Optimize Lithium Mine Material Handling to Reduce Conveyor Downtime

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Mining Material Handling Background and Objectives

Lithium mining has emerged as a critical industry in the global transition to clean energy, with lithium being the essential component in rechargeable batteries powering electric vehicles and renewable energy storage systems. The material handling systems in lithium mines, particularly conveyor systems, represent a crucial link in the production chain that directly impacts operational efficiency and production output. Historical data indicates that conveyor downtime in lithium mining operations can account for up to 15-20% of total production losses, translating to significant financial implications for mining companies.

The evolution of material handling technology in lithium mining has progressed from manual methods to increasingly automated systems over the past three decades. Early lithium mining operations relied heavily on truck haulage and basic conveyor systems that were prone to frequent failures and required extensive maintenance. The technological trajectory has since moved toward more sophisticated conveyor designs with improved durability, monitoring capabilities, and maintenance protocols.

Current industry benchmarks suggest that best-in-class lithium mining operations maintain conveyor availability rates of 95-97%, while average performers typically achieve 85-90%. This performance gap highlights the significant opportunity for optimization across the industry. The technical challenges are compounded by the harsh operating environments of lithium mines, which often include exposure to corrosive materials, extreme temperatures, and abrasive substances that accelerate equipment wear.

The primary objective of this technical research is to identify and evaluate innovative approaches to optimize material handling systems in lithium mining operations, with a specific focus on reducing conveyor downtime. This includes investigating advanced monitoring technologies, predictive maintenance strategies, material flow optimization techniques, and conveyor component innovations that can enhance system reliability and performance.

Secondary objectives include quantifying the potential operational and financial benefits of implementing these optimizations, establishing implementation roadmaps tailored to different scales of mining operations, and identifying key performance indicators that can effectively measure improvement in conveyor system reliability. The research also aims to explore how emerging technologies such as artificial intelligence, machine learning, and Internet of Things (IoT) can be leveraged to create intelligent material handling systems capable of self-diagnosis and adaptive operation.

The findings from this research will provide lithium mining operators with actionable insights and technical solutions to address one of their most persistent operational challenges, ultimately contributing to more efficient and sustainable lithium production to meet growing global demand.

The evolution of material handling technology in lithium mining has progressed from manual methods to increasingly automated systems over the past three decades. Early lithium mining operations relied heavily on truck haulage and basic conveyor systems that were prone to frequent failures and required extensive maintenance. The technological trajectory has since moved toward more sophisticated conveyor designs with improved durability, monitoring capabilities, and maintenance protocols.

Current industry benchmarks suggest that best-in-class lithium mining operations maintain conveyor availability rates of 95-97%, while average performers typically achieve 85-90%. This performance gap highlights the significant opportunity for optimization across the industry. The technical challenges are compounded by the harsh operating environments of lithium mines, which often include exposure to corrosive materials, extreme temperatures, and abrasive substances that accelerate equipment wear.

The primary objective of this technical research is to identify and evaluate innovative approaches to optimize material handling systems in lithium mining operations, with a specific focus on reducing conveyor downtime. This includes investigating advanced monitoring technologies, predictive maintenance strategies, material flow optimization techniques, and conveyor component innovations that can enhance system reliability and performance.

Secondary objectives include quantifying the potential operational and financial benefits of implementing these optimizations, establishing implementation roadmaps tailored to different scales of mining operations, and identifying key performance indicators that can effectively measure improvement in conveyor system reliability. The research also aims to explore how emerging technologies such as artificial intelligence, machine learning, and Internet of Things (IoT) can be leveraged to create intelligent material handling systems capable of self-diagnosis and adaptive operation.

The findings from this research will provide lithium mining operators with actionable insights and technical solutions to address one of their most persistent operational challenges, ultimately contributing to more efficient and sustainable lithium production to meet growing global demand.

Market Demand Analysis for Efficient Lithium Production

The global lithium market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Market research indicates that global lithium demand is projected to triple by 2025 and increase nearly sixfold by 2030 compared to 2020 levels. This exponential growth trajectory places immense pressure on lithium mining operations to optimize production efficiency and minimize operational disruptions.

Material handling systems, particularly conveyor networks, represent critical infrastructure in lithium mining operations. Industry data reveals that conveyor downtime accounts for approximately 17% of total production losses in mining operations, with each hour of unplanned downtime potentially costing between $80,000 and $150,000 depending on the scale of operations. This economic impact underscores the urgent market need for more reliable material handling solutions.

The lithium battery supply chain has become increasingly strategic for major economies. Countries including the United States, European Union members, and Japan have classified lithium as a critical mineral, implementing policies to secure supply chains and incentivize domestic production. These policy shifts have created additional market pressure for mining operations to maximize output while maintaining cost competitiveness.

End-users across industries are demanding more consistent lithium supply to support manufacturing schedules. Automotive manufacturers, in particular, have begun entering direct supply agreements with mining companies, emphasizing the importance of production reliability. These agreements often include performance clauses related to delivery consistency, further highlighting the market value of reduced downtime in mining operations.

The market is also witnessing increased demand for sustainable mining practices. Environmental certifications and reduced carbon footprints have become competitive advantages in securing contracts with environmentally conscious manufacturers. Optimized material handling systems that reduce energy consumption while increasing uptime align perfectly with this market trend.

Regional analysis shows particularly strong demand growth in Asia-Pacific markets, where battery gigafactory construction continues at a rapid pace. North American demand is accelerating as domestic battery production capacity expands in response to policy incentives. This geographic distribution of demand creates additional logistical challenges that efficient production must address.

Market forecasts suggest that mining operations capable of demonstrating superior operational reliability through reduced conveyor downtime can command premium pricing in supply agreements. Industry surveys indicate that battery manufacturers are willing to pay 5-8% premiums for guaranteed supply consistency, representing a significant revenue opportunity for optimized operations.

Material handling systems, particularly conveyor networks, represent critical infrastructure in lithium mining operations. Industry data reveals that conveyor downtime accounts for approximately 17% of total production losses in mining operations, with each hour of unplanned downtime potentially costing between $80,000 and $150,000 depending on the scale of operations. This economic impact underscores the urgent market need for more reliable material handling solutions.

The lithium battery supply chain has become increasingly strategic for major economies. Countries including the United States, European Union members, and Japan have classified lithium as a critical mineral, implementing policies to secure supply chains and incentivize domestic production. These policy shifts have created additional market pressure for mining operations to maximize output while maintaining cost competitiveness.

End-users across industries are demanding more consistent lithium supply to support manufacturing schedules. Automotive manufacturers, in particular, have begun entering direct supply agreements with mining companies, emphasizing the importance of production reliability. These agreements often include performance clauses related to delivery consistency, further highlighting the market value of reduced downtime in mining operations.

The market is also witnessing increased demand for sustainable mining practices. Environmental certifications and reduced carbon footprints have become competitive advantages in securing contracts with environmentally conscious manufacturers. Optimized material handling systems that reduce energy consumption while increasing uptime align perfectly with this market trend.

Regional analysis shows particularly strong demand growth in Asia-Pacific markets, where battery gigafactory construction continues at a rapid pace. North American demand is accelerating as domestic battery production capacity expands in response to policy incentives. This geographic distribution of demand creates additional logistical challenges that efficient production must address.

Market forecasts suggest that mining operations capable of demonstrating superior operational reliability through reduced conveyor downtime can command premium pricing in supply agreements. Industry surveys indicate that battery manufacturers are willing to pay 5-8% premiums for guaranteed supply consistency, representing a significant revenue opportunity for optimized operations.

Current Conveyor Systems Challenges in Lithium Mining

Conveyor systems in lithium mining operations face significant challenges that directly impact operational efficiency and production costs. The harsh mining environment, characterized by abrasive lithium-bearing materials, dust, and varying temperature conditions, accelerates wear on conveyor components. Belt damage, roller failures, and misalignment issues occur frequently, leading to unplanned downtime that can cost operations between $10,000 and $50,000 per hour depending on the mine's scale.

Material handling challenges are particularly acute in lithium mining due to the unique properties of lithium ore. The material's high moisture content and fine particle size create adhesion problems, causing material buildup on rollers and pulleys. This accumulation not only increases power consumption but also leads to belt tracking issues and premature component failure. Additionally, the corrosive nature of some lithium compounds accelerates the deterioration of metal components in conveyor systems.

Maintenance practices present another significant challenge. Many lithium mining operations still rely on reactive or time-based maintenance approaches rather than condition-based strategies. This results in either excessive downtime due to unexpected failures or inefficient resource allocation when components are replaced before reaching their useful life. The remote location of many lithium mines further complicates maintenance logistics, with replacement parts often requiring days or weeks to arrive.

Energy efficiency represents a growing concern as operational costs and environmental considerations gain prominence. Current conveyor systems in lithium mining typically consume between 50-70% more energy than optimally designed systems due to factors such as oversizing, inefficient motors, and high friction components. This excessive energy consumption not only increases operational costs but also contributes to a larger carbon footprint.

Control systems and monitoring capabilities in existing conveyor installations often lack the sophistication needed for modern mining operations. Many systems operate without real-time load monitoring, predictive analytics, or automated adjustment capabilities. This technological gap prevents operators from identifying potential failures before they occur and optimizing conveyor performance based on changing material characteristics or production requirements.

Safety concerns remain paramount, with conveyor-related accidents accounting for approximately 30-40% of all mining equipment incidents. Inadequate guarding, insufficient emergency stop systems, and limited operator training contribute to this safety risk. Furthermore, dust generation during material transfer creates both health hazards for workers and environmental compliance challenges for mining operations.

The integration of conveyor systems with other mining processes presents coordination difficulties. Mismatched capacities between crushing, screening, and conveying equipment create bottlenecks and material handling inefficiencies. These synchronization issues are exacerbated by limited automation and communication between different process control systems.

Material handling challenges are particularly acute in lithium mining due to the unique properties of lithium ore. The material's high moisture content and fine particle size create adhesion problems, causing material buildup on rollers and pulleys. This accumulation not only increases power consumption but also leads to belt tracking issues and premature component failure. Additionally, the corrosive nature of some lithium compounds accelerates the deterioration of metal components in conveyor systems.

Maintenance practices present another significant challenge. Many lithium mining operations still rely on reactive or time-based maintenance approaches rather than condition-based strategies. This results in either excessive downtime due to unexpected failures or inefficient resource allocation when components are replaced before reaching their useful life. The remote location of many lithium mines further complicates maintenance logistics, with replacement parts often requiring days or weeks to arrive.

Energy efficiency represents a growing concern as operational costs and environmental considerations gain prominence. Current conveyor systems in lithium mining typically consume between 50-70% more energy than optimally designed systems due to factors such as oversizing, inefficient motors, and high friction components. This excessive energy consumption not only increases operational costs but also contributes to a larger carbon footprint.

Control systems and monitoring capabilities in existing conveyor installations often lack the sophistication needed for modern mining operations. Many systems operate without real-time load monitoring, predictive analytics, or automated adjustment capabilities. This technological gap prevents operators from identifying potential failures before they occur and optimizing conveyor performance based on changing material characteristics or production requirements.

Safety concerns remain paramount, with conveyor-related accidents accounting for approximately 30-40% of all mining equipment incidents. Inadequate guarding, insufficient emergency stop systems, and limited operator training contribute to this safety risk. Furthermore, dust generation during material transfer creates both health hazards for workers and environmental compliance challenges for mining operations.

The integration of conveyor systems with other mining processes presents coordination difficulties. Mismatched capacities between crushing, screening, and conveying equipment create bottlenecks and material handling inefficiencies. These synchronization issues are exacerbated by limited automation and communication between different process control systems.

Current Downtime Reduction Strategies and Implementations

01 Conveyor monitoring and maintenance systems

Advanced monitoring systems are employed in lithium mines to track conveyor performance and predict potential failures before they lead to downtime. These systems utilize sensors and data analytics to monitor critical parameters such as belt tension, motor temperature, and bearing conditions. By implementing predictive maintenance strategies, mining operations can schedule maintenance during planned downtime periods, significantly reducing unexpected conveyor failures and associated production losses.- Conveyor monitoring and maintenance systems: Advanced monitoring systems are employed in lithium mines to track conveyor performance and predict potential failures before they lead to downtime. These systems utilize sensors and data analytics to monitor critical parameters such as belt tension, motor temperature, and vibration levels. By implementing predictive maintenance strategies, mining operations can schedule repairs during planned downtime periods, significantly reducing unexpected conveyor failures and associated production losses.

- Automated material handling solutions: Automated systems for handling lithium ore and processed materials help minimize conveyor downtime by optimizing load distribution and reducing mechanical stress. These solutions include robotic loading systems, automated transfer points, and intelligent routing mechanisms that can adapt to changing operational conditions. By reducing manual intervention and implementing consistent material flow patterns, these systems decrease the wear and tear on conveyor components, extending equipment life and reducing maintenance-related downtime.

- Redundant conveyor systems and quick-change components: Lithium mining operations implement redundant conveyor systems and modular components that can be quickly replaced to minimize downtime. These systems include parallel conveyor lines, bypass options, and standardized components designed for rapid exchange. When a conveyor failure occurs, production can be temporarily rerouted while repairs are made, maintaining operational continuity. The use of standardized, modular components allows maintenance teams to quickly replace damaged parts without extensive system disassembly.

- Remote diagnostics and control systems: Remote monitoring and control technologies enable real-time diagnostics and troubleshooting of conveyor systems in lithium mines, reducing response time to potential issues. These systems allow engineers to assess conveyor performance from centralized control rooms or even off-site locations, identifying problems before they escalate into failures causing extended downtime. Remote control capabilities also enable operators to make adjustments to conveyor operations without physically accessing potentially hazardous areas, improving both efficiency and safety.

- Environmental adaptation and protection systems: Specialized conveyor designs and protective measures address the harsh environmental conditions often found in lithium mining operations, which can contribute to conveyor failures and downtime. These systems include dust suppression technologies, corrosion-resistant materials, and climate control solutions for sensitive components. By protecting conveyor systems from environmental factors such as extreme temperatures, dust, and corrosive materials, these adaptations significantly extend equipment lifespan and reduce environment-related failures that would otherwise cause operational downtime.

02 Automated material handling solutions

Automated systems for material handling in lithium mines include robotic loaders, autonomous vehicles, and smart conveyor systems that can adapt to changing operational conditions. These technologies reduce human intervention requirements and improve efficiency in material transport. Automation helps maintain consistent operation speeds, reduces handling errors, and minimizes downtime by eliminating operator-related delays and improving overall system reliability in harsh mining environments.Expand Specific Solutions03 Fault detection and rapid response systems

Specialized fault detection systems are implemented to quickly identify conveyor malfunctions in lithium mining operations. These systems include real-time monitoring tools that can detect belt misalignment, material spillage, or component failures. When issues are detected, automated alerts are generated for maintenance teams, allowing for rapid response and minimizing downtime. Some advanced systems can automatically adjust operations or safely shut down equipment to prevent catastrophic failures.Expand Specific Solutions04 Specialized conveyor designs for lithium mining

Conveyor systems specifically engineered for lithium mining applications feature robust designs that can withstand harsh environmental conditions and abrasive materials. These specialized conveyors incorporate wear-resistant components, dust containment systems, and modular designs that facilitate quick replacement of damaged parts. Some designs include redundant systems that allow for continued operation at reduced capacity during partial failures, significantly reducing total downtime during maintenance events.Expand Specific Solutions05 Integrated control and communication networks

Comprehensive control systems integrate various components of material handling operations in lithium mines through advanced communication networks. These systems provide centralized monitoring and control capabilities, allowing operators to manage multiple conveyor lines and transfer points from a single interface. The integration enables coordinated responses to disruptions, load balancing between parallel systems, and efficient rerouting of materials when a conveyor section requires maintenance, thereby minimizing the impact of localized downtime on overall production.Expand Specific Solutions

Key Industry Players in Mining Conveyor Solutions

The lithium mine material handling optimization market is in a growth phase, characterized by increasing demand for efficient conveyor systems to reduce downtime in mining operations. The market is expanding rapidly due to the global surge in lithium demand for electric vehicle batteries. Technologically, solutions range from emerging to mature, with companies like Komatsu, Caterpillar, and Siemens leading with advanced automation and predictive maintenance systems. Chinese players such as Contemporary Amperex Technology and Hefei Guoxuan are gaining prominence by integrating battery manufacturing expertise with mining efficiency solutions. Academic institutions like the University of Tokyo and University of Science & Technology Beijing are contributing research innovations, while specialized firms like Lilac Solutions are developing novel extraction technologies that complement material handling improvements.

Siemens AG

Technical Solution: Siemens has engineered the SIMINE Material Handling System specifically optimized for lithium mining operations. This comprehensive solution integrates their SIMATIC automation technology with advanced drive systems and digital twin modeling to minimize conveyor downtime. The system employs distributed control architecture with redundant PLC networks that maintain operation even during partial system failures. Siemens' solution features their proprietary Condition Monitoring System (CMS) that utilizes acoustic sensors and thermal imaging to detect early signs of component wear or failure in conveyor systems. Their Digital Enterprise platform creates virtual models of the entire material handling process, enabling simulation-based optimization before physical implementation. The system also incorporates SIPLUS extreme components designed specifically to withstand the harsh conditions of lithium mining environments, including resistance to dust, chemical exposure, and temperature fluctuations.

Strengths: Industry-leading automation integration capabilities; comprehensive digital twin modeling allows for virtual testing of modifications; modular design enables scalable implementation. Weaknesses: Higher complexity requires specialized technical expertise for maintenance; significant initial investment compared to conventional systems; optimization benefits may take longer to realize in existing operations versus new installations.

EPIROC ROCK DRILLS AB

Technical Solution: Epiroc has developed the SmartROC Mining System with specialized modules for lithium mining material handling. Their solution focuses on optimizing the entire material flow from extraction to conveyor transport, addressing downtime issues at their source. The system employs their patented Rig Control System (RCS) that coordinates drilling and blasting operations to produce optimally sized material that reduces crusher and conveyor jams. Their conveyor optimization technology includes the BeltVision monitoring system that uses high-definition cameras and machine vision algorithms to detect potential belt issues including tears, misalignment, and material buildup. Epiroc's solution also features their Certiq telematics platform that provides real-time monitoring of conveyor performance metrics and automatically adjusts operational parameters to prevent conditions that lead to downtime. The system incorporates predictive maintenance scheduling based on actual operating conditions rather than fixed time intervals, ensuring maintenance occurs before failures while avoiding unnecessary downtime for scheduled maintenance.

Strengths: Holistic approach addressing material handling from extraction through transport; robust equipment designed specifically for harsh mining environments; integration with drilling and crushing operations for comprehensive optimization. Weaknesses: Greater focus on upstream processes than specialized conveyor technology; requires coordination across multiple operational departments; implementation complexity in existing operations with mixed equipment fleets.

Critical Technologies for Conveyor Reliability Enhancement

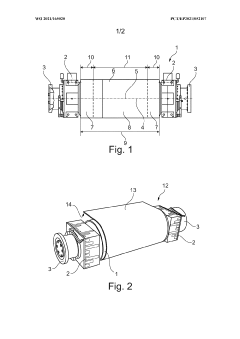

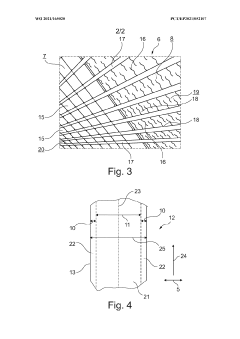

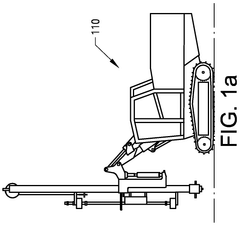

Conveyor-belt drum with sliding regions

PatentWO2021165020A1

Innovation

- A conveyor belt drum design featuring a drive area with cleats for efficient force transmission and sliding areas with aluminum oxide coatings, where the drive area is strategically minimized to reduce wear, allowing the conveyor belt to slide on the sliding areas, thereby reducing friction and wear on the edges.

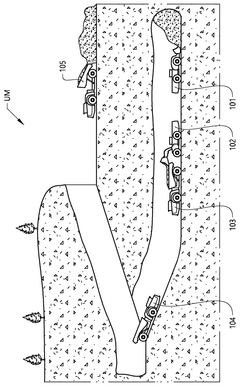

Just in time assistance for mining machine

PatentWO2025116787A1

Innovation

- A method that collects data on task time consumption to determine expected completion times for tasks performed by mining and construction machines, allowing for adjustments in machine speed to minimize downtime between tasks.

Environmental Impact Assessment of Material Handling Systems

Material handling systems in lithium mining operations have significant environmental implications that must be thoroughly assessed. The extraction and processing of lithium, a critical component for batteries in electric vehicles and renewable energy storage, involves extensive material movement that can impact surrounding ecosystems. Conveyor systems, while efficient for transporting ore, create environmental challenges including dust generation, noise pollution, and habitat disruption along their routes.

Dust emissions from conveyor transfer points represent a major environmental concern, potentially affecting air quality and causing respiratory issues for both workers and nearby communities. These particulates can also settle on vegetation, disrupting photosynthesis and potentially entering local water systems. Modern dust suppression technologies, including water sprays, enclosures, and filtration systems, can significantly reduce these emissions but require regular maintenance to remain effective.

Energy consumption of material handling systems constitutes another environmental consideration. Traditional conveyor systems demand substantial electricity, contributing to carbon emissions when powered by non-renewable sources. The implementation of regenerative braking systems, energy-efficient motors, and variable frequency drives can reduce energy requirements by 15-30%, decreasing the overall carbon footprint of mining operations.

Water usage and potential contamination present additional environmental challenges. Wet dust suppression methods consume significant water resources in often water-scarce mining regions. Runoff from these systems may contain suspended solids and potentially harmful chemicals that can impact local watersheds. Closed-loop water systems and dry dust collection alternatives offer more sustainable approaches but may require higher initial investment.

Land disturbance from conveyor installations creates habitat fragmentation and can disrupt wildlife migration patterns. The physical footprint of conveyor foundations, support structures, and access roads contributes to ecosystem alteration. Elevated conveyor designs and wildlife crossings can mitigate some of these impacts, though complete avoidance of ecological disruption remains challenging in large-scale operations.

Noise pollution from conveyor operations affects both workers and local wildlife, potentially disrupting communication, breeding patterns, and natural behaviors of sensitive species. Sound-dampening technologies, enclosed systems, and strategic placement of conveyors away from sensitive habitats can reduce acoustic impacts, though these considerations must be integrated early in system design phases to be most effective.

Dust emissions from conveyor transfer points represent a major environmental concern, potentially affecting air quality and causing respiratory issues for both workers and nearby communities. These particulates can also settle on vegetation, disrupting photosynthesis and potentially entering local water systems. Modern dust suppression technologies, including water sprays, enclosures, and filtration systems, can significantly reduce these emissions but require regular maintenance to remain effective.

Energy consumption of material handling systems constitutes another environmental consideration. Traditional conveyor systems demand substantial electricity, contributing to carbon emissions when powered by non-renewable sources. The implementation of regenerative braking systems, energy-efficient motors, and variable frequency drives can reduce energy requirements by 15-30%, decreasing the overall carbon footprint of mining operations.

Water usage and potential contamination present additional environmental challenges. Wet dust suppression methods consume significant water resources in often water-scarce mining regions. Runoff from these systems may contain suspended solids and potentially harmful chemicals that can impact local watersheds. Closed-loop water systems and dry dust collection alternatives offer more sustainable approaches but may require higher initial investment.

Land disturbance from conveyor installations creates habitat fragmentation and can disrupt wildlife migration patterns. The physical footprint of conveyor foundations, support structures, and access roads contributes to ecosystem alteration. Elevated conveyor designs and wildlife crossings can mitigate some of these impacts, though complete avoidance of ecological disruption remains challenging in large-scale operations.

Noise pollution from conveyor operations affects both workers and local wildlife, potentially disrupting communication, breeding patterns, and natural behaviors of sensitive species. Sound-dampening technologies, enclosed systems, and strategic placement of conveyors away from sensitive habitats can reduce acoustic impacts, though these considerations must be integrated early in system design phases to be most effective.

Predictive Maintenance Technologies for Conveyor Longevity

Predictive maintenance technologies represent a significant advancement in conveyor system management for lithium mining operations. These technologies utilize sophisticated sensor networks that continuously monitor critical parameters including vibration patterns, temperature fluctuations, motor current signatures, and belt alignment. The integration of these sensors with advanced analytics platforms enables real-time data processing and anomaly detection before catastrophic failures occur.

Machine learning algorithms form the backbone of modern predictive maintenance systems, analyzing historical failure data to identify patterns that precede equipment breakdown. These algorithms become increasingly accurate over time as they process more operational data, allowing for highly precise failure predictions. In lithium mining environments, where conveyor systems operate under harsh conditions with abrasive materials, these predictive capabilities can extend equipment life by 25-40% according to recent industry studies.

IoT connectivity has revolutionized conveyor maintenance by enabling seamless data transmission from remote mining locations to centralized monitoring centers. This connectivity allows maintenance teams to receive instant alerts when parameters deviate from optimal ranges, facilitating prompt intervention. The implementation of digital twin technology further enhances maintenance capabilities by creating virtual replicas of physical conveyor systems that simulate wear patterns and predict maintenance needs with remarkable accuracy.

Thermal imaging technologies have proven particularly valuable for detecting overheating components in conveyor systems before they cause belt damage or fires. These systems can be mounted at strategic points along conveyor routes to continuously monitor bearing temperatures and other critical components. Complementing thermal monitoring, acoustic sensors detect subtle changes in operational sounds that often precede mechanical failures, providing an additional layer of predictive capability.

Automated lubrication systems triggered by predictive analytics represent another technological advancement in conveyor maintenance. These systems deliver precise amounts of lubricant exactly when needed, reducing friction-related failures while minimizing lubricant waste. For lithium mining operations, where conveyor systems may extend for kilometers across challenging terrain, drone-based inspection technologies equipped with high-resolution cameras and sensors offer efficient monitoring capabilities without requiring system shutdown.

The integration of these technologies into comprehensive maintenance management software platforms allows mining operations to transition from reactive to proactive maintenance strategies, significantly reducing unplanned downtime. Advanced systems now incorporate augmented reality interfaces that guide maintenance personnel through repair procedures, reducing human error and accelerating maintenance activities when intervention becomes necessary.

Machine learning algorithms form the backbone of modern predictive maintenance systems, analyzing historical failure data to identify patterns that precede equipment breakdown. These algorithms become increasingly accurate over time as they process more operational data, allowing for highly precise failure predictions. In lithium mining environments, where conveyor systems operate under harsh conditions with abrasive materials, these predictive capabilities can extend equipment life by 25-40% according to recent industry studies.

IoT connectivity has revolutionized conveyor maintenance by enabling seamless data transmission from remote mining locations to centralized monitoring centers. This connectivity allows maintenance teams to receive instant alerts when parameters deviate from optimal ranges, facilitating prompt intervention. The implementation of digital twin technology further enhances maintenance capabilities by creating virtual replicas of physical conveyor systems that simulate wear patterns and predict maintenance needs with remarkable accuracy.

Thermal imaging technologies have proven particularly valuable for detecting overheating components in conveyor systems before they cause belt damage or fires. These systems can be mounted at strategic points along conveyor routes to continuously monitor bearing temperatures and other critical components. Complementing thermal monitoring, acoustic sensors detect subtle changes in operational sounds that often precede mechanical failures, providing an additional layer of predictive capability.

Automated lubrication systems triggered by predictive analytics represent another technological advancement in conveyor maintenance. These systems deliver precise amounts of lubricant exactly when needed, reducing friction-related failures while minimizing lubricant waste. For lithium mining operations, where conveyor systems may extend for kilometers across challenging terrain, drone-based inspection technologies equipped with high-resolution cameras and sensors offer efficient monitoring capabilities without requiring system shutdown.

The integration of these technologies into comprehensive maintenance management software platforms allows mining operations to transition from reactive to proactive maintenance strategies, significantly reducing unplanned downtime. Advanced systems now incorporate augmented reality interfaces that guide maintenance personnel through repair procedures, reducing human error and accelerating maintenance activities when intervention becomes necessary.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!