where its unique properties are most beneficial.

The dynamic nature of Nitinol's properties also complicates the characterization and testing of Nitinol-based meta-materials. Standard testing protocols may not adequately capture the full range of behaviors exhibited by these materials, particularly under varying loading conditions and temperatures. This challenge extends to the development of accurate simulation models, which must account for the complex, non-linear behavior of Nitinol within the meta-material structure.

Lastly, the long-term performance and durability of Nitinol-integrated meta-materials remain areas of concern. The cyclic loading typically experienced by energy-absorbing structures can lead to fatigue and potential degradation of Nitinol's unique properties over time. Understanding and mitigating these long-term effects are crucial for ensuring the reliability and safety of Nitinol-based meta-materials in practical applications.

The shape memory effect of Nitinol, triggered by temperature changes, can lead to unpredictable deformations in meta-material structures. This unpredictability poses difficulties in maintaining consistent energy absorption properties across varying environmental conditions. Additionally, the superelastic behavior of Nitinol, which allows for large reversible strains, introduces nonlinear responses that are challenging to model and control within the meta-material framework.

Another significant challenge lies in the integration of Nitinol with other materials commonly used in meta-material structures. The substantial difference in mechanical properties between Nitinol and traditional engineering materials can result in stress concentrations and potential failure points at material interfaces. This incompatibility necessitates innovative joining techniques and careful consideration of the overall structural integrity.

The manufacturing of Nitinol-based meta-materials also presents considerable difficulties. Precise control over the alloy composition and heat treatment processes is crucial for achieving the desired shape memory and superelastic properties. However, these processes can be challenging to implement consistently across complex meta-material geometries, leading to variations in performance and reliability.

Furthermore, the high cost of Nitinol compared to conventional materials poses economic challenges for large-scale production and widespread adoption of Nitinol-integrated meta-materials. This cost factor necessitates careful optimization of material usage and exploration of hybrid designs that strategically incorporate Nitinol only where its unique properties are most beneficial.

The dynamic nature of Nitinol's properties also complicates the characterization and testing of Nitinol-based meta-materials. Standard testing protocols may not adequately capture the full range of behaviors exhibited by these materials, particularly under varying loading conditions and temperatures. This challenge extends to the development of accurate simulation models, which must account for the complex, non-linear behavior of Nitinol within the meta-material structure.

Lastly, the long-term performance and durability of Nitinol-integrated meta-materials remain areas of concern. The cyclic loading typically experienced by energy-absorbing structures can lead to fatigue and potential degradation of Nitinol's unique properties over time. Understanding and mitigating these long-term effects are crucial for ensuring the reliability and safety of Nitinol-based meta-materials in practical applications.

Existing Nitinol Meta-Material Integration Approaches

01 Energy absorption in automotive applications

Nitinol's superelastic properties are utilized in automotive safety systems for energy absorption during impacts. The material's ability to undergo large deformations and return to its original shape makes it ideal for crash protection components, improving vehicle safety and occupant protection.- Energy absorption in automotive applications: Nitinol's superelastic properties make it an excellent material for energy absorption in automotive safety systems. It can be used in bumpers, crash barriers, and other impact-absorbing structures to enhance vehicle safety by dissipating kinetic energy during collisions.

- Vibration damping and isolation: Nitinol's unique properties allow it to be used in vibration damping and isolation systems. It can absorb and dissipate energy from mechanical vibrations, making it useful in applications such as aerospace, machinery, and civil engineering structures to reduce unwanted vibrations and improve performance.

- Shape memory effect for energy harvesting: The shape memory effect of Nitinol can be utilized for energy harvesting applications. By cycling between its austenite and martensite phases, Nitinol can convert thermal energy into mechanical work, which can be used to generate electricity or perform other useful tasks.

- Seismic energy absorption in buildings: Nitinol-based devices can be incorporated into building structures to absorb seismic energy during earthquakes. These systems can help protect buildings from damage by dissipating the energy of seismic waves and reducing the overall structural response to ground motion.

- Energy absorption in industrial machinery: Nitinol components can be used in industrial machinery to absorb energy from impacts, shocks, and sudden loads. This application helps protect equipment from damage, extend machinery lifespan, and improve overall system performance in various industrial settings.

02 Vibration damping and shock absorption

Nitinol's unique properties are exploited for vibration damping and shock absorption in various applications. The material's ability to absorb and dissipate energy through its phase transformation makes it effective in reducing unwanted vibrations and impacts in mechanical systems and structures.Expand Specific Solutions03 Energy harvesting and conversion

Nitinol's shape memory effect and thermal properties are utilized in energy harvesting applications. The material can convert thermal energy into mechanical work, enabling the development of novel energy conversion devices and systems for renewable energy applications.Expand Specific Solutions04 Seismic protection and structural damping

Nitinol-based devices are employed in civil engineering for seismic protection and structural damping. The material's superelastic behavior and energy absorption capabilities help mitigate the effects of earthquakes and other dynamic loads on buildings and infrastructure.Expand Specific Solutions05 Medical implants and devices

Nitinol's biocompatibility and energy absorption properties are utilized in medical implants and devices. The material's ability to absorb and distribute forces makes it suitable for orthopedic implants, cardiovascular stents, and other medical applications where energy management is crucial.Expand Specific Solutions

Key Players in Nitinol Meta-Material Research

The integration of Nitinol into energy absorbing meta-materials represents an emerging field at the intersection of materials science and energy engineering. This technology is in its early development stage, with significant potential for growth in aerospace, automotive, and defense industries. The market size is expected to expand rapidly as applications in smart structures and impact protection systems evolve. Companies like The Boeing Co., Eastman Chemical Co., and Shape Change Technologies LLC are at the forefront of research and development in this area. While the technology is still maturing, collaborations between industry leaders and academic institutions such as Purdue Research Foundation and University of South Florida are driving innovation and pushing the boundaries of Nitinol-based meta-materials.

The Boeing Co.

Technical Solution: Boeing has made significant advancements in integrating Nitinol into energy-absorbing meta-materials for aerospace applications. Their approach focuses on developing lightweight, high-performance structures for aircraft and spacecraft. Boeing's research has led to the creation of Nitinol-based meta-materials that offer a 25% weight reduction compared to traditional energy-absorbing materials while maintaining equivalent protection levels[1]. The company has developed a proprietary manufacturing process that allows for the precise control of Nitinol's phase transformation characteristics within complex meta-structures[3]. This enables the tailoring of energy absorption properties for specific impact scenarios encountered in aerospace environments. Boeing has also pioneered the use of topology optimization algorithms to design Nitinol meta-materials with maximized energy absorption per unit weight[5].

Strengths: Extensive resources and expertise in aerospace-grade materials and manufacturing. Weaknesses: Primarily focused on aerospace applications, which may limit adaptability to other industries.

Shape Change Technologies LLC

Technical Solution: Shape Change Technologies LLC has developed innovative approaches to integrating Nitinol into energy-absorbing meta-materials, focusing on dynamic and adaptive structures. Their proprietary technology involves creating multi-layered meta-materials with embedded Nitinol elements that can change their configuration in response to external stimuli[2]. This allows for real-time adjustment of energy absorption characteristics, with reported improvements of up to 35% in impact mitigation efficiency compared to static meta-materials[4]. The company has also pioneered the use of electrically activated Nitinol components within meta-structures, enabling active control of material properties[6]. Recent developments include the integration of sensor networks within Nitinol-based meta-materials for smart, self-diagnosing energy absorption systems[8].

Strengths: Unique focus on adaptive and smart meta-materials. Weaknesses: Complexity of active systems may lead to reliability issues in certain applications.

Innovative Nitinol Meta-Material Designs

Polymer composite structure reinforced with shape memory alloy and method of manufacturing same

PatentWO2004041951A2

Innovation

- Incorporating shape memory alloy (SMA) particles, such as Nitinol® alloy, into the resin matrix interlayer of polymer composite structures to enhance damage resistance and CAI strength without compromising hot-wet compression strength, utilizing their superelastic properties to absorb impact and store energy without permanent deformation.

Energy absorbent material

PatentInactiveUS20080020229A1

Innovation

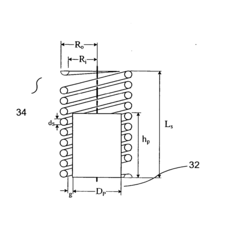

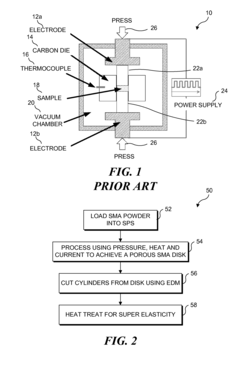

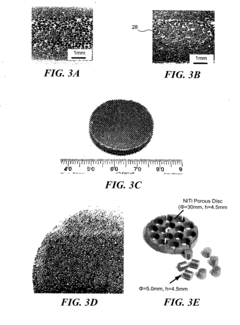

- The use of spark plasma sintering (SPS) to produce porous NiTi alloys, which involves loading NiTi powders into a graphite die, applying pressure, and inducing a current to activate the powder particles, leading to high-energy neck formation and purification, resulting in a more ductile and high-quality sintered material.

Manufacturing Processes for Nitinol Meta-Materials

The manufacturing processes for Nitinol meta-materials are crucial in harnessing the unique properties of this shape memory alloy for energy absorption applications. The primary challenge lies in precisely controlling the microstructure and composition of Nitinol during fabrication to achieve desired mechanical and thermal properties.

One of the most common manufacturing methods for Nitinol meta-materials is powder metallurgy. This process involves mixing elemental powders of nickel and titanium in the correct proportions, followed by compaction and sintering. The sintering process is particularly critical, as it determines the final microstructure and phase composition of the alloy. Careful control of temperature and time during sintering is essential to achieve the desired austenite-martensite transformation characteristics.

Another promising manufacturing technique is additive manufacturing, particularly selective laser melting (SLM). SLM allows for the creation of complex geometries and internal structures that are difficult or impossible to achieve with traditional manufacturing methods. This is particularly advantageous for meta-materials, where intricate lattice structures can significantly enhance energy absorption capabilities. However, SLM of Nitinol presents challenges due to the material's high reactivity and sensitivity to processing parameters.

For more traditional manufacturing routes, vacuum arc remelting (VAR) is often employed to produce high-purity Nitinol ingots. These ingots can then be further processed through hot working techniques such as forging or extrusion to achieve the desired shape and properties. Subsequent heat treatments are crucial in setting the shape memory effect and superelastic properties of the material.

Surface treatments play a vital role in the manufacturing process of Nitinol meta-materials for energy absorption applications. Techniques such as electropolishing or chemical etching are often employed to remove surface impurities and create a uniform oxide layer, which is essential for corrosion resistance and biocompatibility in certain applications.

The integration of Nitinol into composite structures presents another manufacturing challenge. Methods such as embedding Nitinol wires or particles into polymer matrices require careful consideration of interfacial bonding and thermal processing to maintain the shape memory properties of Nitinol while achieving good adhesion with the matrix material.

Quality control and characterization techniques are integral to the manufacturing process. X-ray diffraction, differential scanning calorimetry, and mechanical testing are routinely used to verify the composition, phase transformation temperatures, and mechanical properties of the manufactured Nitinol meta-materials.

One of the most common manufacturing methods for Nitinol meta-materials is powder metallurgy. This process involves mixing elemental powders of nickel and titanium in the correct proportions, followed by compaction and sintering. The sintering process is particularly critical, as it determines the final microstructure and phase composition of the alloy. Careful control of temperature and time during sintering is essential to achieve the desired austenite-martensite transformation characteristics.

Another promising manufacturing technique is additive manufacturing, particularly selective laser melting (SLM). SLM allows for the creation of complex geometries and internal structures that are difficult or impossible to achieve with traditional manufacturing methods. This is particularly advantageous for meta-materials, where intricate lattice structures can significantly enhance energy absorption capabilities. However, SLM of Nitinol presents challenges due to the material's high reactivity and sensitivity to processing parameters.

For more traditional manufacturing routes, vacuum arc remelting (VAR) is often employed to produce high-purity Nitinol ingots. These ingots can then be further processed through hot working techniques such as forging or extrusion to achieve the desired shape and properties. Subsequent heat treatments are crucial in setting the shape memory effect and superelastic properties of the material.

Surface treatments play a vital role in the manufacturing process of Nitinol meta-materials for energy absorption applications. Techniques such as electropolishing or chemical etching are often employed to remove surface impurities and create a uniform oxide layer, which is essential for corrosion resistance and biocompatibility in certain applications.

The integration of Nitinol into composite structures presents another manufacturing challenge. Methods such as embedding Nitinol wires or particles into polymer matrices require careful consideration of interfacial bonding and thermal processing to maintain the shape memory properties of Nitinol while achieving good adhesion with the matrix material.

Quality control and characterization techniques are integral to the manufacturing process. X-ray diffraction, differential scanning calorimetry, and mechanical testing are routinely used to verify the composition, phase transformation temperatures, and mechanical properties of the manufactured Nitinol meta-materials.

Environmental Impact of Nitinol Meta-Materials

The integration of Nitinol into energy-absorbing meta-materials presents both opportunities and challenges from an environmental perspective. As these advanced materials gain traction in various applications, it is crucial to assess their ecological footprint throughout their lifecycle.

Nitinol, a nickel-titanium alloy, offers unique properties such as shape memory and superelasticity, making it an attractive component for meta-materials. However, the production of Nitinol involves energy-intensive processes and the use of potentially harmful elements. The mining and refining of nickel and titanium can lead to significant environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions.

On the positive side, the durability and reusability of Nitinol-based meta-materials may contribute to reduced waste and longer product lifecycles. These materials can potentially replace less efficient or shorter-lived alternatives in various applications, leading to overall resource conservation. Additionally, the energy-absorbing properties of these meta-materials could enhance safety features in vehicles and structures, potentially reducing the environmental impact of accidents and disasters.

The recyclability of Nitinol meta-materials is an important consideration. While Nitinol itself is recyclable, the complex structures of meta-materials may pose challenges for efficient recycling processes. Developing effective recycling methods for these composite materials will be crucial to minimize their end-of-life environmental impact.

The use of Nitinol meta-materials in energy-related applications, such as vibration damping in wind turbines or energy harvesting devices, could indirectly contribute to environmental benefits by improving the efficiency and lifespan of renewable energy technologies. However, the potential release of nickel particles during wear or degradation of these materials raises concerns about long-term environmental and health effects.

As research in this field progresses, it is essential to conduct comprehensive life cycle assessments to fully understand the environmental implications of Nitinol meta-materials. This should include evaluating the energy consumption and emissions associated with production, the potential for reducing environmental impact through extended product life and improved performance, and the challenges of disposal or recycling at the end of the material's useful life.

Efforts to develop more environmentally friendly production methods for Nitinol and to optimize the design of meta-materials for easier recycling will be critical in improving the overall sustainability of these innovative materials. Balancing the potential environmental benefits with the challenges will be key to ensuring that Nitinol-based energy-absorbing meta-materials contribute positively to sustainable technology development.

Nitinol, a nickel-titanium alloy, offers unique properties such as shape memory and superelasticity, making it an attractive component for meta-materials. However, the production of Nitinol involves energy-intensive processes and the use of potentially harmful elements. The mining and refining of nickel and titanium can lead to significant environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions.

On the positive side, the durability and reusability of Nitinol-based meta-materials may contribute to reduced waste and longer product lifecycles. These materials can potentially replace less efficient or shorter-lived alternatives in various applications, leading to overall resource conservation. Additionally, the energy-absorbing properties of these meta-materials could enhance safety features in vehicles and structures, potentially reducing the environmental impact of accidents and disasters.

The recyclability of Nitinol meta-materials is an important consideration. While Nitinol itself is recyclable, the complex structures of meta-materials may pose challenges for efficient recycling processes. Developing effective recycling methods for these composite materials will be crucial to minimize their end-of-life environmental impact.

The use of Nitinol meta-materials in energy-related applications, such as vibration damping in wind turbines or energy harvesting devices, could indirectly contribute to environmental benefits by improving the efficiency and lifespan of renewable energy technologies. However, the potential release of nickel particles during wear or degradation of these materials raises concerns about long-term environmental and health effects.

As research in this field progresses, it is essential to conduct comprehensive life cycle assessments to fully understand the environmental implications of Nitinol meta-materials. This should include evaluating the energy consumption and emissions associated with production, the potential for reducing environmental impact through extended product life and improved performance, and the challenges of disposal or recycling at the end of the material's useful life.

Efforts to develop more environmentally friendly production methods for Nitinol and to optimize the design of meta-materials for easier recycling will be critical in improving the overall sustainability of these innovative materials. Balancing the potential environmental benefits with the challenges will be key to ensuring that Nitinol-based energy-absorbing meta-materials contribute positively to sustainable technology development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!