OLED Reliability in Automotive Displays: Testing and Results

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Automotive OLED Display Technology Evolution and Objectives

The automotive display market has witnessed a significant transformation over the past decade, evolving from simple instrument clusters to sophisticated infotainment systems. OLED (Organic Light Emitting Diode) technology has emerged as a promising solution for next-generation automotive displays due to its superior visual performance, flexibility, and potential for innovative form factors. The evolution of OLED technology in automotive applications can be traced through several distinct phases, each marked by technological breakthroughs and increasing industry adoption.

In the early 2010s, OLED displays were primarily confined to consumer electronics, with automotive applications limited by reliability concerns under extreme temperature conditions and prolonged exposure to sunlight. By 2015, advancements in OLED materials science enabled the first premium vehicles to incorporate small OLED displays in secondary interfaces. The period from 2016 to 2019 saw significant improvements in OLED durability and manufacturing processes, allowing for larger implementations in concept vehicles and limited production models.

The current phase (2020-2023) represents a critical inflection point, with major automotive manufacturers integrating OLED technology into production vehicles across multiple segments. This acceleration has been driven by breakthroughs in encapsulation techniques, thermal management solutions, and the development of automotive-grade OLED materials with enhanced resistance to environmental stressors.

Looking at the technical evolution, first-generation automotive OLEDs suffered from limited lifespans (approximately 10,000 hours) and significant brightness degradation when exposed to temperatures above 85°C. Current generation displays have achieved operational lifespans exceeding 30,000 hours with stable performance across the automotive temperature range (-40°C to 105°C), representing a transformative improvement in reliability metrics.

The primary objectives for OLED reliability testing in automotive applications focus on several critical parameters: operational longevity under varying temperature conditions, resistance to humidity ingress, color stability under UV exposure, and performance consistency during thermal cycling. Additional objectives include validating mechanical durability against vibration and shock, as well as assessing degradation patterns under accelerated aging conditions to predict real-world performance over a vehicle's lifecycle.

Industry standards for automotive displays, such as USCAR-24 and AEC-Q100, have been adapted to address the unique characteristics of OLED technology, establishing new testing protocols and performance thresholds. The ultimate goal remains achieving a minimum 15-year operational lifespan with less than 20% luminance degradation under automotive conditions, a benchmark that continues to drive innovation in materials science and manufacturing processes.

In the early 2010s, OLED displays were primarily confined to consumer electronics, with automotive applications limited by reliability concerns under extreme temperature conditions and prolonged exposure to sunlight. By 2015, advancements in OLED materials science enabled the first premium vehicles to incorporate small OLED displays in secondary interfaces. The period from 2016 to 2019 saw significant improvements in OLED durability and manufacturing processes, allowing for larger implementations in concept vehicles and limited production models.

The current phase (2020-2023) represents a critical inflection point, with major automotive manufacturers integrating OLED technology into production vehicles across multiple segments. This acceleration has been driven by breakthroughs in encapsulation techniques, thermal management solutions, and the development of automotive-grade OLED materials with enhanced resistance to environmental stressors.

Looking at the technical evolution, first-generation automotive OLEDs suffered from limited lifespans (approximately 10,000 hours) and significant brightness degradation when exposed to temperatures above 85°C. Current generation displays have achieved operational lifespans exceeding 30,000 hours with stable performance across the automotive temperature range (-40°C to 105°C), representing a transformative improvement in reliability metrics.

The primary objectives for OLED reliability testing in automotive applications focus on several critical parameters: operational longevity under varying temperature conditions, resistance to humidity ingress, color stability under UV exposure, and performance consistency during thermal cycling. Additional objectives include validating mechanical durability against vibration and shock, as well as assessing degradation patterns under accelerated aging conditions to predict real-world performance over a vehicle's lifecycle.

Industry standards for automotive displays, such as USCAR-24 and AEC-Q100, have been adapted to address the unique characteristics of OLED technology, establishing new testing protocols and performance thresholds. The ultimate goal remains achieving a minimum 15-year operational lifespan with less than 20% luminance degradation under automotive conditions, a benchmark that continues to drive innovation in materials science and manufacturing processes.

Market Analysis for OLED in Automotive HMI Applications

The automotive display market is witnessing a significant shift towards OLED technology, with the global automotive display market projected to reach $30.8 billion by 2025, growing at a CAGR of 8.2% from 2020. Within this broader market, OLED displays are experiencing accelerated adoption, particularly in premium and luxury vehicle segments where enhanced user experience and aesthetic appeal are paramount considerations.

The demand for OLED in automotive Human-Machine Interface (HMI) applications is primarily driven by several key factors. First, the superior visual performance of OLED displays, including perfect black levels, infinite contrast ratios, and wider color gamut, enables more intuitive and visually appealing interfaces. This aligns with the automotive industry's increasing focus on creating differentiated user experiences as vehicles evolve toward becoming digital mobility platforms.

Consumer expectations are increasingly shaped by experiences with OLED technology in consumer electronics, creating a spillover effect into automotive expectations. Market research indicates that 67% of new car buyers consider display quality and responsiveness as important factors in their purchasing decisions, up from 43% just five years ago.

From a regional perspective, Europe and North America currently lead in OLED adoption for automotive applications, with premium German manufacturers like Audi, BMW, and Mercedes-Benz integrating OLED displays into their flagship models. The Asia-Pacific region, particularly China, is expected to demonstrate the fastest growth rate in the coming years, driven by domestic manufacturers seeking to compete on technology and user experience.

Market segmentation analysis reveals that instrument clusters and center information displays represent the largest application areas for automotive OLED, accounting for approximately 58% of the market. However, emerging applications such as passenger entertainment displays and smart surface integrations are expected to grow at above-market rates over the next five years.

The market structure is currently characterized by a premium price positioning, with OLED displays commanding a 30-40% price premium over comparable LCD solutions. However, this gap is expected to narrow as manufacturing scales and yield rates improve, potentially accelerating adoption in mid-market vehicle segments by 2024-2025.

A critical market consideration for automotive OLED adoption remains reliability concerns, particularly regarding operational lifetime under automotive conditions. Recent reliability testing results showing improvements in high-temperature performance and reduced burn-in susceptibility are positively influencing market forecasts, with several tier-one suppliers reporting increased RFQs for OLED-based solutions from OEMs previously hesitant about the technology.

The demand for OLED in automotive Human-Machine Interface (HMI) applications is primarily driven by several key factors. First, the superior visual performance of OLED displays, including perfect black levels, infinite contrast ratios, and wider color gamut, enables more intuitive and visually appealing interfaces. This aligns with the automotive industry's increasing focus on creating differentiated user experiences as vehicles evolve toward becoming digital mobility platforms.

Consumer expectations are increasingly shaped by experiences with OLED technology in consumer electronics, creating a spillover effect into automotive expectations. Market research indicates that 67% of new car buyers consider display quality and responsiveness as important factors in their purchasing decisions, up from 43% just five years ago.

From a regional perspective, Europe and North America currently lead in OLED adoption for automotive applications, with premium German manufacturers like Audi, BMW, and Mercedes-Benz integrating OLED displays into their flagship models. The Asia-Pacific region, particularly China, is expected to demonstrate the fastest growth rate in the coming years, driven by domestic manufacturers seeking to compete on technology and user experience.

Market segmentation analysis reveals that instrument clusters and center information displays represent the largest application areas for automotive OLED, accounting for approximately 58% of the market. However, emerging applications such as passenger entertainment displays and smart surface integrations are expected to grow at above-market rates over the next five years.

The market structure is currently characterized by a premium price positioning, with OLED displays commanding a 30-40% price premium over comparable LCD solutions. However, this gap is expected to narrow as manufacturing scales and yield rates improve, potentially accelerating adoption in mid-market vehicle segments by 2024-2025.

A critical market consideration for automotive OLED adoption remains reliability concerns, particularly regarding operational lifetime under automotive conditions. Recent reliability testing results showing improvements in high-temperature performance and reduced burn-in susceptibility are positively influencing market forecasts, with several tier-one suppliers reporting increased RFQs for OLED-based solutions from OEMs previously hesitant about the technology.

OLED Reliability Challenges in Harsh Automotive Environments

The automotive industry presents one of the most challenging environments for display technologies, with OLED displays facing particularly severe reliability challenges. Unlike consumer electronics, automotive displays must maintain performance integrity under extreme temperature fluctuations ranging from -40°C to +85°C, far exceeding the typical 0°C to 40°C range of consumer devices. These thermal stresses significantly impact OLED material stability, accelerating degradation mechanisms and reducing operational lifespan.

Humidity and moisture represent another critical challenge, as automotive cabins experience humidity levels from 5% to 95%, with condensation cycles that can compromise the hermetic sealing of OLED panels. Even minor moisture ingress can catalyze chemical reactions that lead to dark spot formation and pixel degradation, particularly at the edges of the display where sealing is most vulnerable.

Continuous vibration and mechanical shock present unique challenges for automotive OLEDs. Vehicle displays must withstand constant vibrations of 10-500 Hz and occasional impacts up to 100G during their operational lifetime. These mechanical stresses can compromise the structural integrity of thin-film transistors, pixel connections, and encapsulation layers, leading to premature failure modes not typically observed in stationary applications.

UV radiation exposure through windshields and windows accelerates photochemical degradation of organic materials in OLEDs. Studies indicate that automotive-grade displays may receive up to 5 times more cumulative UV exposure than consumer devices, necessitating enhanced UV-filtering solutions and more stable organic compounds to maintain color accuracy and brightness over the vehicle's lifetime.

Power supply variations in automotive electrical systems, which can fluctuate between 9-16V and experience transient spikes up to 40V, create additional stress on OLED driver circuits. These fluctuations can cause uneven aging across the display if not properly managed through sophisticated power conditioning systems.

The expected operational lifetime for automotive components (typically 10-15 years) far exceeds consumer electronics (2-3 years), requiring OLED technologies to demonstrate unprecedented longevity. This extended lifetime requirement is particularly challenging given that blue OLED emitters typically show faster degradation rates than red or green counterparts, leading to color shift over time.

Additionally, automotive displays operate at higher brightness levels (typically 600-1000 nits) than consumer devices to ensure readability in direct sunlight, which accelerates the aging process of organic materials. This high-brightness requirement creates a fundamental tension between performance specifications and reliability targets that must be carefully balanced in automotive OLED applications.

Humidity and moisture represent another critical challenge, as automotive cabins experience humidity levels from 5% to 95%, with condensation cycles that can compromise the hermetic sealing of OLED panels. Even minor moisture ingress can catalyze chemical reactions that lead to dark spot formation and pixel degradation, particularly at the edges of the display where sealing is most vulnerable.

Continuous vibration and mechanical shock present unique challenges for automotive OLEDs. Vehicle displays must withstand constant vibrations of 10-500 Hz and occasional impacts up to 100G during their operational lifetime. These mechanical stresses can compromise the structural integrity of thin-film transistors, pixel connections, and encapsulation layers, leading to premature failure modes not typically observed in stationary applications.

UV radiation exposure through windshields and windows accelerates photochemical degradation of organic materials in OLEDs. Studies indicate that automotive-grade displays may receive up to 5 times more cumulative UV exposure than consumer devices, necessitating enhanced UV-filtering solutions and more stable organic compounds to maintain color accuracy and brightness over the vehicle's lifetime.

Power supply variations in automotive electrical systems, which can fluctuate between 9-16V and experience transient spikes up to 40V, create additional stress on OLED driver circuits. These fluctuations can cause uneven aging across the display if not properly managed through sophisticated power conditioning systems.

The expected operational lifetime for automotive components (typically 10-15 years) far exceeds consumer electronics (2-3 years), requiring OLED technologies to demonstrate unprecedented longevity. This extended lifetime requirement is particularly challenging given that blue OLED emitters typically show faster degradation rates than red or green counterparts, leading to color shift over time.

Additionally, automotive displays operate at higher brightness levels (typically 600-1000 nits) than consumer devices to ensure readability in direct sunlight, which accelerates the aging process of organic materials. This high-brightness requirement creates a fundamental tension between performance specifications and reliability targets that must be carefully balanced in automotive OLED applications.

Current OLED Reliability Testing Methodologies and Standards

01 Encapsulation techniques for OLED reliability

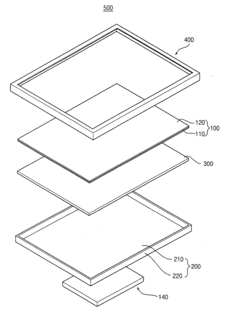

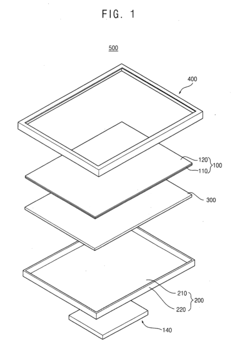

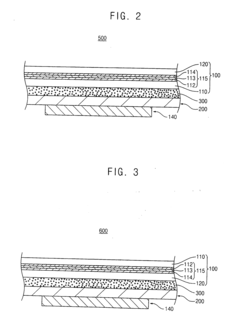

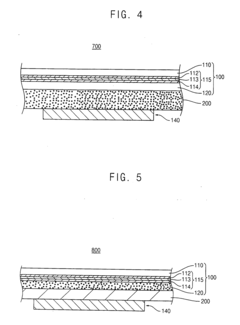

Various encapsulation methods are employed to protect OLED displays from environmental factors like moisture and oxygen, which can significantly degrade device performance. Advanced techniques include thin-film encapsulation, multi-layer barrier structures, and hermetic sealing technologies. These approaches effectively prevent the penetration of harmful elements, extending the operational lifetime of OLED displays and maintaining their luminance efficiency over time.- Encapsulation techniques for OLED reliability: Various encapsulation methods are employed to protect OLED displays from environmental factors such as moisture and oxygen, which can significantly degrade device performance. Advanced thin-film encapsulation layers, barrier films, and hermetic sealing technologies help extend the operational lifetime of OLEDs by preventing the penetration of harmful elements. These techniques often involve multiple layers of inorganic and organic materials to create effective moisture barriers while maintaining flexibility where required.

- Pixel circuit designs for uniform aging: Specialized pixel circuit architectures are developed to ensure uniform aging and consistent brightness across the OLED display over time. These circuits incorporate compensation mechanisms for threshold voltage shifts and current variations that occur as OLED materials degrade. By implementing advanced driving schemes, current programming methods, and feedback systems, these designs can significantly improve the long-term reliability and image quality of OLED displays, preventing issues like image retention and uneven brightness.

- Material innovations for extended lifetime: Novel OLED materials are developed to enhance operational stability and extend device lifetime. These include improved emissive materials with higher quantum efficiency, more stable host materials, and robust charge transport layers. By engineering molecular structures that resist degradation mechanisms such as exciton quenching and chemical decomposition, these materials can significantly improve the reliability of OLED displays under various operating conditions, including high brightness levels and elevated temperatures.

- Thermal management solutions: Effective thermal management systems are implemented to prevent temperature-related degradation in OLED displays. These solutions include heat dissipation structures, thermal interface materials, and active cooling mechanisms that help maintain optimal operating temperatures. By controlling heat generation and distribution across the display panel, these approaches mitigate thermal stress on OLED materials and driving circuits, thereby enhancing device reliability and preventing accelerated aging that occurs at elevated temperatures.

- Stress testing and reliability prediction methods: Advanced testing methodologies and predictive models are developed to evaluate and forecast OLED display reliability. These include accelerated aging tests, stress testing under various environmental conditions, and statistical models that correlate test results with real-world performance. By identifying potential failure mechanisms and quantifying their impact on device lifetime, these methods enable manufacturers to optimize display designs and materials for enhanced reliability before mass production, as well as to provide accurate lifetime estimates for different usage scenarios.

02 Thermal management solutions for OLED longevity

Heat generation during OLED operation can accelerate device degradation and reduce reliability. Innovative thermal management solutions include heat dissipation structures, thermally conductive materials, and optimized device architectures that minimize thermal stress. These solutions help maintain stable operating temperatures, prevent thermal degradation of organic materials, and significantly improve the overall reliability and lifetime of OLED displays.Expand Specific Solutions03 Material innovations for enhanced OLED stability

Advanced materials play a crucial role in improving OLED reliability. Novel organic emitters, charge transport materials, and electrode compositions with enhanced stability under electrical stress and environmental conditions are being developed. These materials demonstrate improved resistance to degradation mechanisms, reduced efficiency loss over time, and better compatibility with manufacturing processes, resulting in more reliable and longer-lasting OLED displays.Expand Specific Solutions04 Driving scheme optimizations for reliability enhancement

Specialized driving schemes and compensation algorithms are implemented to improve OLED display reliability. These include voltage/current compensation techniques, aging compensation algorithms, and optimized refresh methods that reduce electrical stress on pixels. By dynamically adjusting driving parameters based on usage patterns and device conditions, these approaches minimize degradation mechanisms like voltage drift and threshold voltage shifts, extending the useful life of OLED displays.Expand Specific Solutions05 Structural design improvements for mechanical durability

Mechanical reliability of OLED displays is enhanced through innovative structural designs. Flexible substrates, stress-relieving layers, neutral plane concepts, and reinforced edge structures improve resistance to bending, folding, and impact damage. These structural improvements allow OLED displays to maintain performance integrity under mechanical stress, making them suitable for applications requiring flexibility or durability while preserving their electrical and optical characteristics.Expand Specific Solutions

Key Automotive Display Manufacturers and OLED Suppliers

The OLED reliability in automotive displays market is currently in a growth phase, with increasing adoption despite technical challenges. The market is projected to expand significantly as automotive manufacturers integrate more advanced display technologies. In terms of technological maturity, companies like Samsung Display, LG Display, and BOE Technology Group are leading with established OLED manufacturing capabilities and automotive-specific solutions. Continental Automotive Technologies and AUDI AG are driving integration requirements, while specialized players like Tianma Microelectronics and Visionox are developing automotive-grade OLED technologies with enhanced durability. Testing methodologies are advancing through collaborations between display manufacturers and automotive OEMs to address temperature extremes, vibration resistance, and long-term reliability concerns unique to automotive environments.

Samsung Display Co., Ltd.

Technical Solution: Samsung has developed advanced OLED reliability solutions specifically for automotive environments through their Samsung Advanced OLED Technology for Automotive (SAOTA) platform. Their approach includes multi-layer encapsulation technology that provides superior protection against moisture and oxygen penetration, critical for automotive environments where displays face extreme temperature variations (-40°C to 85°C). Samsung implements accelerated aging tests that simulate up to 10 years of automotive use conditions, including high-temperature operation (85°C), high-humidity exposure (85% RH), and thermal cycling tests. Their proprietary compensation algorithms dynamically adjust pixel driving to prevent burn-in effects, particularly important for fixed UI elements in automotive displays[1]. Samsung's automotive OLEDs incorporate specialized blue emitters with extended lifetimes, achieving over 30,000 hours of operation at typical automotive brightness levels while maintaining color accuracy within automotive specifications[3].

Strengths: Industry-leading encapsulation technology providing superior moisture resistance; comprehensive testing protocols exceeding automotive standards; advanced compensation algorithms for burn-in prevention. Weaknesses: Higher production costs compared to LCD alternatives; limited production capacity specifically for automotive-grade OLED panels; relatively new entrant to automotive supply chains compared to established players.

LG Display Co., Ltd.

Technical Solution: LG Display has pioneered P-OLED (Plastic OLED) technology specifically engineered for automotive environments, featuring a flexible plastic substrate instead of glass that enhances durability against vibration and impact. Their automotive OLED reliability testing protocol includes rigorous environmental stress screening with over 5,000 hours of high-temperature operation testing (85°C), 1,000 thermal shock cycles (-40°C to 85°C), and vibration testing at frequencies matching automotive cabin conditions (10-500Hz). LG implements a multi-barrier thin film encapsulation (TFE) structure with alternating inorganic and organic layers that achieves a water vapor transmission rate below 10^-6 g/m²/day, critical for preventing moisture-induced degradation in automotive environments[2]. Their displays undergo accelerated lifetime testing simulating 15 years of automotive use, with specialized testing for dashboard applications where sunlight readability is crucial (tested at 30,000+ lux ambient light conditions)[4]. LG's automotive OLEDs feature localized brightness enhancement technology that selectively boosts brightness in areas exposed to direct sunlight while maintaining normal operation elsewhere to extend overall panel lifetime.

Strengths: Industry-leading P-OLED technology offering superior flexibility and durability; extensive automotive-specific reliability testing protocols; established relationships with major automotive OEMs. Weaknesses: Higher cost structure compared to traditional display technologies; challenges with uniform production of large-format automotive displays; potential for image retention in static interface elements over extended use periods.

Critical Patents and Research on Automotive OLED Durability

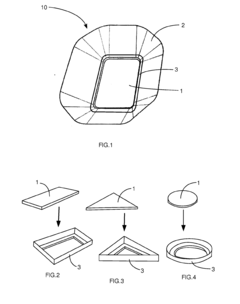

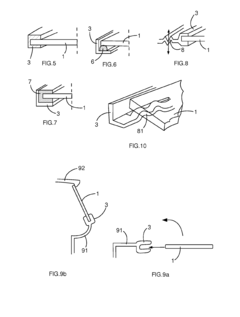

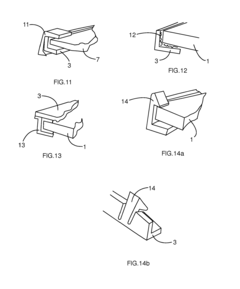

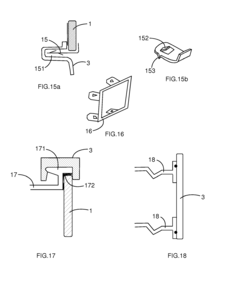

Lighting and/or signalling device for an automobile including a surface light source

PatentInactiveEP2592331A1

Innovation

- A lighting and/or signaling device for vehicles that incorporates a surface light source, such as an OLED, with a fixing element and a damping element to absorb vibrations and mechanical stresses, enhancing the reliability and durability of the OLEDs by using a flexible and deformable damping element to connect the surface light source to the vehicle structure.

Organic light-emitting diode display device

PatentActiveUS20080007159A1

Innovation

- Incorporating a heat insulating member made of porous polymer between the display panel and the driving circuit part, or between the display panel and the receiving container, to prevent heat generated by the driving circuit from reaching the light-emitting layer, thereby maintaining a lower temperature and reducing degradation.

Thermal Management Solutions for Automotive OLED Displays

Thermal management represents a critical challenge for automotive OLED displays, as these displays are particularly sensitive to temperature fluctuations. Unlike their LCD counterparts, OLED displays experience accelerated degradation when operating at elevated temperatures, which can significantly impact their reliability and longevity in automotive environments.

Current thermal management solutions for automotive OLED displays employ multi-layered approaches to address heat dissipation. Passive cooling techniques include specialized heat-spreading materials integrated into display assemblies, such as graphite sheets and metal heat sinks. These materials effectively conduct heat away from critical display components, preventing localized hotspots that could accelerate pixel degradation.

Active cooling systems have also been developed specifically for automotive OLED implementations. Microfluidic cooling channels embedded within display housings allow for efficient heat transfer without adding significant bulk to the assembly. Additionally, thermoelectric cooling elements strategically positioned behind high-heat-generating areas provide targeted temperature control during peak operation conditions.

Advanced thermal interface materials (TIMs) play a crucial role in optimizing heat transfer between components. Recent developments in nano-enhanced TIMs have demonstrated thermal conductivity improvements of up to 45% compared to conventional materials, enabling more efficient heat dissipation while maintaining the slim profile demanded by automotive interior design requirements.

Computational fluid dynamics (CFD) modeling has become an essential tool in the design phase of automotive OLED displays. These simulations allow engineers to identify potential thermal issues before physical prototyping, optimizing airflow patterns and component placement to maximize natural convection cooling effects within the confined dashboard environment.

Adaptive thermal management systems represent the cutting edge of this technology. These systems utilize temperature sensors distributed throughout the display assembly to continuously monitor thermal conditions. When temperature thresholds are approached, the system can dynamically adjust display brightness, activate cooling mechanisms, or redistribute processing loads to prevent thermal damage while maintaining essential functionality.

Testing protocols for these thermal solutions typically involve accelerated aging under various temperature profiles that simulate extreme automotive conditions, from cold starts in sub-zero environments to prolonged exposure to direct sunlight. Results indicate that properly implemented thermal management systems can extend OLED display lifetime by 30-40% under automotive operating conditions compared to displays without specialized thermal considerations.

Current thermal management solutions for automotive OLED displays employ multi-layered approaches to address heat dissipation. Passive cooling techniques include specialized heat-spreading materials integrated into display assemblies, such as graphite sheets and metal heat sinks. These materials effectively conduct heat away from critical display components, preventing localized hotspots that could accelerate pixel degradation.

Active cooling systems have also been developed specifically for automotive OLED implementations. Microfluidic cooling channels embedded within display housings allow for efficient heat transfer without adding significant bulk to the assembly. Additionally, thermoelectric cooling elements strategically positioned behind high-heat-generating areas provide targeted temperature control during peak operation conditions.

Advanced thermal interface materials (TIMs) play a crucial role in optimizing heat transfer between components. Recent developments in nano-enhanced TIMs have demonstrated thermal conductivity improvements of up to 45% compared to conventional materials, enabling more efficient heat dissipation while maintaining the slim profile demanded by automotive interior design requirements.

Computational fluid dynamics (CFD) modeling has become an essential tool in the design phase of automotive OLED displays. These simulations allow engineers to identify potential thermal issues before physical prototyping, optimizing airflow patterns and component placement to maximize natural convection cooling effects within the confined dashboard environment.

Adaptive thermal management systems represent the cutting edge of this technology. These systems utilize temperature sensors distributed throughout the display assembly to continuously monitor thermal conditions. When temperature thresholds are approached, the system can dynamically adjust display brightness, activate cooling mechanisms, or redistribute processing loads to prevent thermal damage while maintaining essential functionality.

Testing protocols for these thermal solutions typically involve accelerated aging under various temperature profiles that simulate extreme automotive conditions, from cold starts in sub-zero environments to prolonged exposure to direct sunlight. Results indicate that properly implemented thermal management systems can extend OLED display lifetime by 30-40% under automotive operating conditions compared to displays without specialized thermal considerations.

Safety Certification Requirements for Vehicle Display Systems

Automotive display systems must adhere to stringent safety certification requirements due to their critical role in vehicle operation and driver information systems. For OLED displays in automotive applications, these requirements are particularly demanding given the harsh operating conditions and safety-critical nature of automotive environments. The primary certification standards include ISO 26262 (Functional Safety for Road Vehicles), which categorizes automotive systems into Automotive Safety Integrity Levels (ASIL) from A to D based on risk assessment. OLED displays in instrument clusters typically require ASIL B or C certification, while entertainment displays may qualify for lower ratings.

The ECE Regulation No. 21 governs interior fittings and specifically addresses display systems regarding impact resistance and fragmentation behavior during accidents. This standard ensures that OLED displays do not create additional hazards during collision events. Additionally, the SAE J3168 standard specifically addresses optical performance requirements for automotive displays, including criteria for readability under various lighting conditions, which is crucial for OLED technology given its high contrast capabilities.

Environmental testing requirements outlined in ISO 16750 are particularly relevant for OLED reliability assessment, specifying temperature ranges (-40°C to +85°C), humidity resistance, vibration tolerance, and electromagnetic compatibility (EMC) standards. OLED displays must demonstrate consistent performance across these extreme conditions without degradation that could compromise safety-critical information display.

The EMC requirements defined in CISPR 25 and ISO 11452 are especially challenging for OLED technology due to its active-matrix driving circuits. These standards ensure that displays neither emit electromagnetic interference that could affect other vehicle systems nor are susceptible to external electromagnetic fields that could cause display malfunctions or information loss.

Photometric and colorimetric requirements in the automotive context are governed by standards like SAE J1757-1, which specifies minimum luminance levels (typically 600-1000 cd/m² for daylight readability) and color gamut specifications. OLED technology must maintain these specifications throughout its operational lifetime despite known degradation mechanisms.

The certification process for automotive OLED displays involves extensive documentation of the design process, risk analysis, verification testing, and validation procedures. Manufacturers must implement robust quality management systems compliant with IATF 16949, the automotive industry's quality management standard, and provide evidence of reliability testing that simulates the full vehicle lifecycle, typically 10-15 years of operation under varying conditions.

The ECE Regulation No. 21 governs interior fittings and specifically addresses display systems regarding impact resistance and fragmentation behavior during accidents. This standard ensures that OLED displays do not create additional hazards during collision events. Additionally, the SAE J3168 standard specifically addresses optical performance requirements for automotive displays, including criteria for readability under various lighting conditions, which is crucial for OLED technology given its high contrast capabilities.

Environmental testing requirements outlined in ISO 16750 are particularly relevant for OLED reliability assessment, specifying temperature ranges (-40°C to +85°C), humidity resistance, vibration tolerance, and electromagnetic compatibility (EMC) standards. OLED displays must demonstrate consistent performance across these extreme conditions without degradation that could compromise safety-critical information display.

The EMC requirements defined in CISPR 25 and ISO 11452 are especially challenging for OLED technology due to its active-matrix driving circuits. These standards ensure that displays neither emit electromagnetic interference that could affect other vehicle systems nor are susceptible to external electromagnetic fields that could cause display malfunctions or information loss.

Photometric and colorimetric requirements in the automotive context are governed by standards like SAE J1757-1, which specifies minimum luminance levels (typically 600-1000 cd/m² for daylight readability) and color gamut specifications. OLED technology must maintain these specifications throughout its operational lifetime despite known degradation mechanisms.

The certification process for automotive OLED displays involves extensive documentation of the design process, risk analysis, verification testing, and validation procedures. Manufacturers must implement robust quality management systems compliant with IATF 16949, the automotive industry's quality management standard, and provide evidence of reliability testing that simulates the full vehicle lifecycle, typically 10-15 years of operation under varying conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!