OLED Color Accuracy vs Print: Measuring Fidelity Across Types

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Color Reproduction Technology Background and Objectives

The evolution of display technology has witnessed significant advancements over the past few decades, with OLED (Organic Light-Emitting Diode) emerging as a revolutionary technology in the field of visual reproduction. Since the first practical OLED device was developed by Eastman Kodak in 1987, this technology has transformed from laboratory curiosity to mainstream display solution. The fundamental principle of OLED—utilizing organic compounds that emit light when electricity is applied—has enabled thinner, lighter, and more flexible displays with superior color reproduction capabilities compared to traditional LCD technology.

Color accuracy in digital displays represents one of the most critical aspects of visual technology, particularly as digital content creation and consumption continue to expand across industries. The challenge of faithfully reproducing colors as they appear in the physical world has been a persistent technological hurdle. OLED technology has made significant strides in addressing this challenge through its ability to produce pure blacks, high contrast ratios, and wide color gamuts, yet achieving perfect fidelity to printed materials remains elusive.

The technical evolution of OLED color reproduction has progressed through several key phases: from early implementations with limited color accuracy to current high-end displays capable of reproducing over 100% of the DCI-P3 color space. This progression has been driven by advancements in organic materials science, pixel architecture, and color management algorithms. Contemporary research focuses on expanding color gamut coverage while maintaining accuracy across the entire spectrum of visible colors.

The primary objective of current OLED color reproduction technology is to achieve perceptual equivalence between digital displays and physical printed materials across various viewing conditions. This goal encompasses several technical challenges, including accurate color mapping between different color spaces, compensation for ambient lighting conditions, and addressing the fundamental differences between emissive (OLED) and reflective (print) color reproduction methods.

Industry standards for color accuracy measurement have evolved alongside display technology, with metrics such as Delta-E becoming increasingly sophisticated to better quantify human color perception. The current benchmark for professional applications typically requires a Delta-E value below 2.0, representing a color difference that is imperceptible to the average human observer. However, achieving this level of accuracy consistently across the entire color spectrum and between different media types remains challenging.

The convergence of OLED technology with advanced color management systems presents promising opportunities for bridging the gap between digital and print color reproduction. Recent developments in quantum dot-enhanced OLED (QD-OLED) technology and micro-LED displays suggest potential pathways toward even greater color accuracy and consistency, potentially revolutionizing industries where color fidelity is paramount, such as fashion, graphic design, and fine art reproduction.

Color accuracy in digital displays represents one of the most critical aspects of visual technology, particularly as digital content creation and consumption continue to expand across industries. The challenge of faithfully reproducing colors as they appear in the physical world has been a persistent technological hurdle. OLED technology has made significant strides in addressing this challenge through its ability to produce pure blacks, high contrast ratios, and wide color gamuts, yet achieving perfect fidelity to printed materials remains elusive.

The technical evolution of OLED color reproduction has progressed through several key phases: from early implementations with limited color accuracy to current high-end displays capable of reproducing over 100% of the DCI-P3 color space. This progression has been driven by advancements in organic materials science, pixel architecture, and color management algorithms. Contemporary research focuses on expanding color gamut coverage while maintaining accuracy across the entire spectrum of visible colors.

The primary objective of current OLED color reproduction technology is to achieve perceptual equivalence between digital displays and physical printed materials across various viewing conditions. This goal encompasses several technical challenges, including accurate color mapping between different color spaces, compensation for ambient lighting conditions, and addressing the fundamental differences between emissive (OLED) and reflective (print) color reproduction methods.

Industry standards for color accuracy measurement have evolved alongside display technology, with metrics such as Delta-E becoming increasingly sophisticated to better quantify human color perception. The current benchmark for professional applications typically requires a Delta-E value below 2.0, representing a color difference that is imperceptible to the average human observer. However, achieving this level of accuracy consistently across the entire color spectrum and between different media types remains challenging.

The convergence of OLED technology with advanced color management systems presents promising opportunities for bridging the gap between digital and print color reproduction. Recent developments in quantum dot-enhanced OLED (QD-OLED) technology and micro-LED displays suggest potential pathways toward even greater color accuracy and consistency, potentially revolutionizing industries where color fidelity is paramount, such as fashion, graphic design, and fine art reproduction.

Market Demand for Color-Accurate Display Solutions

The color accuracy market is experiencing unprecedented growth, driven by increasing demands across multiple industries where precise color reproduction is critical. Professional sectors including graphic design, photography, video production, and print media have traditionally been the primary consumers of color-accurate display solutions. However, the market has expanded significantly as consumers become more discerning about visual quality in their everyday devices.

Recent market research indicates that the global market for color-accurate displays reached $4.2 billion in 2022, with projections showing growth at a CAGR of 11.3% through 2028. This expansion is particularly evident in the premium consumer electronics segment, where manufacturers are increasingly marketing color accuracy as a key differentiator for high-end smartphones, tablets, and televisions.

The creative professional market remains the strongest driver, with 78% of professional designers and photographers considering color accuracy as "extremely important" in their purchase decisions. These professionals require displays that can accurately represent the CMYK color space used in printing, alongside standard RGB color spaces. The disconnect between what appears on screen versus final printed output (known as the "screen-to-print gap") continues to be a significant pain point, creating demand for solutions that bridge digital and physical color reproduction.

Healthcare represents another rapidly growing segment, with medical imaging requiring increasingly precise color reproduction for accurate diagnostics. The market for medical-grade color-accurate displays alone grew by 15.7% in 2022, outpacing the overall display market growth rate.

E-commerce is driving consumer awareness of color accuracy issues, as online shoppers increasingly expect product colors displayed on screens to match physical items received. Studies show that color discrepancies account for approximately 22% of product returns in fashion e-commerce, creating significant economic incentives for improved color fidelity across the digital-physical divide.

The automotive industry has emerged as a new frontier for color-accurate displays, with in-vehicle entertainment systems and digital dashboards requiring precise color reproduction that maintains visibility and accuracy across varying lighting conditions. This sector is expected to grow at 18.2% annually through 2027.

Geographically, North America and Europe currently dominate market demand, accounting for 63% of global revenue. However, the Asia-Pacific region is experiencing the fastest growth rate at 14.5% annually, driven by expanding creative industries in China, Japan, and South Korea, alongside increasing consumer awareness of display quality metrics.

Recent market research indicates that the global market for color-accurate displays reached $4.2 billion in 2022, with projections showing growth at a CAGR of 11.3% through 2028. This expansion is particularly evident in the premium consumer electronics segment, where manufacturers are increasingly marketing color accuracy as a key differentiator for high-end smartphones, tablets, and televisions.

The creative professional market remains the strongest driver, with 78% of professional designers and photographers considering color accuracy as "extremely important" in their purchase decisions. These professionals require displays that can accurately represent the CMYK color space used in printing, alongside standard RGB color spaces. The disconnect between what appears on screen versus final printed output (known as the "screen-to-print gap") continues to be a significant pain point, creating demand for solutions that bridge digital and physical color reproduction.

Healthcare represents another rapidly growing segment, with medical imaging requiring increasingly precise color reproduction for accurate diagnostics. The market for medical-grade color-accurate displays alone grew by 15.7% in 2022, outpacing the overall display market growth rate.

E-commerce is driving consumer awareness of color accuracy issues, as online shoppers increasingly expect product colors displayed on screens to match physical items received. Studies show that color discrepancies account for approximately 22% of product returns in fashion e-commerce, creating significant economic incentives for improved color fidelity across the digital-physical divide.

The automotive industry has emerged as a new frontier for color-accurate displays, with in-vehicle entertainment systems and digital dashboards requiring precise color reproduction that maintains visibility and accuracy across varying lighting conditions. This sector is expected to grow at 18.2% annually through 2027.

Geographically, North America and Europe currently dominate market demand, accounting for 63% of global revenue. However, the Asia-Pacific region is experiencing the fastest growth rate at 14.5% annually, driven by expanding creative industries in China, Japan, and South Korea, alongside increasing consumer awareness of display quality metrics.

Current Color Fidelity Challenges Between OLED and Print

The color accuracy gap between OLED displays and printed materials represents one of the most significant challenges in digital-to-physical color reproduction. Current OLED displays operate on RGB color models with self-emissive pixels capable of producing vibrant, high-contrast colors with excellent black levels. However, these displays struggle to accurately represent the full gamut of colors achievable in professional print, which typically uses CMYK color models with subtractive color mixing principles.

A fundamental technical limitation stems from the different color spaces involved. While OLED displays commonly support sRGB or DCI-P3 color spaces, professional printing often utilizes wider gamuts like Adobe RGB or even custom color spaces. This discrepancy creates inherent translation issues when content moves between digital and physical mediums, particularly affecting brand colors and fine art reproduction where precision is paramount.

Color temperature inconsistency presents another significant challenge. OLED displays emit light at color temperatures typically ranging from 6500K to 9300K, while printed materials are viewed under ambient lighting conditions that can vary dramatically from 2700K (warm indoor lighting) to 5500K (daylight). This variance creates a moving target for color matching, as the perceived colors shift depending on viewing conditions.

Metamerism effects further complicate the situation, where colors that appear identical under one lighting condition look different under another. This phenomenon is particularly problematic when matching OLED-displayed colors to printed materials, as the spectral power distribution of OLED-emitted light differs fundamentally from reflected light off printed surfaces.

Current calibration methods also face limitations. While OLED displays can be calibrated using colorimeters and spectrophotometers, these calibrations often fail to account for the full complexity of human color perception across different viewing environments. Additionally, the calibration stability of OLED displays remains problematic, with color accuracy drifting over time due to organic material degradation.

Surface properties create another dimension of complexity. Printed materials exhibit various surface characteristics—glossy, matte, textured—that affect how light interacts with pigments. OLED displays, with their uniform glass or plastic surfaces, cannot replicate these tactile and reflective properties that influence color perception.

The industry currently lacks standardized cross-media color management workflows that effectively bridge these technological differences. While color management systems like ICC profiles attempt to address these issues, they remain imperfect solutions that require significant expertise to implement correctly and still cannot overcome certain fundamental physical limitations of the different color reproduction technologies.

A fundamental technical limitation stems from the different color spaces involved. While OLED displays commonly support sRGB or DCI-P3 color spaces, professional printing often utilizes wider gamuts like Adobe RGB or even custom color spaces. This discrepancy creates inherent translation issues when content moves between digital and physical mediums, particularly affecting brand colors and fine art reproduction where precision is paramount.

Color temperature inconsistency presents another significant challenge. OLED displays emit light at color temperatures typically ranging from 6500K to 9300K, while printed materials are viewed under ambient lighting conditions that can vary dramatically from 2700K (warm indoor lighting) to 5500K (daylight). This variance creates a moving target for color matching, as the perceived colors shift depending on viewing conditions.

Metamerism effects further complicate the situation, where colors that appear identical under one lighting condition look different under another. This phenomenon is particularly problematic when matching OLED-displayed colors to printed materials, as the spectral power distribution of OLED-emitted light differs fundamentally from reflected light off printed surfaces.

Current calibration methods also face limitations. While OLED displays can be calibrated using colorimeters and spectrophotometers, these calibrations often fail to account for the full complexity of human color perception across different viewing environments. Additionally, the calibration stability of OLED displays remains problematic, with color accuracy drifting over time due to organic material degradation.

Surface properties create another dimension of complexity. Printed materials exhibit various surface characteristics—glossy, matte, textured—that affect how light interacts with pigments. OLED displays, with their uniform glass or plastic surfaces, cannot replicate these tactile and reflective properties that influence color perception.

The industry currently lacks standardized cross-media color management workflows that effectively bridge these technological differences. While color management systems like ICC profiles attempt to address these issues, they remain imperfect solutions that require significant expertise to implement correctly and still cannot overcome certain fundamental physical limitations of the different color reproduction technologies.

Current Color Calibration and Matching Methodologies

01 Color calibration and management systems for OLED displays

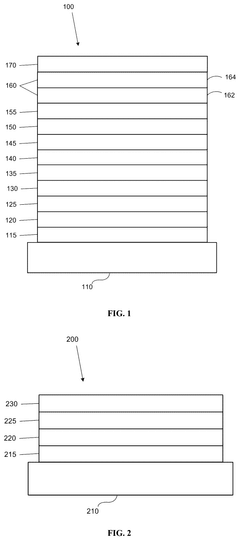

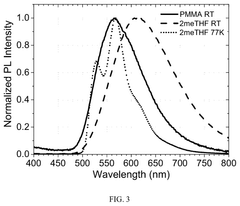

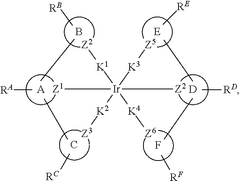

Color calibration and management systems are essential for ensuring accurate color reproduction on OLED displays. These systems involve measuring and adjusting color parameters to match standardized color spaces. Advanced algorithms can compensate for variations in OLED materials and aging effects, maintaining consistent color accuracy over the display's lifetime. These calibration techniques enable OLED displays to accurately represent colors as they would appear in print media.- Color calibration techniques for OLED displays: Various calibration methods are employed to ensure accurate color reproduction in OLED displays. These techniques involve measuring and adjusting color parameters to match standardized color spaces, compensating for manufacturing variations, and implementing feedback systems that continuously monitor and correct color output. Advanced algorithms can analyze display characteristics and apply appropriate corrections to maintain color accuracy across the display's lifetime.

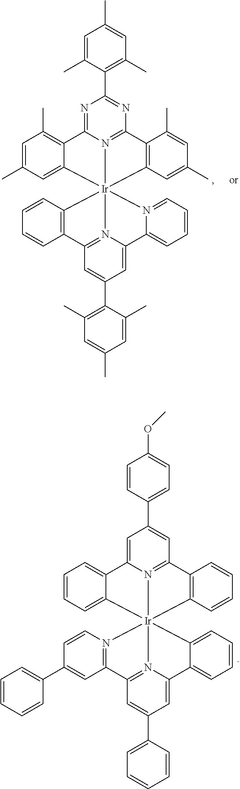

- OLED material composition for improved color accuracy: Specific organic materials and layer structures in OLED displays can significantly impact color accuracy. By engineering the chemical composition of emissive materials, manufacturers can achieve more precise color points and wider color gamuts. Multi-layer structures with specialized color filters and quantum dot technologies enhance color purity and stability, while novel pixel architectures help maintain consistent color reproduction across different brightness levels.

- Color matching systems between OLED displays and print media: Systems and methods for ensuring color consistency between digital OLED displays and physical print media involve sophisticated color management workflows. These include spectral matching algorithms, device-independent color spaces, and cross-media color profiles that account for the fundamental differences between emissive (OLED) and reflective (print) color reproduction. Real-time preview systems allow for accurate representation of how digital content will appear when printed.

- Compensation techniques for environmental factors affecting color accuracy: Environmental factors such as ambient light, temperature, and viewing angle can significantly impact perceived color accuracy in OLED displays. Advanced compensation systems use integrated sensors to detect these environmental variables and dynamically adjust display parameters. Adaptive brightness and color temperature controls ensure consistent color perception across different viewing conditions, while specialized optical films reduce glare and maintain color fidelity when comparing to print media.

- Pixel structure innovations for enhanced color reproduction: Novel pixel architectures and subpixel arrangements in OLED displays can significantly improve color accuracy. These include specialized subpixel geometries, micro-cavity structures that enhance specific wavelengths, and advanced driving schemes that reduce color shifts. High-resolution pixel arrangements with optimized color filters better reproduce the subtle color variations found in print media, while innovations in pixel density and arrangement minimize color fringing and improve text rendering.

02 OLED material composition for improved color accuracy

The composition of OLED materials significantly impacts color accuracy. Specialized organic compounds and pixel structures can be engineered to produce more precise color gamuts that better match print media standards. Multi-layer OLED structures with optimized light-emitting materials help achieve more accurate color reproduction. Innovations in material science allow for displays that can reproduce a wider range of colors with greater fidelity to printed materials.Expand Specific Solutions03 Color matching technologies between OLED displays and print media

Technologies specifically designed to match colors between OLED displays and print media involve sophisticated color space conversion algorithms and spectral matching techniques. These systems analyze the spectral characteristics of both mediums and create transformation matrices to ensure visual consistency. Some solutions incorporate real-time adjustment capabilities that account for ambient lighting conditions, viewing angles, and substrate properties of print media to achieve perceptual color matching.Expand Specific Solutions04 OLED display architecture for print-accurate color reproduction

Specialized OLED display architectures can be designed to more accurately reproduce print colors. These include pixel arrangements that minimize color shifts at different viewing angles, sub-pixel structures that better approximate the reflective properties of ink on paper, and integrated sensing systems that can detect ambient conditions. Advanced driving schemes and compensation circuits help maintain color consistency across the entire display surface, mimicking the uniform appearance of printed materials.Expand Specific Solutions05 Hybrid solutions combining OLED technology with print media characteristics

Hybrid approaches integrate aspects of both OLED technology and traditional print media to achieve superior color accuracy. These solutions may include specialized surface treatments that give OLED displays paper-like optical properties, ambient light rejection technologies that mimic how printed materials appear under various lighting conditions, and adaptive brightness systems that adjust display output to match the perceived brightness of print media. Some implementations also incorporate physical color references or embedded calibration tools.Expand Specific Solutions

Leading Companies in Display and Color Management

The OLED color accuracy versus print fidelity landscape is evolving rapidly, with the market currently in a growth phase as display technologies mature. The global market for color-accurate displays is expanding significantly, driven by professional and consumer demand for precise color reproduction. Technologically, companies like Samsung Display, BOE Technology, and LG Display (via Global OLED Technology) lead OLED development, while traditional print color management remains dominated by X-Rite and Eastman Kodak. The convergence of these fields is creating new opportunities, with companies like OSRAM Opto Semiconductors and Applied Materials developing technologies to bridge the gap between OLED display accuracy and print color fidelity. Research collaborations between display manufacturers and color science specialists are accelerating progress toward achieving print-equivalent color reproduction in digital displays.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive color accuracy solution for their OLED displays called "Print-True Color" technology. This system incorporates multi-point color calibration during manufacturing, ensuring each panel meets strict color accuracy standards before leaving the factory. BOE's approach includes proprietary compensation algorithms that account for the inherent differences between emissive (OLED) and reflective (print) color reproduction methods. Their latest OLED panels feature 10-bit color depth processing with advanced color management systems that can simulate various print color profiles including SWOP, FOGRA, and GRACoL standards. BOE has implemented specialized spectral power distribution optimization techniques that allow their OLED displays to more accurately represent the subtle color nuances found in printed materials. Additionally, their displays incorporate ambient light sensors that automatically adjust color temperature and gamma to maintain perceptual color consistency across different viewing environments, addressing one of the key challenges in matching display output to print references.

Strengths: Comprehensive factory calibration process ensures consistent quality; specialized algorithms for print-to-display color matching; advanced ambient light compensation. Weaknesses: Technology primarily focused on professional markets with less implementation in consumer products; requires periodic recalibration for optimal performance; higher manufacturing costs compared to standard OLED panels.

HP Development Co. LP

Technical Solution: HP has developed DreamColor technology, a comprehensive color management solution that addresses the challenges of matching OLED display output to print materials. Their approach combines hardware calibration with sophisticated software algorithms to ensure consistent color reproduction across different media. HP's solution incorporates factory-calibrated OLED panels with delta-E values below 1.0 across the entire color gamut, significantly exceeding industry standards. Their proprietary color mapping technology creates device-specific color transformations that account for the fundamental differences between emissive OLED displays and reflective print surfaces. HP has implemented specialized gamut mapping algorithms that intelligently compress the wider color gamut of OLED displays to match print color spaces while preserving color relationships and detail. Their technology includes ambient light compensation that adjusts display output based on viewing conditions to maintain perceptual color matching with print materials. HP's solution also features built-in verification tools that provide objective measurements of color accuracy between display and print output, allowing for continuous optimization of color fidelity across the workflow.

Strengths: End-to-end solution covering both display and print technologies; sophisticated gamut mapping algorithms; built-in verification tools for objective measurement. Weaknesses: Premium pricing positions technology primarily for professional markets; requires HP ecosystem for optimal performance; complex setup process for achieving maximum accuracy.

Key Color Science Innovations and Standards

Organic electroluminescent materials and devices

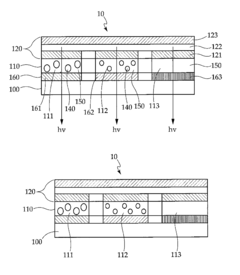

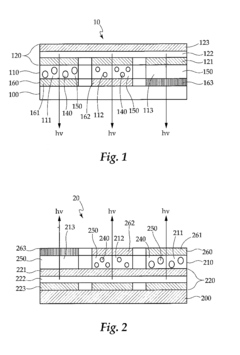

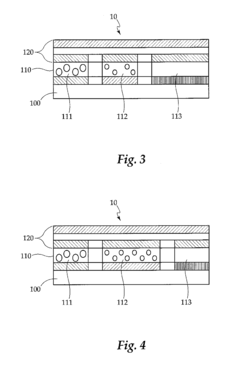

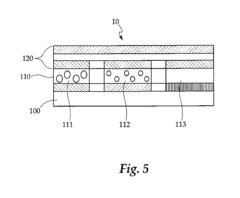

PatentPendingUS20240365658A1

Innovation

- A novel compound of Formula I is introduced, which includes specific monocyclic or polycyclic ring systems and electron-withdrawing groups, used in OLED formulations and devices to enhance color emission properties, allowing for improved color accuracy and efficiency by optimizing the energy levels and structural configurations of the organic layers.

Color organic light-emitting diode display device

PatentActiveUS8564187B2

Innovation

- Incorporating a color conversion layer between the white light emitting diode and the color filter layer, utilizing semiconductor nanocrystals dispersed in an organic binding material, such as polycarbonate or polyacrylate, to enhance the conversion of white light into red and green colors, while maintaining blue light emission.

Color Gamut Limitations and Expansion Techniques

The color gamut represents the range of colors a display device can reproduce, and OLED displays face inherent limitations in accurately matching printed materials. Current OLED displays typically cover between 70-100% of the DCI-P3 color space, while high-quality print can achieve colors within the CMYK gamut that fall outside this range. This fundamental difference creates challenges when attempting to achieve color fidelity across these different media types.

Several technical approaches have emerged to expand OLED color gamuts. Quantum dot enhancement films (QDEF) represent a significant advancement, allowing for purer color emission by narrowing the spectral output of each primary color. This technology can expand the color gamut by up to 25% compared to conventional OLED displays, bringing them closer to print capabilities in certain color regions.

Material innovations have also contributed to gamut expansion. New emitter materials, particularly those utilizing thermally activated delayed fluorescence (TADF), demonstrate improved color purity and efficiency. These materials can achieve narrower emission spectra, resulting in more saturated colors that extend the boundaries of reproducible color space, particularly in the green-cyan regions where traditional OLEDs often underperform compared to print.

Computational color mapping techniques offer another approach to addressing gamut limitations. Advanced color management systems (CMS) employ sophisticated algorithms to map colors from wider gamuts to the display's native capabilities while preserving perceptual relationships. Techniques such as gamut mapping with perceptual intent and chromatic adaptation transformations help maintain the visual impression of printed materials even when the exact colorimetric values cannot be reproduced.

Multi-primary color systems represent a more radical solution, moving beyond the traditional RGB structure to incorporate additional primary colors. Some experimental OLED displays have implemented four, five, or even six primary colors, significantly expanding the color gamut. These systems can achieve up to 90% coverage of visible colors, approaching the theoretical maximum for surface color reproduction and substantially closing the gap with print capabilities.

Hardware calibration systems have become increasingly sophisticated, allowing for precise adjustment of color output across the entire gamut. Factory calibration combined with on-device sensors enables continuous monitoring and adjustment of color accuracy throughout the display's lifecycle. This approach helps maintain consistency between OLED displays and print references, even as components age and performance characteristics change over time.

Several technical approaches have emerged to expand OLED color gamuts. Quantum dot enhancement films (QDEF) represent a significant advancement, allowing for purer color emission by narrowing the spectral output of each primary color. This technology can expand the color gamut by up to 25% compared to conventional OLED displays, bringing them closer to print capabilities in certain color regions.

Material innovations have also contributed to gamut expansion. New emitter materials, particularly those utilizing thermally activated delayed fluorescence (TADF), demonstrate improved color purity and efficiency. These materials can achieve narrower emission spectra, resulting in more saturated colors that extend the boundaries of reproducible color space, particularly in the green-cyan regions where traditional OLEDs often underperform compared to print.

Computational color mapping techniques offer another approach to addressing gamut limitations. Advanced color management systems (CMS) employ sophisticated algorithms to map colors from wider gamuts to the display's native capabilities while preserving perceptual relationships. Techniques such as gamut mapping with perceptual intent and chromatic adaptation transformations help maintain the visual impression of printed materials even when the exact colorimetric values cannot be reproduced.

Multi-primary color systems represent a more radical solution, moving beyond the traditional RGB structure to incorporate additional primary colors. Some experimental OLED displays have implemented four, five, or even six primary colors, significantly expanding the color gamut. These systems can achieve up to 90% coverage of visible colors, approaching the theoretical maximum for surface color reproduction and substantially closing the gap with print capabilities.

Hardware calibration systems have become increasingly sophisticated, allowing for precise adjustment of color output across the entire gamut. Factory calibration combined with on-device sensors enables continuous monitoring and adjustment of color accuracy throughout the display's lifecycle. This approach helps maintain consistency between OLED displays and print references, even as components age and performance characteristics change over time.

Human Perception Factors in Display vs Print Evaluation

Human perception plays a critical role in evaluating color accuracy between OLED displays and printed materials. The human visual system processes color information through three types of cone cells sensitive to different wavelengths, creating a complex perceptual experience that cannot be fully captured by technical measurements alone. This biological foundation creates inherent differences in how viewers perceive colors across different media.

When comparing OLED displays to print, several key perceptual factors influence viewer assessment. Ambient lighting conditions significantly impact color perception, with displays emitting light (additive color) while printed materials reflect light (subtractive color). This fundamental difference means that the same color values can appear dramatically different between media types depending on viewing environment. Research indicates that viewers tend to perceive OLED colors as more vibrant under low-light conditions, while printed materials maintain more consistent appearance across varied lighting.

Viewing angle represents another critical perceptual variable. While modern OLED displays have improved off-axis color consistency, they still exhibit some degree of color shift when viewed from extreme angles. Printed materials generally maintain more consistent color appearance across viewing angles, though glossy prints may suffer from reflective glare that alters perceived color accuracy.

Psychological factors further complicate cross-media color evaluation. Studies show that viewers have different expectations for digital versus printed color, with higher tolerance for certain color variations in displays compared to print. Memory colors—particularly skin tones, brand colors, and natural elements—serve as perceptual anchors against which viewers judge overall color fidelity. Research by Fairchild and Johnson (2004) demonstrated that viewers prioritize the accuracy of these memory colors over technical color metrics.

Adaptation mechanisms also influence cross-media evaluation. The human visual system adjusts to the white point of different media, creating a normalized reference frame. This adaptation occurs more readily with self-luminous displays than with reflective print media, resulting in different perceptual baselines for color judgment. Viewers typically require 5-10 minutes to fully adapt to a new white point, which can significantly impact side-by-side comparisons of OLED and print materials.

Fatigue effects further complicate extended evaluation sessions, with studies showing decreased sensitivity to subtle color differences after prolonged viewing. This phenomenon affects display evaluation more significantly than print assessment due to the direct light emission from OLED screens.

When comparing OLED displays to print, several key perceptual factors influence viewer assessment. Ambient lighting conditions significantly impact color perception, with displays emitting light (additive color) while printed materials reflect light (subtractive color). This fundamental difference means that the same color values can appear dramatically different between media types depending on viewing environment. Research indicates that viewers tend to perceive OLED colors as more vibrant under low-light conditions, while printed materials maintain more consistent appearance across varied lighting.

Viewing angle represents another critical perceptual variable. While modern OLED displays have improved off-axis color consistency, they still exhibit some degree of color shift when viewed from extreme angles. Printed materials generally maintain more consistent color appearance across viewing angles, though glossy prints may suffer from reflective glare that alters perceived color accuracy.

Psychological factors further complicate cross-media color evaluation. Studies show that viewers have different expectations for digital versus printed color, with higher tolerance for certain color variations in displays compared to print. Memory colors—particularly skin tones, brand colors, and natural elements—serve as perceptual anchors against which viewers judge overall color fidelity. Research by Fairchild and Johnson (2004) demonstrated that viewers prioritize the accuracy of these memory colors over technical color metrics.

Adaptation mechanisms also influence cross-media evaluation. The human visual system adjusts to the white point of different media, creating a normalized reference frame. This adaptation occurs more readily with self-luminous displays than with reflective print media, resulting in different perceptual baselines for color judgment. Viewers typically require 5-10 minutes to fully adapt to a new white point, which can significantly impact side-by-side comparisons of OLED and print materials.

Fatigue effects further complicate extended evaluation sessions, with studies showing decreased sensitivity to subtle color differences after prolonged viewing. This phenomenon affects display evaluation more significantly than print assessment due to the direct light emission from OLED screens.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!