Parameter Transfer From Lab Machines To Industrial PBF-LB Systems

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PBF-LB Technology Background and Objectives

Powder Bed Fusion-Laser Beam (PBF-LB) technology has emerged as a transformative additive manufacturing process over the past three decades, evolving from experimental prototyping systems to sophisticated industrial production platforms. This metal 3D printing technology utilizes high-powered lasers to selectively melt and fuse metal powder particles layer by layer, creating complex geometries that would be impossible with traditional manufacturing methods.

The evolution of PBF-LB systems has been marked by significant technological advancements in laser sources, scanning strategies, powder handling mechanisms, and process monitoring capabilities. Early systems in the 1990s featured relatively low-powered lasers and limited build volumes, primarily serving research and development purposes. By the mid-2000s, commercial systems began incorporating higher-powered lasers, improved scanning algorithms, and enhanced thermal management, enabling the production of functional metal parts with improved mechanical properties.

Recent years have witnessed an acceleration in PBF-LB technology development, with multi-laser systems, in-situ monitoring solutions, and automated powder handling becoming standard features in industrial machines. This progression has expanded the application scope from prototyping to end-use parts production across aerospace, medical, automotive, and energy sectors.

Despite these advancements, a persistent challenge in the PBF-LB ecosystem is the parameter transfer between laboratory-scale machines and industrial production systems. Laboratory machines typically operate under highly controlled conditions with smaller build volumes and different thermal characteristics compared to their industrial counterparts. This disparity creates significant hurdles when attempting to scale processes from research to production environments.

The primary technical objective in addressing parameter transfer challenges is to establish robust methodologies for translating process parameters across different machine architectures while maintaining consistent part quality and material properties. This includes developing standardized approaches for scaling laser parameters, scan strategies, and thermal management techniques that account for the fundamental differences between laboratory and industrial systems.

Additional objectives include creating comprehensive material qualification frameworks that can be applied across different machine platforms, developing physics-based models that accurately predict process outcomes across varying system architectures, and establishing digital twins that enable virtual parameter optimization before physical implementation.

The successful resolution of parameter transfer challenges would significantly accelerate the industrialization of PBF-LB technology, reducing the time and cost associated with qualifying new materials and processes while improving overall manufacturing reliability. This would further cement PBF-LB's position as a mainstream manufacturing technology capable of meeting the demanding requirements of high-value industries.

The evolution of PBF-LB systems has been marked by significant technological advancements in laser sources, scanning strategies, powder handling mechanisms, and process monitoring capabilities. Early systems in the 1990s featured relatively low-powered lasers and limited build volumes, primarily serving research and development purposes. By the mid-2000s, commercial systems began incorporating higher-powered lasers, improved scanning algorithms, and enhanced thermal management, enabling the production of functional metal parts with improved mechanical properties.

Recent years have witnessed an acceleration in PBF-LB technology development, with multi-laser systems, in-situ monitoring solutions, and automated powder handling becoming standard features in industrial machines. This progression has expanded the application scope from prototyping to end-use parts production across aerospace, medical, automotive, and energy sectors.

Despite these advancements, a persistent challenge in the PBF-LB ecosystem is the parameter transfer between laboratory-scale machines and industrial production systems. Laboratory machines typically operate under highly controlled conditions with smaller build volumes and different thermal characteristics compared to their industrial counterparts. This disparity creates significant hurdles when attempting to scale processes from research to production environments.

The primary technical objective in addressing parameter transfer challenges is to establish robust methodologies for translating process parameters across different machine architectures while maintaining consistent part quality and material properties. This includes developing standardized approaches for scaling laser parameters, scan strategies, and thermal management techniques that account for the fundamental differences between laboratory and industrial systems.

Additional objectives include creating comprehensive material qualification frameworks that can be applied across different machine platforms, developing physics-based models that accurately predict process outcomes across varying system architectures, and establishing digital twins that enable virtual parameter optimization before physical implementation.

The successful resolution of parameter transfer challenges would significantly accelerate the industrialization of PBF-LB technology, reducing the time and cost associated with qualifying new materials and processes while improving overall manufacturing reliability. This would further cement PBF-LB's position as a mainstream manufacturing technology capable of meeting the demanding requirements of high-value industries.

Industrial Market Demand for Parameter Transfer Solutions

The additive manufacturing (AM) industry is experiencing significant growth, with the global market projected to reach $51 billion by 2030, growing at a CAGR of approximately 20%. Within this expanding landscape, Powder Bed Fusion-Laser Beam (PBF-LB) systems represent one of the most widely adopted metal AM technologies in industrial settings. The transition from laboratory-scale research to industrial implementation, however, creates substantial demand for reliable parameter transfer solutions.

Manufacturing industries, particularly aerospace, automotive, medical, and energy sectors, are increasingly adopting metal AM technologies for production parts rather than just prototyping. These industries require consistent part quality, reproducibility, and certification across different machine platforms. The inability to transfer process parameters effectively between laboratory systems and industrial machines represents a significant barrier to wider industrial adoption.

A recent survey of manufacturing companies revealed that 78% of industrial users consider parameter transferability a critical factor in their AM implementation strategy. The same survey indicated that companies spend an average of 3-4 months and $50,000-$100,000 in resources to requalify parameters when scaling from laboratory to production systems, creating substantial market demand for streamlined transfer solutions.

The defense and aerospace sectors demonstrate particularly strong demand, with requirements for distributed manufacturing capabilities where identical parts must be produced at different locations using different machine systems. These industries are willing to invest significantly in solutions that enable seamless parameter transfer to maintain consistent part quality across their global supply chains.

Medical device manufacturers face similar challenges, with regulatory requirements demanding consistent production processes regardless of the specific machine used. The ability to transfer validated parameters from development to production environments represents a key market need, with potential to reduce time-to-market by up to 60% for new medical devices.

Small and medium enterprises (SMEs) represent another significant market segment, as they often lack resources for extensive parameter development. Solutions enabling these companies to leverage parameters developed in research institutions would substantially lower barriers to AM adoption in this sector.

Geographically, North America and Europe currently show the strongest demand for parameter transfer solutions, aligned with their mature AM ecosystems. However, rapidly growing markets in Asia, particularly China, Japan, and South Korea, are expected to generate increasing demand as their industrial AM implementation accelerates.

Machine manufacturers themselves constitute another key market segment, with growing interest in offering parameter transferability as a competitive advantage. This has created a secondary market for software and methodology solutions that can be integrated into existing machine ecosystems.

Manufacturing industries, particularly aerospace, automotive, medical, and energy sectors, are increasingly adopting metal AM technologies for production parts rather than just prototyping. These industries require consistent part quality, reproducibility, and certification across different machine platforms. The inability to transfer process parameters effectively between laboratory systems and industrial machines represents a significant barrier to wider industrial adoption.

A recent survey of manufacturing companies revealed that 78% of industrial users consider parameter transferability a critical factor in their AM implementation strategy. The same survey indicated that companies spend an average of 3-4 months and $50,000-$100,000 in resources to requalify parameters when scaling from laboratory to production systems, creating substantial market demand for streamlined transfer solutions.

The defense and aerospace sectors demonstrate particularly strong demand, with requirements for distributed manufacturing capabilities where identical parts must be produced at different locations using different machine systems. These industries are willing to invest significantly in solutions that enable seamless parameter transfer to maintain consistent part quality across their global supply chains.

Medical device manufacturers face similar challenges, with regulatory requirements demanding consistent production processes regardless of the specific machine used. The ability to transfer validated parameters from development to production environments represents a key market need, with potential to reduce time-to-market by up to 60% for new medical devices.

Small and medium enterprises (SMEs) represent another significant market segment, as they often lack resources for extensive parameter development. Solutions enabling these companies to leverage parameters developed in research institutions would substantially lower barriers to AM adoption in this sector.

Geographically, North America and Europe currently show the strongest demand for parameter transfer solutions, aligned with their mature AM ecosystems. However, rapidly growing markets in Asia, particularly China, Japan, and South Korea, are expected to generate increasing demand as their industrial AM implementation accelerates.

Machine manufacturers themselves constitute another key market segment, with growing interest in offering parameter transferability as a competitive advantage. This has created a secondary market for software and methodology solutions that can be integrated into existing machine ecosystems.

Lab-to-Industrial Scale-up Challenges

The transition from laboratory-scale powder bed fusion laser beam (PBF-LB) systems to industrial production environments presents significant challenges that often impede successful technology transfer. Laboratory machines typically operate under highly controlled conditions with smaller build volumes, while industrial systems must maintain consistent quality across larger build areas with higher throughput requirements. This fundamental difference creates a parameter translation gap that requires systematic approaches to overcome.

One of the primary challenges is the variation in laser systems between lab and industrial equipment. Industrial machines frequently employ multiple lasers with different power characteristics, scan strategies, and beam profiles compared to single-laser laboratory setups. These differences significantly impact energy density distribution across the powder bed, requiring comprehensive recalibration of process parameters rather than simple linear scaling.

Thermal management represents another critical hurdle in scale-up efforts. The larger build volumes in industrial systems create different thermal gradients and cooling rates that directly affect microstructure development and residual stress formation. Laboratory-optimized parameters often fail to account for these thermal variations, leading to inconsistent mechanical properties and dimensional accuracy in scaled-up production.

Material handling differences further complicate parameter transfer. Industrial systems typically utilize different powder spreading mechanisms, layer thickness capabilities, and powder recycling protocols. These variations alter powder bed characteristics such as packing density and thermal conductivity, necessitating adjustments to energy input parameters to achieve equivalent melt pool dynamics.

Atmospheric control presents additional challenges during scale-up. Industrial systems may exhibit different oxygen levels, gas flow patterns, and pressure conditions compared to laboratory environments. These atmospheric variations influence oxidation behavior, spatter formation, and condensate removal, all of which affect process stability and part quality.

Monitoring and control system disparities between lab and industrial equipment create further complications. Industrial machines often employ different sensor technologies, data acquisition rates, and control algorithms. This technological mismatch makes direct transfer of process monitoring strategies difficult, requiring adaptation of quality assurance protocols for production environments.

Economic considerations also impact parameter transfer strategies. Industrial production demands higher throughput and material efficiency than laboratory research, often necessitating compromises between optimal part properties and production economics. Parameters that maximize mechanical performance in laboratory settings may prove economically unfeasible at industrial scale due to slower build rates or higher energy consumption.

One of the primary challenges is the variation in laser systems between lab and industrial equipment. Industrial machines frequently employ multiple lasers with different power characteristics, scan strategies, and beam profiles compared to single-laser laboratory setups. These differences significantly impact energy density distribution across the powder bed, requiring comprehensive recalibration of process parameters rather than simple linear scaling.

Thermal management represents another critical hurdle in scale-up efforts. The larger build volumes in industrial systems create different thermal gradients and cooling rates that directly affect microstructure development and residual stress formation. Laboratory-optimized parameters often fail to account for these thermal variations, leading to inconsistent mechanical properties and dimensional accuracy in scaled-up production.

Material handling differences further complicate parameter transfer. Industrial systems typically utilize different powder spreading mechanisms, layer thickness capabilities, and powder recycling protocols. These variations alter powder bed characteristics such as packing density and thermal conductivity, necessitating adjustments to energy input parameters to achieve equivalent melt pool dynamics.

Atmospheric control presents additional challenges during scale-up. Industrial systems may exhibit different oxygen levels, gas flow patterns, and pressure conditions compared to laboratory environments. These atmospheric variations influence oxidation behavior, spatter formation, and condensate removal, all of which affect process stability and part quality.

Monitoring and control system disparities between lab and industrial equipment create further complications. Industrial machines often employ different sensor technologies, data acquisition rates, and control algorithms. This technological mismatch makes direct transfer of process monitoring strategies difficult, requiring adaptation of quality assurance protocols for production environments.

Economic considerations also impact parameter transfer strategies. Industrial production demands higher throughput and material efficiency than laboratory research, often necessitating compromises between optimal part properties and production economics. Parameters that maximize mechanical performance in laboratory settings may prove economically unfeasible at industrial scale due to slower build rates or higher energy consumption.

Current Parameter Transfer Approaches and Frameworks

01 Parameter optimization in PBF-LB simulation systems

Parameter optimization is crucial in Powder Bed Fusion-Lattice Boltzmann (PBF-LB) systems to ensure accurate simulation results. This involves fine-tuning various parameters such as relaxation times, collision operators, and boundary conditions to match experimental data. The optimization process typically employs machine learning algorithms to automatically adjust parameters based on validation datasets, improving the accuracy and efficiency of the simulation.- Parameter optimization in PBF-LB simulation systems: Parameter optimization techniques are crucial in Particle-Based Flow Lattice Boltzmann (PBF-LB) systems to ensure accurate simulation results. These techniques involve adjusting various parameters such as relaxation time, grid resolution, and boundary conditions to achieve optimal performance. Advanced algorithms can automatically tune these parameters based on simulation requirements, improving computational efficiency and result accuracy in fluid dynamics simulations.

- Data transfer mechanisms in distributed PBF-LB computing: Efficient data transfer mechanisms are essential for distributed computing implementations of PBF-LB systems. These mechanisms facilitate the exchange of boundary information between computational nodes, manage memory allocation for particle data, and synchronize simulation states across multiple processors. Optimized data transfer protocols reduce communication overhead and improve scalability for large-scale fluid dynamics simulations.

- Parameter adaptation for multi-physics PBF-LB applications: Multi-physics applications of PBF-LB systems require sophisticated parameter adaptation strategies to handle interactions between different physical phenomena. These strategies involve dynamic adjustment of simulation parameters based on local flow conditions, material properties, and phase transitions. Adaptive parameter transfer techniques enable accurate modeling of complex scenarios such as multiphase flows, thermal effects, and chemical reactions within a unified simulation framework.

- Machine learning approaches for parameter transfer in PBF-LB: Machine learning approaches are increasingly being applied to parameter transfer problems in PBF-LB systems. These methods use training data from high-fidelity simulations to develop models that can predict optimal parameter settings for new simulation scenarios. Neural networks and other AI techniques can identify complex relationships between simulation conditions and parameter values, enabling more efficient parameter transfer across different scales and physical conditions.

- Real-time parameter adjustment in PBF-LB control systems: Real-time parameter adjustment techniques allow PBF-LB systems to respond dynamically to changing simulation conditions. These techniques involve continuous monitoring of simulation stability and accuracy metrics, with automatic parameter updates to maintain optimal performance. Feedback control mechanisms can detect numerical instabilities or physical inconsistencies and adjust relevant parameters accordingly, ensuring robust operation in complex and time-varying flow scenarios.

02 Data transfer mechanisms in distributed PBF-LB computing

Efficient data transfer mechanisms are essential for distributed computing implementations of PBF-LB systems. These mechanisms facilitate the exchange of boundary information between adjacent computational domains, enabling parallel processing across multiple computing nodes. Advanced techniques include asynchronous communication protocols, optimized memory access patterns, and load balancing algorithms to minimize communication overhead and maximize computational throughput.Expand Specific Solutions03 Parameter transfer between multi-scale PBF-LB models

Multi-scale modeling in PBF-LB systems requires effective parameter transfer between models operating at different scales. This involves mapping parameters from microscopic to mesoscopic and macroscopic levels while preserving physical consistency. Techniques include scale bridging methods, hierarchical parameter estimation, and adaptive parameter refinement to ensure accurate representation of physical phenomena across different spatial and temporal scales.Expand Specific Solutions04 Machine learning for parameter prediction in PBF-LB systems

Machine learning approaches are increasingly used for parameter prediction in PBF-LB systems. These methods leverage historical simulation data and experimental results to develop predictive models that can estimate optimal parameters for new simulation scenarios. Techniques include neural networks, genetic algorithms, and Bayesian optimization to identify complex relationships between input parameters and simulation outcomes, reducing the need for extensive parameter sweeps.Expand Specific Solutions05 Real-time parameter adjustment in PBF-LB process control

Real-time parameter adjustment capabilities are essential for process control in PBF-LB manufacturing systems. This involves continuous monitoring of process variables and dynamic adjustment of simulation parameters to maintain consistency between virtual models and physical processes. Feedback control loops integrate sensor data with simulation outputs to optimize process parameters during operation, improving manufacturing quality and repeatability.Expand Specific Solutions

Key Players in Industrial Additive Manufacturing

The parameter transfer from lab machines to industrial PBF-LB systems market is currently in an early growth phase, characterized by increasing adoption across manufacturing sectors. The global market size is expanding rapidly, driven by the growing demand for additive manufacturing solutions in aerospace, automotive, and medical industries. Technologically, the field remains in development with varying maturity levels among key players. Companies like Hitachi, NTT, and JEOL demonstrate advanced capabilities in parameter optimization and transfer protocols, while academic institutions such as Johns Hopkins University and Shanghai University contribute significant research advancements. Chinese enterprises including NARI Technology and Tencent are making substantial investments in industrial applications, focusing on bridging the lab-to-production gap through AI-enhanced parameter mapping and real-time monitoring systems.

Endress+Hauser Gmbh+Co KG

Technical Solution: Endress+Hauser has developed a sophisticated parameter transfer system for PBF-LB processes that emphasizes process monitoring and control. Their solution integrates advanced sensor networks throughout both laboratory and industrial machines to create comprehensive process fingerprints. These fingerprints capture critical parameters including thermal profiles, gas flow patterns, and powder bed characteristics. The company's approach utilizes a multi-physics simulation model that predicts how changes in machine architecture affect process outcomes, enabling parameter scaling between different system sizes. Endress+Hauser's technology incorporates adaptive control algorithms that continuously refine parameter sets based on real-time feedback from industrial systems. Their framework includes a standardized qualification methodology that verifies transferred parameters meet quality requirements through mechanical testing and microstructural analysis. The system also features a knowledge management component that documents parameter transfer cases, building an institutional memory that accelerates future transfers. This comprehensive approach enables manufacturers to rapidly translate optimized laboratory parameters to industrial settings while maintaining consistent part quality.

Strengths: Endress+Hauser's extensive experience in industrial measurement and process control provides robust monitoring capabilities essential for parameter transfer. Their adaptive control algorithms offer continuous optimization during production. Weaknesses: The extensive sensor integration required may increase implementation costs and complexity, potentially limiting adoption in smaller manufacturing operations.

Hitachi Ltd.

Technical Solution: Hitachi has developed a comprehensive parameter transfer framework for Powder Bed Fusion Laser Beam (PBF-LB) systems that bridges laboratory-scale machines to industrial applications. Their approach utilizes digital twin technology to create virtual representations of both lab and industrial machines, enabling parameter mapping and prediction. The system incorporates machine learning algorithms that analyze historical production data to identify correlations between process parameters across different machine scales. Hitachi's solution includes real-time monitoring systems with multiple sensors (thermal cameras, melt pool monitors) that provide feedback for parameter adjustment during the scaling process. Their framework also features a standardized calibration protocol that accounts for differences in laser characteristics, build chamber environments, and powder bed dynamics between lab and industrial systems. This systematic approach allows for efficient transfer of optimized parameters while minimizing the need for extensive trial-and-error experimentation on expensive industrial equipment.

Strengths: Hitachi's extensive experience in industrial automation and digital transformation provides a solid foundation for parameter transfer solutions. Their integrated approach combining digital twins with machine learning offers robust predictive capabilities. Weaknesses: The system may require significant computational resources and specialized expertise to implement effectively in diverse manufacturing environments.

Critical Technologies for Successful Parameter Migration

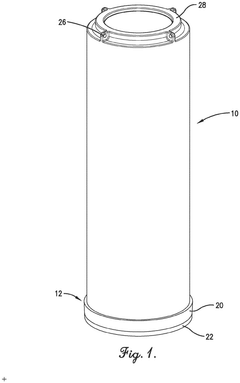

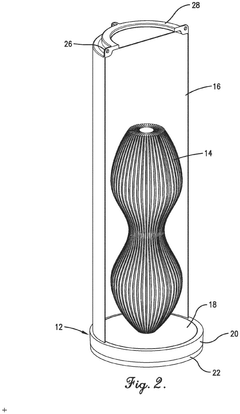

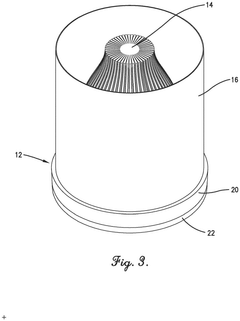

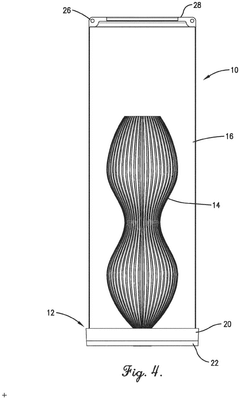

Method for three-dimensional printed powder containment

PatentPendingEP4509249A2

Innovation

- A method involving the simultaneous 3D printing of a canister with the printed part using a single additive manufacturing process, allowing for the containment of powder within the canister, which can then be transported and processed separately for powder removal and recycling.

Material-specific Considerations in Parameter Transfer

The successful transfer of process parameters from laboratory-scale machines to industrial Powder Bed Fusion-Laser Beam (PBF-LB) systems requires careful consideration of material-specific properties and behaviors. Different materials exhibit unique responses to laser energy input, thermal gradients, and cooling rates, necessitating tailored parameter adjustments during scale-up operations.

Metal powders commonly used in PBF-LB processes, such as titanium alloys, aluminum alloys, nickel-based superalloys, and stainless steels, each present distinct challenges. Titanium alloys, for instance, are highly reactive with oxygen at elevated temperatures, requiring stringent atmospheric controls that may differ between laboratory and industrial systems. The thermal conductivity of aluminum alloys, significantly higher than that of titanium or nickel alloys, demands specific energy density adjustments when transferring parameters to larger build platforms.

Powder characteristics play a crucial role in parameter transfer strategies. Particle size distribution, morphology, flowability, and packing density can vary between powder batches and suppliers, affecting the energy absorption and melt pool dynamics. Industrial systems often utilize different powder spreading mechanisms compared to laboratory machines, potentially altering the effective layer thickness and necessitating compensatory parameter adjustments.

The thermal behavior of materials during processing represents another critical consideration. Materials with high thermal expansion coefficients require careful control of temperature gradients to minimize residual stresses and distortion. When scaling to industrial systems with larger build volumes and different cooling conditions, heat accumulation effects become more pronounced, potentially requiring reduced energy inputs or modified scan strategies to maintain consistent microstructural properties.

Oxidation sensitivity varies significantly among materials, with reactive metals like titanium and aluminum demanding more stringent oxygen control. Industrial systems may feature different gas flow patterns and atmospheric control capabilities compared to laboratory equipment, necessitating adjustments to process parameters to maintain equivalent oxygen content in the build chamber and prevent material degradation.

Reflectivity and absorptivity characteristics of different materials directly impact laser-material interactions. Materials with high reflectivity, such as aluminum and copper alloys, may respond differently to variations in laser spot size, beam profile, and power density between laboratory and industrial systems. Parameter transfer must account for these differences to achieve consistent energy absorption and melt pool characteristics.

Microstructural development pathways are material-dependent and significantly influence mechanical properties. The cooling rates, which often differ between laboratory and industrial systems due to build volume and thermal management variations, must be carefully controlled through parameter adjustments to achieve target microstructures and mechanical performance in the scaled-up process.

Metal powders commonly used in PBF-LB processes, such as titanium alloys, aluminum alloys, nickel-based superalloys, and stainless steels, each present distinct challenges. Titanium alloys, for instance, are highly reactive with oxygen at elevated temperatures, requiring stringent atmospheric controls that may differ between laboratory and industrial systems. The thermal conductivity of aluminum alloys, significantly higher than that of titanium or nickel alloys, demands specific energy density adjustments when transferring parameters to larger build platforms.

Powder characteristics play a crucial role in parameter transfer strategies. Particle size distribution, morphology, flowability, and packing density can vary between powder batches and suppliers, affecting the energy absorption and melt pool dynamics. Industrial systems often utilize different powder spreading mechanisms compared to laboratory machines, potentially altering the effective layer thickness and necessitating compensatory parameter adjustments.

The thermal behavior of materials during processing represents another critical consideration. Materials with high thermal expansion coefficients require careful control of temperature gradients to minimize residual stresses and distortion. When scaling to industrial systems with larger build volumes and different cooling conditions, heat accumulation effects become more pronounced, potentially requiring reduced energy inputs or modified scan strategies to maintain consistent microstructural properties.

Oxidation sensitivity varies significantly among materials, with reactive metals like titanium and aluminum demanding more stringent oxygen control. Industrial systems may feature different gas flow patterns and atmospheric control capabilities compared to laboratory equipment, necessitating adjustments to process parameters to maintain equivalent oxygen content in the build chamber and prevent material degradation.

Reflectivity and absorptivity characteristics of different materials directly impact laser-material interactions. Materials with high reflectivity, such as aluminum and copper alloys, may respond differently to variations in laser spot size, beam profile, and power density between laboratory and industrial systems. Parameter transfer must account for these differences to achieve consistent energy absorption and melt pool characteristics.

Microstructural development pathways are material-dependent and significantly influence mechanical properties. The cooling rates, which often differ between laboratory and industrial systems due to build volume and thermal management variations, must be carefully controlled through parameter adjustments to achieve target microstructures and mechanical performance in the scaled-up process.

Quality Assurance Protocols for Transferred Parameters

Establishing robust quality assurance protocols is essential when transferring parameters from laboratory machines to industrial Powder Bed Fusion-Laser Beam (PBF-LB) systems. These protocols serve as the critical bridge between experimental validation and full-scale production implementation, ensuring that the transferred parameters consistently yield parts meeting specified quality standards.

The foundation of effective quality assurance begins with comprehensive documentation of all transferred parameters, including laser power, scan speed, hatch spacing, layer thickness, and build platform temperature. Each parameter must be accompanied by its acceptable tolerance ranges, determined through statistical analysis of laboratory results. This documentation forms the basis for all subsequent verification activities.

Verification testing represents the core of quality assurance protocols, requiring a multi-tiered approach. Initial verification should include standardized test specimens that evaluate fundamental material properties such as density, porosity, surface roughness, and dimensional accuracy. These specimens must be produced using the transferred parameters on the target industrial system and compared against laboratory benchmarks. Statistical process control methods should be applied to establish control limits for each quality characteristic.

Advanced verification protocols must address mechanical performance through tensile, fatigue, and hardness testing. Microstructural analysis using optical microscopy, SEM, and XRD techniques provides critical insights into material consistency across different machine platforms. These analyses should be conducted according to established standards such as ASTM F3303 for additive manufacturing.

Real-time monitoring systems play an increasingly important role in quality assurance for parameter transfer. Melt pool monitoring, layer-wise imaging, and acoustic emission analysis enable continuous validation of process stability. These monitoring systems should be calibrated to detect deviations from expected behavior based on laboratory reference data, with clearly defined intervention protocols when anomalies are detected.

Qualification procedures must include build-to-build repeatability testing, where multiple production runs using transferred parameters are evaluated for consistency. Environmental factors such as powder recycling effects, chamber atmosphere control, and thermal management must be incorporated into these procedures, as they often differ significantly between laboratory and industrial settings.

Finally, a formal parameter certification process should be established, requiring sign-off from both R&D and production teams. This certification should include detailed validation reports, process capability indices, and specific recommendations for in-process quality control measures. Regular review cycles must be scheduled to assess parameter performance over time, particularly when material batches change or equipment undergoes maintenance.

The foundation of effective quality assurance begins with comprehensive documentation of all transferred parameters, including laser power, scan speed, hatch spacing, layer thickness, and build platform temperature. Each parameter must be accompanied by its acceptable tolerance ranges, determined through statistical analysis of laboratory results. This documentation forms the basis for all subsequent verification activities.

Verification testing represents the core of quality assurance protocols, requiring a multi-tiered approach. Initial verification should include standardized test specimens that evaluate fundamental material properties such as density, porosity, surface roughness, and dimensional accuracy. These specimens must be produced using the transferred parameters on the target industrial system and compared against laboratory benchmarks. Statistical process control methods should be applied to establish control limits for each quality characteristic.

Advanced verification protocols must address mechanical performance through tensile, fatigue, and hardness testing. Microstructural analysis using optical microscopy, SEM, and XRD techniques provides critical insights into material consistency across different machine platforms. These analyses should be conducted according to established standards such as ASTM F3303 for additive manufacturing.

Real-time monitoring systems play an increasingly important role in quality assurance for parameter transfer. Melt pool monitoring, layer-wise imaging, and acoustic emission analysis enable continuous validation of process stability. These monitoring systems should be calibrated to detect deviations from expected behavior based on laboratory reference data, with clearly defined intervention protocols when anomalies are detected.

Qualification procedures must include build-to-build repeatability testing, where multiple production runs using transferred parameters are evaluated for consistency. Environmental factors such as powder recycling effects, chamber atmosphere control, and thermal management must be incorporated into these procedures, as they often differ significantly between laboratory and industrial settings.

Finally, a formal parameter certification process should be established, requiring sign-off from both R&D and production teams. This certification should include detailed validation reports, process capability indices, and specific recommendations for in-process quality control measures. Regular review cycles must be scheduled to assess parameter performance over time, particularly when material batches change or equipment undergoes maintenance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!