Pintle Hitch and Its Influence on Heavy Industry Transport Efficiency

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The pintle hitch has undergone significant evolution since its inception, playing a crucial role in enhancing heavy industry transport efficiency. Initially developed in the early 20th century, the pintle hitch was designed to provide a robust and versatile coupling mechanism for heavy-duty vehicles and trailers.

In its early stages, the pintle hitch consisted of a simple hook-and-eye design, offering basic connectivity between the towing vehicle and the trailer. This rudimentary design, while functional, had limitations in terms of stability and load-bearing capacity, which restricted its applications in heavy industry transport.

The 1950s and 1960s saw substantial improvements in pintle hitch design. Engineers introduced reinforced materials and more sophisticated locking mechanisms, significantly enhancing the hitch's strength and reliability. These advancements allowed for increased payload capacities and improved safety in heavy transport operations.

During the 1970s and 1980s, the focus shifted towards improving the ergonomics and ease of use of pintle hitches. Manufacturers developed quick-release mechanisms and adjustable height features, reducing coupling and uncoupling times and improving overall operational efficiency in industrial settings.

The 1990s marked a turning point in pintle hitch evolution with the integration of electronic systems. Sensors and monitoring devices were incorporated to provide real-time data on hitch status, load distribution, and potential safety issues. This technological leap significantly enhanced the safety and efficiency of heavy transport operations.

In the early 2000s, the emphasis on environmental sustainability led to the development of lightweight yet durable materials for pintle hitches. These innovations reduced the overall weight of the hitch system without compromising its strength, contributing to improved fuel efficiency in heavy transport vehicles.

Recent years have seen the emergence of smart pintle hitches, equipped with advanced features such as automatic coupling systems, integrated brake controllers, and wireless connectivity. These cutting-edge designs not only streamline the hitching process but also provide valuable data for fleet management and predictive maintenance.

The ongoing evolution of pintle hitches continues to focus on enhancing safety, efficiency, and adaptability in heavy industry transport. Current research and development efforts are exploring the integration of artificial intelligence and machine learning algorithms to further optimize hitch performance and anticipate potential issues before they occur.

As the heavy industry sector embraces Industry 4.0 principles, the future of pintle hitch evolution is likely to involve greater integration with autonomous vehicle systems and smart infrastructure, paving the way for more efficient and safer heavy transport operations.

In its early stages, the pintle hitch consisted of a simple hook-and-eye design, offering basic connectivity between the towing vehicle and the trailer. This rudimentary design, while functional, had limitations in terms of stability and load-bearing capacity, which restricted its applications in heavy industry transport.

The 1950s and 1960s saw substantial improvements in pintle hitch design. Engineers introduced reinforced materials and more sophisticated locking mechanisms, significantly enhancing the hitch's strength and reliability. These advancements allowed for increased payload capacities and improved safety in heavy transport operations.

During the 1970s and 1980s, the focus shifted towards improving the ergonomics and ease of use of pintle hitches. Manufacturers developed quick-release mechanisms and adjustable height features, reducing coupling and uncoupling times and improving overall operational efficiency in industrial settings.

The 1990s marked a turning point in pintle hitch evolution with the integration of electronic systems. Sensors and monitoring devices were incorporated to provide real-time data on hitch status, load distribution, and potential safety issues. This technological leap significantly enhanced the safety and efficiency of heavy transport operations.

In the early 2000s, the emphasis on environmental sustainability led to the development of lightweight yet durable materials for pintle hitches. These innovations reduced the overall weight of the hitch system without compromising its strength, contributing to improved fuel efficiency in heavy transport vehicles.

Recent years have seen the emergence of smart pintle hitches, equipped with advanced features such as automatic coupling systems, integrated brake controllers, and wireless connectivity. These cutting-edge designs not only streamline the hitching process but also provide valuable data for fleet management and predictive maintenance.

The ongoing evolution of pintle hitches continues to focus on enhancing safety, efficiency, and adaptability in heavy industry transport. Current research and development efforts are exploring the integration of artificial intelligence and machine learning algorithms to further optimize hitch performance and anticipate potential issues before they occur.

As the heavy industry sector embraces Industry 4.0 principles, the future of pintle hitch evolution is likely to involve greater integration with autonomous vehicle systems and smart infrastructure, paving the way for more efficient and safer heavy transport operations.

Market Demand Analysis

The market demand for Pintle Hitch technology in heavy industry transport has been steadily increasing due to its significant impact on efficiency and safety. This growth is driven by the expanding heavy-duty transportation sector, particularly in construction, mining, and logistics industries. The global heavy-duty vehicle market, which heavily relies on Pintle Hitch systems, is projected to grow at a compound annual growth rate (CAGR) of 3.5% from 2021 to 2026.

One of the primary factors fueling this demand is the need for improved towing capacity and stability in heavy-duty vehicles. Pintle Hitch systems offer superior strength and durability compared to traditional ball hitches, making them ideal for hauling heavy loads over rough terrains. This capability is particularly crucial in industries such as construction and mining, where large equipment and materials need to be transported frequently.

The logistics and transportation sector is another key driver of market demand for Pintle Hitch technology. With the rise of e-commerce and global trade, there is an increasing need for efficient and reliable transportation of goods. Pintle Hitches allow for the secure coupling of multiple trailers, enabling the transport of larger loads and reducing the number of trips required. This efficiency translates to significant cost savings and improved productivity for logistics companies.

In the agricultural sector, the demand for Pintle Hitch systems is also on the rise. Modern farming practices require the movement of heavy machinery and large quantities of produce, making robust and reliable hitching systems essential. The versatility of Pintle Hitches in accommodating various trailer types and sizes makes them particularly attractive to farmers and agricultural businesses.

The market demand is further bolstered by stringent safety regulations in the transportation industry. Pintle Hitch systems offer enhanced safety features, such as improved articulation and reduced risk of trailer separation, which align well with regulatory requirements. This has led to increased adoption of Pintle Hitch technology in commercial fleets and government vehicles.

Geographically, North America and Europe currently dominate the Pintle Hitch market, owing to their well-established heavy industries and stringent safety standards. However, rapid industrialization and infrastructure development in emerging economies of Asia-Pacific and Latin America are expected to create significant market opportunities in these regions.

As environmental concerns gain prominence, there is a growing demand for Pintle Hitch systems that can support the transition to electric and hybrid heavy-duty vehicles. This trend is likely to shape the future market landscape, with manufacturers focusing on developing lightweight yet robust Pintle Hitch solutions compatible with next-generation vehicles.

One of the primary factors fueling this demand is the need for improved towing capacity and stability in heavy-duty vehicles. Pintle Hitch systems offer superior strength and durability compared to traditional ball hitches, making them ideal for hauling heavy loads over rough terrains. This capability is particularly crucial in industries such as construction and mining, where large equipment and materials need to be transported frequently.

The logistics and transportation sector is another key driver of market demand for Pintle Hitch technology. With the rise of e-commerce and global trade, there is an increasing need for efficient and reliable transportation of goods. Pintle Hitches allow for the secure coupling of multiple trailers, enabling the transport of larger loads and reducing the number of trips required. This efficiency translates to significant cost savings and improved productivity for logistics companies.

In the agricultural sector, the demand for Pintle Hitch systems is also on the rise. Modern farming practices require the movement of heavy machinery and large quantities of produce, making robust and reliable hitching systems essential. The versatility of Pintle Hitches in accommodating various trailer types and sizes makes them particularly attractive to farmers and agricultural businesses.

The market demand is further bolstered by stringent safety regulations in the transportation industry. Pintle Hitch systems offer enhanced safety features, such as improved articulation and reduced risk of trailer separation, which align well with regulatory requirements. This has led to increased adoption of Pintle Hitch technology in commercial fleets and government vehicles.

Geographically, North America and Europe currently dominate the Pintle Hitch market, owing to their well-established heavy industries and stringent safety standards. However, rapid industrialization and infrastructure development in emerging economies of Asia-Pacific and Latin America are expected to create significant market opportunities in these regions.

As environmental concerns gain prominence, there is a growing demand for Pintle Hitch systems that can support the transition to electric and hybrid heavy-duty vehicles. This trend is likely to shape the future market landscape, with manufacturers focusing on developing lightweight yet robust Pintle Hitch solutions compatible with next-generation vehicles.

Technical Challenges

The implementation of pintle hitch technology in heavy industry transport faces several significant technical challenges that need to be addressed to maximize efficiency and safety. One of the primary obstacles is the design of a robust and durable pintle hitch mechanism capable of withstanding the extreme loads and stresses associated with heavy-duty applications. The constant exposure to harsh environmental conditions, including vibrations, shocks, and corrosive elements, demands advanced materials and engineering solutions to ensure long-term reliability.

Another critical challenge lies in the development of standardized pintle hitch systems that can accommodate a wide range of trailer configurations and load capacities. The diversity of heavy industry transport requirements necessitates a versatile design that can be easily adapted to different vehicle types and sizes while maintaining optimal performance and safety standards. This standardization effort is further complicated by the need to comply with varying regional regulations and industry-specific requirements across different sectors of heavy industry.

The integration of smart technologies into pintle hitch systems presents both opportunities and challenges. While advanced sensors and monitoring systems can significantly enhance safety and efficiency, their implementation requires overcoming issues related to power supply, data connectivity, and environmental protection. Developing robust and reliable electronic components that can withstand the harsh conditions of heavy industry environments remains a significant technical hurdle.

Weight reduction without compromising structural integrity is another key challenge in pintle hitch design. As the transport industry strives for increased fuel efficiency and payload capacity, there is a growing demand for lighter yet stronger materials and innovative design approaches. This challenge requires a delicate balance between reducing weight and maintaining the necessary strength and durability to handle heavy loads safely.

The dynamic behavior of pintle hitch systems under various operating conditions poses complex engineering challenges. Addressing issues such as trailer sway, jackknifing, and uneven load distribution requires sophisticated modeling and simulation techniques, as well as extensive real-world testing. Developing advanced control systems and stability enhancement technologies that can effectively mitigate these risks across a wide range of operational scenarios is a significant technical undertaking.

Lastly, the challenge of improving the ease of use and maintenance of pintle hitch systems without compromising their performance or safety features is crucial for widespread adoption in heavy industry transport. This includes developing user-friendly coupling and uncoupling mechanisms, implementing fail-safe features, and designing systems that facilitate quick and efficient maintenance procedures to minimize downtime and operational disruptions.

Another critical challenge lies in the development of standardized pintle hitch systems that can accommodate a wide range of trailer configurations and load capacities. The diversity of heavy industry transport requirements necessitates a versatile design that can be easily adapted to different vehicle types and sizes while maintaining optimal performance and safety standards. This standardization effort is further complicated by the need to comply with varying regional regulations and industry-specific requirements across different sectors of heavy industry.

The integration of smart technologies into pintle hitch systems presents both opportunities and challenges. While advanced sensors and monitoring systems can significantly enhance safety and efficiency, their implementation requires overcoming issues related to power supply, data connectivity, and environmental protection. Developing robust and reliable electronic components that can withstand the harsh conditions of heavy industry environments remains a significant technical hurdle.

Weight reduction without compromising structural integrity is another key challenge in pintle hitch design. As the transport industry strives for increased fuel efficiency and payload capacity, there is a growing demand for lighter yet stronger materials and innovative design approaches. This challenge requires a delicate balance between reducing weight and maintaining the necessary strength and durability to handle heavy loads safely.

The dynamic behavior of pintle hitch systems under various operating conditions poses complex engineering challenges. Addressing issues such as trailer sway, jackknifing, and uneven load distribution requires sophisticated modeling and simulation techniques, as well as extensive real-world testing. Developing advanced control systems and stability enhancement technologies that can effectively mitigate these risks across a wide range of operational scenarios is a significant technical undertaking.

Lastly, the challenge of improving the ease of use and maintenance of pintle hitch systems without compromising their performance or safety features is crucial for widespread adoption in heavy industry transport. This includes developing user-friendly coupling and uncoupling mechanisms, implementing fail-safe features, and designing systems that facilitate quick and efficient maintenance procedures to minimize downtime and operational disruptions.

Current Hitch Solutions

01 Improved pintle hitch designs for enhanced stability

Advanced pintle hitch designs focus on improving stability during transport. These designs incorporate features such as reinforced mounting brackets, adjustable height mechanisms, and shock-absorbing elements to reduce vibration and enhance overall towing performance. The improved stability contributes to better transport efficiency by minimizing swaying and improving control.- Improved pintle hitch designs for enhanced stability: Advanced pintle hitch designs focus on improving stability during transport. These designs incorporate features such as adjustable height mechanisms, reinforced coupling points, and shock-absorbing elements. These enhancements contribute to a smoother ride, reduced wear on components, and increased overall transport efficiency.

- Integration of pintle hitches with specialized transport systems: Pintle hitches are being integrated into specialized transport systems for improved efficiency. These systems may include custom-designed trailers, multi-axle configurations, or adaptable mounting platforms. The integration allows for better weight distribution, increased payload capacity, and enhanced maneuverability in various terrains and conditions.

- Automated coupling and decoupling mechanisms: Automated systems for coupling and decoupling pintle hitches are being developed to increase transport efficiency. These mechanisms utilize sensors, hydraulic or pneumatic actuators, and electronic controls to streamline the hitching process. This automation reduces the time and labor required for connecting and disconnecting trailers, improving overall operational efficiency.

- Lightweight materials and optimized designs for fuel efficiency: The use of lightweight materials and optimized designs in pintle hitch construction contributes to improved fuel efficiency. Advanced alloys, composite materials, and innovative structural designs reduce the overall weight of the hitch system without compromising strength. This weight reduction leads to decreased fuel consumption and increased payload capacity.

- Smart monitoring and diagnostics for pintle hitch systems: Integration of smart monitoring and diagnostic technologies in pintle hitch systems enhances transport efficiency. These systems incorporate sensors to monitor load distribution, wear and tear, and potential failures. Real-time data analysis and predictive maintenance capabilities help prevent breakdowns, optimize performance, and extend the lifespan of the hitch components.

02 Integration of pintle hitches with specialized equipment

Pintle hitches are integrated with specialized equipment to improve transport efficiency in various industries. This includes applications in agriculture, construction, and military vehicles. The integration allows for quick attachment and detachment of trailers or implements, reducing downtime and improving overall operational efficiency.Expand Specific Solutions03 Lightweight and durable materials for pintle hitch construction

The use of lightweight and durable materials in pintle hitch construction contributes to improved transport efficiency. These materials, such as high-strength alloys and composite materials, reduce the overall weight of the hitch while maintaining or enhancing its strength and durability. The reduced weight leads to improved fuel efficiency and increased payload capacity.Expand Specific Solutions04 Multi-functional pintle hitch systems

Multi-functional pintle hitch systems are designed to accommodate various types of trailers and equipment, improving versatility and transport efficiency. These systems may include interchangeable components, adjustable coupling mechanisms, or integrated auxiliary functions such as electrical connections or hydraulic systems. The versatility of these systems reduces the need for multiple hitches and simplifies the towing process.Expand Specific Solutions05 Automated and smart pintle hitch technologies

Advanced pintle hitch technologies incorporate automation and smart features to enhance transport efficiency. These may include sensors for monitoring hitch status, automatic coupling and uncoupling mechanisms, and integration with vehicle control systems. Such technologies improve safety, reduce human error, and streamline the hitching process, leading to more efficient transport operations.Expand Specific Solutions

Key Industry Players

The pintle hitch technology in heavy industry transport is in a mature growth phase, with a stable market size driven by ongoing demand in logistics and construction sectors. The technology's maturity is evident from established players like Deere & Co. and WESTFALIA-Automotive GmbH offering advanced solutions. However, innovation continues, as seen in Ford Global Technologies LLC's research efforts. The competitive landscape is diverse, with traditional manufacturers like Curt Manufacturing LLC and ACPS Automotive GmbH competing alongside newer entrants such as Teleswivel LLC, indicating a dynamic market with opportunities for both incremental improvements and disruptive innovations in hitch design and efficiency.

WESTFALIA-Automotive GmbH

Technical Solution: WESTFALIA-Automotive GmbH has developed advanced pintle hitch systems that significantly enhance heavy industry transport efficiency. Their innovative designs incorporate high-strength materials and precision engineering to increase towing capacity and stability. The company's pintle hitches feature a unique locking mechanism that ensures secure coupling between the towing vehicle and trailer, reducing the risk of disconnection during transit[1]. Additionally, WESTFALIA has implemented smart sensors in their pintle hitch systems, allowing for real-time monitoring of load distribution and hitch performance, which contributes to improved safety and efficiency in heavy transport operations[2].

Strengths: Advanced locking mechanism for secure coupling, smart sensor integration for real-time monitoring. Weaknesses: Potentially higher cost due to advanced features, may require specialized maintenance.

Ford Global Technologies LLC

Technical Solution: Ford Global Technologies LLC has made significant strides in pintle hitch technology for heavy industry transport. Their research has led to the development of a dynamic load-sensing pintle hitch system that automatically adjusts to varying load conditions[3]. This adaptive technology helps to optimize weight distribution and improve vehicle handling, particularly during cornering and braking. Ford has also integrated their pintle hitch designs with vehicle telematics systems, allowing for remote monitoring and diagnostics of hitch performance and wear[4]. Furthermore, the company has patented a modular pintle hitch design that allows for easy customization and replacement of components, reducing maintenance downtime for heavy transport fleets[5].

Strengths: Dynamic load-sensing technology, integration with vehicle telematics, modular design for easy maintenance. Weaknesses: May be more complex to operate, potentially higher initial cost compared to traditional systems.

Core Pintle Innovations

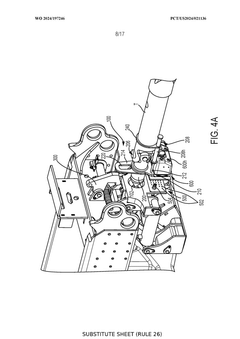

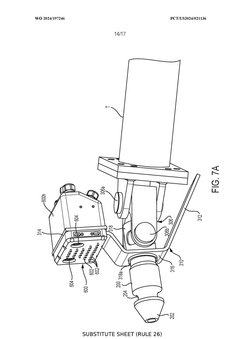

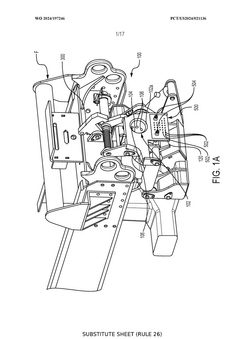

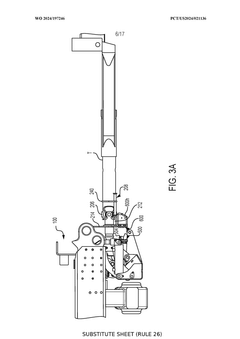

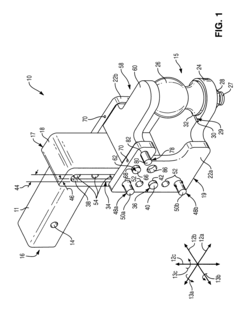

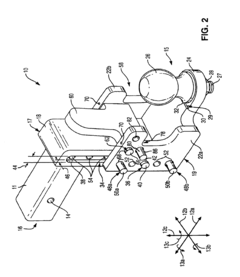

Apparatus, system, and method for connecting a towed vehicle to a towing vehicle

PatentWO2024197246A2

Innovation

- A hitch apparatus featuring a receiver tube with aligned apertures and ball bearings that secure an elongate shaft via a collar, allowing for remote activation and enabling roll rotation, while a manifold connects electrical and pneumatic systems between towing and towed vehicles, facilitating secure and automated coupling.

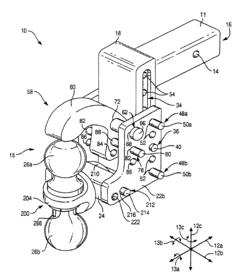

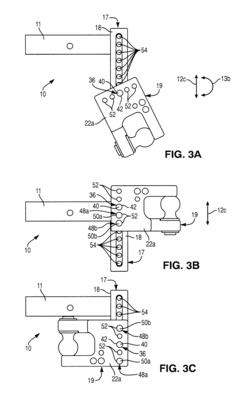

Stowable-lock, convertible-pintle hitch

PatentInactiveUS6789815B2

Innovation

- A stowable pintle hitch system with a trunnion, base, and mount configuration that allows for adjustable positioning and locking, enabling the hitch to be easily secured and released, accommodating twisting motions through a retainer mechanism that pivots and translates, and includes a silencing spacer for reduced noise and wear.

Safety Regulations

Safety regulations play a crucial role in the implementation and operation of pintle hitch systems in heavy industry transport. These regulations are designed to ensure the safe and efficient use of pintle hitches, minimizing risks associated with towing heavy loads and enhancing overall transport safety.

One of the primary safety regulations concerning pintle hitches is the requirement for proper weight ratings. Manufacturers must clearly specify the maximum gross trailer weight (GTW) and tongue weight that a pintle hitch can safely handle. This information is essential for operators to select the appropriate hitch for their specific load requirements, preventing overloading and potential accidents.

Additionally, safety regulations mandate regular inspections and maintenance of pintle hitch systems. These inspections typically include checking for wear, damage, or deformation of the hitch components, ensuring proper lubrication, and verifying the integrity of mounting hardware. Scheduled maintenance helps identify potential issues before they lead to equipment failure or accidents during transport operations.

Another important aspect of safety regulations is the requirement for proper installation and mounting of pintle hitches. Guidelines often specify the type and grade of bolts to be used, torque specifications, and reinforcement requirements for the vehicle frame. Compliance with these installation standards is crucial for maintaining the structural integrity of the hitch system under heavy loads and dynamic forces experienced during transport.

Safety regulations also address the use of secondary attachment devices, such as safety chains or cables. These secondary systems are designed to prevent complete separation of the trailer from the towing vehicle in case of primary hitch failure. Regulations typically specify the minimum strength requirements for these safety devices and provide guidelines for their proper installation and use.

Furthermore, safety regulations often include operator training and certification requirements. Drivers and operators responsible for coupling and uncoupling trailers using pintle hitches must be adequately trained in proper procedures, load distribution, and safety checks. This training helps reduce the risk of operator error and ensures that safety protocols are consistently followed during transport operations.

In many jurisdictions, safety regulations also mandate the use of specific signaling and lighting systems for vehicles equipped with pintle hitches. These requirements may include additional brake lights, turn signals, and reflectors to enhance visibility and communication with other road users, particularly important when maneuvering large, heavy loads.

Lastly, safety regulations often address the need for proper documentation and record-keeping related to pintle hitch systems. This may include maintaining logs of inspections, repairs, and load capacities, which can be crucial for compliance audits and in the event of accidents or equipment failures.

One of the primary safety regulations concerning pintle hitches is the requirement for proper weight ratings. Manufacturers must clearly specify the maximum gross trailer weight (GTW) and tongue weight that a pintle hitch can safely handle. This information is essential for operators to select the appropriate hitch for their specific load requirements, preventing overloading and potential accidents.

Additionally, safety regulations mandate regular inspections and maintenance of pintle hitch systems. These inspections typically include checking for wear, damage, or deformation of the hitch components, ensuring proper lubrication, and verifying the integrity of mounting hardware. Scheduled maintenance helps identify potential issues before they lead to equipment failure or accidents during transport operations.

Another important aspect of safety regulations is the requirement for proper installation and mounting of pintle hitches. Guidelines often specify the type and grade of bolts to be used, torque specifications, and reinforcement requirements for the vehicle frame. Compliance with these installation standards is crucial for maintaining the structural integrity of the hitch system under heavy loads and dynamic forces experienced during transport.

Safety regulations also address the use of secondary attachment devices, such as safety chains or cables. These secondary systems are designed to prevent complete separation of the trailer from the towing vehicle in case of primary hitch failure. Regulations typically specify the minimum strength requirements for these safety devices and provide guidelines for their proper installation and use.

Furthermore, safety regulations often include operator training and certification requirements. Drivers and operators responsible for coupling and uncoupling trailers using pintle hitches must be adequately trained in proper procedures, load distribution, and safety checks. This training helps reduce the risk of operator error and ensures that safety protocols are consistently followed during transport operations.

In many jurisdictions, safety regulations also mandate the use of specific signaling and lighting systems for vehicles equipped with pintle hitches. These requirements may include additional brake lights, turn signals, and reflectors to enhance visibility and communication with other road users, particularly important when maneuvering large, heavy loads.

Lastly, safety regulations often address the need for proper documentation and record-keeping related to pintle hitch systems. This may include maintaining logs of inspections, repairs, and load capacities, which can be crucial for compliance audits and in the event of accidents or equipment failures.

Environmental Impact

The environmental impact of Pintle Hitch technology in heavy industry transport is a critical consideration for sustainable development. This innovative coupling system has the potential to significantly reduce fuel consumption and emissions through improved efficiency in heavy-duty vehicle operations.

One of the primary environmental benefits of Pintle Hitch technology is its ability to enhance load distribution and stability. By optimizing the connection between the tractor and trailer, it reduces the overall drag and resistance during transport. This improved aerodynamics leads to decreased fuel consumption, which directly translates to lower greenhouse gas emissions per ton of cargo transported.

Furthermore, the Pintle Hitch system's durability and longevity contribute to a reduction in the frequency of equipment replacement. This extended lifespan of transport components results in less manufacturing-related environmental impact and reduced waste generation over time. The robust nature of Pintle Hitch connections also minimizes the risk of accidents and spillages, which can have severe environmental consequences, especially when transporting hazardous materials.

The technology's role in enabling more efficient multi-trailer configurations is another significant factor in its environmental impact. By allowing for longer and heavier combination vehicles, Pintle Hitch systems can reduce the number of trips required for the same cargo volume. This consolidation of loads leads to fewer vehicles on the road, reducing overall traffic congestion and the associated environmental pressures.

Additionally, the improved maneuverability provided by Pintle Hitch systems allows for more precise navigation in challenging terrains. This capability can help minimize the need for extensive road infrastructure development in sensitive ecological areas, preserving natural habitats and reducing the environmental footprint of transport routes.

The adoption of Pintle Hitch technology also aligns with broader sustainability goals in the transport sector. As industries strive to meet increasingly stringent environmental regulations, the efficiency gains offered by this technology provide a practical pathway to compliance. The reduced emissions and improved fuel economy contribute to national and international efforts to combat climate change and improve air quality in urban areas.

However, it is important to note that the environmental benefits of Pintle Hitch technology are maximized when integrated with other sustainable practices in the transport industry. This includes the adoption of alternative fuels, optimized route planning, and driver training programs focused on eco-friendly driving techniques. The synergy between these various approaches can lead to a more comprehensive reduction in the environmental impact of heavy industry transport.

One of the primary environmental benefits of Pintle Hitch technology is its ability to enhance load distribution and stability. By optimizing the connection between the tractor and trailer, it reduces the overall drag and resistance during transport. This improved aerodynamics leads to decreased fuel consumption, which directly translates to lower greenhouse gas emissions per ton of cargo transported.

Furthermore, the Pintle Hitch system's durability and longevity contribute to a reduction in the frequency of equipment replacement. This extended lifespan of transport components results in less manufacturing-related environmental impact and reduced waste generation over time. The robust nature of Pintle Hitch connections also minimizes the risk of accidents and spillages, which can have severe environmental consequences, especially when transporting hazardous materials.

The technology's role in enabling more efficient multi-trailer configurations is another significant factor in its environmental impact. By allowing for longer and heavier combination vehicles, Pintle Hitch systems can reduce the number of trips required for the same cargo volume. This consolidation of loads leads to fewer vehicles on the road, reducing overall traffic congestion and the associated environmental pressures.

Additionally, the improved maneuverability provided by Pintle Hitch systems allows for more precise navigation in challenging terrains. This capability can help minimize the need for extensive road infrastructure development in sensitive ecological areas, preserving natural habitats and reducing the environmental footprint of transport routes.

The adoption of Pintle Hitch technology also aligns with broader sustainability goals in the transport sector. As industries strive to meet increasingly stringent environmental regulations, the efficiency gains offered by this technology provide a practical pathway to compliance. The reduced emissions and improved fuel economy contribute to national and international efforts to combat climate change and improve air quality in urban areas.

However, it is important to note that the environmental benefits of Pintle Hitch technology are maximized when integrated with other sustainable practices in the transport industry. This includes the adoption of alternative fuels, optimized route planning, and driver training programs focused on eco-friendly driving techniques. The synergy between these various approaches can lead to a more comprehensive reduction in the environmental impact of heavy industry transport.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!