Optimal Pintle Hitch Strategies in Hybrid Vehicle Systems

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The pintle hitch has undergone significant evolution since its inception, adapting to the changing needs of vehicle systems, particularly in the context of hybrid vehicles. Initially developed for military applications in the mid-20th century, the pintle hitch has transitioned from a simple towing mechanism to a sophisticated component in modern hybrid vehicle systems.

In its early stages, the pintle hitch was primarily used for heavy-duty towing in military and industrial applications. The design focused on strength and durability, with little emphasis on efficiency or integration with vehicle systems. As civilian applications grew, the pintle hitch began to evolve, incorporating features for improved safety and ease of use.

The advent of electronic systems in vehicles marked a turning point in pintle hitch evolution. Sensors and control systems were integrated to monitor towing conditions, providing real-time data on load distribution, stability, and potential hazards. This integration laid the groundwork for more advanced applications in hybrid vehicle systems.

With the rise of hybrid vehicles, the pintle hitch underwent further transformation. Engineers began to explore ways to leverage the unique characteristics of hybrid powertrains to enhance towing capabilities. This led to the development of regenerative braking systems that could capture energy during deceleration and use it to assist in towing operations.

The integration of electric motors in hybrid vehicles opened new possibilities for pintle hitch design. Manufacturers began experimenting with electrically-assisted hitches that could provide additional torque when needed, reducing strain on the primary engine and improving fuel efficiency during towing.

As hybrid systems became more sophisticated, so did the pintle hitch strategies. Advanced control algorithms were developed to optimize power distribution between the internal combustion engine and electric motors during towing operations. These systems could dynamically adjust power output based on road conditions, load weight, and driver input.

The latest evolution in pintle hitch technology for hybrid vehicles focuses on predictive systems. By leveraging GPS data, terrain information, and real-time traffic updates, these advanced hitches can anticipate changes in towing conditions and preemptively adjust vehicle systems for optimal performance and efficiency.

Looking forward, the evolution of pintle hitches in hybrid vehicle systems is likely to continue, with a focus on further integration with autonomous driving technologies, improved energy management, and enhanced safety features. As hybrid and electric vehicles become more prevalent, pintle hitch strategies will play an increasingly crucial role in maximizing the efficiency and capabilities of these advanced powertrains.

In its early stages, the pintle hitch was primarily used for heavy-duty towing in military and industrial applications. The design focused on strength and durability, with little emphasis on efficiency or integration with vehicle systems. As civilian applications grew, the pintle hitch began to evolve, incorporating features for improved safety and ease of use.

The advent of electronic systems in vehicles marked a turning point in pintle hitch evolution. Sensors and control systems were integrated to monitor towing conditions, providing real-time data on load distribution, stability, and potential hazards. This integration laid the groundwork for more advanced applications in hybrid vehicle systems.

With the rise of hybrid vehicles, the pintle hitch underwent further transformation. Engineers began to explore ways to leverage the unique characteristics of hybrid powertrains to enhance towing capabilities. This led to the development of regenerative braking systems that could capture energy during deceleration and use it to assist in towing operations.

The integration of electric motors in hybrid vehicles opened new possibilities for pintle hitch design. Manufacturers began experimenting with electrically-assisted hitches that could provide additional torque when needed, reducing strain on the primary engine and improving fuel efficiency during towing.

As hybrid systems became more sophisticated, so did the pintle hitch strategies. Advanced control algorithms were developed to optimize power distribution between the internal combustion engine and electric motors during towing operations. These systems could dynamically adjust power output based on road conditions, load weight, and driver input.

The latest evolution in pintle hitch technology for hybrid vehicles focuses on predictive systems. By leveraging GPS data, terrain information, and real-time traffic updates, these advanced hitches can anticipate changes in towing conditions and preemptively adjust vehicle systems for optimal performance and efficiency.

Looking forward, the evolution of pintle hitches in hybrid vehicle systems is likely to continue, with a focus on further integration with autonomous driving technologies, improved energy management, and enhanced safety features. As hybrid and electric vehicles become more prevalent, pintle hitch strategies will play an increasingly crucial role in maximizing the efficiency and capabilities of these advanced powertrains.

Hybrid Vehicle Market

The hybrid vehicle market has experienced significant growth and transformation over the past decade, driven by increasing environmental concerns, stringent emissions regulations, and advancements in electric vehicle technology. This market segment has evolved from niche offerings to mainstream automotive options, with major manufacturers expanding their hybrid lineups to meet growing consumer demand.

Global sales of hybrid vehicles have shown a steady upward trend, with particularly strong adoption in regions like North America, Europe, and Asia-Pacific. The market has been characterized by a diverse range of hybrid technologies, including full hybrids, plug-in hybrids, and mild hybrids, each catering to different consumer preferences and use cases.

In recent years, the hybrid vehicle market has faced both opportunities and challenges. On the positive side, improvements in battery technology have led to increased electric-only driving ranges and overall system efficiency. This has made hybrid vehicles more attractive to consumers seeking improved fuel economy without the range anxiety associated with fully electric vehicles.

However, the market has also encountered headwinds. The rapid advancement of fully electric vehicles has begun to erode some of the advantages previously held by hybrids. Additionally, fluctuating fuel prices have influenced consumer purchasing decisions, with periods of lower fuel costs potentially reducing the perceived economic benefits of hybrid technology.

Despite these challenges, the hybrid vehicle market continues to demonstrate resilience and adaptability. Manufacturers are increasingly focusing on developing more sophisticated hybrid powertrains, including those that integrate advanced technologies like artificial intelligence and machine learning to optimize energy management and driving performance.

The market has also seen a shift towards hybridization in larger vehicle segments, including SUVs and light trucks. This expansion has opened up new opportunities for growth and innovation, particularly in regions where these vehicle types are popular.

Looking ahead, the hybrid vehicle market is expected to continue evolving. The integration of hybrid technology with other emerging automotive trends, such as autonomous driving and connected car features, is likely to create new value propositions for consumers. Additionally, the development of more efficient and cost-effective hybrid systems may help maintain the market's competitiveness in the face of growing electric vehicle adoption.

Global sales of hybrid vehicles have shown a steady upward trend, with particularly strong adoption in regions like North America, Europe, and Asia-Pacific. The market has been characterized by a diverse range of hybrid technologies, including full hybrids, plug-in hybrids, and mild hybrids, each catering to different consumer preferences and use cases.

In recent years, the hybrid vehicle market has faced both opportunities and challenges. On the positive side, improvements in battery technology have led to increased electric-only driving ranges and overall system efficiency. This has made hybrid vehicles more attractive to consumers seeking improved fuel economy without the range anxiety associated with fully electric vehicles.

However, the market has also encountered headwinds. The rapid advancement of fully electric vehicles has begun to erode some of the advantages previously held by hybrids. Additionally, fluctuating fuel prices have influenced consumer purchasing decisions, with periods of lower fuel costs potentially reducing the perceived economic benefits of hybrid technology.

Despite these challenges, the hybrid vehicle market continues to demonstrate resilience and adaptability. Manufacturers are increasingly focusing on developing more sophisticated hybrid powertrains, including those that integrate advanced technologies like artificial intelligence and machine learning to optimize energy management and driving performance.

The market has also seen a shift towards hybridization in larger vehicle segments, including SUVs and light trucks. This expansion has opened up new opportunities for growth and innovation, particularly in regions where these vehicle types are popular.

Looking ahead, the hybrid vehicle market is expected to continue evolving. The integration of hybrid technology with other emerging automotive trends, such as autonomous driving and connected car features, is likely to create new value propositions for consumers. Additionally, the development of more efficient and cost-effective hybrid systems may help maintain the market's competitiveness in the face of growing electric vehicle adoption.

Pintle Hitch Challenges

The integration of pintle hitches in hybrid vehicle systems presents several significant challenges that require innovative solutions. One of the primary issues is the dynamic load distribution between the towing vehicle and the trailer. In hybrid systems, the constant shifting between electric and combustion power sources can lead to inconsistent power delivery, affecting the stability and control of the towed load. This variability in power output necessitates a more sophisticated pintle hitch design that can adapt to these fluctuations in real-time.

Another critical challenge is the energy management and regenerative braking capabilities of hybrid vehicles when coupled with a trailer. The additional weight and momentum of the trailer can significantly impact the vehicle's energy recovery systems, potentially reducing overall efficiency. Engineers must develop strategies to optimize the regenerative braking process while maintaining safe and stable towing operations, which may require advanced sensors and control algorithms integrated into the pintle hitch mechanism.

The increased complexity of hybrid powertrains also introduces challenges in terms of weight distribution and center of gravity management. Pintle hitches for hybrid vehicles must be designed to accommodate the unique weight distribution characteristics of these systems, which often include heavy battery packs and dual power sources. This complexity can affect the vehicle's handling, braking, and overall performance, especially when towing heavy loads.

Thermal management presents another significant hurdle in pintle hitch design for hybrid vehicles. The heat generated by electric motors and battery systems, combined with the additional thermal load from towing, requires innovative cooling solutions. Engineers must develop pintle hitches that can effectively dissipate heat and prevent overheating of critical components, ensuring the longevity and reliability of both the hitch and the vehicle's hybrid systems.

Furthermore, the integration of advanced driver assistance systems (ADAS) and autonomous driving features in hybrid vehicles introduces new challenges for pintle hitch design. These systems must be calibrated to account for the presence of a trailer, requiring sophisticated sensors and algorithms that can accurately detect and respond to the altered vehicle dynamics. Developing pintle hitches that can seamlessly interface with these advanced systems while maintaining safety and performance standards is a complex engineering task.

Lastly, the environmental impact and sustainability of pintle hitch systems in hybrid vehicles must be addressed. As hybrid vehicles are designed to reduce emissions and improve fuel efficiency, the pintle hitch must not significantly compromise these benefits. This challenge requires the development of lightweight, aerodynamic hitch designs that minimize drag and maintain the vehicle's eco-friendly performance, even when towing.

Another critical challenge is the energy management and regenerative braking capabilities of hybrid vehicles when coupled with a trailer. The additional weight and momentum of the trailer can significantly impact the vehicle's energy recovery systems, potentially reducing overall efficiency. Engineers must develop strategies to optimize the regenerative braking process while maintaining safe and stable towing operations, which may require advanced sensors and control algorithms integrated into the pintle hitch mechanism.

The increased complexity of hybrid powertrains also introduces challenges in terms of weight distribution and center of gravity management. Pintle hitches for hybrid vehicles must be designed to accommodate the unique weight distribution characteristics of these systems, which often include heavy battery packs and dual power sources. This complexity can affect the vehicle's handling, braking, and overall performance, especially when towing heavy loads.

Thermal management presents another significant hurdle in pintle hitch design for hybrid vehicles. The heat generated by electric motors and battery systems, combined with the additional thermal load from towing, requires innovative cooling solutions. Engineers must develop pintle hitches that can effectively dissipate heat and prevent overheating of critical components, ensuring the longevity and reliability of both the hitch and the vehicle's hybrid systems.

Furthermore, the integration of advanced driver assistance systems (ADAS) and autonomous driving features in hybrid vehicles introduces new challenges for pintle hitch design. These systems must be calibrated to account for the presence of a trailer, requiring sophisticated sensors and algorithms that can accurately detect and respond to the altered vehicle dynamics. Developing pintle hitches that can seamlessly interface with these advanced systems while maintaining safety and performance standards is a complex engineering task.

Lastly, the environmental impact and sustainability of pintle hitch systems in hybrid vehicles must be addressed. As hybrid vehicles are designed to reduce emissions and improve fuel efficiency, the pintle hitch must not significantly compromise these benefits. This challenge requires the development of lightweight, aerodynamic hitch designs that minimize drag and maintain the vehicle's eco-friendly performance, even when towing.

Current Hitch Solutions

01 Design optimization for pintle hitch systems

Optimal strategies for pintle hitch design focus on improving stability, strength, and ease of use. This includes enhancing the structural integrity of the hitch, optimizing the geometry for better load distribution, and incorporating features that facilitate smoother coupling and uncoupling processes. Advanced materials and manufacturing techniques may be employed to reduce weight while maintaining or improving performance.- Design optimization for pintle hitch systems: Improving the design of pintle hitch systems through optimization techniques. This includes enhancing the structural integrity, weight distribution, and overall performance of the hitch. Advanced modeling and simulation tools are used to analyze stress points and improve durability. The optimized designs aim to increase towing capacity and stability while reducing wear and tear.

- Smart pintle hitch systems with sensors and connectivity: Integration of sensors and connectivity features in pintle hitch systems for real-time monitoring and data collection. These smart systems can provide information on load distribution, trailer alignment, and potential safety issues. They may also offer features like automatic coupling and decoupling, as well as integration with vehicle telematics systems for improved fleet management.

- Adaptive control strategies for pintle hitch systems: Development of adaptive control algorithms for pintle hitch systems to optimize performance under various conditions. These strategies may include dynamic adjustment of coupling tension, automatic compensation for road conditions, and intelligent load balancing. The adaptive systems aim to enhance stability, reduce wear, and improve overall towing efficiency.

- Materials innovation for pintle hitch components: Exploration of advanced materials and manufacturing techniques to improve the performance and durability of pintle hitch components. This may include the use of high-strength alloys, composite materials, or novel surface treatments to reduce friction and wear. The goal is to create lighter, stronger, and more durable pintle hitch systems that can withstand higher loads and harsh environmental conditions.

- Integration of pintle hitch systems with vehicle automation: Strategies for integrating pintle hitch systems with autonomous and semi-autonomous vehicle technologies. This includes developing systems for automated hitching and unhitching, as well as incorporating pintle hitch data into vehicle control systems for improved handling and safety during towing operations. The integration aims to enhance overall vehicle performance and reduce driver workload in towing scenarios.

02 Integration of smart technologies in pintle hitches

Incorporating smart technologies into pintle hitch systems can significantly enhance their functionality and safety. This may include sensors for monitoring load distribution, automated coupling systems, and integration with vehicle control systems. These technologies can provide real-time feedback to drivers, assist in hitching operations, and improve overall towing safety and efficiency.Expand Specific Solutions03 Optimization algorithms for pintle hitch performance

Developing and implementing optimization algorithms can lead to improved pintle hitch designs and performance. These algorithms may consider factors such as vehicle dynamics, load characteristics, and road conditions to optimize the hitch's behavior under various scenarios. Machine learning and AI techniques can be applied to continuously refine and adapt the hitch's performance based on real-world data.Expand Specific Solutions04 Enhanced safety features for pintle hitch systems

Optimal strategies for pintle hitches include the development of advanced safety features. These may encompass fail-safe mechanisms, improved locking systems, and integration with vehicle safety systems. Additionally, designs that minimize the risk of jackknifing, improve stability during cornering, and enhance overall towing safety are crucial aspects of pintle hitch optimization.Expand Specific Solutions05 Eco-friendly and sustainable pintle hitch solutions

Developing environmentally friendly and sustainable pintle hitch solutions is an emerging strategy. This includes using recycled or sustainable materials, designing for longevity and easy maintenance, and optimizing aerodynamics to reduce fuel consumption during towing. Additionally, integrating pintle hitches with electric and hybrid vehicle systems presents new challenges and opportunities for innovation.Expand Specific Solutions

Key Industry Players

The competitive landscape for "Optimal Pintle Hitch Strategies in Hybrid Vehicle Systems" is evolving rapidly, reflecting the automotive industry's transition towards electrification. This niche technology is in its early development stage, with market size expected to grow as hybrid vehicles gain popularity. The technology's maturity is still emerging, with major players like Toyota, Nissan, and Ford leading research efforts. Companies such as Bosch, ZF Friedrichshafen, and Schaeffler are likely contributing expertise in automotive components. As the industry progresses, collaboration between traditional automakers and specialized technology firms will be crucial for advancing pintle hitch systems in hybrid vehicles.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced hybrid pintle hitch system for their hybrid vehicles, particularly focusing on SUVs and light trucks. The system integrates a high-strength, lightweight pintle hitch with the vehicle's hybrid powertrain, allowing for seamless power distribution between towing and propulsion needs. Toyota's strategy involves using regenerative braking to capture energy during deceleration and downhill towing, which is then stored in the hybrid battery for later use[1]. The system also incorporates adaptive damping technology to minimize vibrations and improve ride comfort during towing operations[3].

Strengths: Improved fuel efficiency during towing, reduced wear on the hybrid powertrain, and enhanced towing stability. Weaknesses: Potentially higher initial cost and complexity compared to traditional towing systems.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a smart pintle hitch system for hybrid vehicles that integrates with their eAxle technology. This system uses advanced sensors and control algorithms to optimize power distribution between the electric motor and internal combustion engine during towing operations. The pintle hitch is equipped with load-sensing capabilities that communicate with the vehicle's hybrid management system, allowing for real-time adjustments to power output and torque distribution[2]. Additionally, Bosch's system incorporates predictive route analysis to preemptively adjust the hybrid powertrain's operation based on upcoming terrain and towing conditions[4].

Strengths: Highly integrated with hybrid powertrain for optimal efficiency, advanced predictive capabilities. Weaknesses: May require frequent software updates, potential for increased complexity in maintenance.

Innovative Hitch Design

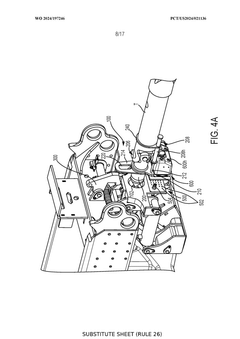

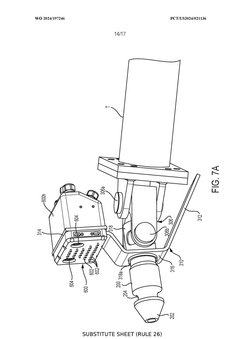

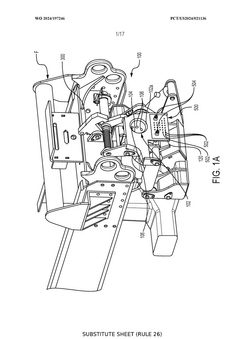

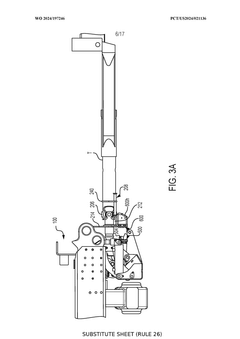

Apparatus, system, and method for connecting a towed vehicle to a towing vehicle

PatentWO2024197246A2

Innovation

- A hitch apparatus featuring a receiver tube with aligned apertures and ball bearings that secure an elongate shaft via a collar, allowing for remote activation and enabling roll rotation, while a manifold connects electrical and pneumatic systems between towing and towed vehicles, facilitating secure and automated coupling.

Dual trailer hitch

PatentActiveUS7673894B2

Innovation

- A dual trailer hitch system with a rigid hitch body featuring interchangeable ball and lunette eye connectors, adjustable height, and longitudinal position, allowing for quick conversion between hitch types and orientations to suit different towing conditions.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development and implementation of optimal pintle hitch strategies in hybrid vehicle systems. These regulations, established by governmental bodies and environmental agencies, set strict limits on the amount of pollutants that vehicles can emit into the atmosphere. As hybrid vehicles continue to gain popularity, manufacturers must ensure that their pintle hitch systems comply with these regulations while maintaining optimal performance.

One of the primary focuses of emissions regulations is the reduction of greenhouse gases, particularly carbon dioxide (CO2). Hybrid vehicles, by their nature, are designed to reduce CO2 emissions through the combination of internal combustion engines and electric motors. However, the integration of pintle hitch systems can potentially impact the overall emissions profile of these vehicles. Manufacturers must carefully consider how the additional weight and aerodynamic changes introduced by pintle hitches affect fuel consumption and, consequently, emissions.

Nitrogen oxides (NOx) and particulate matter (PM) are also key targets of emissions regulations. These pollutants are particularly relevant to hybrid vehicles equipped with diesel engines, which are often used in larger vehicles capable of towing. Pintle hitch strategies must be developed with consideration for how towing affects the production of these emissions, especially during acceleration and high-load conditions.

The implementation of real-world driving emissions (RDE) tests has further complicated the regulatory landscape. These tests aim to measure emissions under actual driving conditions, including scenarios where vehicles are towing trailers or other equipment. As a result, optimal pintle hitch strategies must not only perform well in laboratory settings but also maintain low emissions during real-world use.

Emissions regulations also vary by region, with some areas implementing more stringent standards than others. For example, the European Union's Euro 6 standards and California's LEV III regulations are among the most demanding in the world. Manufacturers developing pintle hitch systems for hybrid vehicles must ensure compliance across multiple markets, which may require different strategies or technologies depending on the specific regulatory requirements.

The trend towards zero-emission vehicles (ZEVs) is another factor influencing pintle hitch strategies in hybrid systems. As regulations increasingly favor fully electric vehicles, hybrid manufacturers must demonstrate that their pintle hitch-equipped vehicles can achieve emissions levels approaching those of ZEVs, particularly in urban environments where air quality concerns are most pressing.

In response to these regulatory challenges, manufacturers are exploring innovative solutions such as intelligent control systems that optimize the balance between electric and combustion power based on towing conditions. Additionally, advanced materials and designs are being employed to reduce the weight impact of pintle hitches, thereby minimizing their effect on overall vehicle emissions.

One of the primary focuses of emissions regulations is the reduction of greenhouse gases, particularly carbon dioxide (CO2). Hybrid vehicles, by their nature, are designed to reduce CO2 emissions through the combination of internal combustion engines and electric motors. However, the integration of pintle hitch systems can potentially impact the overall emissions profile of these vehicles. Manufacturers must carefully consider how the additional weight and aerodynamic changes introduced by pintle hitches affect fuel consumption and, consequently, emissions.

Nitrogen oxides (NOx) and particulate matter (PM) are also key targets of emissions regulations. These pollutants are particularly relevant to hybrid vehicles equipped with diesel engines, which are often used in larger vehicles capable of towing. Pintle hitch strategies must be developed with consideration for how towing affects the production of these emissions, especially during acceleration and high-load conditions.

The implementation of real-world driving emissions (RDE) tests has further complicated the regulatory landscape. These tests aim to measure emissions under actual driving conditions, including scenarios where vehicles are towing trailers or other equipment. As a result, optimal pintle hitch strategies must not only perform well in laboratory settings but also maintain low emissions during real-world use.

Emissions regulations also vary by region, with some areas implementing more stringent standards than others. For example, the European Union's Euro 6 standards and California's LEV III regulations are among the most demanding in the world. Manufacturers developing pintle hitch systems for hybrid vehicles must ensure compliance across multiple markets, which may require different strategies or technologies depending on the specific regulatory requirements.

The trend towards zero-emission vehicles (ZEVs) is another factor influencing pintle hitch strategies in hybrid systems. As regulations increasingly favor fully electric vehicles, hybrid manufacturers must demonstrate that their pintle hitch-equipped vehicles can achieve emissions levels approaching those of ZEVs, particularly in urban environments where air quality concerns are most pressing.

In response to these regulatory challenges, manufacturers are exploring innovative solutions such as intelligent control systems that optimize the balance between electric and combustion power based on towing conditions. Additionally, advanced materials and designs are being employed to reduce the weight impact of pintle hitches, thereby minimizing their effect on overall vehicle emissions.

Safety Considerations

Safety considerations are paramount when implementing optimal pintle hitch strategies in hybrid vehicle systems. The integration of a pintle hitch in a hybrid vehicle introduces unique challenges that require careful attention to ensure the safety of both the vehicle occupants and other road users.

One of the primary safety concerns is the impact of the pintle hitch on the vehicle's stability and handling characteristics. The additional weight and altered weight distribution caused by the hitch and any towed load can significantly affect the vehicle's center of gravity. This change may lead to increased body roll during cornering and potentially compromise the effectiveness of the vehicle's stability control systems. To address this issue, advanced electronic stability control algorithms specifically tailored for hybrid vehicles with pintle hitches must be developed and implemented.

The regenerative braking system, a key feature of hybrid vehicles, also requires special consideration when a pintle hitch is in use. The added mass of a trailer can affect the efficiency and effectiveness of regenerative braking, potentially leading to reduced energy recovery and increased wear on the conventional friction brakes. Safety systems must be designed to seamlessly transition between regenerative and friction braking while maintaining optimal stopping performance, even under varying load conditions.

Another critical safety aspect is the integration of the pintle hitch with the hybrid powertrain. The sudden engagement or disengagement of the electric motor during towing operations could cause unexpected jerking or loss of traction. To mitigate this risk, sophisticated torque management systems must be developed to ensure smooth power delivery and maintain vehicle stability under all driving conditions.

The electrical systems of hybrid vehicles pose unique safety challenges when combined with a pintle hitch. Proper insulation and protection of high-voltage components are essential to prevent electrical hazards, especially in wet conditions or during trailer coupling and uncoupling operations. Additionally, electromagnetic compatibility between the vehicle's hybrid systems and any electrical systems on the trailer must be ensured to prevent interference that could compromise safety-critical functions.

Visibility and lighting considerations are also crucial when implementing pintle hitch strategies in hybrid vehicles. The presence of a trailer can significantly impact rearward visibility, necessitating the integration of advanced camera systems and sensors to provide a comprehensive view of the vehicle's surroundings. Furthermore, the electrical interface between the hybrid vehicle and the trailer must be designed to ensure proper functioning of all lighting and signaling systems, including brake lights, turn signals, and reverse lights.

One of the primary safety concerns is the impact of the pintle hitch on the vehicle's stability and handling characteristics. The additional weight and altered weight distribution caused by the hitch and any towed load can significantly affect the vehicle's center of gravity. This change may lead to increased body roll during cornering and potentially compromise the effectiveness of the vehicle's stability control systems. To address this issue, advanced electronic stability control algorithms specifically tailored for hybrid vehicles with pintle hitches must be developed and implemented.

The regenerative braking system, a key feature of hybrid vehicles, also requires special consideration when a pintle hitch is in use. The added mass of a trailer can affect the efficiency and effectiveness of regenerative braking, potentially leading to reduced energy recovery and increased wear on the conventional friction brakes. Safety systems must be designed to seamlessly transition between regenerative and friction braking while maintaining optimal stopping performance, even under varying load conditions.

Another critical safety aspect is the integration of the pintle hitch with the hybrid powertrain. The sudden engagement or disengagement of the electric motor during towing operations could cause unexpected jerking or loss of traction. To mitigate this risk, sophisticated torque management systems must be developed to ensure smooth power delivery and maintain vehicle stability under all driving conditions.

The electrical systems of hybrid vehicles pose unique safety challenges when combined with a pintle hitch. Proper insulation and protection of high-voltage components are essential to prevent electrical hazards, especially in wet conditions or during trailer coupling and uncoupling operations. Additionally, electromagnetic compatibility between the vehicle's hybrid systems and any electrical systems on the trailer must be ensured to prevent interference that could compromise safety-critical functions.

Visibility and lighting considerations are also crucial when implementing pintle hitch strategies in hybrid vehicles. The presence of a trailer can significantly impact rearward visibility, necessitating the integration of advanced camera systems and sensors to provide a comprehensive view of the vehicle's surroundings. Furthermore, the electrical interface between the hybrid vehicle and the trailer must be designed to ensure proper functioning of all lighting and signaling systems, including brake lights, turn signals, and reverse lights.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!