ORB Cathode vs Anode Architectures: Which Topologies Deliver Best Power Density?

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ORB Battery Evolution

The evolution of ORB (Omnidirectional Radial Battery) technology has been marked by significant advancements in both cathode and anode architectures. Initially, ORB designs focused on improving energy density through novel electrode configurations. Early iterations explored radial arrangements of electrodes, aiming to maximize the surface area for ion exchange within a compact form factor.

As research progressed, engineers began to differentiate between cathode-centric and anode-centric designs. Cathode-focused architectures prioritized the optimization of active material utilization and ionic conductivity within the positive electrode. These designs often featured intricate cathode structures with enhanced porosity and carefully engineered particle morphologies to facilitate rapid lithium-ion diffusion.

Conversely, anode-centric topologies concentrated on improving the negative electrode's capacity and rate capability. Innovations in this area included the development of high-surface-area carbon materials and the integration of silicon-based composites to boost energy storage potential. These advancements aimed to address the limitations of traditional graphite anodes, particularly in high-power applications.

The pursuit of superior power density became a driving force in ORB development. Researchers explored various electrode geometries, including interdigitated, spiral, and honeycomb structures, each offering unique advantages in terms of ion transport and electron conduction. The goal was to minimize internal resistance and maximize the electrode-electrolyte interface area.

Parallel to electrode design improvements, electrolyte formulations evolved to complement the advanced architectures. Novel electrolyte compositions and additives were introduced to enhance ionic conductivity, improve interfacial stability, and mitigate unwanted side reactions. This synergistic approach between electrode design and electrolyte optimization played a crucial role in pushing the boundaries of ORB performance.

Recent years have seen a convergence of cathode and anode innovations, with researchers focusing on holistic cell designs that leverage the strengths of both electrodes. This integrated approach has led to the development of hybrid architectures that combine the best features of cathode and anode-centric designs. These advanced topologies aim to achieve a balance between energy density, power output, and cycle life.

The ongoing evolution of ORB technology continues to explore new materials, nano-engineered structures, and advanced manufacturing techniques. Researchers are investigating the potential of 3D-printed electrodes, self-assembling nanostructures, and biomimetic designs inspired by natural energy storage systems. These cutting-edge approaches hold promise for further enhancing power density and overall battery performance in future ORB iterations.

As research progressed, engineers began to differentiate between cathode-centric and anode-centric designs. Cathode-focused architectures prioritized the optimization of active material utilization and ionic conductivity within the positive electrode. These designs often featured intricate cathode structures with enhanced porosity and carefully engineered particle morphologies to facilitate rapid lithium-ion diffusion.

Conversely, anode-centric topologies concentrated on improving the negative electrode's capacity and rate capability. Innovations in this area included the development of high-surface-area carbon materials and the integration of silicon-based composites to boost energy storage potential. These advancements aimed to address the limitations of traditional graphite anodes, particularly in high-power applications.

The pursuit of superior power density became a driving force in ORB development. Researchers explored various electrode geometries, including interdigitated, spiral, and honeycomb structures, each offering unique advantages in terms of ion transport and electron conduction. The goal was to minimize internal resistance and maximize the electrode-electrolyte interface area.

Parallel to electrode design improvements, electrolyte formulations evolved to complement the advanced architectures. Novel electrolyte compositions and additives were introduced to enhance ionic conductivity, improve interfacial stability, and mitigate unwanted side reactions. This synergistic approach between electrode design and electrolyte optimization played a crucial role in pushing the boundaries of ORB performance.

Recent years have seen a convergence of cathode and anode innovations, with researchers focusing on holistic cell designs that leverage the strengths of both electrodes. This integrated approach has led to the development of hybrid architectures that combine the best features of cathode and anode-centric designs. These advanced topologies aim to achieve a balance between energy density, power output, and cycle life.

The ongoing evolution of ORB technology continues to explore new materials, nano-engineered structures, and advanced manufacturing techniques. Researchers are investigating the potential of 3D-printed electrodes, self-assembling nanostructures, and biomimetic designs inspired by natural energy storage systems. These cutting-edge approaches hold promise for further enhancing power density and overall battery performance in future ORB iterations.

Market Demand Analysis

The market demand for high power density solutions in battery technologies, particularly in the context of ORB (Oxygen Reduction Battery) architectures, has been steadily increasing. This growth is primarily driven by the expanding electric vehicle (EV) market, portable electronics sector, and the rising need for efficient energy storage systems in renewable energy applications.

In the EV market, manufacturers are constantly seeking ways to improve the range and performance of their vehicles while reducing weight and cost. ORB technologies, whether cathode or anode-based, offer promising solutions to these challenges. The global EV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, indicating a substantial potential market for advanced battery technologies.

The consumer electronics industry also presents a significant market opportunity for high power density battery solutions. With the increasing functionality and power requirements of smartphones, laptops, and wearable devices, there is a growing demand for batteries that can deliver more power in smaller form factors. This sector's continuous innovation and product cycles create a constant need for improved battery technologies.

In the renewable energy sector, the intermittent nature of solar and wind power generation necessitates efficient and high-capacity energy storage solutions. Grid-scale energy storage systems utilizing advanced battery technologies are becoming increasingly important for balancing supply and demand. The global energy storage market is expected to grow substantially, with some estimates suggesting a tenfold increase in the next decade.

The industrial and aerospace sectors are also showing increased interest in high power density battery solutions. In industrial applications, there is a growing trend towards electrification of heavy machinery and equipment, driving demand for more powerful and efficient battery systems. The aerospace industry, particularly in the development of electric aircraft and drones, requires batteries with exceptional power-to-weight ratios.

However, the market demand is not uniform across all regions. Developed economies in North America, Europe, and parts of Asia are currently leading in the adoption of advanced battery technologies. Emerging markets, while showing potential, may have different priorities and adoption rates influenced by factors such as infrastructure development and regulatory environments.

The competitive landscape in this market is intense, with both established battery manufacturers and innovative startups vying for market share. This competition is driving rapid technological advancements and pushing the boundaries of what's possible in terms of power density and efficiency.

In conclusion, the market demand for high power density battery solutions, including those based on ORB architectures, is robust and growing across multiple sectors. The key drivers are the automotive industry's shift towards electrification, the ever-increasing power requirements of consumer electronics, and the growing need for efficient energy storage in renewable energy systems. As technology continues to advance, the market is likely to see further expansion, with potential for new applications and use cases emerging.

In the EV market, manufacturers are constantly seeking ways to improve the range and performance of their vehicles while reducing weight and cost. ORB technologies, whether cathode or anode-based, offer promising solutions to these challenges. The global EV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, indicating a substantial potential market for advanced battery technologies.

The consumer electronics industry also presents a significant market opportunity for high power density battery solutions. With the increasing functionality and power requirements of smartphones, laptops, and wearable devices, there is a growing demand for batteries that can deliver more power in smaller form factors. This sector's continuous innovation and product cycles create a constant need for improved battery technologies.

In the renewable energy sector, the intermittent nature of solar and wind power generation necessitates efficient and high-capacity energy storage solutions. Grid-scale energy storage systems utilizing advanced battery technologies are becoming increasingly important for balancing supply and demand. The global energy storage market is expected to grow substantially, with some estimates suggesting a tenfold increase in the next decade.

The industrial and aerospace sectors are also showing increased interest in high power density battery solutions. In industrial applications, there is a growing trend towards electrification of heavy machinery and equipment, driving demand for more powerful and efficient battery systems. The aerospace industry, particularly in the development of electric aircraft and drones, requires batteries with exceptional power-to-weight ratios.

However, the market demand is not uniform across all regions. Developed economies in North America, Europe, and parts of Asia are currently leading in the adoption of advanced battery technologies. Emerging markets, while showing potential, may have different priorities and adoption rates influenced by factors such as infrastructure development and regulatory environments.

The competitive landscape in this market is intense, with both established battery manufacturers and innovative startups vying for market share. This competition is driving rapid technological advancements and pushing the boundaries of what's possible in terms of power density and efficiency.

In conclusion, the market demand for high power density battery solutions, including those based on ORB architectures, is robust and growing across multiple sectors. The key drivers are the automotive industry's shift towards electrification, the ever-increasing power requirements of consumer electronics, and the growing need for efficient energy storage in renewable energy systems. As technology continues to advance, the market is likely to see further expansion, with potential for new applications and use cases emerging.

Current ORB Challenges

The current challenges facing Orbital Resonance Booster (ORB) technology primarily revolve around optimizing power density while maintaining system stability and efficiency. One of the key issues is the trade-off between cathode and anode architectures in ORB designs. Each topology presents unique advantages and limitations that significantly impact overall performance.

Cathode-based ORB architectures have shown promise in achieving high power densities due to their ability to concentrate electron emission. However, they face challenges in heat management and electrode degradation over time. The intense electron bombardment on the cathode surface can lead to material erosion and reduced lifespan, necessitating frequent maintenance or replacement.

Conversely, anode-based designs offer improved durability and thermal stability but often struggle to match the power density levels of their cathode counterparts. The primary challenge lies in optimizing the anode geometry to enhance electron collection efficiency without compromising the overall system compactness.

Another significant hurdle in ORB development is the management of plasma instabilities, particularly in high-power regimes. Both cathode and anode architectures must contend with phenomena such as ion acoustic turbulence and electron cyclotron instabilities, which can disrupt the resonance conditions and reduce overall efficiency.

The scaling of ORB systems to meet increasing power demands presents additional challenges. As power levels rise, maintaining uniform plasma distribution and preventing localized hot spots becomes increasingly difficult. This scaling issue affects both cathode and anode designs, albeit in different ways, requiring innovative approaches to electrode design and cooling systems.

Material selection remains a critical challenge across all ORB architectures. The search for materials that can withstand the extreme conditions of high-temperature plasma environments while maintaining optimal electrical and thermal properties is ongoing. This challenge is particularly acute for cathode-based systems, where material degradation can significantly impact performance over time.

Furthermore, the integration of ORB technology with existing power systems poses compatibility challenges. Adapting ORB outputs to match the requirements of various applications, from spacecraft propulsion to terrestrial power generation, requires sophisticated power conditioning and control systems. This integration challenge is common to both cathode and anode architectures, necessitating advancements in power electronics and system-level design.

In conclusion, while both cathode and anode ORB architectures show promise for delivering high power densities, they each face unique challenges that must be addressed to realize their full potential. Overcoming these hurdles will require interdisciplinary research efforts, combining advances in materials science, plasma physics, and electrical engineering to push the boundaries of ORB technology.

Cathode-based ORB architectures have shown promise in achieving high power densities due to their ability to concentrate electron emission. However, they face challenges in heat management and electrode degradation over time. The intense electron bombardment on the cathode surface can lead to material erosion and reduced lifespan, necessitating frequent maintenance or replacement.

Conversely, anode-based designs offer improved durability and thermal stability but often struggle to match the power density levels of their cathode counterparts. The primary challenge lies in optimizing the anode geometry to enhance electron collection efficiency without compromising the overall system compactness.

Another significant hurdle in ORB development is the management of plasma instabilities, particularly in high-power regimes. Both cathode and anode architectures must contend with phenomena such as ion acoustic turbulence and electron cyclotron instabilities, which can disrupt the resonance conditions and reduce overall efficiency.

The scaling of ORB systems to meet increasing power demands presents additional challenges. As power levels rise, maintaining uniform plasma distribution and preventing localized hot spots becomes increasingly difficult. This scaling issue affects both cathode and anode designs, albeit in different ways, requiring innovative approaches to electrode design and cooling systems.

Material selection remains a critical challenge across all ORB architectures. The search for materials that can withstand the extreme conditions of high-temperature plasma environments while maintaining optimal electrical and thermal properties is ongoing. This challenge is particularly acute for cathode-based systems, where material degradation can significantly impact performance over time.

Furthermore, the integration of ORB technology with existing power systems poses compatibility challenges. Adapting ORB outputs to match the requirements of various applications, from spacecraft propulsion to terrestrial power generation, requires sophisticated power conditioning and control systems. This integration challenge is common to both cathode and anode architectures, necessitating advancements in power electronics and system-level design.

In conclusion, while both cathode and anode ORB architectures show promise for delivering high power densities, they each face unique challenges that must be addressed to realize their full potential. Overcoming these hurdles will require interdisciplinary research efforts, combining advances in materials science, plasma physics, and electrical engineering to push the boundaries of ORB technology.

Topology Comparison

01 Electrode design for improved power density

Optimizing electrode design in ORB architectures can significantly enhance power density. This includes using advanced materials, nanostructured electrodes, and innovative geometries to increase the active surface area and improve oxygen release and reduction kinetics. Such designs can lead to faster charge/discharge rates and higher overall power output.- Electrode design for improved power density: Optimizing electrode design in ORB architectures can significantly enhance power density. This includes using advanced materials, nanostructured electrodes, and innovative geometries to increase the active surface area and facilitate faster oxygen release and reduction reactions.

- Electrolyte composition for enhanced performance: Developing specialized electrolyte compositions can improve the overall performance and power density of ORBs. This may involve using ionic liquids, polymer electrolytes, or additives that promote faster ion transport and oxygen diffusion within the battery system.

- Oxygen storage and release mechanisms: Implementing efficient oxygen storage and release mechanisms is crucial for increasing the power density of ORBs. This can include using novel oxygen carriers, catalysts, or porous materials that facilitate rapid oxygen evolution and consumption during battery operation.

- Thermal management systems: Incorporating advanced thermal management systems can help maintain optimal operating temperatures and prevent performance degradation in high-power ORB architectures. This may involve using phase change materials, heat spreaders, or active cooling systems to dissipate excess heat generated during battery operation.

- Integration of energy harvesting technologies: Combining ORB architectures with energy harvesting technologies can enhance overall power density and system efficiency. This approach may involve integrating solar cells, thermoelectric generators, or other renewable energy sources to supplement the battery's power output and extend its operational life.

02 Electrolyte composition for enhanced oxygen transport

Developing specialized electrolyte compositions can improve oxygen transport and release in ORB systems. This may involve using ionic liquids, polymer electrolytes, or additives that facilitate oxygen diffusion and solubility. Enhanced oxygen transport can lead to increased power density by reducing mass transfer limitations.Expand Specific Solutions03 Catalysts for efficient oxygen evolution and reduction

Incorporating advanced catalysts can significantly improve the efficiency of oxygen evolution and reduction reactions in ORBs. Novel catalyst materials, such as metal oxides, perovskites, or carbon-based materials, can lower activation energies and increase reaction rates, thereby enhancing power density.Expand Specific Solutions04 Thermal management for high-power ORB systems

Implementing effective thermal management strategies is crucial for maintaining high power density in ORB architectures. This may include advanced cooling systems, heat-dissipating materials, or phase change materials to regulate temperature and prevent performance degradation during high-power operation.Expand Specific Solutions05 Hybrid ORB systems for enhanced power output

Combining ORB technology with other energy storage or conversion systems can lead to improved power density. Hybrid architectures may integrate supercapacitors, fuel cells, or conventional batteries to leverage the strengths of multiple technologies and achieve higher power output and faster response times.Expand Specific Solutions

Key ORB Manufacturers

The competition landscape for ORB Cathode vs Anode Architectures in power density optimization is in a dynamic growth phase, with significant market potential driven by the increasing demand for high-performance energy storage solutions. The market is characterized by a mix of established players and innovative startups, each contributing to technological advancements. Companies like A123 Systems, LG Energy Solution, and Echion Technologies are at the forefront, developing novel materials and architectures to enhance power density. Academic institutions such as MIT and Northwestern University are also playing crucial roles in fundamental research. The technology is approaching maturity, with commercial applications emerging, but there's still room for breakthrough innovations that could reshape the competitive landscape.

Echion Technologies Ltd.

Technical Solution: Echion Technologies specializes in advanced anode materials for lithium-ion batteries, focusing on niobium-based mixed metal oxides. Their proprietary XNO® (mixed niobium oxide) technology enables ultra-fast charging capabilities while maintaining high energy density. This anode material allows for a 6C charge rate (10-minute charge) without significant capacity loss or degradation[1]. The XNO® anode architecture is designed to overcome the limitations of traditional graphite anodes, offering improved power density and cycle life. Echion's approach involves carefully engineered nanostructures that facilitate rapid lithium-ion insertion and extraction, resulting in enhanced charge/discharge rates and overall battery performance[2].

Strengths: Ultra-fast charging capability, high power density, improved cycle life. Weaknesses: Potentially higher production costs, limited commercial-scale production experience.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed a novel cathode architecture called the "hybrid surface redox" cathode. This design combines a conventional intercalation cathode with a thin surface layer of redox-active material. The hybrid structure allows for faster ion transport and electron transfer, resulting in improved power density. The cathode utilizes a core of nickel-rich NCM (nickel cobalt manganese) material with a surface layer of lithium-rich material, enabling high energy density while maintaining excellent rate capability[3]. Additionally, MIT has explored 3D electrode architectures, such as interdigitated electrode designs, which increase the active surface area and reduce ion diffusion distances, further enhancing power density[4].

Strengths: Innovative cathode design, improved power and energy density, potential for scalability. Weaknesses: Complexity in manufacturing, potential increase in production costs.

Power Density Innovations

Surface-mediated cells with high power density and high energy density

PatentActiveUS8895189B2

Innovation

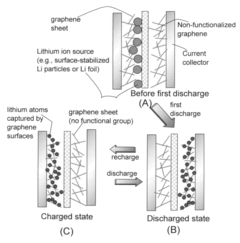

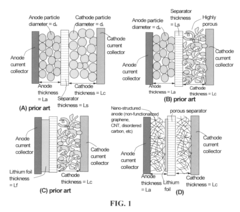

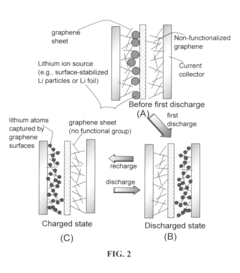

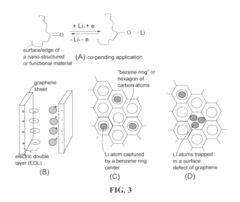

- The development of a surface-mediated cell (SMC) that facilitates the exchange of lithium ions between massive anode and cathode surfaces, eliminating the need for solid-state diffusion and utilizing high-specific-surface-area materials like graphene to achieve rapid charge and discharge cycles.

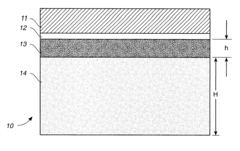

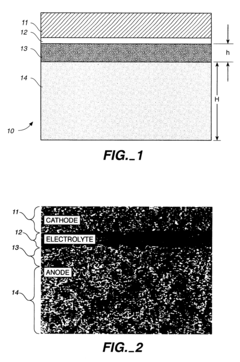

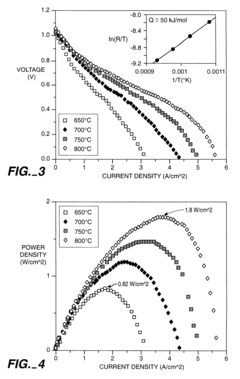

High power density solid oxide fuel cell having a graded anode

PatentInactiveUS6228521B1

Innovation

- A graded anode design is implemented using a mixture of nickel oxide and YSZ (zirconium oxide doped with yttrium oxide), with varying porosity levels to allow for easier gas transport and sufficient thickness for mechanical reliability, achieved through specific processing steps including consolidation, sintering, and reduction in a controlled atmosphere.

Material Advancements

Material advancements play a crucial role in determining the performance and efficiency of ORB (Oxygen Redox Battery) cathode and anode architectures. Recent developments in material science have led to significant improvements in power density for both cathode and anode topologies.

For cathode materials, researchers have focused on enhancing the stability and conductivity of oxygen-rich compounds. Lithium-rich layered oxides (LLOs) have emerged as promising candidates due to their high theoretical capacity and structural stability. These materials, such as Li1.2Ni0.13Mn0.54Co0.13O2, have demonstrated improved cycling performance and higher energy density compared to traditional cathode materials.

Nanostructured cathode materials have also gained attention for their ability to facilitate faster ion transport and enhance electrochemical kinetics. Carbon-coated nanoparticles and hierarchical porous structures have shown promising results in improving the power density of ORB cathodes.

On the anode side, silicon-based materials have been extensively studied due to their high theoretical capacity. However, challenges related to volume expansion during cycling have led to the development of silicon-carbon composites and silicon nanowires. These advanced materials offer improved cycling stability and higher power density compared to traditional graphite anodes.

Metal oxides, such as titanium dioxide (TiO2) and tin oxide (SnO2), have also shown potential as anode materials for ORBs. Their high theoretical capacity and structural stability make them attractive candidates for high-power applications. Researchers have explored various nanostructured forms of these materials, including nanotubes and nanosheets, to optimize their electrochemical performance.

Conductive additives and binders play a crucial role in enhancing the overall performance of both cathode and anode materials. Advanced carbon materials, such as graphene and carbon nanotubes, have been incorporated into electrode formulations to improve conductivity and mechanical stability. Novel binders, including water-soluble polymers and self-healing materials, have been developed to enhance the cohesion between active materials and current collectors.

The development of solid electrolytes has also contributed to advancements in ORB architectures. Ceramic and polymer-based solid electrolytes offer improved safety and enable the use of high-voltage cathode materials, potentially leading to higher power density in both cathode and anode configurations.

In conclusion, material advancements have significantly impacted the performance of ORB cathode and anode architectures. While both topologies have benefited from these developments, the specific impact on power density varies depending on the particular materials and configurations employed. Continued research in this field is essential to further optimize the power density of ORB systems and determine which topology ultimately delivers the best performance.

For cathode materials, researchers have focused on enhancing the stability and conductivity of oxygen-rich compounds. Lithium-rich layered oxides (LLOs) have emerged as promising candidates due to their high theoretical capacity and structural stability. These materials, such as Li1.2Ni0.13Mn0.54Co0.13O2, have demonstrated improved cycling performance and higher energy density compared to traditional cathode materials.

Nanostructured cathode materials have also gained attention for their ability to facilitate faster ion transport and enhance electrochemical kinetics. Carbon-coated nanoparticles and hierarchical porous structures have shown promising results in improving the power density of ORB cathodes.

On the anode side, silicon-based materials have been extensively studied due to their high theoretical capacity. However, challenges related to volume expansion during cycling have led to the development of silicon-carbon composites and silicon nanowires. These advanced materials offer improved cycling stability and higher power density compared to traditional graphite anodes.

Metal oxides, such as titanium dioxide (TiO2) and tin oxide (SnO2), have also shown potential as anode materials for ORBs. Their high theoretical capacity and structural stability make them attractive candidates for high-power applications. Researchers have explored various nanostructured forms of these materials, including nanotubes and nanosheets, to optimize their electrochemical performance.

Conductive additives and binders play a crucial role in enhancing the overall performance of both cathode and anode materials. Advanced carbon materials, such as graphene and carbon nanotubes, have been incorporated into electrode formulations to improve conductivity and mechanical stability. Novel binders, including water-soluble polymers and self-healing materials, have been developed to enhance the cohesion between active materials and current collectors.

The development of solid electrolytes has also contributed to advancements in ORB architectures. Ceramic and polymer-based solid electrolytes offer improved safety and enable the use of high-voltage cathode materials, potentially leading to higher power density in both cathode and anode configurations.

In conclusion, material advancements have significantly impacted the performance of ORB cathode and anode architectures. While both topologies have benefited from these developments, the specific impact on power density varies depending on the particular materials and configurations employed. Continued research in this field is essential to further optimize the power density of ORB systems and determine which topology ultimately delivers the best performance.

Thermal Management

Thermal management is a critical aspect in the design and operation of ORB (Oxygen Reduction Battery) systems, particularly when comparing cathode and anode architectures for optimal power density. The thermal characteristics of these systems significantly impact their performance, efficiency, and longevity.

In cathode-based ORB architectures, heat generation is primarily concentrated at the cathode-electrolyte interface due to the oxygen reduction reaction. This localized heat production can lead to temperature gradients across the cell, potentially causing thermal stress and degradation of materials. Effective thermal management strategies for cathode architectures often involve the use of heat spreaders or cooling plates to distribute heat more evenly and maintain optimal operating temperatures.

Conversely, anode-based ORB architectures typically exhibit a more distributed heat generation profile. The oxidation reactions occurring at the anode tend to produce heat more uniformly across the cell structure. This can potentially simplify thermal management requirements, as the heat distribution is inherently more balanced. However, the overall heat generation may be higher in anode-based systems, necessitating robust cooling mechanisms to maintain efficiency.

The choice between cathode and anode architectures significantly influences the thermal management approach. Cathode-based systems may require more sophisticated localized cooling solutions, while anode-based systems might benefit from overall cell cooling strategies. The thermal conductivity of materials used in each architecture also plays a crucial role in heat dissipation and temperature control.

Advanced thermal management techniques, such as phase change materials (PCMs) and micro-channel cooling, are being explored to enhance the thermal performance of both architectures. PCMs can absorb excess heat during high-power operation and release it during low-power periods, helping to maintain more stable temperatures. Micro-channel cooling systems offer improved heat transfer rates and can be integrated into the cell structure for efficient thermal regulation.

The impact of thermal management on power density is substantial. Effective thermal control allows for higher current densities and more aggressive operating conditions, directly translating to improved power density. However, the additional weight and complexity of thermal management systems must be carefully balanced against the gains in power output to optimize overall system performance.

In conclusion, while both cathode and anode architectures present unique thermal challenges, the key to achieving optimal power density lies in tailoring the thermal management strategy to the specific heat generation characteristics of each topology. Innovative cooling technologies and material choices will continue to play a crucial role in pushing the boundaries of ORB performance and efficiency.

In cathode-based ORB architectures, heat generation is primarily concentrated at the cathode-electrolyte interface due to the oxygen reduction reaction. This localized heat production can lead to temperature gradients across the cell, potentially causing thermal stress and degradation of materials. Effective thermal management strategies for cathode architectures often involve the use of heat spreaders or cooling plates to distribute heat more evenly and maintain optimal operating temperatures.

Conversely, anode-based ORB architectures typically exhibit a more distributed heat generation profile. The oxidation reactions occurring at the anode tend to produce heat more uniformly across the cell structure. This can potentially simplify thermal management requirements, as the heat distribution is inherently more balanced. However, the overall heat generation may be higher in anode-based systems, necessitating robust cooling mechanisms to maintain efficiency.

The choice between cathode and anode architectures significantly influences the thermal management approach. Cathode-based systems may require more sophisticated localized cooling solutions, while anode-based systems might benefit from overall cell cooling strategies. The thermal conductivity of materials used in each architecture also plays a crucial role in heat dissipation and temperature control.

Advanced thermal management techniques, such as phase change materials (PCMs) and micro-channel cooling, are being explored to enhance the thermal performance of both architectures. PCMs can absorb excess heat during high-power operation and release it during low-power periods, helping to maintain more stable temperatures. Micro-channel cooling systems offer improved heat transfer rates and can be integrated into the cell structure for efficient thermal regulation.

The impact of thermal management on power density is substantial. Effective thermal control allows for higher current densities and more aggressive operating conditions, directly translating to improved power density. However, the additional weight and complexity of thermal management systems must be carefully balanced against the gains in power output to optimize overall system performance.

In conclusion, while both cathode and anode architectures present unique thermal challenges, the key to achieving optimal power density lies in tailoring the thermal management strategy to the specific heat generation characteristics of each topology. Innovative cooling technologies and material choices will continue to play a crucial role in pushing the boundaries of ORB performance and efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!