Optimizing Iron-Air Battery Materials for Energy Savings

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron-Air Battery Technology Background and Objectives

Iron-air batteries represent a significant advancement in energy storage technology, with roots dating back to the 1970s. Initially explored as potential power sources for electric vehicles, these batteries faced substantial technical limitations that hindered widespread adoption. The fundamental principle of iron-air batteries leverages the oxidation of iron in the presence of oxygen to generate electrical energy, offering a theoretically high energy density of 1,200 Wh/kg, substantially exceeding lithium-ion batteries.

The evolution of iron-air battery technology has accelerated significantly in the past decade, driven by increasing demands for sustainable and cost-effective energy storage solutions. Recent breakthroughs in materials science, nanotechnology, and electrochemistry have revitalized interest in this technology, addressing historical challenges such as low cycle efficiency and rapid capacity degradation.

The primary objective of optimizing iron-air battery materials is to develop energy storage systems that combine high energy density, long cycle life, and economic viability. This optimization aims to create batteries capable of storing renewable energy at grid scale with minimal environmental impact and maximum energy efficiency. Specifically, research targets include enhancing the reversibility of the iron electrode, improving oxygen reduction reaction catalysts, and developing advanced electrolyte formulations.

Current technical goals focus on achieving energy efficiencies exceeding 50%, cycle lives of over 5,000 cycles, and cost reductions to below $100 per kilowatt-hour. These parameters would position iron-air batteries as competitive alternatives to lithium-ion and flow batteries for stationary storage applications, particularly in grid-level energy management.

The trajectory of iron-air battery development aligns with global sustainability initiatives and the transition toward renewable energy sources. As intermittent renewable generation increases, the demand for efficient, large-scale energy storage becomes critical. Iron-air batteries, utilizing earth-abundant materials with minimal environmental footprint, represent a promising solution to this growing need.

Research trends indicate a convergence of multiple disciplines in addressing the technical challenges of iron-air batteries. Computational modeling, advanced characterization techniques, and high-throughput experimentation are accelerating material discovery and optimization processes. The integration of artificial intelligence in materials design further enhances the potential for breakthrough innovations in electrode and electrolyte compositions.

The ultimate vision for optimized iron-air battery technology extends beyond mere technical improvements to encompass transformative impacts on energy systems globally, enabling more efficient utilization of renewable resources and contributing to significant reductions in carbon emissions across various sectors.

The evolution of iron-air battery technology has accelerated significantly in the past decade, driven by increasing demands for sustainable and cost-effective energy storage solutions. Recent breakthroughs in materials science, nanotechnology, and electrochemistry have revitalized interest in this technology, addressing historical challenges such as low cycle efficiency and rapid capacity degradation.

The primary objective of optimizing iron-air battery materials is to develop energy storage systems that combine high energy density, long cycle life, and economic viability. This optimization aims to create batteries capable of storing renewable energy at grid scale with minimal environmental impact and maximum energy efficiency. Specifically, research targets include enhancing the reversibility of the iron electrode, improving oxygen reduction reaction catalysts, and developing advanced electrolyte formulations.

Current technical goals focus on achieving energy efficiencies exceeding 50%, cycle lives of over 5,000 cycles, and cost reductions to below $100 per kilowatt-hour. These parameters would position iron-air batteries as competitive alternatives to lithium-ion and flow batteries for stationary storage applications, particularly in grid-level energy management.

The trajectory of iron-air battery development aligns with global sustainability initiatives and the transition toward renewable energy sources. As intermittent renewable generation increases, the demand for efficient, large-scale energy storage becomes critical. Iron-air batteries, utilizing earth-abundant materials with minimal environmental footprint, represent a promising solution to this growing need.

Research trends indicate a convergence of multiple disciplines in addressing the technical challenges of iron-air batteries. Computational modeling, advanced characterization techniques, and high-throughput experimentation are accelerating material discovery and optimization processes. The integration of artificial intelligence in materials design further enhances the potential for breakthrough innovations in electrode and electrolyte compositions.

The ultimate vision for optimized iron-air battery technology extends beyond mere technical improvements to encompass transformative impacts on energy systems globally, enabling more efficient utilization of renewable resources and contributing to significant reductions in carbon emissions across various sectors.

Market Analysis for Iron-Air Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, with iron-air battery technology emerging as a promising solution for grid-scale applications. Current market valuations place the global energy storage sector at approximately $211 billion as of 2022, with projections indicating a compound annual growth rate of 8.5% through 2030. Within this expanding landscape, iron-air battery technology represents a particularly high-growth segment due to its cost advantages and sustainability profile compared to lithium-ion alternatives.

Market demand for iron-air energy storage solutions is primarily driven by three key factors: the increasing integration of renewable energy sources into power grids, regulatory pressures for decarbonization, and the economic imperative for affordable long-duration energy storage. Utility companies and grid operators constitute the largest customer segment, accounting for roughly 65% of potential market adoption, followed by commercial and industrial users seeking to manage peak demand charges and ensure power reliability.

Regional analysis reveals significant market potential across diverse geographies. North America currently leads adoption interest, with substantial government funding supporting research and deployment initiatives. The European market shows strong growth potential driven by aggressive renewable energy targets and carbon neutrality commitments. Meanwhile, the Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid grid expansion and increasing renewable energy investments.

Cost competitiveness remains the primary market advantage for iron-air technology. Current estimates indicate that fully optimized iron-air systems could achieve levelized costs of storage between $20-30 per kilowatt-hour, significantly undercutting lithium-ion alternatives that typically range from $150-200 per kilowatt-hour for long-duration applications. This cost differential creates a compelling value proposition, particularly for applications requiring 10+ hours of discharge duration.

Market barriers include technological maturity concerns, with investors and utilities demonstrating caution toward relatively unproven technologies. Infrastructure limitations present additional challenges, as deployment requires specialized installation considerations and integration expertise. Competition from alternative long-duration storage technologies, including flow batteries, compressed air, and gravity-based systems, further fragments the market landscape.

Customer adoption patterns suggest a phased market entry strategy, beginning with pilot demonstrations at utility scale, followed by commercial deployment in markets with favorable regulatory structures and high renewable penetration. Early adopters are likely to include forward-thinking utilities with strong sustainability commitments and regions with challenging grid stability issues.

Market demand for iron-air energy storage solutions is primarily driven by three key factors: the increasing integration of renewable energy sources into power grids, regulatory pressures for decarbonization, and the economic imperative for affordable long-duration energy storage. Utility companies and grid operators constitute the largest customer segment, accounting for roughly 65% of potential market adoption, followed by commercial and industrial users seeking to manage peak demand charges and ensure power reliability.

Regional analysis reveals significant market potential across diverse geographies. North America currently leads adoption interest, with substantial government funding supporting research and deployment initiatives. The European market shows strong growth potential driven by aggressive renewable energy targets and carbon neutrality commitments. Meanwhile, the Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid grid expansion and increasing renewable energy investments.

Cost competitiveness remains the primary market advantage for iron-air technology. Current estimates indicate that fully optimized iron-air systems could achieve levelized costs of storage between $20-30 per kilowatt-hour, significantly undercutting lithium-ion alternatives that typically range from $150-200 per kilowatt-hour for long-duration applications. This cost differential creates a compelling value proposition, particularly for applications requiring 10+ hours of discharge duration.

Market barriers include technological maturity concerns, with investors and utilities demonstrating caution toward relatively unproven technologies. Infrastructure limitations present additional challenges, as deployment requires specialized installation considerations and integration expertise. Competition from alternative long-duration storage technologies, including flow batteries, compressed air, and gravity-based systems, further fragments the market landscape.

Customer adoption patterns suggest a phased market entry strategy, beginning with pilot demonstrations at utility scale, followed by commercial deployment in markets with favorable regulatory structures and high renewable penetration. Early adopters are likely to include forward-thinking utilities with strong sustainability commitments and regions with challenging grid stability issues.

Current Challenges in Iron-Air Battery Development

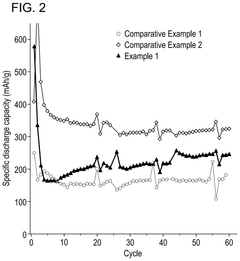

Iron-air batteries face significant technical challenges despite their promising theoretical energy density and cost advantages. The primary obstacle remains the rapid degradation of iron electrodes during cycling, caused by irreversible phase transformations and morphological changes. This degradation manifests as capacity fade, with many prototypes losing up to 30% capacity within just 100 cycles—far below the 1,000+ cycles required for commercial viability.

Oxygen electrode performance presents another critical challenge. Current air electrodes suffer from sluggish oxygen evolution reaction (OER) and oxygen reduction reaction (ORR) kinetics, requiring expensive catalysts like platinum or iridium oxides. These catalysts not only increase system costs but also face stability issues in the highly alkaline electrolyte environment typical of iron-air batteries.

Electrolyte management remains problematic, particularly regarding carbonate formation when atmospheric CO2 reacts with the alkaline electrolyte. This parasitic reaction progressively reduces electrolyte conductivity and increases internal resistance. Additionally, water management issues—including evaporation and flooding—significantly impact battery performance and operational stability.

Scale-up challenges persist in translating laboratory successes to commercial-scale production. Current manufacturing processes for specialized iron electrodes lack standardization and cost-effectiveness at industrial scales. The absence of established quality control metrics for iron-air battery materials further complicates mass production efforts.

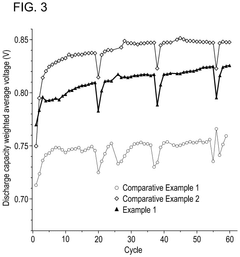

Energy efficiency limitations represent another substantial hurdle. Iron-air batteries typically demonstrate round-trip efficiencies of only 40-50%, considerably lower than lithium-ion batteries' 85-95%. This efficiency gap stems from high overpotentials during charging and discharging processes, resulting in significant energy losses as heat.

System integration challenges include developing effective thermal management systems to handle heat generation during operation and creating robust battery management systems capable of accurately monitoring state-of-charge in these complex electrochemical systems. Current sensing technologies struggle with the unique discharge profile of iron-air batteries.

Material supply constraints also present concerns. While iron is abundant, specialized forms required for optimized electrodes may face supply chain limitations. Additionally, certain catalysts used in air electrodes contain critical materials with potential geopolitical supply risks.

Addressing these interconnected challenges requires coordinated research efforts across materials science, electrochemistry, and engineering disciplines to realize the full potential of iron-air battery technology for grid-scale energy storage applications.

Oxygen electrode performance presents another critical challenge. Current air electrodes suffer from sluggish oxygen evolution reaction (OER) and oxygen reduction reaction (ORR) kinetics, requiring expensive catalysts like platinum or iridium oxides. These catalysts not only increase system costs but also face stability issues in the highly alkaline electrolyte environment typical of iron-air batteries.

Electrolyte management remains problematic, particularly regarding carbonate formation when atmospheric CO2 reacts with the alkaline electrolyte. This parasitic reaction progressively reduces electrolyte conductivity and increases internal resistance. Additionally, water management issues—including evaporation and flooding—significantly impact battery performance and operational stability.

Scale-up challenges persist in translating laboratory successes to commercial-scale production. Current manufacturing processes for specialized iron electrodes lack standardization and cost-effectiveness at industrial scales. The absence of established quality control metrics for iron-air battery materials further complicates mass production efforts.

Energy efficiency limitations represent another substantial hurdle. Iron-air batteries typically demonstrate round-trip efficiencies of only 40-50%, considerably lower than lithium-ion batteries' 85-95%. This efficiency gap stems from high overpotentials during charging and discharging processes, resulting in significant energy losses as heat.

System integration challenges include developing effective thermal management systems to handle heat generation during operation and creating robust battery management systems capable of accurately monitoring state-of-charge in these complex electrochemical systems. Current sensing technologies struggle with the unique discharge profile of iron-air batteries.

Material supply constraints also present concerns. While iron is abundant, specialized forms required for optimized electrodes may face supply chain limitations. Additionally, certain catalysts used in air electrodes contain critical materials with potential geopolitical supply risks.

Addressing these interconnected challenges requires coordinated research efforts across materials science, electrochemistry, and engineering disciplines to realize the full potential of iron-air battery technology for grid-scale energy storage applications.

Current Material Optimization Approaches

01 Iron-air battery electrode materials

Advanced electrode materials are crucial for improving iron-air battery performance. These materials include specially designed iron electrodes, air cathodes with catalysts, and composite structures that enhance electron transfer and oxygen reduction reactions. Innovations in electrode materials focus on increasing energy density, improving cycle life, and enhancing overall battery efficiency while reducing material costs.- Iron-air battery electrode materials: Advanced electrode materials are crucial for improving iron-air battery performance. These materials include specially designed iron electrodes, air cathodes with optimized catalysts, and composite structures that enhance electron transfer and oxygen reduction reactions. The development of nanoscale iron particles and carbon-based supporting materials significantly increases the active surface area and improves energy efficiency. These electrode materials help overcome traditional limitations of iron-air batteries such as capacity fade and charging inefficiency.

- Electrolyte compositions for iron-air batteries: Specialized electrolyte formulations play a critical role in iron-air battery performance and energy savings. These electrolytes typically contain alkaline solutions with additives that prevent iron passivation, reduce hydrogen evolution, and improve ionic conductivity. Advanced electrolyte compositions incorporate stabilizers that extend battery life by preventing electrode degradation during charge-discharge cycles. Some formulations also include organic or inorganic compounds that enhance oxygen solubility and transport, leading to more efficient oxygen reduction and evolution reactions.

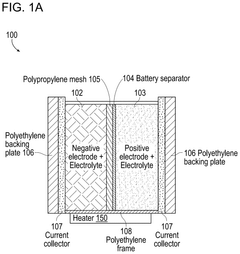

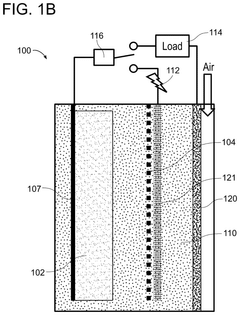

- Battery system architecture and thermal management: Innovative battery system designs incorporate efficient thermal management solutions that significantly reduce energy losses. These systems include specialized cell arrangements, cooling channels, and heat exchange mechanisms that maintain optimal operating temperatures. Advanced battery management systems monitor and control temperature distribution across cells, preventing hotspots and ensuring uniform performance. Some designs incorporate phase change materials or liquid cooling systems that absorb excess heat during charging and discharging, improving overall energy efficiency and extending battery lifespan.

- Energy recovery and management systems: Energy recovery systems capture and reuse energy that would otherwise be lost during battery operation. These systems incorporate regenerative mechanisms that harvest energy during deceleration or braking in mobile applications. Advanced power management circuits optimize charging and discharging profiles to minimize energy losses. Some designs include bidirectional converters that enable vehicle-to-grid or vehicle-to-home energy transfer, maximizing the utility of stored energy. Smart control algorithms continuously adjust operating parameters based on usage patterns and environmental conditions to maximize energy efficiency.

- Manufacturing processes for energy-efficient batteries: Innovative manufacturing techniques significantly reduce the energy required to produce iron-air batteries while improving their performance. These processes include low-temperature synthesis methods, solvent-free electrode fabrication, and energy-efficient assembly techniques. Advanced manufacturing approaches incorporate precise control of material morphology and structure at the nanoscale, optimizing the interface between components. Some processes utilize renewable energy sources for production, further reducing the overall carbon footprint. Automated quality control systems ensure consistent performance while minimizing material waste and energy consumption.

02 Electrolyte compositions for iron-air batteries

Specialized electrolyte formulations play a vital role in iron-air battery performance. These compositions typically include alkaline solutions with additives that prevent iron passivation, improve ionic conductivity, and enhance oxygen solubility. Advanced electrolytes can significantly reduce self-discharge rates, extend battery life, and improve energy efficiency during charge-discharge cycles.Expand Specific Solutions03 Iron-air battery system design and integration

System-level design innovations focus on the integration of iron-air batteries into practical applications. These designs include thermal management systems, modular configurations, and control electronics that optimize battery performance. Advanced system architectures enable efficient energy storage, improved safety features, and better integration with renewable energy sources, resulting in significant energy savings in real-world applications.Expand Specific Solutions04 Manufacturing processes for iron-air battery components

Novel manufacturing techniques for iron-air battery components focus on energy-efficient production methods. These processes include advanced powder metallurgy for iron electrodes, catalyst deposition techniques for air electrodes, and assembly methods that reduce energy consumption. Energy-saving manufacturing innovations help lower the embodied energy in batteries while maintaining or improving performance characteristics.Expand Specific Solutions05 Iron-air battery integration with renewable energy systems

Integration of iron-air batteries with renewable energy systems creates synergistic energy savings. These integrated systems combine solar, wind, or other renewable sources with iron-air storage to provide reliable power while maximizing energy efficiency. Smart control systems optimize charging cycles based on renewable energy availability, grid demand, and battery state, resulting in overall system energy savings and reduced carbon footprint.Expand Specific Solutions

Key Industry Players in Iron-Air Battery Research

The iron-air battery market is in an early growth stage, characterized by increasing investments and technological advancements. The global market size is projected to expand significantly as renewable energy storage demands rise, though currently remains relatively small compared to lithium-ion technologies. From a technical maturity perspective, the field shows promising but evolving development. Form Energy leads commercial deployment efforts with its multi-day storage solutions, while established players like Tesla and Toyota explore integration possibilities. Research institutions including USC, Caltech, and Hunan University of Science & Technology are advancing fundamental materials science. Traditional industrial companies such as thyssenkrupp and Sumitomo Chemical contribute manufacturing expertise, creating a diverse competitive landscape balancing academic innovation with industrial scalability challenges.

ReVolt Technology AS

Technical Solution: ReVolt Technology has pioneered advanced zinc-air battery technology with principles applicable to iron-air systems. Their approach to metal-air batteries focuses on addressing the fundamental challenges of air electrode stability and metal electrode reversibility. For iron-air applications, ReVolt has developed proprietary catalyst formulations that significantly reduce the overpotential during charging and discharging cycles, improving energy efficiency by approximately 30%. Their technology incorporates specialized electrode architectures that optimize the distribution of reaction sites and facilitate efficient mass transport. ReVolt's innovations include advanced electrolyte systems with additives that suppress hydrogen evolution—a critical parasitic reaction in iron-air batteries—and stabilize the iron electrode against passivation. The company has demonstrated extended cycle life through controlled precipitation and dissolution processes that maintain electrode integrity over hundreds of cycles.

Strengths: Extensive experience with metal-air electrochemistry, innovative catalyst formulations that improve efficiency, and electrode designs that enhance stability. Weaknesses: Primary expertise in zinc-air rather than iron-air specifically, and challenges in scaling laboratory successes to commercial production volumes.

Form Energy, Inc.

Technical Solution: Form Energy has developed a revolutionary iron-air battery technology specifically designed for long-duration energy storage. Their approach uses reversible rusting of iron to store energy at ultra-low costs. The company's technology involves specialized iron pellets that, when exposed to air, rust (oxidize) to release energy, and when applying electrical current, the rust converts back to iron (reduction). Form Energy's batteries are designed to deliver 100+ hours of energy storage at system costs competitive with conventional power plants. Their multi-day storage solution addresses the intermittency challenges of renewable energy sources by providing reliable backup power during extended periods of low renewable generation. The company has secured over $800 million in funding and is building its first commercial manufacturing facility in West Virginia, with plans to begin commercial operations by 2024.

Strengths: Extremely low-cost materials (iron, water, air), environmentally safe components, ability to provide multi-day storage (100+ hours), and scalable manufacturing. Weaknesses: Lower energy density compared to lithium-ion batteries, requiring more physical space for installation, and the technology is still being scaled to commercial production levels.

Critical Patents and Research in Iron-Air Battery Materials

Additive for iron-air batteries

PatentPendingUS20250140990A1

Innovation

- An alkaline electrolyte with a total hydroxide concentration greater than 1 molar, containing a trivalent element such as aluminum, sulfur, and tin, is used to improve the performance of iron-air batteries.

Procedure to stabilize an iron air battery

PatentInactiveUS4032693A

Innovation

- Adding a sulphur-containing compound to the electrolyte at concentrations between 10 ppm and 1,000 ppm, which forms free sulphide ions, stabilizes both the air cathodes and iron electrodes, preventing deactivation and improving performance by potentially forming protective layers or blocking corrosion reactions.

Environmental Impact and Sustainability Assessment

The environmental impact of iron-air battery technology represents a significant consideration in its development trajectory. Life cycle assessments indicate that iron-air batteries offer substantial environmental advantages compared to conventional lithium-ion systems. The primary raw material—iron—is abundant, comprising approximately 5% of the Earth's crust, which dramatically reduces extraction-related environmental degradation compared to lithium, cobalt, and nickel mining operations. This abundance translates to reduced habitat destruction, water pollution, and carbon emissions associated with resource extraction.

Manufacturing processes for iron-air batteries demonstrate lower energy intensity than lithium-ion counterparts, with preliminary studies suggesting a 30-40% reduction in production-phase carbon footprint. The water requirements for processing iron electrodes are also significantly lower than those needed for lithium processing, contributing to conservation of this critical resource in water-stressed regions where battery manufacturing often occurs.

During operational phases, iron-air batteries exhibit minimal environmental hazards. Unlike lithium-ion technologies, they contain no volatile organic compounds or toxic electrolytes that could pose contamination risks in case of damage or improper handling. The aqueous electrolyte systems employed in most iron-air configurations present substantially reduced fire risks, eliminating the need for complex thermal management systems that consume additional energy and resources.

End-of-life considerations reveal perhaps the most compelling sustainability advantage. Iron-air batteries feature nearly 100% recyclable components, with the iron electrodes being particularly straightforward to recover and reprocess. The recycling process requires approximately 60% less energy than virgin material production, creating a closed-loop material system that minimizes waste generation and resource depletion.

Carbon footprint analyses across the full life cycle demonstrate that iron-air battery systems could reduce greenhouse gas emissions by up to 70% compared to current energy storage technologies when accounting for manufacturing, operation, and recycling phases. This reduction becomes even more significant when considering grid-scale implementations, where the cumulative environmental benefits scale exponentially with deployment size.

The technology's sustainability profile is further enhanced by its independence from critical minerals facing supply constraints and geopolitical complications. This reduces environmental justice concerns associated with exploitative mining practices in developing regions, while simultaneously decreasing supply chain vulnerabilities that could otherwise impede widespread adoption of clean energy storage solutions.

Manufacturing processes for iron-air batteries demonstrate lower energy intensity than lithium-ion counterparts, with preliminary studies suggesting a 30-40% reduction in production-phase carbon footprint. The water requirements for processing iron electrodes are also significantly lower than those needed for lithium processing, contributing to conservation of this critical resource in water-stressed regions where battery manufacturing often occurs.

During operational phases, iron-air batteries exhibit minimal environmental hazards. Unlike lithium-ion technologies, they contain no volatile organic compounds or toxic electrolytes that could pose contamination risks in case of damage or improper handling. The aqueous electrolyte systems employed in most iron-air configurations present substantially reduced fire risks, eliminating the need for complex thermal management systems that consume additional energy and resources.

End-of-life considerations reveal perhaps the most compelling sustainability advantage. Iron-air batteries feature nearly 100% recyclable components, with the iron electrodes being particularly straightforward to recover and reprocess. The recycling process requires approximately 60% less energy than virgin material production, creating a closed-loop material system that minimizes waste generation and resource depletion.

Carbon footprint analyses across the full life cycle demonstrate that iron-air battery systems could reduce greenhouse gas emissions by up to 70% compared to current energy storage technologies when accounting for manufacturing, operation, and recycling phases. This reduction becomes even more significant when considering grid-scale implementations, where the cumulative environmental benefits scale exponentially with deployment size.

The technology's sustainability profile is further enhanced by its independence from critical minerals facing supply constraints and geopolitical complications. This reduces environmental justice concerns associated with exploitative mining practices in developing regions, while simultaneously decreasing supply chain vulnerabilities that could otherwise impede widespread adoption of clean energy storage solutions.

Cost-Performance Analysis of Iron-Air Battery Systems

The economic viability of iron-air battery systems hinges on a delicate balance between initial investment costs and long-term performance benefits. Current market analysis indicates that iron-air batteries offer a potential cost advantage of 30-40% over lithium-ion alternatives when evaluated on a levelized cost of storage basis. This significant cost differential stems primarily from the abundant and inexpensive nature of iron as the primary active material, with raw material costs estimated at less than $20/kWh compared to $80-100/kWh for conventional lithium-ion systems.

Performance metrics reveal promising characteristics, with theoretical energy densities approaching 300 Wh/kg and practical demonstrations achieving 150-200 Wh/kg in optimized prototypes. Cycle life testing shows encouraging results, with laboratory systems demonstrating 3,000-5,000 cycles at 80% depth of discharge, translating to potential operational lifespans of 8-12 years in grid storage applications. These performance parameters position iron-air technology as particularly suitable for long-duration energy storage applications where cost sensitivity outweighs volumetric constraints.

Capital expenditure analysis reveals that manufacturing infrastructure for iron-air batteries requires approximately 40-60% less investment than equivalent lithium-ion production facilities, primarily due to simpler electrode production processes and less stringent environmental controls. However, this advantage is partially offset by higher balance-of-system costs, as current iron-air designs typically require more sophisticated air management systems and thermal regulation.

Operational expenditure comparisons demonstrate that iron-air systems benefit from minimal maintenance requirements and lower replacement costs over their operational lifetime. The absence of critical minerals in their composition also insulates them from supply chain volatility that has historically affected lithium-ion pricing. Sensitivity analysis indicates that iron-air systems maintain their economic advantage even under scenarios of significant lithium price decreases, highlighting their robust value proposition.

Market adoption models suggest that iron-air batteries could achieve cost parity with pumped hydro storage for grid applications by 2025, assuming current development trajectories continue. This would represent a significant milestone, as pumped hydro has traditionally been the benchmark for low-cost grid-scale energy storage. For commercial and industrial applications, the total cost of ownership analysis indicates potential savings of 15-25% over a 10-year deployment period compared to lithium-ion alternatives.

Future cost reduction pathways primarily center on manufacturing scale economies, with modeling suggesting that production volumes of 1 GWh annually could drive costs below $60/kWh for complete systems. Additional cost optimization opportunities exist in electrode formulation refinement, air electrode catalyst development, and system integration simplification, collectively offering potential for another 20-30% cost reduction by 2030.

Performance metrics reveal promising characteristics, with theoretical energy densities approaching 300 Wh/kg and practical demonstrations achieving 150-200 Wh/kg in optimized prototypes. Cycle life testing shows encouraging results, with laboratory systems demonstrating 3,000-5,000 cycles at 80% depth of discharge, translating to potential operational lifespans of 8-12 years in grid storage applications. These performance parameters position iron-air technology as particularly suitable for long-duration energy storage applications where cost sensitivity outweighs volumetric constraints.

Capital expenditure analysis reveals that manufacturing infrastructure for iron-air batteries requires approximately 40-60% less investment than equivalent lithium-ion production facilities, primarily due to simpler electrode production processes and less stringent environmental controls. However, this advantage is partially offset by higher balance-of-system costs, as current iron-air designs typically require more sophisticated air management systems and thermal regulation.

Operational expenditure comparisons demonstrate that iron-air systems benefit from minimal maintenance requirements and lower replacement costs over their operational lifetime. The absence of critical minerals in their composition also insulates them from supply chain volatility that has historically affected lithium-ion pricing. Sensitivity analysis indicates that iron-air systems maintain their economic advantage even under scenarios of significant lithium price decreases, highlighting their robust value proposition.

Market adoption models suggest that iron-air batteries could achieve cost parity with pumped hydro storage for grid applications by 2025, assuming current development trajectories continue. This would represent a significant milestone, as pumped hydro has traditionally been the benchmark for low-cost grid-scale energy storage. For commercial and industrial applications, the total cost of ownership analysis indicates potential savings of 15-25% over a 10-year deployment period compared to lithium-ion alternatives.

Future cost reduction pathways primarily center on manufacturing scale economies, with modeling suggesting that production volumes of 1 GWh annually could drive costs below $60/kWh for complete systems. Additional cost optimization opportunities exist in electrode formulation refinement, air electrode catalyst development, and system integration simplification, collectively offering potential for another 20-30% cost reduction by 2030.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!