ORB Manufacturing Scale-Up: From Lab Cast Films to Roll-to-Roll Coating

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ORB Scale-Up Background and Objectives

Organic-inorganic hybrid perovskites (ORBs) have emerged as a promising class of materials for next-generation optoelectronic devices, particularly in the field of photovoltaics. The rapid progress in ORB-based solar cells has been remarkable, with power conversion efficiencies surpassing 25% in just over a decade of research. This unprecedented growth has sparked intense interest in scaling up ORB manufacturing processes to enable commercial production of large-area, high-performance devices.

The transition from laboratory-scale cast films to industrial roll-to-roll (R2R) coating represents a critical step in the commercialization of ORB technology. This scale-up process aims to bridge the gap between small-area, high-efficiency devices produced in controlled laboratory environments and the large-scale, cost-effective production required for market penetration. The primary objective of this technological advancement is to maintain the exceptional optoelectronic properties of ORBs while adapting the fabrication methods to continuous, high-throughput manufacturing processes.

The development of R2R coating techniques for ORBs faces several challenges, including the need for precise control over film thickness, composition, and crystallization kinetics. These factors are crucial for achieving uniform, high-quality perovskite layers across large areas. Additionally, the scale-up process must address issues related to material stability, environmental sensitivity, and long-term device performance, which are inherent to perovskite materials.

Another key objective of the ORB manufacturing scale-up is to optimize the deposition and processing conditions to ensure compatibility with flexible substrates. This aspect is particularly important for enabling the production of lightweight, conformable solar cells and other optoelectronic devices, opening up new application possibilities in building-integrated photovoltaics and portable electronics.

The evolution of ORB manufacturing techniques has seen significant progress in recent years, with various approaches being explored to overcome the limitations of traditional spin-coating methods. These include blade coating, slot-die coating, and spray coating, each offering unique advantages in terms of scalability and process control. The ultimate goal is to develop a robust, reproducible, and cost-effective R2R coating process that can deliver ORB films with properties comparable to those achieved in laboratory-scale devices.

As the field progresses, researchers and industry partners are focusing on addressing key technological hurdles, such as solvent engineering, precursor formulation optimization, and in-line annealing techniques. These efforts aim to enhance film quality, increase production speeds, and improve overall device performance in large-area modules. The successful scale-up of ORB manufacturing has the potential to revolutionize the renewable energy sector, paving the way for widespread adoption of high-efficiency, low-cost perovskite-based solar cells and other optoelectronic devices.

The transition from laboratory-scale cast films to industrial roll-to-roll (R2R) coating represents a critical step in the commercialization of ORB technology. This scale-up process aims to bridge the gap between small-area, high-efficiency devices produced in controlled laboratory environments and the large-scale, cost-effective production required for market penetration. The primary objective of this technological advancement is to maintain the exceptional optoelectronic properties of ORBs while adapting the fabrication methods to continuous, high-throughput manufacturing processes.

The development of R2R coating techniques for ORBs faces several challenges, including the need for precise control over film thickness, composition, and crystallization kinetics. These factors are crucial for achieving uniform, high-quality perovskite layers across large areas. Additionally, the scale-up process must address issues related to material stability, environmental sensitivity, and long-term device performance, which are inherent to perovskite materials.

Another key objective of the ORB manufacturing scale-up is to optimize the deposition and processing conditions to ensure compatibility with flexible substrates. This aspect is particularly important for enabling the production of lightweight, conformable solar cells and other optoelectronic devices, opening up new application possibilities in building-integrated photovoltaics and portable electronics.

The evolution of ORB manufacturing techniques has seen significant progress in recent years, with various approaches being explored to overcome the limitations of traditional spin-coating methods. These include blade coating, slot-die coating, and spray coating, each offering unique advantages in terms of scalability and process control. The ultimate goal is to develop a robust, reproducible, and cost-effective R2R coating process that can deliver ORB films with properties comparable to those achieved in laboratory-scale devices.

As the field progresses, researchers and industry partners are focusing on addressing key technological hurdles, such as solvent engineering, precursor formulation optimization, and in-line annealing techniques. These efforts aim to enhance film quality, increase production speeds, and improve overall device performance in large-area modules. The successful scale-up of ORB manufacturing has the potential to revolutionize the renewable energy sector, paving the way for widespread adoption of high-efficiency, low-cost perovskite-based solar cells and other optoelectronic devices.

Market Analysis for ORB Coated Products

The market for ORB (Optically Reflective Barrier) coated products is experiencing significant growth, driven by the increasing demand for advanced optical materials in various industries. The transition from lab-scale cast films to roll-to-roll coating processes represents a crucial step in meeting this rising market demand and achieving economies of scale.

The electronics industry, particularly the display sector, is a primary driver for ORB coated products. With the proliferation of smartphones, tablets, and large-format displays, manufacturers are seeking materials that can enhance screen brightness, reduce power consumption, and improve overall display performance. ORB coatings offer these benefits, making them highly attractive for next-generation display technologies.

Another key market segment for ORB coated products is the automotive industry. As vehicle manufacturers increasingly incorporate advanced driver assistance systems (ADAS) and heads-up displays (HUDs), the demand for high-performance optical materials is growing. ORB coatings can significantly improve the clarity and visibility of these systems, enhancing both safety and user experience.

The aerospace and defense sectors also present substantial opportunities for ORB coated products. These industries require materials with exceptional optical properties for applications such as cockpit displays, sensor systems, and protective coatings for optical equipment. The durability and performance characteristics of ORB coatings make them well-suited for these demanding environments.

In the renewable energy sector, ORB coatings show promise for improving the efficiency of solar panels and other photovoltaic devices. By enhancing light capture and reducing reflection losses, these coatings can contribute to increased energy output and improved overall system performance.

The global market for advanced optical coatings, including ORB products, is projected to grow steadily over the next decade. This growth is fueled by ongoing technological advancements, increasing adoption of smart devices, and the expansion of IoT applications across various industries.

However, the market for ORB coated products also faces challenges. The high cost of production, particularly in the transition from lab-scale to industrial-scale manufacturing, may limit adoption in price-sensitive applications. Additionally, competition from alternative technologies and materials could impact market penetration in certain sectors.

Despite these challenges, the overall market outlook for ORB coated products remains positive. The successful scale-up of manufacturing processes from lab cast films to roll-to-roll coating is expected to significantly reduce production costs and increase availability, potentially opening up new market opportunities and applications.

The electronics industry, particularly the display sector, is a primary driver for ORB coated products. With the proliferation of smartphones, tablets, and large-format displays, manufacturers are seeking materials that can enhance screen brightness, reduce power consumption, and improve overall display performance. ORB coatings offer these benefits, making them highly attractive for next-generation display technologies.

Another key market segment for ORB coated products is the automotive industry. As vehicle manufacturers increasingly incorporate advanced driver assistance systems (ADAS) and heads-up displays (HUDs), the demand for high-performance optical materials is growing. ORB coatings can significantly improve the clarity and visibility of these systems, enhancing both safety and user experience.

The aerospace and defense sectors also present substantial opportunities for ORB coated products. These industries require materials with exceptional optical properties for applications such as cockpit displays, sensor systems, and protective coatings for optical equipment. The durability and performance characteristics of ORB coatings make them well-suited for these demanding environments.

In the renewable energy sector, ORB coatings show promise for improving the efficiency of solar panels and other photovoltaic devices. By enhancing light capture and reducing reflection losses, these coatings can contribute to increased energy output and improved overall system performance.

The global market for advanced optical coatings, including ORB products, is projected to grow steadily over the next decade. This growth is fueled by ongoing technological advancements, increasing adoption of smart devices, and the expansion of IoT applications across various industries.

However, the market for ORB coated products also faces challenges. The high cost of production, particularly in the transition from lab-scale to industrial-scale manufacturing, may limit adoption in price-sensitive applications. Additionally, competition from alternative technologies and materials could impact market penetration in certain sectors.

Despite these challenges, the overall market outlook for ORB coated products remains positive. The successful scale-up of manufacturing processes from lab cast films to roll-to-roll coating is expected to significantly reduce production costs and increase availability, potentially opening up new market opportunities and applications.

Current Challenges in ORB Manufacturing

The transition from laboratory-scale cast films to roll-to-roll coating presents several significant challenges in ORB (Organic-Inorganic Perovskite) manufacturing. One of the primary obstacles is maintaining consistent film quality and performance across larger areas. In lab settings, small-scale cast films can be produced with high precision and control, but scaling up to continuous roll-to-roll processes introduces variables that can affect film uniformity and functionality.

Material handling and deposition pose another major challenge. The precise control of precursor solutions, their mixing ratios, and deposition rates becomes more complex in a high-speed, continuous production environment. Ensuring uniform thickness and composition across the entire width and length of the substrate requires sophisticated engineering solutions and real-time monitoring systems.

Environmental control is crucial for ORB manufacturing, and maintaining optimal conditions becomes increasingly difficult at scale. Factors such as temperature, humidity, and atmospheric composition must be tightly regulated throughout the coating process to prevent degradation of the perovskite materials and ensure consistent crystallization. This necessitates the development of advanced environmental chambers and control systems capable of maintaining stable conditions over extended production runs.

The drying and annealing processes, critical for perovskite crystal formation, present unique challenges in roll-to-roll manufacturing. The rapid thermal treatment required for optimal crystal growth must be precisely controlled and uniformly applied across the moving substrate. This demands innovative heating technologies and thermal management systems that can deliver consistent results at high throughput rates.

Defect management and quality control become more complex at scale. Identifying and mitigating defects in real-time during high-speed production requires advanced inspection systems and rapid response mechanisms. Developing non-destructive testing methods that can operate at production speeds is essential for maintaining product quality and yield rates.

Substrate handling and tension control are critical factors that impact film quality in roll-to-roll processes. Ensuring proper alignment, preventing wrinkles or distortions, and maintaining consistent tension throughout the coating process are engineering challenges that directly affect the final product's performance and reliability.

Lastly, the scale-up process must address the challenge of materials efficiency and waste reduction. Optimizing precursor utilization, minimizing overspray, and developing effective recycling methods for excess materials are crucial for improving the economic viability and environmental sustainability of large-scale ORB manufacturing.

Material handling and deposition pose another major challenge. The precise control of precursor solutions, their mixing ratios, and deposition rates becomes more complex in a high-speed, continuous production environment. Ensuring uniform thickness and composition across the entire width and length of the substrate requires sophisticated engineering solutions and real-time monitoring systems.

Environmental control is crucial for ORB manufacturing, and maintaining optimal conditions becomes increasingly difficult at scale. Factors such as temperature, humidity, and atmospheric composition must be tightly regulated throughout the coating process to prevent degradation of the perovskite materials and ensure consistent crystallization. This necessitates the development of advanced environmental chambers and control systems capable of maintaining stable conditions over extended production runs.

The drying and annealing processes, critical for perovskite crystal formation, present unique challenges in roll-to-roll manufacturing. The rapid thermal treatment required for optimal crystal growth must be precisely controlled and uniformly applied across the moving substrate. This demands innovative heating technologies and thermal management systems that can deliver consistent results at high throughput rates.

Defect management and quality control become more complex at scale. Identifying and mitigating defects in real-time during high-speed production requires advanced inspection systems and rapid response mechanisms. Developing non-destructive testing methods that can operate at production speeds is essential for maintaining product quality and yield rates.

Substrate handling and tension control are critical factors that impact film quality in roll-to-roll processes. Ensuring proper alignment, preventing wrinkles or distortions, and maintaining consistent tension throughout the coating process are engineering challenges that directly affect the final product's performance and reliability.

Lastly, the scale-up process must address the challenge of materials efficiency and waste reduction. Optimizing precursor utilization, minimizing overspray, and developing effective recycling methods for excess materials are crucial for improving the economic viability and environmental sustainability of large-scale ORB manufacturing.

Roll-to-Roll ORB Coating Solutions

01 Electrode material development for ORB scale-up

Development of advanced electrode materials is crucial for scaling up organic redox batteries. This includes the synthesis and optimization of organic compounds with high redox activity, stability, and conductivity. Researchers are focusing on improving the performance and durability of these materials to enhance the overall efficiency and lifespan of large-scale ORBs.- Electrode material development for ORB scale-up: Development of advanced electrode materials is crucial for scaling up organic redox batteries. This includes the synthesis and optimization of organic compounds with high redox activity, stability, and conductivity. Researchers are focusing on improving the performance and durability of these materials to enhance battery capacity and cycle life for large-scale applications.

- Electrolyte formulation for large-scale ORB production: Developing suitable electrolyte formulations is essential for scaling up organic redox batteries. This involves optimizing the composition and concentration of organic redox-active species, supporting electrolytes, and additives. The focus is on improving ionic conductivity, electrochemical stability, and compatibility with electrode materials to enhance overall battery performance in large-scale manufacturing.

- Cell design and assembly techniques for mass production: Efficient cell design and assembly techniques are critical for scaling up ORB manufacturing. This includes developing standardized cell architectures, optimizing component layouts, and implementing automated assembly processes. The goal is to improve production efficiency, reduce costs, and ensure consistent quality in large-scale battery manufacturing.

- Quality control and testing methods for scaled-up production: Implementing robust quality control and testing methods is essential for ensuring the reliability and performance of scaled-up ORB production. This involves developing standardized protocols for material characterization, cell performance evaluation, and safety testing. Advanced diagnostic tools and in-line monitoring systems are being integrated to maintain consistent quality throughout the manufacturing process.

- Process optimization and automation for large-scale manufacturing: Optimizing manufacturing processes and implementing automation are key factors in scaling up ORB production. This includes developing continuous production methods, integrating advanced process control systems, and implementing smart manufacturing technologies. The focus is on improving production efficiency, reducing costs, and ensuring consistent quality in large-scale battery manufacturing.

02 Electrolyte formulation for large-scale ORB production

Developing suitable electrolyte formulations is essential for scaling up ORB manufacturing. This involves optimizing the composition of organic solvents, supporting electrolytes, and additives to enhance ionic conductivity, electrochemical stability, and compatibility with electrode materials. The focus is on creating electrolyte systems that maintain performance over extended cycling in large-scale applications.Expand Specific Solutions03 Cell design and assembly techniques for mass production

Scaling up ORB manufacturing requires innovative cell design and assembly techniques. This includes developing efficient methods for electrode coating, stacking, and packaging of large-format cells. Researchers are working on automated assembly processes and modular designs to facilitate mass production while maintaining consistent quality and performance.Expand Specific Solutions04 Battery management systems for large-scale ORB applications

Implementing advanced battery management systems is crucial for the successful scale-up of ORBs. This involves developing sophisticated monitoring and control algorithms to optimize the performance and longevity of large-scale battery systems. Key focus areas include state-of-charge estimation, thermal management, and balancing techniques tailored for organic redox chemistries.Expand Specific Solutions05 Manufacturing process optimization for cost-effective scale-up

Optimizing manufacturing processes is essential for cost-effective scale-up of ORB production. This includes developing efficient synthesis routes for organic active materials, improving electrode fabrication techniques, and streamlining cell assembly processes. Researchers are focusing on reducing material waste, energy consumption, and production time to make large-scale ORB manufacturing economically viable.Expand Specific Solutions

Key Players in ORB Coating Industry

The ORB manufacturing scale-up from lab cast films to roll-to-roll coating is in an early development stage, with significant potential for market growth. The technology's maturity varies among key players, with established companies like Nitto Denko, FUJIFILM, and Applied Materials likely leading in roll-to-roll coating expertise. Emerging players such as EPG AG and SiO2 Medical Products are focusing on innovative coating solutions. The market is poised for expansion as demand for advanced coatings in electronics, healthcare, and industrial applications increases. Companies like DuPont and Shin-Etsu Chemical bring extensive materials science knowledge, potentially accelerating the technology's development and commercialization.

Nitto Denko Corp.

Technical Solution: Nitto Denko has developed advanced roll-to-roll coating technologies for ORB (Optically Reflective Barrier) manufacturing scale-up. Their approach involves a multi-layer coating process that allows for precise control of film thickness and optical properties. The company utilizes a proprietary tension control system to maintain uniform coating across large surface areas, crucial for transitioning from lab-scale to industrial production. Nitto Denko's process incorporates in-line quality monitoring using spectroscopic techniques to ensure consistent ORB performance[1]. They have also implemented a novel drying method that reduces defects and improves film uniformity, enabling production speeds up to 100 meters per minute[3].

Strengths: Extensive experience in roll-to-roll coating, proprietary tension control system, and in-line quality monitoring. Weaknesses: High initial investment costs for equipment and potential challenges in maintaining consistent quality at high production speeds.

FUJIFILM Corp.

Technical Solution: FUJIFILM has leveraged its expertise in photographic film production to develop a scalable ORB manufacturing process. Their approach utilizes a modified slot-die coating technique, which allows for precise deposition of multiple thin layers simultaneously. FUJIFILM's process incorporates nano-dispersion technology to ensure uniform distribution of reflective particles within the ORB structure[2]. The company has also developed a specialized curing process that uses UV radiation to rapidly solidify the coated layers, enabling faster production speeds. FUJIFILM's scale-up strategy includes the use of modular coating units that can be easily integrated into existing production lines, facilitating the transition from lab-scale to industrial-scale manufacturing[4].

Strengths: Expertise in thin-film coating, nano-dispersion technology, and modular production units. Weaknesses: Potential limitations in substrate compatibility and the need for specialized UV curing equipment.

Core Patents in ORB Scale-Up Process

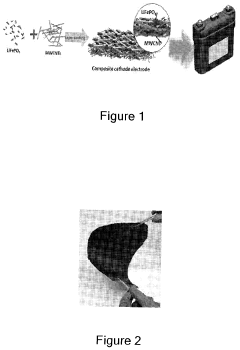

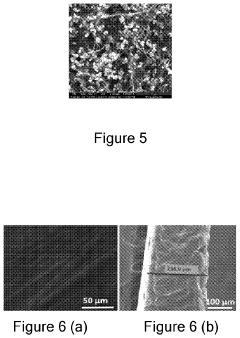

Carbon nanotube nanocomposite based lithium-ion battery

PatentInactiveUS20220227629A1

Innovation

- Development of carbon nanotube (CNT) nanocomposites for both cathode and anode materials, combined with a polyethylene oxide (PEO)-based solid electrolyte, using a hydrothermal process and surface-engineered tape casting technique, to enhance electrochemical performance and facilitate mass production through a 'Roll-to-Roll' process.

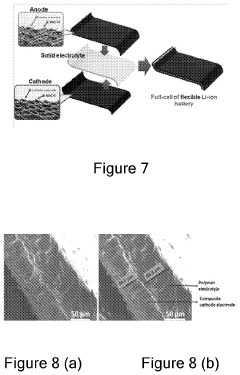

Hybrid radical energy storage device and method of making

PatentActiveUS20120295166A1

Innovation

- A hybrid solid-state electrochemical device is developed, featuring a pre-lithiated nanostructured anode, a stable polymeric organic radical-based cathode, and a high-performance solid-state polymer electrolyte, which enhances energy density and cycle stability, while minimizing flammability and temperature effects.

Cost-Benefit Analysis of Scale-Up

The cost-benefit analysis of scaling up ORB manufacturing from lab cast films to roll-to-roll coating is a critical consideration for commercialization. This transition offers significant advantages in terms of production efficiency and cost reduction, but also presents challenges that must be carefully evaluated.

One of the primary benefits of scaling up to roll-to-roll coating is the substantial increase in production capacity. While lab cast films are limited in size and production rate, roll-to-roll processes can produce continuous sheets of material at much higher speeds. This increased throughput can lead to economies of scale, reducing the per-unit cost of production. Additionally, roll-to-roll coating allows for more uniform and consistent film quality over larger areas, which is crucial for many applications.

However, the initial investment required for roll-to-roll equipment is considerable. The cost of purchasing and installing industrial-scale coating machinery, along with associated infrastructure, can be a significant barrier to entry. This upfront capital expenditure must be weighed against the projected long-term savings and increased revenue from higher production volumes.

Operational costs also shift when scaling up. While material costs may decrease due to bulk purchasing power, energy consumption and labor requirements often increase. Skilled operators are needed to manage the more complex roll-to-roll systems, potentially raising labor costs. Maintenance and quality control processes also become more intricate and costly at larger scales.

The transition to roll-to-roll coating may necessitate reformulation of the ORB material to optimize its properties for the new coating process. This R&D effort represents an additional cost but is essential for ensuring product quality and process efficiency. The reformulation may also open up opportunities for improved performance or new applications, potentially expanding market reach.

Waste reduction is another important factor to consider. Roll-to-roll processes typically generate less waste compared to batch production methods, leading to material savings. However, the initial setup and optimization phase may produce significant waste until the process is fine-tuned, which should be factored into the cost analysis.

Ultimately, the decision to scale up must be based on a comprehensive assessment of market demand, production targets, and financial projections. The increased production capacity must be justified by sufficient market demand to avoid overproduction and inventory costs. A phased approach to scaling up may help mitigate risks and allow for iterative improvements in the manufacturing process.

One of the primary benefits of scaling up to roll-to-roll coating is the substantial increase in production capacity. While lab cast films are limited in size and production rate, roll-to-roll processes can produce continuous sheets of material at much higher speeds. This increased throughput can lead to economies of scale, reducing the per-unit cost of production. Additionally, roll-to-roll coating allows for more uniform and consistent film quality over larger areas, which is crucial for many applications.

However, the initial investment required for roll-to-roll equipment is considerable. The cost of purchasing and installing industrial-scale coating machinery, along with associated infrastructure, can be a significant barrier to entry. This upfront capital expenditure must be weighed against the projected long-term savings and increased revenue from higher production volumes.

Operational costs also shift when scaling up. While material costs may decrease due to bulk purchasing power, energy consumption and labor requirements often increase. Skilled operators are needed to manage the more complex roll-to-roll systems, potentially raising labor costs. Maintenance and quality control processes also become more intricate and costly at larger scales.

The transition to roll-to-roll coating may necessitate reformulation of the ORB material to optimize its properties for the new coating process. This R&D effort represents an additional cost but is essential for ensuring product quality and process efficiency. The reformulation may also open up opportunities for improved performance or new applications, potentially expanding market reach.

Waste reduction is another important factor to consider. Roll-to-roll processes typically generate less waste compared to batch production methods, leading to material savings. However, the initial setup and optimization phase may produce significant waste until the process is fine-tuned, which should be factored into the cost analysis.

Ultimately, the decision to scale up must be based on a comprehensive assessment of market demand, production targets, and financial projections. The increased production capacity must be justified by sufficient market demand to avoid overproduction and inventory costs. A phased approach to scaling up may help mitigate risks and allow for iterative improvements in the manufacturing process.

Quality Control in R2R ORB Production

Quality control is a critical aspect of roll-to-roll (R2R) organic rainbow (ORB) production, ensuring consistent and high-quality output at scale. The transition from laboratory-scale cast films to industrial R2R coating processes introduces numerous challenges that must be addressed through rigorous quality control measures.

One of the primary quality control considerations in R2R ORB production is the uniformity of coating thickness. Variations in thickness can lead to inconsistencies in optical properties and performance of the final product. To maintain tight control over coating thickness, advanced in-line measurement techniques such as optical interferometry or X-ray fluorescence are employed. These methods provide real-time feedback, allowing for immediate adjustments to the coating parameters.

Surface defects pose another significant challenge in R2R ORB production. Imperfections such as pinholes, streaks, or particulate contamination can severely impact the functionality of the ORB films. To mitigate these issues, high-resolution camera systems are integrated into the production line, continuously scanning the moving web for defects. Machine learning algorithms process the image data in real-time, identifying and categorizing defects for prompt corrective action.

Chemical composition and structural integrity of the ORB layers are crucial for optimal performance. Spectroscopic techniques, including Raman spectroscopy and Fourier-transform infrared spectroscopy (FTIR), are utilized to monitor the chemical composition of the coating in-line. These methods can detect subtle changes in molecular structure or the presence of contaminants that may affect the final product quality.

Environmental control within the R2R production facility is paramount. Temperature, humidity, and particulate levels must be tightly regulated to prevent adverse effects on the coating process. Advanced HVAC systems with HEPA filtration, coupled with continuous environmental monitoring, ensure optimal conditions for ORB production.

Process parameters such as web tension, coating speed, and drying conditions significantly influence the quality of R2R ORB products. Sophisticated process control systems with feedback loops are implemented to maintain these parameters within specified tolerances. Data logging and statistical process control techniques are employed to identify trends and potential issues before they manifest as quality problems.

To ensure long-term stability and performance of ORB films, accelerated aging tests are conducted on samples taken from the production line. These tests simulate various environmental conditions and usage scenarios, providing insights into the durability and reliability of the product over time.

Traceability is a key component of quality control in R2R ORB production. Each roll of produced film is assigned a unique identifier, linking it to specific production parameters, raw material batches, and quality control data. This comprehensive tracking system facilitates root cause analysis in the event of quality issues and supports continuous improvement initiatives.

One of the primary quality control considerations in R2R ORB production is the uniformity of coating thickness. Variations in thickness can lead to inconsistencies in optical properties and performance of the final product. To maintain tight control over coating thickness, advanced in-line measurement techniques such as optical interferometry or X-ray fluorescence are employed. These methods provide real-time feedback, allowing for immediate adjustments to the coating parameters.

Surface defects pose another significant challenge in R2R ORB production. Imperfections such as pinholes, streaks, or particulate contamination can severely impact the functionality of the ORB films. To mitigate these issues, high-resolution camera systems are integrated into the production line, continuously scanning the moving web for defects. Machine learning algorithms process the image data in real-time, identifying and categorizing defects for prompt corrective action.

Chemical composition and structural integrity of the ORB layers are crucial for optimal performance. Spectroscopic techniques, including Raman spectroscopy and Fourier-transform infrared spectroscopy (FTIR), are utilized to monitor the chemical composition of the coating in-line. These methods can detect subtle changes in molecular structure or the presence of contaminants that may affect the final product quality.

Environmental control within the R2R production facility is paramount. Temperature, humidity, and particulate levels must be tightly regulated to prevent adverse effects on the coating process. Advanced HVAC systems with HEPA filtration, coupled with continuous environmental monitoring, ensure optimal conditions for ORB production.

Process parameters such as web tension, coating speed, and drying conditions significantly influence the quality of R2R ORB products. Sophisticated process control systems with feedback loops are implemented to maintain these parameters within specified tolerances. Data logging and statistical process control techniques are employed to identify trends and potential issues before they manifest as quality problems.

To ensure long-term stability and performance of ORB films, accelerated aging tests are conducted on samples taken from the production line. These tests simulate various environmental conditions and usage scenarios, providing insights into the durability and reliability of the product over time.

Traceability is a key component of quality control in R2R ORB production. Each roll of produced film is assigned a unique identifier, linking it to specific production parameters, raw material batches, and quality control data. This comprehensive tracking system facilitates root cause analysis in the event of quality issues and supports continuous improvement initiatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!