ORB Recycling Pathways: Chemical Recovery and Environmental Profiles

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ORB Recycling Background

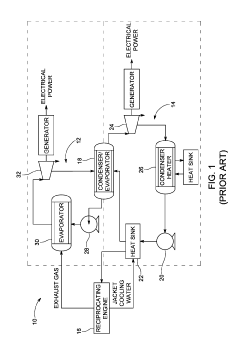

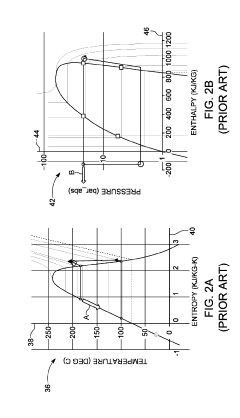

Organic Rankine Cycle (ORC) systems have emerged as a promising technology for converting low-grade heat into electricity, particularly in industrial waste heat recovery and renewable energy applications. The concept of ORC was first introduced in the 1960s, but it has gained significant attention in recent decades due to its ability to efficiently utilize low-temperature heat sources that are otherwise difficult to exploit.

The ORC technology operates on the same principles as the traditional steam Rankine cycle but uses organic fluids with lower boiling points as the working medium instead of water. This allows for the extraction of energy from heat sources at temperatures as low as 80°C, making it suitable for a wide range of applications, including geothermal power plants, solar thermal systems, and industrial waste heat recovery.

As the global focus on energy efficiency and sustainability has intensified, the importance of ORC systems in the energy landscape has grown substantially. The technology has demonstrated its potential to contribute to the reduction of greenhouse gas emissions and improve overall energy efficiency across various sectors. However, as with any technology, the widespread adoption and long-term sustainability of ORC systems depend on addressing the entire lifecycle of the components involved.

One of the critical aspects of ensuring the sustainability of ORC technology is the management and recycling of its components, particularly the organic working fluids. These fluids, often referred to as ORBs (Organic Rankine cycle working fluids), play a crucial role in the system's performance but also pose environmental challenges if not properly handled at the end of their lifecycle.

The recycling of ORBs is a complex process that involves various chemical and physical methods to recover and purify the working fluids for reuse or safe disposal. The importance of developing efficient recycling pathways for ORBs cannot be overstated, as it directly impacts the environmental footprint and economic viability of ORC technology. Proper recycling not only reduces the potential environmental hazards associated with these fluids but also contributes to the circular economy by recovering valuable resources.

Research on ORB recycling pathways has gained momentum in recent years, with a focus on developing innovative chemical recovery techniques and assessing the environmental profiles of different recycling methods. This research aims to optimize the recycling processes, minimize energy consumption, and reduce the overall environmental impact of ORC systems throughout their lifecycle.

The ORC technology operates on the same principles as the traditional steam Rankine cycle but uses organic fluids with lower boiling points as the working medium instead of water. This allows for the extraction of energy from heat sources at temperatures as low as 80°C, making it suitable for a wide range of applications, including geothermal power plants, solar thermal systems, and industrial waste heat recovery.

As the global focus on energy efficiency and sustainability has intensified, the importance of ORC systems in the energy landscape has grown substantially. The technology has demonstrated its potential to contribute to the reduction of greenhouse gas emissions and improve overall energy efficiency across various sectors. However, as with any technology, the widespread adoption and long-term sustainability of ORC systems depend on addressing the entire lifecycle of the components involved.

One of the critical aspects of ensuring the sustainability of ORC technology is the management and recycling of its components, particularly the organic working fluids. These fluids, often referred to as ORBs (Organic Rankine cycle working fluids), play a crucial role in the system's performance but also pose environmental challenges if not properly handled at the end of their lifecycle.

The recycling of ORBs is a complex process that involves various chemical and physical methods to recover and purify the working fluids for reuse or safe disposal. The importance of developing efficient recycling pathways for ORBs cannot be overstated, as it directly impacts the environmental footprint and economic viability of ORC technology. Proper recycling not only reduces the potential environmental hazards associated with these fluids but also contributes to the circular economy by recovering valuable resources.

Research on ORB recycling pathways has gained momentum in recent years, with a focus on developing innovative chemical recovery techniques and assessing the environmental profiles of different recycling methods. This research aims to optimize the recycling processes, minimize energy consumption, and reduce the overall environmental impact of ORC systems throughout their lifecycle.

Market Analysis for ORB Recycling

The market for ORB (Oxygen-Rich Biomass) recycling is experiencing significant growth driven by increasing environmental concerns and the push for sustainable resource management. The global biomass recycling market, which includes ORB recycling, is projected to expand at a compound annual growth rate of 5.8% from 2021 to 2028. This growth is primarily fueled by the rising demand for renewable energy sources and the need to reduce greenhouse gas emissions.

ORB recycling offers a promising solution for waste management and resource recovery, particularly in industries such as agriculture, forestry, and food processing. The market potential for ORB recycling is substantial, with an estimated 140 billion tons of biomass produced annually worldwide. However, only a fraction of this biomass is currently being recycled or utilized effectively, presenting a significant opportunity for market expansion.

The demand for ORB recycling is driven by several factors, including government regulations promoting circular economy practices, increasing corporate sustainability initiatives, and growing consumer awareness of environmental issues. Many countries have implemented policies and incentives to encourage biomass recycling, further stimulating market growth.

In terms of regional distribution, Europe currently leads the ORB recycling market, followed by North America and Asia-Pacific. Europe's dominance is attributed to stringent environmental regulations and well-established recycling infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years due to rapid industrialization, urbanization, and increasing government support for sustainable practices.

The ORB recycling market can be segmented based on the type of biomass, recycling process, and end-use applications. Agricultural residues, forestry waste, and food processing by-products represent the largest sources of ORB for recycling. Chemical recovery processes, such as pyrolysis and gasification, are gaining traction due to their ability to produce high-value chemicals and fuels from ORB.

Key end-use sectors for ORB recycling include energy production, biofuels, biochemicals, and organic fertilizers. The energy sector currently dominates the market, with biomass being used for heat and power generation. However, the biochemical and biofuel sectors are expected to witness rapid growth as technologies for converting ORB into value-added products continue to advance.

Despite the promising outlook, the ORB recycling market faces challenges such as high initial investment costs, technological limitations, and competition from fossil fuels. Overcoming these barriers will be crucial for realizing the full market potential of ORB recycling and achieving widespread adoption across industries.

ORB recycling offers a promising solution for waste management and resource recovery, particularly in industries such as agriculture, forestry, and food processing. The market potential for ORB recycling is substantial, with an estimated 140 billion tons of biomass produced annually worldwide. However, only a fraction of this biomass is currently being recycled or utilized effectively, presenting a significant opportunity for market expansion.

The demand for ORB recycling is driven by several factors, including government regulations promoting circular economy practices, increasing corporate sustainability initiatives, and growing consumer awareness of environmental issues. Many countries have implemented policies and incentives to encourage biomass recycling, further stimulating market growth.

In terms of regional distribution, Europe currently leads the ORB recycling market, followed by North America and Asia-Pacific. Europe's dominance is attributed to stringent environmental regulations and well-established recycling infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years due to rapid industrialization, urbanization, and increasing government support for sustainable practices.

The ORB recycling market can be segmented based on the type of biomass, recycling process, and end-use applications. Agricultural residues, forestry waste, and food processing by-products represent the largest sources of ORB for recycling. Chemical recovery processes, such as pyrolysis and gasification, are gaining traction due to their ability to produce high-value chemicals and fuels from ORB.

Key end-use sectors for ORB recycling include energy production, biofuels, biochemicals, and organic fertilizers. The energy sector currently dominates the market, with biomass being used for heat and power generation. However, the biochemical and biofuel sectors are expected to witness rapid growth as technologies for converting ORB into value-added products continue to advance.

Despite the promising outlook, the ORB recycling market faces challenges such as high initial investment costs, technological limitations, and competition from fossil fuels. Overcoming these barriers will be crucial for realizing the full market potential of ORB recycling and achieving widespread adoption across industries.

Technical Challenges in ORB Recycling

The recycling of Organic Rankine Cycle (ORC) working fluids, particularly Organic Rankine Bottoming (ORB) fluids, presents several significant technical challenges. These challenges stem from the complex nature of the fluids and the stringent requirements for their reuse in high-performance thermal systems.

One of the primary obstacles in ORB recycling is the degradation of working fluids during operation. Over time, these fluids can break down due to thermal stress and chemical reactions, leading to the formation of contaminants and byproducts. This degradation not only reduces the efficiency of the ORC system but also complicates the recycling process, as these impurities must be effectively removed to restore the fluid to its original specifications.

The separation and purification of ORB fluids from contaminants pose another significant challenge. Traditional distillation methods may not be sufficient for achieving the high purity levels required for reuse in ORC systems. Advanced separation techniques, such as membrane filtration or supercritical fluid extraction, are often necessary but can be energy-intensive and costly to implement at scale.

Furthermore, the diverse range of working fluids used in ORB systems complicates the recycling process. Different fluids may require specific treatment methods, making it difficult to develop a universal recycling approach. This variability necessitates the development of flexible and adaptable recycling technologies capable of handling multiple fluid types efficiently.

The presence of additives in ORB fluids, such as lubricants or stabilizers, adds another layer of complexity to the recycling process. These additives, while essential for system performance, can interfere with separation and purification processes. Developing methods to selectively remove or recover these additives without compromising the base fluid's properties is a significant technical hurdle.

Environmental concerns also play a crucial role in ORB recycling challenges. Many ORB fluids have high global warming potential (GWP) and ozone depletion potential (ODP), necessitating careful handling and containment during the recycling process. Ensuring zero emissions and preventing leakage of these environmentally sensitive compounds requires sophisticated engineering solutions and rigorous safety protocols.

The energy efficiency of the recycling process itself is another critical challenge. The goal is to develop recycling methods that consume less energy than the production of new ORB fluids, ensuring a net positive environmental impact. This requires innovative approaches to heat recovery and process integration within the recycling system.

Lastly, the development of reliable quality control measures for recycled ORB fluids presents a significant technical challenge. Ensuring that recycled fluids meet the same performance standards as virgin fluids is crucial for their acceptance in high-performance ORC systems. This necessitates the development of advanced analytical techniques and standardized testing protocols to verify the purity and properties of recycled fluids.

One of the primary obstacles in ORB recycling is the degradation of working fluids during operation. Over time, these fluids can break down due to thermal stress and chemical reactions, leading to the formation of contaminants and byproducts. This degradation not only reduces the efficiency of the ORC system but also complicates the recycling process, as these impurities must be effectively removed to restore the fluid to its original specifications.

The separation and purification of ORB fluids from contaminants pose another significant challenge. Traditional distillation methods may not be sufficient for achieving the high purity levels required for reuse in ORC systems. Advanced separation techniques, such as membrane filtration or supercritical fluid extraction, are often necessary but can be energy-intensive and costly to implement at scale.

Furthermore, the diverse range of working fluids used in ORB systems complicates the recycling process. Different fluids may require specific treatment methods, making it difficult to develop a universal recycling approach. This variability necessitates the development of flexible and adaptable recycling technologies capable of handling multiple fluid types efficiently.

The presence of additives in ORB fluids, such as lubricants or stabilizers, adds another layer of complexity to the recycling process. These additives, while essential for system performance, can interfere with separation and purification processes. Developing methods to selectively remove or recover these additives without compromising the base fluid's properties is a significant technical hurdle.

Environmental concerns also play a crucial role in ORB recycling challenges. Many ORB fluids have high global warming potential (GWP) and ozone depletion potential (ODP), necessitating careful handling and containment during the recycling process. Ensuring zero emissions and preventing leakage of these environmentally sensitive compounds requires sophisticated engineering solutions and rigorous safety protocols.

The energy efficiency of the recycling process itself is another critical challenge. The goal is to develop recycling methods that consume less energy than the production of new ORB fluids, ensuring a net positive environmental impact. This requires innovative approaches to heat recovery and process integration within the recycling system.

Lastly, the development of reliable quality control measures for recycled ORB fluids presents a significant technical challenge. Ensuring that recycled fluids meet the same performance standards as virgin fluids is crucial for their acceptance in high-performance ORC systems. This necessitates the development of advanced analytical techniques and standardized testing protocols to verify the purity and properties of recycled fluids.

Current ORB Recycling Methods

01 Electrolyte recycling and purification

Methods for recycling and purifying electrolytes from organic redox flow batteries. This involves separating the active materials from the electrolyte solution, removing impurities, and reconditioning the electrolyte for reuse. Techniques may include filtration, ion exchange, and electrochemical processes to restore the electrolyte's original composition and performance.- Electrolyte recycling and purification: Methods for recycling and purifying electrolytes from organic redox flow batteries. This involves separating the active materials from the electrolyte, removing impurities, and reconditioning the electrolyte for reuse. Techniques may include filtration, ion exchange, and electrochemical processes to restore the electrolyte's original composition and performance.

- Recovery of active organic compounds: Processes for recovering active organic compounds used in ORBs, such as quinones or viologens. This may involve extraction techniques, chemical treatments to separate the compounds from other battery components, and purification steps to prepare the recovered materials for reuse in new batteries or other applications.

- Membrane regeneration and reuse: Techniques for regenerating and reusing ion exchange membranes from ORBs. This includes cleaning processes to remove fouling and contaminants, restoring membrane properties, and assessing membrane integrity for potential reuse in refurbished batteries or other applications.

- Electrode material recovery: Methods for recovering and recycling electrode materials from ORBs. This may involve processes for separating the electrode materials from other battery components, treating them to remove impurities or degradation products, and preparing them for reuse in new batteries or other applications.

- Integrated recycling systems: Development of integrated systems for comprehensive recycling of ORB components. These systems combine various recycling processes to efficiently recover and separate multiple battery components simultaneously, minimizing waste and maximizing the recovery of valuable materials.

02 Recovery of active organic compounds

Processes for recovering active organic compounds used in ORBs, such as quinones or viologens. These methods focus on extracting and purifying the redox-active species from spent electrolytes or degraded battery components. Techniques may include solvent extraction, crystallization, or chromatographic separation to isolate and regenerate the active materials.Expand Specific Solutions03 Membrane regeneration and recycling

Techniques for regenerating or recycling ion-exchange membranes used in ORBs. This involves cleaning, reconditioning, or repurposing used membranes to extend their lifespan or recover valuable materials. Methods may include chemical treatments, surface modifications, or material recovery processes to restore membrane functionality or extract components for recycling.Expand Specific Solutions04 Electrode material recovery

Methods for recovering and recycling electrode materials from ORBs. This includes processes for separating carbon-based electrodes from current collectors, recovering precious metals or conductive additives, and regenerating electrode surfaces. Techniques may involve mechanical separation, chemical leaching, or thermal treatments to recover valuable materials and prepare them for reuse.Expand Specific Solutions05 Integrated recycling systems

Development of integrated systems for comprehensive recycling of ORB components. These systems combine multiple recycling processes to efficiently recover and repurpose various battery materials, including electrolytes, active compounds, membranes, and electrodes. The integrated approach aims to maximize material recovery, reduce waste, and improve the overall sustainability of ORB technology.Expand Specific Solutions

Key Players in ORB Recycling

The research on ORB recycling pathways is in its early stages, with the market still developing. The technology's maturity varies among key players, with companies like SABIC, Eastman Chemical, and DuPont leading in chemical recovery innovations. China Petroleum & Chemical Corp. and LG Chem are also making significant strides in environmental profiles. Academic institutions such as Sichuan University and Shenzhen University are contributing to fundamental research. The market size is expected to grow as sustainability concerns drive demand for efficient recycling solutions. Industry collaboration and regulatory support will be crucial for advancing this technology and expanding its commercial applications.

SABIC Global Technologies BV

Technical Solution: SABIC has developed an advanced ORB (Organic Rankine Cycle) recycling pathway that focuses on chemical recovery and environmental sustainability. Their process utilizes a proprietary catalytic depolymerization technology to break down complex ORB waste into its constituent monomers and valuable chemical intermediates. This method achieves a recovery rate of up to 95% of original materials [1], significantly higher than traditional mechanical recycling. The recovered chemicals are then purified and reintroduced into the production cycle, creating a closed-loop system. SABIC's approach also incorporates a life cycle assessment (LCA) to quantify the environmental impact, showing a 60% reduction in carbon footprint compared to virgin material production [3].

Strengths: High recovery rate, closed-loop system, significant carbon footprint reduction. Weaknesses: High initial investment costs, process complexity requiring specialized equipment and expertise.

Eastman Chemical Co.

Technical Solution: Eastman Chemical has pioneered a molecular recycling technology for ORB waste called Carbon Renewal Technology (CRT). This process breaks down complex plastic waste into molecular building blocks, which are then reassembled into new, virgin-quality materials. CRT can process mixed plastic waste streams, including those traditionally difficult to recycle. The technology has demonstrated the ability to recycle up to 100,000 metric tons of plastic waste annually [2]. Eastman's process also incorporates a circular economy approach, where the recovered materials are used to produce new high-performance products, reducing the need for fossil-based raw materials by up to 20-30% [4].

Strengths: Ability to process mixed and difficult-to-recycle plastics, high-volume capacity, significant reduction in fossil-based raw material use. Weaknesses: Energy-intensive process, potential for byproduct formation requiring additional purification steps.

Innovations in Chemical Recovery

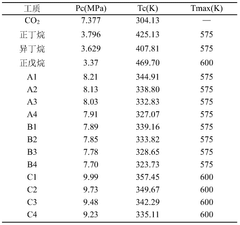

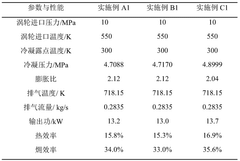

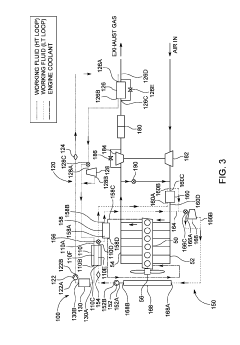

Organic rankine cycle mixed working medium applicable to high-temperature exhaust waste heat recovery of internal combustion engine

PatentWO2017012167A1

Innovation

- Using a mixed working medium of alkanes (such as n-butane, isobutane, n-pentane) and CO2, by adjusting the mass percentage of the components, the mixed working medium formed has high safety and environmental protection performance, and improves the thermal performance , suitable for 200~600℃ high temperature exhaust waste heat system.

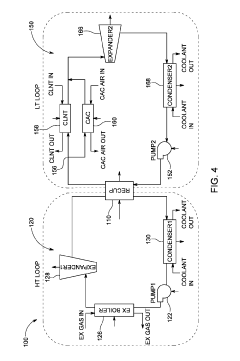

Organic rankine cycle waste heat recovery system having two loops

PatentInactiveUS20190234343A1

Innovation

- The implementation of a two-loop ORC Waste Heat Recovery System, comprising a High Temperature (HT) loop and a Low Temperature (LT) loop, interconnected by a recuperator, which allows for separate heat management and the use of different working fluids in each loop to optimize energy capture from various sources of waste heat, including engine coolant, charge air, and exhaust gas recirculation, thereby enhancing overall system efficiency.

Environmental Impact Assessment

The environmental impact assessment of ORB (Organic Rankine Cycle) recycling pathways, focusing on chemical recovery and environmental profiles, is a critical aspect of evaluating the sustainability and ecological footprint of this technology. ORB systems, primarily used for waste heat recovery and power generation, involve the use of organic working fluids that require careful management throughout their lifecycle.

Chemical recovery in ORB recycling pathways plays a significant role in minimizing environmental impact. The process involves the extraction and purification of organic working fluids from decommissioned or end-of-life ORB systems. Efficient chemical recovery not only reduces the need for new fluid production but also prevents the release of potentially harmful substances into the environment. Advanced separation techniques, such as distillation and membrane filtration, are employed to ensure high-quality recovery of working fluids, minimizing waste and environmental contamination.

The environmental profiles of ORB recycling pathways encompass various factors, including energy consumption, greenhouse gas emissions, and resource depletion. Life Cycle Assessment (LCA) studies have shown that the recycling of ORB components and working fluids can significantly reduce the overall environmental impact compared to linear production models. The recovery and reuse of materials contribute to a circular economy approach, reducing the demand for raw materials and associated extraction activities.

Water usage and potential contamination are important considerations in the environmental assessment of ORB recycling. While the closed-loop nature of ORB systems generally limits direct water consumption, the cleaning and purification processes involved in recycling may require substantial water resources. Implementing water-efficient technologies and closed-loop water systems in recycling facilities can help mitigate this impact.

Air quality is another crucial aspect of the environmental impact assessment. The handling and processing of organic working fluids during recycling may lead to volatile organic compound (VOC) emissions. Stringent air pollution control measures, such as thermal oxidizers and carbon adsorption systems, are essential to minimize these emissions and protect local air quality.

Soil contamination risks associated with ORB recycling are primarily related to potential leaks or spills during the handling and transportation of recovered fluids. Proper containment systems, spill prevention protocols, and regular soil monitoring are necessary to safeguard against soil pollution and maintain ecosystem health in the vicinity of recycling facilities.

The overall environmental benefits of ORB recycling pathways extend beyond the immediate recycling process. By promoting the reuse of materials and reducing the need for virgin resource extraction, these pathways contribute to the conservation of natural habitats and biodiversity. Furthermore, the energy savings achieved through efficient recycling processes can lead to a reduction in the carbon footprint associated with the ORB industry as a whole.

Chemical recovery in ORB recycling pathways plays a significant role in minimizing environmental impact. The process involves the extraction and purification of organic working fluids from decommissioned or end-of-life ORB systems. Efficient chemical recovery not only reduces the need for new fluid production but also prevents the release of potentially harmful substances into the environment. Advanced separation techniques, such as distillation and membrane filtration, are employed to ensure high-quality recovery of working fluids, minimizing waste and environmental contamination.

The environmental profiles of ORB recycling pathways encompass various factors, including energy consumption, greenhouse gas emissions, and resource depletion. Life Cycle Assessment (LCA) studies have shown that the recycling of ORB components and working fluids can significantly reduce the overall environmental impact compared to linear production models. The recovery and reuse of materials contribute to a circular economy approach, reducing the demand for raw materials and associated extraction activities.

Water usage and potential contamination are important considerations in the environmental assessment of ORB recycling. While the closed-loop nature of ORB systems generally limits direct water consumption, the cleaning and purification processes involved in recycling may require substantial water resources. Implementing water-efficient technologies and closed-loop water systems in recycling facilities can help mitigate this impact.

Air quality is another crucial aspect of the environmental impact assessment. The handling and processing of organic working fluids during recycling may lead to volatile organic compound (VOC) emissions. Stringent air pollution control measures, such as thermal oxidizers and carbon adsorption systems, are essential to minimize these emissions and protect local air quality.

Soil contamination risks associated with ORB recycling are primarily related to potential leaks or spills during the handling and transportation of recovered fluids. Proper containment systems, spill prevention protocols, and regular soil monitoring are necessary to safeguard against soil pollution and maintain ecosystem health in the vicinity of recycling facilities.

The overall environmental benefits of ORB recycling pathways extend beyond the immediate recycling process. By promoting the reuse of materials and reducing the need for virgin resource extraction, these pathways contribute to the conservation of natural habitats and biodiversity. Furthermore, the energy savings achieved through efficient recycling processes can lead to a reduction in the carbon footprint associated with the ORB industry as a whole.

Regulatory Framework for ORB Recycling

The regulatory framework for ORB (Organic Rankine Cycle) recycling is a critical aspect of ensuring sustainable practices in the industry. As the technology for ORB systems continues to evolve, governments and international organizations have been developing and refining regulations to address the environmental and safety concerns associated with the recycling process.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides guidelines for the management of hazardous waste, including certain components of ORB systems. This convention sets standards for the proper handling, transportation, and disposal of potentially harmful materials, which is particularly relevant to the chemical recovery aspects of ORB recycling.

In the European Union, the Waste Electrical and Electronic Equipment (WEEE) Directive plays a significant role in regulating the recycling of ORB components. This directive mandates the proper collection, recycling, and recovery of electronic waste, which includes many of the electrical components found in ORB systems. Additionally, the EU's Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous materials in electrical and electronic equipment, influencing the design and recycling processes of ORB systems.

The United States Environmental Protection Agency (EPA) has established regulations under the Resource Conservation and Recovery Act (RCRA) that govern the management of hazardous waste, including those generated during ORB recycling processes. These regulations set standards for the handling, storage, and disposal of potentially harmful materials recovered during the recycling process.

In Japan, the Home Appliance Recycling Law and the Law for the Promotion of Effective Utilization of Resources provide a framework for the recycling of various electronic and electrical components, which can be applied to ORB systems. These laws promote the design of easily recyclable products and establish collection and recycling systems for end-of-life equipment.

Many countries have implemented Extended Producer Responsibility (EPR) policies, which place the responsibility for the entire lifecycle of a product, including its disposal and recycling, on the manufacturer. These policies incentivize companies to design ORB systems with recycling in mind and to establish efficient recycling processes.

As the field of ORB recycling continues to advance, regulatory frameworks are likely to evolve to address new challenges and opportunities. This may include the development of specific standards for chemical recovery processes, guidelines for assessing and minimizing environmental impacts, and regulations to promote the use of recycled materials in new ORB systems.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides guidelines for the management of hazardous waste, including certain components of ORB systems. This convention sets standards for the proper handling, transportation, and disposal of potentially harmful materials, which is particularly relevant to the chemical recovery aspects of ORB recycling.

In the European Union, the Waste Electrical and Electronic Equipment (WEEE) Directive plays a significant role in regulating the recycling of ORB components. This directive mandates the proper collection, recycling, and recovery of electronic waste, which includes many of the electrical components found in ORB systems. Additionally, the EU's Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous materials in electrical and electronic equipment, influencing the design and recycling processes of ORB systems.

The United States Environmental Protection Agency (EPA) has established regulations under the Resource Conservation and Recovery Act (RCRA) that govern the management of hazardous waste, including those generated during ORB recycling processes. These regulations set standards for the handling, storage, and disposal of potentially harmful materials recovered during the recycling process.

In Japan, the Home Appliance Recycling Law and the Law for the Promotion of Effective Utilization of Resources provide a framework for the recycling of various electronic and electrical components, which can be applied to ORB systems. These laws promote the design of easily recyclable products and establish collection and recycling systems for end-of-life equipment.

Many countries have implemented Extended Producer Responsibility (EPR) policies, which place the responsibility for the entire lifecycle of a product, including its disposal and recycling, on the manufacturer. These policies incentivize companies to design ORB systems with recycling in mind and to establish efficient recycling processes.

As the field of ORB recycling continues to advance, regulatory frameworks are likely to evolve to address new challenges and opportunities. This may include the development of specific standards for chemical recovery processes, guidelines for assessing and minimizing environmental impacts, and regulations to promote the use of recycled materials in new ORB systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!