Optimizing Butyrate Production Through Fermentation Techniques

Butyrate Fermentation Background and Objectives

Butyrate, a short-chain fatty acid, has gained significant attention in recent years due to its potential health benefits and industrial applications. The fermentation process for butyrate production has a rich history dating back to the early 20th century when researchers first identified its microbial origins. Over the decades, our understanding of butyrate fermentation has evolved dramatically, driven by advancements in biotechnology and microbiology.

The primary objective of optimizing butyrate production through fermentation techniques is to enhance yield, productivity, and cost-effectiveness. This goal is motivated by the increasing demand for butyrate in various sectors, including pharmaceuticals, food additives, and animal feed supplements. Researchers aim to develop robust and scalable fermentation processes that can meet this growing demand while addressing challenges such as substrate utilization efficiency and product recovery.

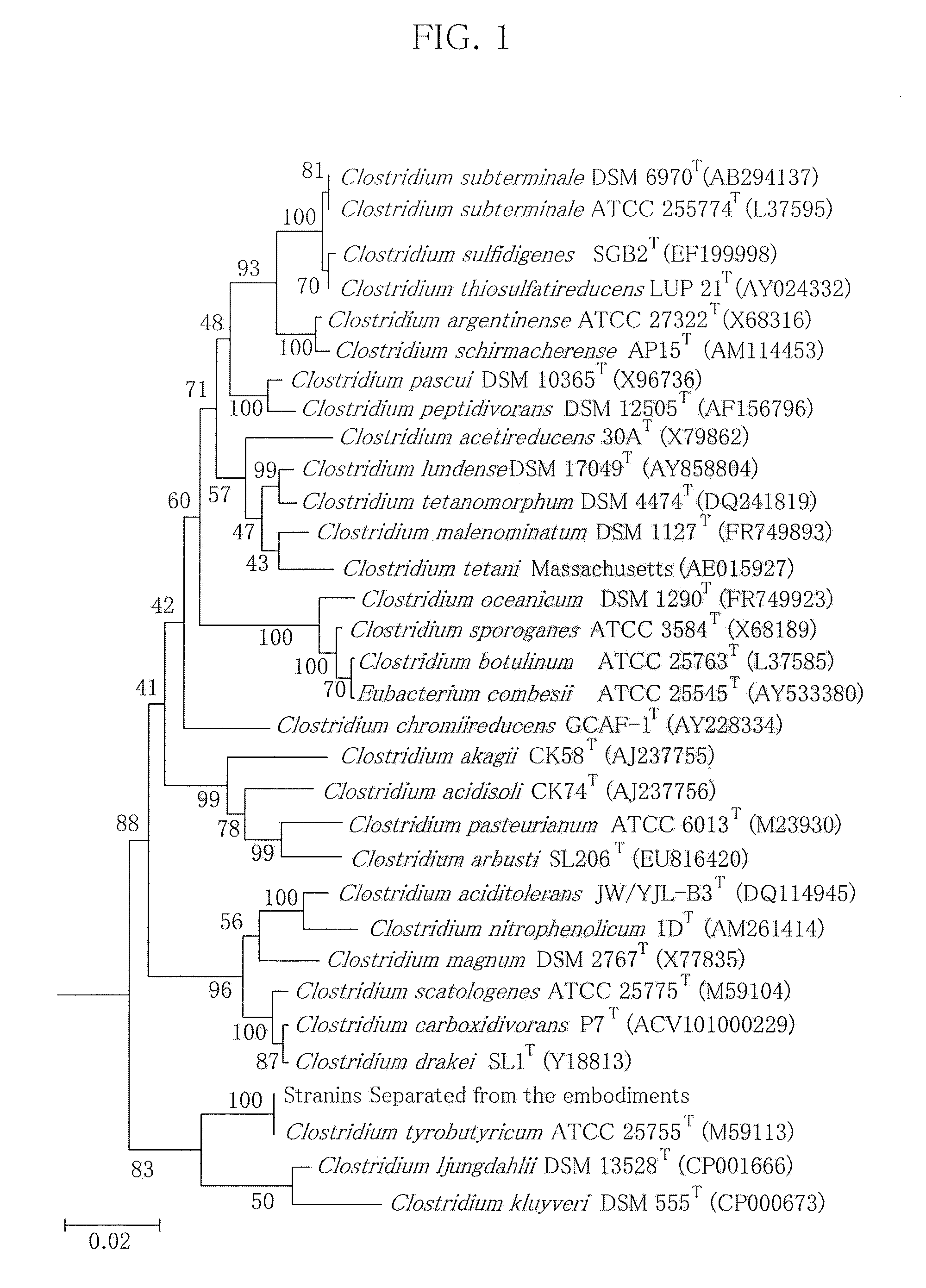

One of the key trends in butyrate fermentation technology is the exploration of novel microbial strains and genetic engineering approaches. Scientists are investigating diverse bacterial species, particularly those from the Clostridium genus, to identify high-yielding butyrate producers. Concurrently, metabolic engineering strategies are being employed to redirect cellular metabolism towards increased butyrate synthesis, often by manipulating key enzymatic pathways.

Another significant trend is the optimization of fermentation conditions and process parameters. This includes the development of advanced bioreactor designs, innovative feeding strategies, and precise control of environmental factors such as pH, temperature, and oxygen levels. These efforts aim to create optimal conditions for butyrate-producing microorganisms, thereby maximizing productivity and yield.

The integration of sustainable practices in butyrate fermentation is also gaining traction. Researchers are exploring the use of renewable feedstocks, such as agricultural waste and lignocellulosic biomass, as substrates for fermentation. This approach not only reduces production costs but also aligns with global sustainability goals by valorizing waste streams and reducing dependence on traditional carbon sources.

As we look towards the future, the field of butyrate fermentation is poised for significant advancements. Emerging technologies like synthetic biology and artificial intelligence are expected to play crucial roles in further optimizing production processes. These tools may enable the design of superior microbial strains and more efficient fermentation strategies, potentially revolutionizing butyrate production on an industrial scale.

Market Analysis for Butyrate Products

The global market for butyrate products has been experiencing significant growth in recent years, driven by increasing awareness of its health benefits and diverse applications across various industries. The butyrate market encompasses a wide range of products, including sodium butyrate, calcium butyrate, and other butyrate derivatives, which find applications in animal feed, pharmaceuticals, food and beverage, and cosmetics industries.

In the animal feed sector, butyrate products have gained traction due to their ability to improve gut health and enhance growth performance in livestock. The ban on antibiotic growth promoters in many countries has further boosted the demand for butyrate as a natural alternative. The pharmaceutical industry has shown growing interest in butyrate for its potential therapeutic applications, particularly in treating gastrointestinal disorders and certain types of cancer.

The food and beverage industry has also witnessed an uptick in the use of butyrate products, primarily as flavor enhancers and preservatives. With the rising consumer preference for natural and clean-label ingredients, butyrate-based additives are becoming increasingly popular. In the cosmetics sector, butyrate derivatives are being explored for their potential skin-beneficial properties, opening up new avenues for market growth.

Market research indicates that the Asia-Pacific region is expected to witness the highest growth rate in the butyrate market, attributed to the rapid expansion of the animal feed industry and increasing adoption of butyrate products in developing countries. North America and Europe continue to be significant markets, driven by stringent regulations on antibiotic use in livestock and growing consumer awareness of gut health.

The butyrate market is characterized by the presence of both large multinational corporations and small to medium-sized enterprises. Key players are focusing on product innovation, strategic partnerships, and geographical expansion to gain a competitive edge. The market is also witnessing increased investment in research and development to explore novel applications of butyrate and improve production efficiency.

Despite the positive growth trajectory, the butyrate market faces challenges such as high production costs and the availability of alternative products. However, ongoing advancements in fermentation techniques for optimizing butyrate production are expected to address these challenges and further drive market growth. As the demand for natural and sustainable ingredients continues to rise across industries, the butyrate market is poised for sustained expansion in the coming years.

Current Challenges in Butyrate Production

Despite significant advancements in fermentation techniques, butyrate production still faces several challenges that hinder its optimization and large-scale implementation. One of the primary obstacles is the low yield and productivity of butyrate in traditional fermentation processes. This is often attributed to the metabolic limitations of the microorganisms used, which struggle to efficiently convert substrates into butyrate at high concentrations.

Another major challenge is the inhibition of microbial growth and butyrate production by the accumulation of butyrate itself. As butyrate concentrations increase during fermentation, it can create an acidic environment that is detrimental to the producing microorganisms, leading to reduced productivity and eventual cessation of the fermentation process. This feedback inhibition necessitates the development of more robust microbial strains or innovative fermentation strategies to overcome this limitation.

The selection of appropriate substrates for butyrate production presents another significant challenge. While various carbon sources can be used, including glucose, xylose, and complex biomass, each substrate comes with its own set of challenges. For instance, lignocellulosic biomass, while abundant and cost-effective, requires extensive pretreatment and hydrolysis, which can add complexity and cost to the production process.

Furthermore, the purification and recovery of butyrate from the fermentation broth remain technically challenging and economically demanding. Traditional separation methods, such as distillation or liquid-liquid extraction, are energy-intensive and often result in significant product loss. The development of more efficient and cost-effective downstream processing techniques is crucial for improving the overall economics of butyrate production.

Maintaining consistent product quality and purity is another ongoing challenge in butyrate production. Fermentation processes can be susceptible to contamination and variability, which can affect the final product's composition and properties. Ensuring strict quality control measures and developing robust fermentation protocols are essential for meeting regulatory standards and market demands.

Lastly, the scaling up of laboratory-optimized processes to industrial production levels presents numerous engineering and economic challenges. Issues such as heat and mass transfer limitations, mixing efficiency, and process control become more pronounced at larger scales, requiring careful consideration and often significant re-optimization of fermentation parameters.

Existing Butyrate Production Methods

01 Microbial fermentation for butyrate production

Butyrate can be produced through microbial fermentation processes using various bacterial strains. These processes often involve optimizing growth conditions, substrate utilization, and metabolic pathways to enhance butyrate yield. Genetic engineering techniques may be employed to improve the efficiency of butyrate-producing microorganisms.- Microbial fermentation for butyrate production: Utilizing microorganisms for the fermentation of various substrates to produce butyrate. This process often involves optimizing fermentation conditions, selecting appropriate microbial strains, and engineering metabolic pathways to enhance butyrate yield.

- Genetic engineering of microorganisms for improved butyrate production: Modifying the genetic makeup of microorganisms to enhance their ability to produce butyrate. This may include introducing genes for key enzymes in the butyrate biosynthesis pathway or altering regulatory mechanisms to increase production efficiency.

- Substrate selection and pretreatment for butyrate production: Identifying and preparing suitable substrates for butyrate production through fermentation. This may involve the use of agricultural waste, lignocellulosic biomass, or other carbon-rich materials, as well as developing effective pretreatment methods to enhance substrate utilization by microorganisms.

- Process optimization and scale-up for industrial butyrate production: Developing and optimizing large-scale production processes for butyrate, including reactor design, process control strategies, and downstream processing techniques. This involves addressing challenges associated with scaling up laboratory processes to industrial levels while maintaining efficiency and product quality.

- Novel applications and formulations of butyrate: Exploring new uses for butyrate in various industries, such as food, pharmaceuticals, and agriculture. This includes developing novel formulations to enhance the stability, bioavailability, or targeted delivery of butyrate for specific applications.

02 Butyrate production from agricultural and industrial waste

Utilizing agricultural and industrial waste as feedstock for butyrate production offers a sustainable approach. This method involves pre-treatment of waste materials, followed by fermentation using specific microbial consortia. The process can be optimized to maximize butyrate yield while reducing waste and environmental impact.Expand Specific Solutions03 Continuous butyrate production systems

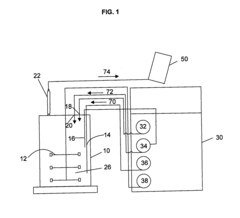

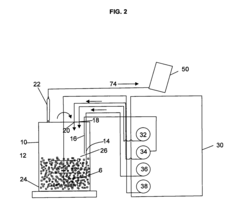

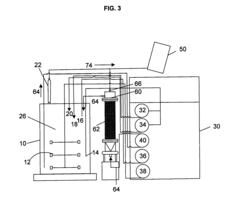

Continuous production systems for butyrate involve the use of bioreactors or fermenters designed for long-term operation. These systems often incorporate immobilized cells, continuous substrate feeding, and product removal to maintain steady-state conditions and improve overall productivity.Expand Specific Solutions04 Butyrate production through chemical synthesis

Chemical synthesis methods for butyrate production involve various reaction pathways and catalysts. These processes may include oxidation of butanol, carbonylation of propylene, or other organic chemistry approaches. The focus is on improving reaction efficiency, selectivity, and yield while minimizing byproducts and environmental impact.Expand Specific Solutions05 Butyrate production for pharmaceutical and nutraceutical applications

Specialized methods for producing high-purity butyrate suitable for pharmaceutical and nutraceutical use are developed. These processes focus on maintaining product quality, ensuring sterility, and meeting regulatory standards. Techniques may include advanced purification methods, controlled release formulations, and stability enhancement strategies.Expand Specific Solutions

Key Players in Butyrate Industry

The optimization of butyrate production through fermentation techniques is in a growth phase, with increasing market demand and technological advancements. The global butyric acid market is projected to expand significantly, driven by applications in various industries. While the technology is evolving, it has reached a moderate level of maturity. Companies like BASF SE, Cargill, Inc., and China Petroleum & Chemical Corp. are leading players, investing in research and development to enhance production efficiency. Academic institutions such as Nanjing Tech University and The Ohio State University are contributing to scientific advancements. Collaborations between industry and academia, exemplified by partnerships involving SK Innovation Co., Ltd. and Jiangnan University, are accelerating progress in this field.

Butamax Advanced Biofuels LLC

Cargill, Inc.

Innovative Approaches in Butyrate Fermentation

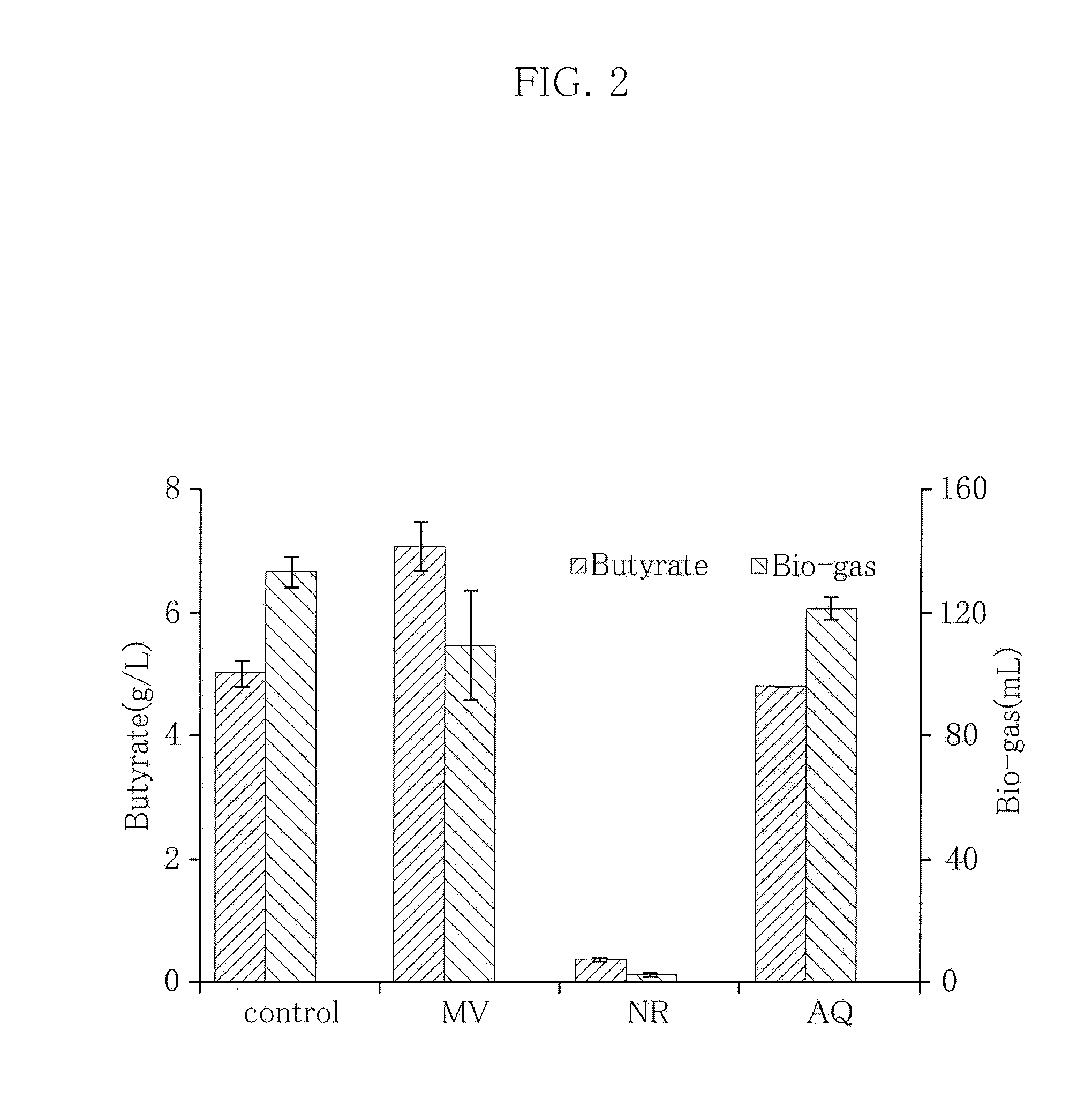

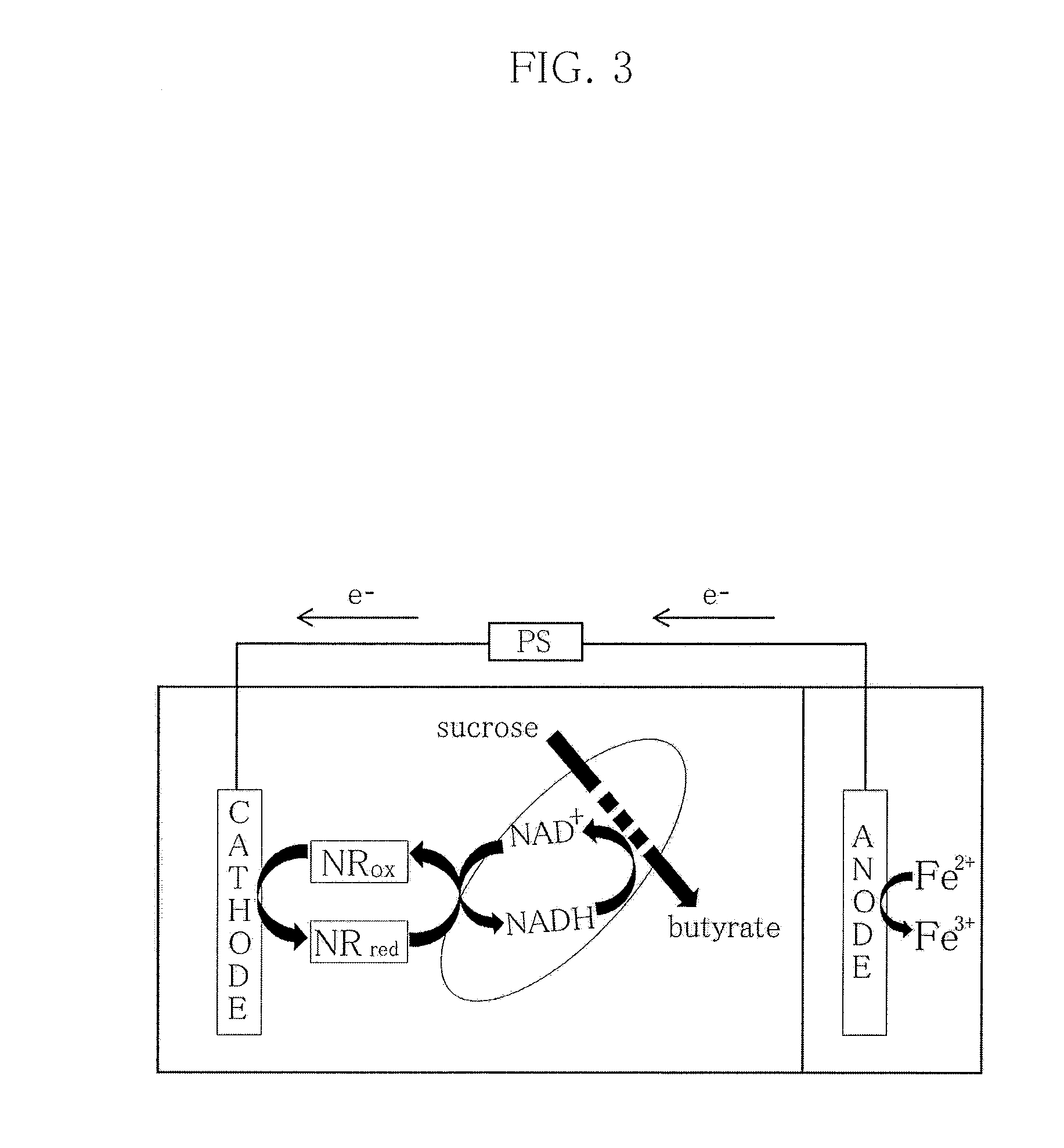

- The method involves adding an electron transfer mediator, such as Methyl Viologen, to the culture medium or using a reduction electrode to provide electrons, thereby enhancing butyrate production by facilitating electron flow and reducing byproduct formation.

- Using lactic acid or a combination of lactic acid and carbohydrates as feedstock with butyric acid-producing bacteria like Clostridium strains to enhance carbon yield and reduce CO2 production, thereby improving the fermentation process.

Regulatory Framework for Butyrate Production

The regulatory framework for butyrate production through fermentation techniques is a critical aspect that manufacturers must navigate to ensure compliance and product safety. In the United States, the Food and Drug Administration (FDA) oversees the regulation of butyrate as a food additive and dietary supplement. The FDA classifies butyrate under the Generally Recognized as Safe (GRAS) category, which allows for its use in food products without premarket approval, provided manufacturers can demonstrate its safety through scientific evidence.

European regulations, governed by the European Food Safety Authority (EFSA), have similar provisions for butyrate production. The EFSA requires thorough safety assessments and documentation for novel food ingredients, including fermentation-derived butyrate. Manufacturers must submit detailed information on the production process, composition, and potential health effects to obtain approval for use in food products within the European Union.

In terms of quality control, Good Manufacturing Practices (GMP) play a crucial role in ensuring the safety and consistency of butyrate production. These guidelines, established by regulatory bodies, outline the minimum requirements for manufacturing, testing, and quality assurance. Adherence to GMP is essential for maintaining regulatory compliance and product integrity throughout the production process.

Environmental regulations also impact butyrate production through fermentation. Waste management and emissions control are key considerations, with local and national environmental protection agencies setting standards for industrial fermentation processes. Manufacturers must implement appropriate waste treatment systems and monitor their environmental impact to meet these regulatory requirements.

Labeling regulations for butyrate-containing products vary depending on the intended use and marketing claims. In the United States, the FDA's labeling guidelines for dietary supplements apply to butyrate products marketed for health benefits. These regulations require clear identification of the product as a dietary supplement, along with accurate ingredient listings and appropriate disclaimer statements.

As the demand for butyrate in various applications grows, regulatory bodies are likely to refine and update their frameworks. Manufacturers engaged in butyrate production through fermentation techniques must stay informed about evolving regulations and be prepared to adapt their processes accordingly. This may involve ongoing communication with regulatory agencies, participation in industry associations, and investment in research to support safety and efficacy claims.

Environmental Impact of Butyrate Fermentation

The environmental impact of butyrate fermentation is a crucial aspect to consider in the optimization of butyrate production through fermentation techniques. This process, while offering significant benefits in various industries, also presents potential environmental challenges that must be addressed.

One of the primary environmental concerns associated with butyrate fermentation is the generation of waste products. The fermentation process typically produces byproducts such as carbon dioxide and other organic compounds, which, if not properly managed, can contribute to greenhouse gas emissions and air pollution. Additionally, the disposal of spent fermentation media and biomass residues requires careful consideration to prevent soil and water contamination.

Water usage is another significant environmental factor in butyrate fermentation. The process often requires substantial amounts of water for media preparation, fermentation, and downstream processing. This high water demand can strain local water resources, particularly in water-scarce regions. Implementing water recycling and efficient purification systems can help mitigate this impact, but it remains a critical consideration in large-scale production.

Energy consumption is also a notable environmental aspect of butyrate fermentation. The process typically requires controlled temperature conditions and continuous agitation, both of which demand significant energy inputs. The source of this energy plays a crucial role in determining the overall environmental footprint of the production process. Utilizing renewable energy sources can substantially reduce the carbon footprint associated with butyrate fermentation.

The choice of feedstock for butyrate fermentation can have far-reaching environmental implications. When agricultural products or byproducts are used as substrates, there may be concerns about land use changes, competition with food production, and potential impacts on biodiversity. Conversely, utilizing waste streams or non-food biomass as feedstock can contribute to waste reduction and resource efficiency, aligning with circular economy principles.

Potential environmental benefits of butyrate production through fermentation should also be considered. Butyrate and its derivatives have applications in various industries, including pharmaceuticals, food, and biofuels. When used as a replacement for petrochemical-derived products, fermentation-produced butyrate can contribute to reducing reliance on fossil fuels and decreasing overall carbon emissions.

In conclusion, while butyrate fermentation offers promising applications, its environmental impact must be carefully managed. Sustainable production practices, such as optimizing resource use, implementing closed-loop systems, and selecting environmentally friendly feedstocks, are essential for minimizing negative environmental effects. As research in this field progresses, developing more efficient and environmentally benign fermentation techniques will be crucial for ensuring the long-term sustainability of butyrate production.