Optimize NMC Battery Charging Rates for Rapid Cycling

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Technology Background and Optimization Goals

Lithium-ion batteries with nickel manganese cobalt oxide (NMC) cathodes have emerged as a dominant technology in the energy storage landscape over the past decade. First commercialized in the early 2000s, NMC batteries have evolved through multiple generations, from NMC111 (equal parts nickel, manganese, and cobalt) to more recent high-nickel formulations like NMC811, which offer higher energy density but present new stability challenges.

The evolution of NMC technology has been driven by the growing demand for higher energy density, longer cycle life, and faster charging capabilities across multiple industries, particularly electric vehicles and portable electronics. Current state-of-the-art NMC batteries typically deliver specific energies of 200-250 Wh/kg at the cell level, with cycle lives ranging from 1,000 to 2,000 cycles under standard conditions.

Rapid charging represents one of the most significant technical challenges for NMC batteries. While conventional charging protocols limit rates to 0.5-1C to preserve battery health, market demands increasingly push for charging rates of 3C or higher, which would enable electric vehicles to recharge in under 20 minutes. However, fast charging induces several degradation mechanisms, including lithium plating, structural disordering, and accelerated SEI growth.

The technical goal of optimizing NMC battery charging rates for rapid cycling encompasses several specific objectives. First, to develop charging protocols that enable 80% state-of-charge within 15 minutes while maintaining 80% capacity retention after 1,000 cycles. Second, to mitigate temperature rise during fast charging to below 10°C to prevent thermal runaway risks. Third, to understand and control the fundamental degradation mechanisms that occur during rapid charging cycles.

Recent advancements in computational modeling and in-situ characterization techniques have provided unprecedented insights into the dynamic processes occurring during fast charging. These tools enable researchers to visualize lithium concentration gradients, phase transformations, and mechanical stresses in real-time, creating opportunities for more sophisticated charging optimization strategies.

The optimization of NMC battery charging rates represents a multidisciplinary challenge requiring innovations in materials science, electrochemistry, thermal management, and control systems. Success in this domain would significantly accelerate electric vehicle adoption by addressing one of the most persistent consumer concerns: charging time. Furthermore, optimized rapid cycling capabilities would expand the application potential of NMC batteries in grid storage, where high power capability for frequency regulation services commands premium value.

The evolution of NMC technology has been driven by the growing demand for higher energy density, longer cycle life, and faster charging capabilities across multiple industries, particularly electric vehicles and portable electronics. Current state-of-the-art NMC batteries typically deliver specific energies of 200-250 Wh/kg at the cell level, with cycle lives ranging from 1,000 to 2,000 cycles under standard conditions.

Rapid charging represents one of the most significant technical challenges for NMC batteries. While conventional charging protocols limit rates to 0.5-1C to preserve battery health, market demands increasingly push for charging rates of 3C or higher, which would enable electric vehicles to recharge in under 20 minutes. However, fast charging induces several degradation mechanisms, including lithium plating, structural disordering, and accelerated SEI growth.

The technical goal of optimizing NMC battery charging rates for rapid cycling encompasses several specific objectives. First, to develop charging protocols that enable 80% state-of-charge within 15 minutes while maintaining 80% capacity retention after 1,000 cycles. Second, to mitigate temperature rise during fast charging to below 10°C to prevent thermal runaway risks. Third, to understand and control the fundamental degradation mechanisms that occur during rapid charging cycles.

Recent advancements in computational modeling and in-situ characterization techniques have provided unprecedented insights into the dynamic processes occurring during fast charging. These tools enable researchers to visualize lithium concentration gradients, phase transformations, and mechanical stresses in real-time, creating opportunities for more sophisticated charging optimization strategies.

The optimization of NMC battery charging rates represents a multidisciplinary challenge requiring innovations in materials science, electrochemistry, thermal management, and control systems. Success in this domain would significantly accelerate electric vehicle adoption by addressing one of the most persistent consumer concerns: charging time. Furthermore, optimized rapid cycling capabilities would expand the application potential of NMC batteries in grid storage, where high power capability for frequency regulation services commands premium value.

Market Demand Analysis for Fast-Charging Battery Solutions

The global market for fast-charging battery solutions has experienced exponential growth in recent years, primarily driven by the rapid adoption of electric vehicles (EVs) and portable electronic devices. The demand for NMC (Nickel Manganese Cobalt) batteries with optimized charging rates has become particularly pronounced as consumers increasingly prioritize reduced charging times as a critical purchasing factor.

Market research indicates that the fast-charging battery market reached $41.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 18.7% through 2030. Within this segment, NMC batteries account for approximately 38% of market share due to their favorable energy density characteristics and potential for charging rate optimization.

The automotive sector represents the largest demand driver, with major manufacturers investing heavily in fast-charging technology to address consumer concerns about EV charging times. A recent industry survey revealed that 73% of potential EV buyers consider charging time a decisive factor, with 65% expressing willingness to pay premium prices for vehicles offering significantly reduced charging durations.

Consumer electronics manufacturers have similarly identified fast-charging capabilities as a key differentiator in the highly competitive smartphone, laptop, and wearable device markets. The average consumer now expects their devices to achieve at least 50% charge in under 30 minutes, creating substantial pressure for battery technology advancement.

The industrial and grid storage sectors are emerging as significant growth areas for optimized NMC batteries. Commercial applications requiring rapid cycling, such as peak shaving and frequency regulation in power grids, represent a market segment growing at 22.3% annually. These applications demand batteries capable of withstanding thousands of rapid charge-discharge cycles while maintaining capacity and thermal stability.

Regional analysis shows Asia-Pacific leading the market with 43% share, followed by North America (28%) and Europe (24%). China dominates manufacturing capacity, while South Korea and Japan lead in advanced NMC chemistry innovations. The European market shows the fastest growth rate at 21.5% annually, driven by aggressive EV adoption policies and renewable energy integration requirements.

Market forecasts suggest that batteries capable of safely charging at rates above 3C (full charge in under 20 minutes) while maintaining cycle life above 1,000 cycles represent the current "sweet spot" for commercial viability across multiple applications. This performance threshold has become the benchmark for new product development in the fast-charging battery space.

Market research indicates that the fast-charging battery market reached $41.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 18.7% through 2030. Within this segment, NMC batteries account for approximately 38% of market share due to their favorable energy density characteristics and potential for charging rate optimization.

The automotive sector represents the largest demand driver, with major manufacturers investing heavily in fast-charging technology to address consumer concerns about EV charging times. A recent industry survey revealed that 73% of potential EV buyers consider charging time a decisive factor, with 65% expressing willingness to pay premium prices for vehicles offering significantly reduced charging durations.

Consumer electronics manufacturers have similarly identified fast-charging capabilities as a key differentiator in the highly competitive smartphone, laptop, and wearable device markets. The average consumer now expects their devices to achieve at least 50% charge in under 30 minutes, creating substantial pressure for battery technology advancement.

The industrial and grid storage sectors are emerging as significant growth areas for optimized NMC batteries. Commercial applications requiring rapid cycling, such as peak shaving and frequency regulation in power grids, represent a market segment growing at 22.3% annually. These applications demand batteries capable of withstanding thousands of rapid charge-discharge cycles while maintaining capacity and thermal stability.

Regional analysis shows Asia-Pacific leading the market with 43% share, followed by North America (28%) and Europe (24%). China dominates manufacturing capacity, while South Korea and Japan lead in advanced NMC chemistry innovations. The European market shows the fastest growth rate at 21.5% annually, driven by aggressive EV adoption policies and renewable energy integration requirements.

Market forecasts suggest that batteries capable of safely charging at rates above 3C (full charge in under 20 minutes) while maintaining cycle life above 1,000 cycles represent the current "sweet spot" for commercial viability across multiple applications. This performance threshold has become the benchmark for new product development in the fast-charging battery space.

Current Limitations and Challenges in NMC Battery Charging

Despite significant advancements in NMC (Nickel Manganese Cobalt) battery technology, several critical limitations continue to impede the optimization of charging rates for rapid cycling applications. The primary challenge stems from the inherent structural instability of NMC cathodes during fast charging processes. When subjected to high charging currents, these materials experience accelerated degradation through mechanisms including lattice distortion, phase transitions, and microcracking, which collectively compromise the battery's cycle life and safety parameters.

Thermal management presents another substantial hurdle in rapid charging scenarios. NMC batteries generate considerable heat during fast charging, with temperature increases potentially exceeding 10-15°C above ambient conditions. This thermal stress triggers parasitic side reactions at the electrode-electrolyte interface, accelerating capacity fade and potentially leading to thermal runaway events in extreme cases.

Lithium plating constitutes a particularly problematic phenomenon during rapid charging operations. At high charging rates, lithium ions cannot intercalate into graphite anodes quickly enough, resulting in metallic lithium deposition on the anode surface. This irreversible process not only reduces available lithium inventory but also creates dendrites that may penetrate the separator, causing internal short circuits and catastrophic failure.

The solid-electrolyte interphase (SEI) layer dynamics further complicate fast charging optimization. Rapid charging disrupts the stability of this protective layer, causing continuous reformation and growth that increases internal resistance and impedes ion transport. Current electrolyte formulations lack the stability required to withstand the electrochemical stress imposed by high charging currents.

From a materials science perspective, the transition metal dissolution from NMC cathodes accelerates during fast charging. Manganese and nickel ions dissolve into the electrolyte and migrate to the anode, contaminating the SEI layer and catalyzing undesirable side reactions. This phenomenon is particularly pronounced in nickel-rich NMC variants (e.g., NMC811) that offer higher energy density but exhibit lower structural stability.

Commercial battery management systems (BMS) currently lack the sophisticated algorithms and sensing capabilities needed to safely push charging rates to theoretical limits. Most systems employ conservative charging protocols that prioritize safety and longevity over charging speed, creating a significant gap between theoretical and practical charging rates.

Manufacturing inconsistencies introduce additional variability that complicates fast charging protocol development. Electrode thickness variations, non-uniform particle distribution, and inconsistent electrolyte wetting create localized "hotspots" during rapid charging that accelerate degradation and increase cell-to-cell performance variation within battery packs.

Thermal management presents another substantial hurdle in rapid charging scenarios. NMC batteries generate considerable heat during fast charging, with temperature increases potentially exceeding 10-15°C above ambient conditions. This thermal stress triggers parasitic side reactions at the electrode-electrolyte interface, accelerating capacity fade and potentially leading to thermal runaway events in extreme cases.

Lithium plating constitutes a particularly problematic phenomenon during rapid charging operations. At high charging rates, lithium ions cannot intercalate into graphite anodes quickly enough, resulting in metallic lithium deposition on the anode surface. This irreversible process not only reduces available lithium inventory but also creates dendrites that may penetrate the separator, causing internal short circuits and catastrophic failure.

The solid-electrolyte interphase (SEI) layer dynamics further complicate fast charging optimization. Rapid charging disrupts the stability of this protective layer, causing continuous reformation and growth that increases internal resistance and impedes ion transport. Current electrolyte formulations lack the stability required to withstand the electrochemical stress imposed by high charging currents.

From a materials science perspective, the transition metal dissolution from NMC cathodes accelerates during fast charging. Manganese and nickel ions dissolve into the electrolyte and migrate to the anode, contaminating the SEI layer and catalyzing undesirable side reactions. This phenomenon is particularly pronounced in nickel-rich NMC variants (e.g., NMC811) that offer higher energy density but exhibit lower structural stability.

Commercial battery management systems (BMS) currently lack the sophisticated algorithms and sensing capabilities needed to safely push charging rates to theoretical limits. Most systems employ conservative charging protocols that prioritize safety and longevity over charging speed, creating a significant gap between theoretical and practical charging rates.

Manufacturing inconsistencies introduce additional variability that complicates fast charging protocol development. Electrode thickness variations, non-uniform particle distribution, and inconsistent electrolyte wetting create localized "hotspots" during rapid charging that accelerate degradation and increase cell-to-cell performance variation within battery packs.

Current Fast-Charging Solutions for NMC Batteries

01 Fast charging protocols for NMC batteries

Various fast charging protocols have been developed specifically for NMC (Nickel Manganese Cobalt) batteries to optimize charging speed while maintaining battery health. These protocols typically involve controlling current and voltage profiles during different stages of charging to prevent overheating and degradation of the cathode material. Advanced algorithms monitor battery temperature, state of charge, and other parameters to dynamically adjust charging rates for optimal performance and longevity.- Fast charging protocols for NMC batteries: Various fast charging protocols have been developed specifically for NMC (Nickel Manganese Cobalt) batteries to optimize charging speed while maintaining battery health. These protocols typically involve controlling current and voltage profiles during different stages of charging to prevent overheating and degradation of the cathode material. Advanced algorithms can adjust charging parameters based on battery state of charge, temperature, and age to maximize charging efficiency while preserving battery lifespan.

- Temperature management during NMC battery charging: Temperature control is critical during the charging of NMC batteries to prevent thermal runaway and extend battery life. Cooling systems and thermal management techniques are employed to maintain optimal temperature ranges during charging, especially at higher rates. Some approaches include active cooling systems, passive heat dissipation designs, and charging rate modulation based on temperature feedback. These methods help prevent degradation of the nickel-rich cathode material that is particularly sensitive to high temperatures.

- Constant current-constant voltage (CC-CV) charging for NMC batteries: The CC-CV charging method is widely used for NMC batteries, where charging begins with a constant current phase until reaching a predetermined voltage, then switches to a constant voltage phase as current gradually decreases. This approach balances charging speed with battery safety and longevity. Modifications to the traditional CC-CV method include multi-stage current profiles and adaptive voltage thresholds based on battery chemistry and state of health to optimize the charging process for NMC batteries.

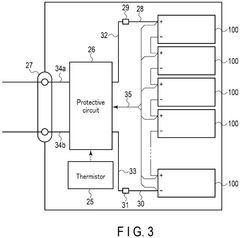

- Battery management systems for NMC charging optimization: Advanced battery management systems (BMS) are designed to optimize the charging rates of NMC batteries by monitoring various parameters such as cell voltage, current, and temperature. These systems employ sophisticated algorithms to determine the optimal charging profile based on the battery's state of charge, health, and operating conditions. The BMS can adjust charging parameters in real-time to maximize charging efficiency while preventing conditions that could lead to accelerated degradation or safety issues.

- Pulse charging techniques for NMC batteries: Pulse charging involves applying current to the battery in pulses rather than continuously, with rest periods between pulses. This technique can improve charging efficiency and reduce heat generation in NMC batteries. The pulse parameters, including amplitude, duration, and frequency, can be optimized based on the specific NMC chemistry and battery design. Some advanced pulse charging methods incorporate variable pulse widths and amplitudes that adapt to the battery's state of charge to further enhance charging performance and battery longevity.

02 Temperature management during NMC battery charging

Temperature control is critical during the charging of NMC batteries as excessive heat can accelerate degradation of the cathode material and reduce battery lifespan. Cooling systems and thermal management techniques are employed to maintain optimal temperature ranges during charging. Some approaches include active cooling mechanisms, thermal sensors for real-time monitoring, and charging rate adjustments based on temperature feedback to prevent thermal runaway and ensure safe operation.Expand Specific Solutions03 State of charge (SOC) based charging rate control

Charging rates for NMC batteries can be optimized based on the battery's state of charge. Higher charging currents are typically applied at lower SOC levels, gradually decreasing as the battery approaches full charge. This variable rate charging approach helps maximize charging speed while minimizing stress on the battery structure. Advanced battery management systems continuously monitor SOC and adjust charging parameters accordingly to balance between fast charging and battery preservation.Expand Specific Solutions04 Pulse charging techniques for NMC batteries

Pulse charging involves applying current to the battery in controlled pulses rather than continuously. This technique allows for periods of rest between charging pulses, which helps reduce heat buildup and allows ions to distribute more evenly within the NMC cathode material. Various pulse patterns, frequencies, and amplitudes have been developed to optimize the charging process, potentially extending battery life while maintaining acceptable charging speeds.Expand Specific Solutions05 Multi-stage charging protocols for NMC batteries

Multi-stage charging protocols divide the charging process into distinct phases with different current and voltage parameters. Typically, these include a constant current phase for the initial bulk charging, followed by a constant voltage phase as the battery approaches full capacity, and sometimes a float or trickle charge phase to top off the battery. This approach optimizes the balance between charging speed and battery longevity by applying appropriate charging rates at different stages of the charging cycle.Expand Specific Solutions

Critical Patents and Research in Rapid Charging Technology

Lithium nickel manganese cobalt composite oxide used as cathode active material for lithium rechargeable battery, manufacturing method thereof, and lithium rechargeable battery

PatentActiveUS7838148B2

Innovation

- A lithium nickel manganese cobalt composite oxide with an average particle size of 5-40 μm, a BET ratio surface area of 5-25 m2/g, and a tap density of at least 1.70 g/ml, obtained by sintering a mixture of lithium nickel manganese cobalt composite carbonate and a lithium compound at 650-850°C, is used as a cathode active material, enhancing battery performance.

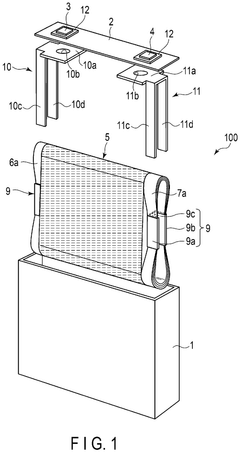

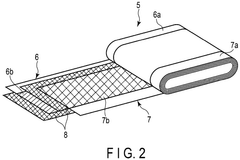

Positive electrode, secondary battery, and battery pack

PatentPendingEP4542663A1

Innovation

- A positive electrode is designed with a lithium-nickel-cobalt-manganese composite oxide represented by the general formula Li a-b Ni 1-x-y-z Co x Mn y M z O 2, where the Co/Mn ratio is 1.0 or less, and the entropy change ΔS at specific stages of charging and discharging is adjusted to be positive, promoting exothermic reactions and improving battery performance.

Thermal Management Strategies for Rapid Cycling

Effective thermal management is critical for optimizing NMC battery charging rates during rapid cycling operations. As charging rates increase, heat generation within the battery cells accelerates exponentially, potentially leading to thermal runaway, reduced cycle life, and safety hazards. Advanced thermal management strategies must balance the competing demands of fast charging and battery longevity.

Active cooling systems represent the most effective approach for high-rate charging scenarios. Liquid cooling systems utilizing water-glycol mixtures or specialized dielectric fluids can remove heat 2-3 times more efficiently than air-based systems. Recent innovations in microchannel cooling plates positioned between cells have demonstrated the ability to maintain temperature gradients below 3°C across battery packs even at 4C charging rates.

Phase change materials (PCMs) offer complementary passive thermal regulation capabilities. These materials absorb excess heat during charging through their latent heat of fusion, effectively creating a thermal buffer. Composite PCMs incorporating graphene or carbon nanotubes have shown enhanced thermal conductivity (>5 W/m·K) while maintaining high latent heat capacity, addressing previous limitations in heat transfer rates.

Predictive thermal management systems utilizing machine learning algorithms represent the cutting edge of rapid cycling optimization. These systems analyze historical charging data, ambient conditions, and battery state parameters to dynamically adjust cooling intensity and charging profiles. Studies indicate that predictive systems can reduce peak temperatures by up to 15% compared to reactive cooling approaches while enabling 20-30% faster charging times.

Cell-level thermal design innovations are equally important for rapid cycling applications. Developments in thermally conductive electrode binders and current collectors with integrated cooling channels have shown promise in laboratory settings. These approaches address the fundamental challenge of heat generation at its source rather than managing heat after it propagates through the cell structure.

Integration of thermal management with battery management systems (BMS) creates synergistic benefits for rapid cycling. Advanced BMS architectures incorporate thermal sensors at strategic locations throughout the pack, enabling spatially-resolved temperature monitoring. This data feeds into charging algorithms that can selectively reduce rates in hotspots while maintaining higher rates in cooler regions, optimizing overall charging speed while preventing localized overheating.

For commercial applications, the cost-benefit analysis of thermal management strategies must consider both capital expenses and operational impacts. While liquid cooling systems typically add 8-12% to initial battery system costs, they can extend battery lifetime by 30-40% under rapid cycling conditions, yielding favorable total cost of ownership metrics for high-utilization applications like commercial electric vehicles or grid storage systems.

Active cooling systems represent the most effective approach for high-rate charging scenarios. Liquid cooling systems utilizing water-glycol mixtures or specialized dielectric fluids can remove heat 2-3 times more efficiently than air-based systems. Recent innovations in microchannel cooling plates positioned between cells have demonstrated the ability to maintain temperature gradients below 3°C across battery packs even at 4C charging rates.

Phase change materials (PCMs) offer complementary passive thermal regulation capabilities. These materials absorb excess heat during charging through their latent heat of fusion, effectively creating a thermal buffer. Composite PCMs incorporating graphene or carbon nanotubes have shown enhanced thermal conductivity (>5 W/m·K) while maintaining high latent heat capacity, addressing previous limitations in heat transfer rates.

Predictive thermal management systems utilizing machine learning algorithms represent the cutting edge of rapid cycling optimization. These systems analyze historical charging data, ambient conditions, and battery state parameters to dynamically adjust cooling intensity and charging profiles. Studies indicate that predictive systems can reduce peak temperatures by up to 15% compared to reactive cooling approaches while enabling 20-30% faster charging times.

Cell-level thermal design innovations are equally important for rapid cycling applications. Developments in thermally conductive electrode binders and current collectors with integrated cooling channels have shown promise in laboratory settings. These approaches address the fundamental challenge of heat generation at its source rather than managing heat after it propagates through the cell structure.

Integration of thermal management with battery management systems (BMS) creates synergistic benefits for rapid cycling. Advanced BMS architectures incorporate thermal sensors at strategic locations throughout the pack, enabling spatially-resolved temperature monitoring. This data feeds into charging algorithms that can selectively reduce rates in hotspots while maintaining higher rates in cooler regions, optimizing overall charging speed while preventing localized overheating.

For commercial applications, the cost-benefit analysis of thermal management strategies must consider both capital expenses and operational impacts. While liquid cooling systems typically add 8-12% to initial battery system costs, they can extend battery lifetime by 30-40% under rapid cycling conditions, yielding favorable total cost of ownership metrics for high-utilization applications like commercial electric vehicles or grid storage systems.

Safety and Longevity Considerations in Fast-Charging Protocols

Fast-charging protocols for NMC (Nickel Manganese Cobalt) batteries present significant safety and longevity challenges that must be carefully addressed. The primary safety concerns include thermal runaway, which can occur when rapid charging generates excessive heat within the battery cells. This heat accumulation can trigger exothermic reactions between the electrolyte and electrode materials, potentially leading to catastrophic failure scenarios including fire or explosion.

Lithium plating represents another critical safety issue, particularly prevalent during fast charging at low temperatures. When lithium ions deposit as metallic lithium on the anode surface rather than intercalating properly, they can form dendrites that may penetrate the separator, causing internal short circuits and subsequent thermal events.

Gas generation during accelerated charging cycles creates additional pressure within cells, potentially compromising structural integrity. This pressure buildup can lead to cell swelling, rupture of safety mechanisms, or in extreme cases, venting of toxic gases.

From a longevity perspective, fast charging protocols significantly impact cycle life through several degradation mechanisms. Accelerated SEI (Solid Electrolyte Interphase) layer growth and breakdown occurs during rapid charging, consuming active lithium and increasing internal resistance. This process is particularly pronounced in NMC chemistry due to the higher operating voltages involved.

Structural degradation of the cathode material represents a major concern specific to NMC batteries. The layered structure of NMC materials can experience phase transitions, particle cracking, and transition metal dissolution during high-rate charging, permanently reducing capacity and power capability.

Advanced monitoring systems have emerged as essential safeguards in fast-charging implementations. These systems typically incorporate real-time temperature sensing at multiple points, differential voltage analysis to detect early signs of lithium plating, and impedance spectroscopy to track internal resistance changes indicative of degradation.

Adaptive charging algorithms represent the state-of-the-art approach to balancing charging speed with safety and longevity. These protocols dynamically adjust current rates based on battery state-of-health, temperature, and voltage response, often implementing multi-stage charging profiles that apply maximum current only within optimal operating windows.

Cell design modifications specifically engineered for fast charging include thinner electrodes to reduce diffusion limitations, advanced thermal management systems, and modified electrode compositions with dopants that enhance structural stability under high current loads.

Lithium plating represents another critical safety issue, particularly prevalent during fast charging at low temperatures. When lithium ions deposit as metallic lithium on the anode surface rather than intercalating properly, they can form dendrites that may penetrate the separator, causing internal short circuits and subsequent thermal events.

Gas generation during accelerated charging cycles creates additional pressure within cells, potentially compromising structural integrity. This pressure buildup can lead to cell swelling, rupture of safety mechanisms, or in extreme cases, venting of toxic gases.

From a longevity perspective, fast charging protocols significantly impact cycle life through several degradation mechanisms. Accelerated SEI (Solid Electrolyte Interphase) layer growth and breakdown occurs during rapid charging, consuming active lithium and increasing internal resistance. This process is particularly pronounced in NMC chemistry due to the higher operating voltages involved.

Structural degradation of the cathode material represents a major concern specific to NMC batteries. The layered structure of NMC materials can experience phase transitions, particle cracking, and transition metal dissolution during high-rate charging, permanently reducing capacity and power capability.

Advanced monitoring systems have emerged as essential safeguards in fast-charging implementations. These systems typically incorporate real-time temperature sensing at multiple points, differential voltage analysis to detect early signs of lithium plating, and impedance spectroscopy to track internal resistance changes indicative of degradation.

Adaptive charging algorithms represent the state-of-the-art approach to balancing charging speed with safety and longevity. These protocols dynamically adjust current rates based on battery state-of-health, temperature, and voltage response, often implementing multi-stage charging profiles that apply maximum current only within optimal operating windows.

Cell design modifications specifically engineered for fast charging include thinner electrodes to reduce diffusion limitations, advanced thermal management systems, and modified electrode compositions with dopants that enhance structural stability under high current loads.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!