Solid vs Liquid Electrolytes for ORBs: Safety and Ionic Conductivity Tradeoffs

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ORB Electrolyte Evolution

The evolution of electrolytes for organic radical batteries (ORBs) has been a critical factor in advancing their performance and safety. Initially, ORBs utilized liquid electrolytes due to their high ionic conductivity and ease of implementation. These early liquid electrolytes were typically composed of organic solvents such as propylene carbonate or ethylene carbonate, with dissolved lithium salts like LiPF6 or LiClO4.

As research progressed, the limitations of liquid electrolytes became apparent. Safety concerns arose due to their flammability and potential for leakage, especially in high-temperature or high-pressure environments. This led to the exploration of gel polymer electrolytes as an intermediate step between liquid and solid electrolytes. Gel polymer electrolytes offered improved safety while maintaining relatively high ionic conductivity.

The next significant milestone in ORB electrolyte evolution was the development of solid polymer electrolytes. These materials, often based on polyethylene oxide (PEO) or polyvinylidene fluoride (PVDF), provided enhanced safety and mechanical stability. However, they initially suffered from lower ionic conductivity compared to their liquid counterparts, particularly at room temperature.

Recent advancements have focused on improving the ionic conductivity of solid electrolytes while maintaining their safety advantages. This has led to the development of composite solid electrolytes, which incorporate inorganic fillers such as ceramic nanoparticles into the polymer matrix. These composites aim to combine the high ionic conductivity of ceramics with the flexibility and processability of polymers.

Another promising direction in ORB electrolyte evolution has been the exploration of ionic liquid-based electrolytes. These materials offer a unique combination of high ionic conductivity, low volatility, and improved safety compared to traditional organic solvent-based liquid electrolytes. Ionic liquids have shown particular promise in high-temperature applications where conventional electrolytes may be unstable.

The most recent trend in ORB electrolyte development is the pursuit of all-solid-state configurations. This approach aims to eliminate liquid components entirely, potentially resolving safety issues and enabling higher energy densities. Research in this area has focused on developing new solid electrolyte materials with high ionic conductivity, such as sulfide-based and oxide-based ceramic electrolytes.

As the field continues to evolve, researchers are exploring novel electrolyte designs that balance safety and ionic conductivity. This includes the development of hybrid electrolyte systems that combine the advantages of different electrolyte types, as well as the investigation of new materials and structures to optimize overall battery performance.

As research progressed, the limitations of liquid electrolytes became apparent. Safety concerns arose due to their flammability and potential for leakage, especially in high-temperature or high-pressure environments. This led to the exploration of gel polymer electrolytes as an intermediate step between liquid and solid electrolytes. Gel polymer electrolytes offered improved safety while maintaining relatively high ionic conductivity.

The next significant milestone in ORB electrolyte evolution was the development of solid polymer electrolytes. These materials, often based on polyethylene oxide (PEO) or polyvinylidene fluoride (PVDF), provided enhanced safety and mechanical stability. However, they initially suffered from lower ionic conductivity compared to their liquid counterparts, particularly at room temperature.

Recent advancements have focused on improving the ionic conductivity of solid electrolytes while maintaining their safety advantages. This has led to the development of composite solid electrolytes, which incorporate inorganic fillers such as ceramic nanoparticles into the polymer matrix. These composites aim to combine the high ionic conductivity of ceramics with the flexibility and processability of polymers.

Another promising direction in ORB electrolyte evolution has been the exploration of ionic liquid-based electrolytes. These materials offer a unique combination of high ionic conductivity, low volatility, and improved safety compared to traditional organic solvent-based liquid electrolytes. Ionic liquids have shown particular promise in high-temperature applications where conventional electrolytes may be unstable.

The most recent trend in ORB electrolyte development is the pursuit of all-solid-state configurations. This approach aims to eliminate liquid components entirely, potentially resolving safety issues and enabling higher energy densities. Research in this area has focused on developing new solid electrolyte materials with high ionic conductivity, such as sulfide-based and oxide-based ceramic electrolytes.

As the field continues to evolve, researchers are exploring novel electrolyte designs that balance safety and ionic conductivity. This includes the development of hybrid electrolyte systems that combine the advantages of different electrolyte types, as well as the investigation of new materials and structures to optimize overall battery performance.

Market Demand Analysis

The market demand for organic redox batteries (ORBs) has been steadily growing due to the increasing need for sustainable and efficient energy storage solutions. As the world transitions towards renewable energy sources, the demand for advanced battery technologies that can effectively store and distribute power has surged.

ORBs have garnered significant attention in recent years, particularly in the context of grid-scale energy storage and electric vehicle applications. The market for these batteries is driven by their potential to offer higher energy density, longer cycle life, and lower production costs compared to traditional lithium-ion batteries.

The choice between solid and liquid electrolytes in ORBs represents a critical decision point for manufacturers and end-users. This choice directly impacts the safety and performance characteristics of the batteries, influencing market adoption rates and potential applications.

Liquid electrolytes have traditionally dominated the ORB market due to their high ionic conductivity, which allows for rapid charge and discharge cycles. This property is particularly valuable in applications requiring quick response times, such as grid frequency regulation and electric vehicle fast charging. However, safety concerns associated with liquid electrolytes, including the risk of leakage and flammability, have prompted research into solid electrolyte alternatives.

Solid electrolytes offer enhanced safety features, addressing many of the concerns associated with liquid electrolytes. The non-flammable nature of solid electrolytes reduces the risk of thermal runaway and fire, making them attractive for applications where safety is paramount, such as in aerospace or large-scale stationary storage near populated areas.

The market demand for solid electrolyte ORBs is growing, driven by industries and applications that prioritize safety over maximum power output. However, the trade-off in ionic conductivity presents a significant challenge, as it can limit the battery's performance in high-power applications.

As a result, the market is seeing a bifurcation in demand. Some sectors, particularly those dealing with large-scale stationary storage or applications in sensitive environments, are showing increased interest in solid electrolyte ORBs. Conversely, applications requiring high power density and rapid charge/discharge capabilities continue to favor liquid electrolyte systems.

The automotive industry, a key driver of battery technology advancement, is closely watching developments in both liquid and solid electrolyte ORBs. The potential for solid electrolytes to enable safer, longer-range electric vehicles is generating significant interest, although concerns about power output and charging times remain.

Overall, the market demand for ORBs is expected to grow substantially in the coming years, with the choice between solid and liquid electrolytes likely to be determined by specific application requirements and advancements in addressing the current limitations of each technology.

ORBs have garnered significant attention in recent years, particularly in the context of grid-scale energy storage and electric vehicle applications. The market for these batteries is driven by their potential to offer higher energy density, longer cycle life, and lower production costs compared to traditional lithium-ion batteries.

The choice between solid and liquid electrolytes in ORBs represents a critical decision point for manufacturers and end-users. This choice directly impacts the safety and performance characteristics of the batteries, influencing market adoption rates and potential applications.

Liquid electrolytes have traditionally dominated the ORB market due to their high ionic conductivity, which allows for rapid charge and discharge cycles. This property is particularly valuable in applications requiring quick response times, such as grid frequency regulation and electric vehicle fast charging. However, safety concerns associated with liquid electrolytes, including the risk of leakage and flammability, have prompted research into solid electrolyte alternatives.

Solid electrolytes offer enhanced safety features, addressing many of the concerns associated with liquid electrolytes. The non-flammable nature of solid electrolytes reduces the risk of thermal runaway and fire, making them attractive for applications where safety is paramount, such as in aerospace or large-scale stationary storage near populated areas.

The market demand for solid electrolyte ORBs is growing, driven by industries and applications that prioritize safety over maximum power output. However, the trade-off in ionic conductivity presents a significant challenge, as it can limit the battery's performance in high-power applications.

As a result, the market is seeing a bifurcation in demand. Some sectors, particularly those dealing with large-scale stationary storage or applications in sensitive environments, are showing increased interest in solid electrolyte ORBs. Conversely, applications requiring high power density and rapid charge/discharge capabilities continue to favor liquid electrolyte systems.

The automotive industry, a key driver of battery technology advancement, is closely watching developments in both liquid and solid electrolyte ORBs. The potential for solid electrolytes to enable safer, longer-range electric vehicles is generating significant interest, although concerns about power output and charging times remain.

Overall, the market demand for ORBs is expected to grow substantially in the coming years, with the choice between solid and liquid electrolytes likely to be determined by specific application requirements and advancements in addressing the current limitations of each technology.

Electrolyte Challenges

The development of organic redox batteries (ORBs) faces significant challenges in electrolyte design, particularly when comparing solid and liquid electrolytes. The primary trade-off lies between safety and ionic conductivity, two critical factors that greatly influence battery performance and viability.

Liquid electrolytes have traditionally been favored due to their high ionic conductivity, which allows for rapid ion transport between electrodes. This characteristic enables faster charge and discharge rates, making liquid electrolytes attractive for high-power applications. However, liquid electrolytes pose substantial safety risks, including flammability and potential leakage. These safety concerns have driven research towards solid electrolytes as a potential alternative.

Solid electrolytes offer enhanced safety features, such as improved thermal stability and reduced risk of leakage. They also provide better mechanical properties, potentially allowing for more compact and flexible battery designs. However, the ionic conductivity of solid electrolytes is generally lower than that of their liquid counterparts, which can limit power output and overall battery performance.

The challenge of improving ionic conductivity in solid electrolytes while maintaining their safety advantages is a key focus of current research. Various approaches are being explored, including the development of new materials, such as ceramic-polymer composites, and the optimization of existing solid electrolyte structures to enhance ion mobility.

Another significant challenge is the interface between the electrolyte and electrodes. In liquid electrolytes, this interface is dynamic and can adapt to changes in electrode structure during cycling. Solid electrolytes, however, form a rigid interface that can lead to poor contact and increased resistance. Addressing this issue requires innovative approaches to electrode and electrolyte design, such as the development of hybrid systems or novel interface engineering techniques.

The stability of electrolytes in contact with organic active materials is also a critical concern. Organic compounds used in ORBs can be highly reactive, potentially leading to degradation of the electrolyte over time. This challenge is particularly pronounced in liquid electrolytes but also affects solid systems. Developing electrolytes that are chemically compatible with a wide range of organic active materials while maintaining their desired properties is an ongoing area of research.

In conclusion, the electrolyte challenges in ORBs center around balancing safety and performance, with solid and liquid electrolytes each offering distinct advantages and drawbacks. Overcoming these challenges will require interdisciplinary approaches, combining materials science, electrochemistry, and engineering to develop innovative solutions that can unlock the full potential of organic redox batteries.

Liquid electrolytes have traditionally been favored due to their high ionic conductivity, which allows for rapid ion transport between electrodes. This characteristic enables faster charge and discharge rates, making liquid electrolytes attractive for high-power applications. However, liquid electrolytes pose substantial safety risks, including flammability and potential leakage. These safety concerns have driven research towards solid electrolytes as a potential alternative.

Solid electrolytes offer enhanced safety features, such as improved thermal stability and reduced risk of leakage. They also provide better mechanical properties, potentially allowing for more compact and flexible battery designs. However, the ionic conductivity of solid electrolytes is generally lower than that of their liquid counterparts, which can limit power output and overall battery performance.

The challenge of improving ionic conductivity in solid electrolytes while maintaining their safety advantages is a key focus of current research. Various approaches are being explored, including the development of new materials, such as ceramic-polymer composites, and the optimization of existing solid electrolyte structures to enhance ion mobility.

Another significant challenge is the interface between the electrolyte and electrodes. In liquid electrolytes, this interface is dynamic and can adapt to changes in electrode structure during cycling. Solid electrolytes, however, form a rigid interface that can lead to poor contact and increased resistance. Addressing this issue requires innovative approaches to electrode and electrolyte design, such as the development of hybrid systems or novel interface engineering techniques.

The stability of electrolytes in contact with organic active materials is also a critical concern. Organic compounds used in ORBs can be highly reactive, potentially leading to degradation of the electrolyte over time. This challenge is particularly pronounced in liquid electrolytes but also affects solid systems. Developing electrolytes that are chemically compatible with a wide range of organic active materials while maintaining their desired properties is an ongoing area of research.

In conclusion, the electrolyte challenges in ORBs center around balancing safety and performance, with solid and liquid electrolytes each offering distinct advantages and drawbacks. Overcoming these challenges will require interdisciplinary approaches, combining materials science, electrochemistry, and engineering to develop innovative solutions that can unlock the full potential of organic redox batteries.

Current Electrolyte Solutions

01 Electrolyte composition for improved safety and conductivity

Organic redox flow batteries can be made safer and more conductive by optimizing the electrolyte composition. This includes using specific organic compounds, additives, and solvents that enhance ionic conductivity while reducing flammability and toxicity risks. Careful selection of these components can lead to improved battery performance and safety characteristics.- Electrolyte composition for improved safety and conductivity: Organic redox flow batteries can be made safer and more conductive by optimizing the electrolyte composition. This includes using specific organic compounds, additives, and solvents that enhance ionic conductivity while maintaining stability and reducing flammability. The careful selection of electrolyte components can significantly improve the overall performance and safety of ORBs.

- Membrane design for enhanced ion transport: The development of advanced membrane materials and designs is crucial for improving the ionic conductivity and safety of organic redox flow batteries. Specialized membranes can facilitate efficient ion transport while preventing crossover of active species, leading to enhanced battery performance and longevity. Novel membrane architectures and compositions are being explored to achieve these goals.

- Redox-active organic molecules for improved safety: Research is focused on developing and implementing novel redox-active organic molecules that offer improved safety characteristics. These molecules are designed to be stable, non-toxic, and environmentally friendly, reducing the risks associated with traditional metal-based redox couples. The careful selection of organic redox species can lead to safer and more sustainable ORB systems.

- Advanced cell and stack design for safety enhancement: Innovative cell and stack designs are being developed to enhance the safety of organic redox flow batteries. These designs focus on improving thermal management, preventing leaks, and incorporating fail-safe mechanisms. By optimizing the physical structure and components of the battery system, overall safety can be significantly improved without compromising performance.

- Monitoring and control systems for safe operation: The implementation of advanced monitoring and control systems is essential for ensuring the safe operation of organic redox flow batteries. These systems can detect potential issues such as temperature fluctuations, pressure changes, or electrolyte imbalances in real-time. By incorporating intelligent management algorithms and safety protocols, the risk of accidents or system failures can be minimized, enhancing overall battery safety and reliability.

02 Membrane design for enhanced ion transport

The design and selection of membranes play a crucial role in the safety and ionic conductivity of organic redox flow batteries. Advanced membrane materials and structures can improve ion selectivity and transport, reducing crossover of active species while maintaining high conductivity. This leads to better battery efficiency and longevity while minimizing potential safety hazards.Expand Specific Solutions03 Redox-active organic molecules for enhanced performance

Developing and utilizing novel redox-active organic molecules can significantly improve the performance and safety of organic redox flow batteries. These molecules can be designed to have high solubility, stability, and reversibility, leading to increased energy density and cycle life. Additionally, selecting molecules with appropriate redox potentials can enhance the overall safety of the battery system.Expand Specific Solutions04 Flow field and electrode design for improved safety

Optimizing the flow field and electrode design in organic redox flow batteries can enhance both safety and ionic conductivity. This includes developing electrode materials with high surface area and catalytic activity, as well as designing flow patterns that ensure uniform distribution of electrolytes. These improvements can lead to better heat dissipation, reduced pressure drop, and more efficient electrochemical reactions.Expand Specific Solutions05 Battery management systems for safety monitoring

Implementing advanced battery management systems (BMS) is crucial for ensuring the safety and optimal performance of organic redox flow batteries. These systems can monitor key parameters such as temperature, pressure, and state of charge, allowing for real-time adjustments and early detection of potential safety issues. Additionally, BMS can optimize charging and discharging processes to maintain high ionic conductivity and extend battery life.Expand Specific Solutions

Key Industry Players

The competition landscape for solid vs liquid electrolytes in organic redox batteries (ORBs) is in a dynamic phase, with the industry transitioning from research to early commercialization. The market size is expanding, driven by growing demand for safer and higher-performance energy storage solutions. Technologically, liquid electrolytes are more mature, but solid electrolytes are rapidly advancing. Key players like Samsung SDI, LG Energy Solution, and Blue Current are investing heavily in solid-state technology, while established companies such as Corning and Solvay continue to improve liquid electrolyte formulations. Universities and research institutes, including Kyoto University and Northwestern University, are also contributing significantly to innovations in both electrolyte types, focusing on enhancing safety and ionic conductivity.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed advanced solid electrolytes for ORBs, focusing on improving safety and ionic conductivity. Their approach involves using a composite electrolyte system that combines inorganic ceramic particles with a polymer matrix. This hybrid structure aims to leverage the high ionic conductivity of ceramics while maintaining the flexibility and processability of polymers[1]. The company has reported achieving ionic conductivities of up to 1 mS/cm at room temperature, which is competitive with liquid electrolytes[3]. Additionally, Samsung SDI has implemented a proprietary coating technology on the ceramic particles to enhance the interfacial stability between the electrolyte and electrodes, addressing a common challenge in solid-state batteries[5].

Strengths: Enhanced safety due to non-flammable solid electrolyte; improved energy density potential. Weaknesses: Higher manufacturing costs; challenges in scaling up production for mass market.

Blue Current, Inc.

Technical Solution: Blue Current specializes in developing solid electrolytes for ORBs with a focus on sulfide-based materials. Their proprietary technology involves synthesizing glass-ceramic sulfide electrolytes with high ionic conductivity, reportedly achieving values up to 25 mS/cm at room temperature[2]. The company has also developed a unique manufacturing process that allows for the production of thin, flexible solid electrolyte sheets, which can be easily integrated into existing battery manufacturing lines[4]. Blue Current's approach addresses the ionic conductivity challenge while maintaining the safety benefits of solid electrolytes. They have also made progress in improving the interfacial contact between the electrolyte and electrodes, a critical factor for overall battery performance[6].

Strengths: High ionic conductivity comparable to liquid electrolytes; improved manufacturability. Weaknesses: Potential reactivity of sulfide electrolytes with moisture; need for protective packaging.

Innovative Electrolyte Research

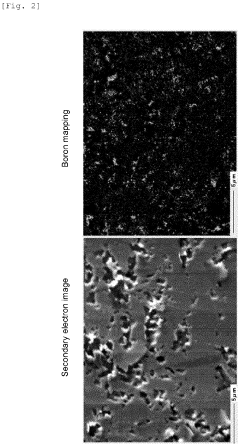

Solid electrolyte composition, solid electrolyte layer, electrode, and battery

PatentWO2023223596A1

Innovation

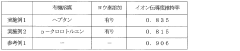

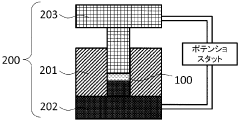

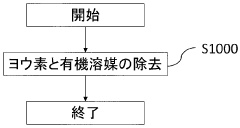

- A solid electrolyte composition incorporating elemental iodine or iodide and an organic solvent, specifically designed to maintain lithium ion conductivity and safety by excluding sulfur and incorporating elements like Li, Y, Cl, Br, and I, with a composition formula that ensures stability and dispersion, forming a dense and efficient solid electrolyte layer for batteries.

Lithium ion-conductive solid electrolyte, and all-solid-state battery

PatentPendingEP4269344A1

Innovation

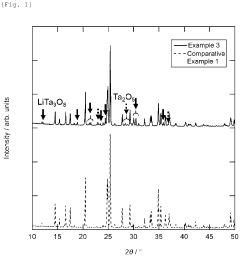

- A lithium ion conductive solid electrolyte with a monoclinic crystal structure, composed of lithium, tantalum, boron, phosphorus, and oxygen, and optionally niobium, having specific a-axis, b-axis, and c-axis lengths, and axis angle β, which provides high ion conductivity and thermal stability, suitable for all-solid-state batteries and other applications.

Safety Regulations

The safety regulations surrounding organic redox batteries (ORBs) are critical in determining the viability and widespread adoption of this emerging energy storage technology. As the debate between solid and liquid electrolytes continues, regulatory bodies are closely monitoring the safety aspects of both options.

For liquid electrolytes, existing regulations primarily focus on containment and leak prevention. These regulations often draw from established guidelines for other liquid-based battery technologies, such as lead-acid and flow batteries. Key safety requirements include robust sealing mechanisms, secondary containment systems, and stringent transportation protocols. Manufacturers must demonstrate compliance with standards related to thermal runaway prevention, electrolyte stability under various environmental conditions, and resistance to physical shock and vibration.

Solid electrolytes, while generally perceived as safer, are subject to a different set of regulatory considerations. Safety regulations for solid electrolytes in ORBs are still evolving, as the technology is relatively new. Current focus areas include material stability, thermal management, and mechanical integrity. Regulatory bodies are particularly interested in the long-term performance and degradation characteristics of solid electrolytes, as well as their behavior under extreme conditions such as high temperatures or mechanical stress.

One of the key challenges in developing safety regulations for ORBs is addressing the unique properties of organic materials used in these batteries. Unlike traditional inorganic battery chemistries, organic compounds may present novel safety concerns that are not fully covered by existing regulatory frameworks. As a result, regulatory agencies are working closely with researchers and industry experts to establish appropriate safety standards and testing protocols specific to ORBs.

The tradeoff between safety and ionic conductivity is a central consideration in regulatory discussions. While solid electrolytes generally offer enhanced safety features, their lower ionic conductivity compared to liquid electrolytes can impact battery performance. Regulators are tasked with balancing these competing factors, potentially leading to differentiated safety requirements based on the specific electrolyte type and intended application of the ORB.

International harmonization of safety regulations for ORBs is an ongoing effort. Organizations such as the International Electrotechnical Commission (IEC) and the United Nations Economic Commission for Europe (UNECE) are working to develop globally recognized standards. These efforts aim to facilitate the international trade and adoption of ORB technologies while ensuring consistent safety levels across different markets.

As the technology matures, it is expected that safety regulations will become more refined and tailored to the specific characteristics of ORBs. This may include the development of new testing methodologies, updated risk assessment models, and revised safety thresholds that account for the unique properties of organic materials and the performance differences between solid and liquid electrolytes.

For liquid electrolytes, existing regulations primarily focus on containment and leak prevention. These regulations often draw from established guidelines for other liquid-based battery technologies, such as lead-acid and flow batteries. Key safety requirements include robust sealing mechanisms, secondary containment systems, and stringent transportation protocols. Manufacturers must demonstrate compliance with standards related to thermal runaway prevention, electrolyte stability under various environmental conditions, and resistance to physical shock and vibration.

Solid electrolytes, while generally perceived as safer, are subject to a different set of regulatory considerations. Safety regulations for solid electrolytes in ORBs are still evolving, as the technology is relatively new. Current focus areas include material stability, thermal management, and mechanical integrity. Regulatory bodies are particularly interested in the long-term performance and degradation characteristics of solid electrolytes, as well as their behavior under extreme conditions such as high temperatures or mechanical stress.

One of the key challenges in developing safety regulations for ORBs is addressing the unique properties of organic materials used in these batteries. Unlike traditional inorganic battery chemistries, organic compounds may present novel safety concerns that are not fully covered by existing regulatory frameworks. As a result, regulatory agencies are working closely with researchers and industry experts to establish appropriate safety standards and testing protocols specific to ORBs.

The tradeoff between safety and ionic conductivity is a central consideration in regulatory discussions. While solid electrolytes generally offer enhanced safety features, their lower ionic conductivity compared to liquid electrolytes can impact battery performance. Regulators are tasked with balancing these competing factors, potentially leading to differentiated safety requirements based on the specific electrolyte type and intended application of the ORB.

International harmonization of safety regulations for ORBs is an ongoing effort. Organizations such as the International Electrotechnical Commission (IEC) and the United Nations Economic Commission for Europe (UNECE) are working to develop globally recognized standards. These efforts aim to facilitate the international trade and adoption of ORB technologies while ensuring consistent safety levels across different markets.

As the technology matures, it is expected that safety regulations will become more refined and tailored to the specific characteristics of ORBs. This may include the development of new testing methodologies, updated risk assessment models, and revised safety thresholds that account for the unique properties of organic materials and the performance differences between solid and liquid electrolytes.

Environmental Impact

The environmental impact of organic redox batteries (ORBs) is a critical consideration in the ongoing debate between solid and liquid electrolytes. Liquid electrolytes, traditionally used in ORBs, have raised concerns due to their potential for leakage and environmental contamination. These electrolytes often contain organic solvents and salts that can be harmful if released into ecosystems. In contrast, solid electrolytes offer a more environmentally friendly alternative, significantly reducing the risk of leakage and subsequent environmental damage.

The production processes for both types of electrolytes also have differing environmental footprints. Liquid electrolytes typically require energy-intensive manufacturing processes and may involve the use of toxic or environmentally harmful chemicals. Solid electrolytes, while potentially requiring high-temperature processing, generally have a lower environmental impact during production. Additionally, the raw materials used in solid electrolytes are often more abundant and less environmentally problematic than those used in liquid electrolytes.

End-of-life considerations further highlight the environmental advantages of solid electrolytes. Liquid electrolyte-based ORBs require careful disposal procedures to prevent environmental contamination. In contrast, solid electrolyte batteries are generally easier to recycle and pose fewer risks during the disposal process. This aspect is particularly important as the demand for energy storage solutions continues to grow, necessitating sustainable lifecycle management practices.

The longevity and stability of solid electrolytes also contribute to their positive environmental profile. With potentially longer lifespans and reduced degradation rates, solid electrolyte ORBs may require less frequent replacement, thereby reducing waste generation and resource consumption over time. This extended lifespan can lead to a lower overall environmental impact when considering the full lifecycle of the battery.

However, it is important to note that the environmental benefits of solid electrolytes must be balanced against their current limitations in ionic conductivity. Lower ionic conductivity may result in reduced energy efficiency, potentially offsetting some of the environmental gains. Ongoing research aims to improve the conductivity of solid electrolytes while maintaining their environmental advantages, striving to achieve an optimal balance between performance and ecological impact.

In conclusion, while both solid and liquid electrolytes present environmental challenges, solid electrolytes generally offer a more environmentally friendly option for ORBs. Their reduced risk of leakage, potentially lower production impact, and easier end-of-life management make them an attractive choice from an environmental perspective. As research progresses, further improvements in solid electrolyte technology are expected to enhance their environmental benefits while addressing performance limitations.

The production processes for both types of electrolytes also have differing environmental footprints. Liquid electrolytes typically require energy-intensive manufacturing processes and may involve the use of toxic or environmentally harmful chemicals. Solid electrolytes, while potentially requiring high-temperature processing, generally have a lower environmental impact during production. Additionally, the raw materials used in solid electrolytes are often more abundant and less environmentally problematic than those used in liquid electrolytes.

End-of-life considerations further highlight the environmental advantages of solid electrolytes. Liquid electrolyte-based ORBs require careful disposal procedures to prevent environmental contamination. In contrast, solid electrolyte batteries are generally easier to recycle and pose fewer risks during the disposal process. This aspect is particularly important as the demand for energy storage solutions continues to grow, necessitating sustainable lifecycle management practices.

The longevity and stability of solid electrolytes also contribute to their positive environmental profile. With potentially longer lifespans and reduced degradation rates, solid electrolyte ORBs may require less frequent replacement, thereby reducing waste generation and resource consumption over time. This extended lifespan can lead to a lower overall environmental impact when considering the full lifecycle of the battery.

However, it is important to note that the environmental benefits of solid electrolytes must be balanced against their current limitations in ionic conductivity. Lower ionic conductivity may result in reduced energy efficiency, potentially offsetting some of the environmental gains. Ongoing research aims to improve the conductivity of solid electrolytes while maintaining their environmental advantages, striving to achieve an optimal balance between performance and ecological impact.

In conclusion, while both solid and liquid electrolytes present environmental challenges, solid electrolytes generally offer a more environmentally friendly option for ORBs. Their reduced risk of leakage, potentially lower production impact, and easier end-of-life management make them an attractive choice from an environmental perspective. As research progresses, further improvements in solid electrolyte technology are expected to enhance their environmental benefits while addressing performance limitations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!