Polyurethane's Evolving Role in Biomedical Applications

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU in Biomedicine: History and Objectives

Polyurethane (PU) has a rich history in biomedical applications, dating back to the 1960s when it was first explored for its potential in artificial heart development. The journey of PU in biomedicine began with its unique combination of flexibility, durability, and biocompatibility, which made it an attractive material for various medical devices and implants.

Over the decades, PU has undergone significant evolution in its composition and applications. Initially used primarily in cardiovascular devices, its role has expanded to encompass a wide range of biomedical fields, including orthopedics, wound healing, and drug delivery systems. This expansion has been driven by continuous advancements in polymer chemistry and a growing understanding of the interactions between synthetic materials and biological systems.

The objectives of PU research in biomedicine have shifted and broadened over time. Early goals focused on improving the mechanical properties and durability of PU for long-term implantable devices. As the field progressed, objectives expanded to include enhancing biocompatibility, reducing foreign body responses, and developing biodegradable PU variants for temporary medical applications.

A significant milestone in PU's biomedical journey was the development of segmented polyurethanes in the 1970s, which allowed for greater control over material properties. This innovation opened up new possibilities for tailoring PU to specific medical needs, from soft, elastic materials for artificial blood vessels to rigid structures for bone tissue engineering.

Recent years have seen a surge in research aimed at creating "smart" polyurethanes with advanced functionalities. These include shape-memory PUs that can change form in response to stimuli, self-healing PUs for prolonged device lifespans, and bioactive PUs that can interact with the body in beneficial ways, such as promoting tissue regeneration or preventing bacterial colonization.

The current objectives in PU biomedical research are multifaceted. They include developing PUs with improved hemocompatibility for blood-contacting devices, creating nanocomposite PUs with enhanced mechanical and biological properties, and engineering PU-based scaffolds for tissue engineering that can better mimic natural extracellular matrices. Additionally, there is a growing focus on sustainable and bio-based PUs to address environmental concerns and improve long-term biocompatibility.

As we look to the future, the goals for PU in biomedicine are becoming increasingly ambitious. Researchers are aiming to create "living" polyurethanes that can adapt and respond to the body's changing needs, develop PU-based artificial organs with complex functionalities, and harness the potential of 3D printing technologies to produce custom PU implants tailored to individual patients. These objectives reflect the evolving role of PU from a passive biomaterial to an active participant in medical treatment and tissue regeneration.

Over the decades, PU has undergone significant evolution in its composition and applications. Initially used primarily in cardiovascular devices, its role has expanded to encompass a wide range of biomedical fields, including orthopedics, wound healing, and drug delivery systems. This expansion has been driven by continuous advancements in polymer chemistry and a growing understanding of the interactions between synthetic materials and biological systems.

The objectives of PU research in biomedicine have shifted and broadened over time. Early goals focused on improving the mechanical properties and durability of PU for long-term implantable devices. As the field progressed, objectives expanded to include enhancing biocompatibility, reducing foreign body responses, and developing biodegradable PU variants for temporary medical applications.

A significant milestone in PU's biomedical journey was the development of segmented polyurethanes in the 1970s, which allowed for greater control over material properties. This innovation opened up new possibilities for tailoring PU to specific medical needs, from soft, elastic materials for artificial blood vessels to rigid structures for bone tissue engineering.

Recent years have seen a surge in research aimed at creating "smart" polyurethanes with advanced functionalities. These include shape-memory PUs that can change form in response to stimuli, self-healing PUs for prolonged device lifespans, and bioactive PUs that can interact with the body in beneficial ways, such as promoting tissue regeneration or preventing bacterial colonization.

The current objectives in PU biomedical research are multifaceted. They include developing PUs with improved hemocompatibility for blood-contacting devices, creating nanocomposite PUs with enhanced mechanical and biological properties, and engineering PU-based scaffolds for tissue engineering that can better mimic natural extracellular matrices. Additionally, there is a growing focus on sustainable and bio-based PUs to address environmental concerns and improve long-term biocompatibility.

As we look to the future, the goals for PU in biomedicine are becoming increasingly ambitious. Researchers are aiming to create "living" polyurethanes that can adapt and respond to the body's changing needs, develop PU-based artificial organs with complex functionalities, and harness the potential of 3D printing technologies to produce custom PU implants tailored to individual patients. These objectives reflect the evolving role of PU from a passive biomaterial to an active participant in medical treatment and tissue regeneration.

Biomedical Market Demand for PU

The biomedical market for polyurethane (PU) has been experiencing significant growth and diversification in recent years. This surge in demand is driven by the unique properties of PU, including its biocompatibility, durability, and versatility, which make it an ideal material for various medical applications. The healthcare industry's continuous quest for innovative materials to improve patient outcomes has positioned PU as a critical component in the development of advanced medical devices and implants.

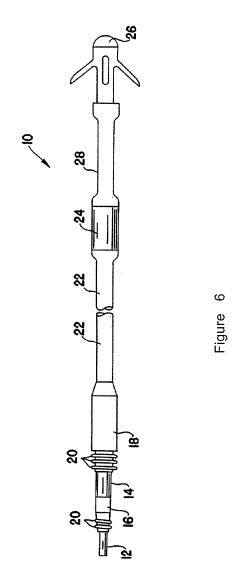

In the field of cardiovascular medicine, PU is increasingly utilized in the production of artificial heart valves, vascular grafts, and pacemaker leads. The material's excellent mechanical properties and resistance to biodegradation make it particularly suitable for long-term implantation. The global market for cardiovascular devices, a significant portion of which incorporates PU, is projected to grow steadily, reflecting the rising prevalence of cardiovascular diseases worldwide.

Orthopedic applications represent another burgeoning sector for PU in biomedicine. The material's shock-absorbing capabilities and ability to mimic natural tissue properties have led to its incorporation in joint replacements, spinal implants, and bone scaffolds. As the global population ages and the incidence of degenerative joint diseases increases, the demand for PU-based orthopedic solutions is expected to rise substantially.

The wound care segment has also seen a surge in PU utilization, particularly in advanced dressings and tissue engineering scaffolds. PU foams and films offer excellent moisture management and bacterial barrier properties, crucial for promoting wound healing and preventing infections. The growing prevalence of chronic wounds, coupled with the rise in diabetic foot ulcers, is driving the expansion of this market segment.

In the realm of drug delivery systems, PU is gaining traction due to its controllable degradation rates and ability to be engineered for sustained release of therapeutic agents. This application is particularly promising in the treatment of chronic diseases, where long-term, controlled drug delivery can significantly improve patient compliance and treatment efficacy.

The biomedical market's demand for PU is further bolstered by advancements in 3D printing technologies. The ability to create custom, patient-specific implants and devices using PU-based materials is opening new avenues for personalized medicine, particularly in reconstructive surgery and tissue engineering applications.

As environmental concerns gain prominence, there is a growing interest in biodegradable and bio-based PUs for medical applications. This trend aligns with the healthcare industry's shift towards more sustainable practices and materials, potentially expanding the market for eco-friendly PU variants in the coming years.

In the field of cardiovascular medicine, PU is increasingly utilized in the production of artificial heart valves, vascular grafts, and pacemaker leads. The material's excellent mechanical properties and resistance to biodegradation make it particularly suitable for long-term implantation. The global market for cardiovascular devices, a significant portion of which incorporates PU, is projected to grow steadily, reflecting the rising prevalence of cardiovascular diseases worldwide.

Orthopedic applications represent another burgeoning sector for PU in biomedicine. The material's shock-absorbing capabilities and ability to mimic natural tissue properties have led to its incorporation in joint replacements, spinal implants, and bone scaffolds. As the global population ages and the incidence of degenerative joint diseases increases, the demand for PU-based orthopedic solutions is expected to rise substantially.

The wound care segment has also seen a surge in PU utilization, particularly in advanced dressings and tissue engineering scaffolds. PU foams and films offer excellent moisture management and bacterial barrier properties, crucial for promoting wound healing and preventing infections. The growing prevalence of chronic wounds, coupled with the rise in diabetic foot ulcers, is driving the expansion of this market segment.

In the realm of drug delivery systems, PU is gaining traction due to its controllable degradation rates and ability to be engineered for sustained release of therapeutic agents. This application is particularly promising in the treatment of chronic diseases, where long-term, controlled drug delivery can significantly improve patient compliance and treatment efficacy.

The biomedical market's demand for PU is further bolstered by advancements in 3D printing technologies. The ability to create custom, patient-specific implants and devices using PU-based materials is opening new avenues for personalized medicine, particularly in reconstructive surgery and tissue engineering applications.

As environmental concerns gain prominence, there is a growing interest in biodegradable and bio-based PUs for medical applications. This trend aligns with the healthcare industry's shift towards more sustainable practices and materials, potentially expanding the market for eco-friendly PU variants in the coming years.

PU Biocompatibility Challenges

Polyurethane (PU) has emerged as a promising material in biomedical applications due to its versatility and tunable properties. However, its widespread adoption in this field faces significant biocompatibility challenges that need to be addressed. One of the primary concerns is the potential for PU to elicit adverse immune responses when implanted in the body. The immune system may recognize PU as a foreign substance, leading to inflammation, encapsulation, or rejection of the implant.

Another critical challenge is the long-term stability of PU in biological environments. The material can undergo degradation over time, potentially releasing harmful byproducts that may cause local or systemic toxicity. This degradation can also compromise the mechanical integrity and functionality of the implant, limiting its lifespan and effectiveness.

The surface properties of PU play a crucial role in its biocompatibility. Unmodified PU surfaces may not provide optimal conditions for cell adhesion and growth, which is essential for tissue integration and healing. Additionally, PU surfaces can be prone to protein adsorption and subsequent bacterial colonization, increasing the risk of infection and biofilm formation.

Hemocompatibility is another significant challenge, particularly for PU-based cardiovascular devices. The interaction between blood components and PU surfaces can lead to thrombosis, platelet activation, and hemolysis, potentially causing serious complications in patients.

The variability in PU composition and manufacturing processes also contributes to biocompatibility issues. Different formulations and processing methods can result in inconsistent material properties and biological responses, making it challenging to establish standardized protocols for biomedical applications.

To address these challenges, researchers are exploring various strategies. Surface modification techniques, such as plasma treatment, grafting of bioactive molecules, and nanostructuring, are being investigated to improve cell adhesion, reduce protein adsorption, and enhance overall biocompatibility. The incorporation of anti-inflammatory and antimicrobial agents into PU matrices is another approach to mitigate immune responses and prevent infections.

Advanced polymer chemistry is being employed to develop novel PU formulations with improved biodegradability and reduced toxicity. This includes the use of bio-based polyols and isocyanates, as well as the incorporation of enzymatically degradable segments in the polymer structure.

Another critical challenge is the long-term stability of PU in biological environments. The material can undergo degradation over time, potentially releasing harmful byproducts that may cause local or systemic toxicity. This degradation can also compromise the mechanical integrity and functionality of the implant, limiting its lifespan and effectiveness.

The surface properties of PU play a crucial role in its biocompatibility. Unmodified PU surfaces may not provide optimal conditions for cell adhesion and growth, which is essential for tissue integration and healing. Additionally, PU surfaces can be prone to protein adsorption and subsequent bacterial colonization, increasing the risk of infection and biofilm formation.

Hemocompatibility is another significant challenge, particularly for PU-based cardiovascular devices. The interaction between blood components and PU surfaces can lead to thrombosis, platelet activation, and hemolysis, potentially causing serious complications in patients.

The variability in PU composition and manufacturing processes also contributes to biocompatibility issues. Different formulations and processing methods can result in inconsistent material properties and biological responses, making it challenging to establish standardized protocols for biomedical applications.

To address these challenges, researchers are exploring various strategies. Surface modification techniques, such as plasma treatment, grafting of bioactive molecules, and nanostructuring, are being investigated to improve cell adhesion, reduce protein adsorption, and enhance overall biocompatibility. The incorporation of anti-inflammatory and antimicrobial agents into PU matrices is another approach to mitigate immune responses and prevent infections.

Advanced polymer chemistry is being employed to develop novel PU formulations with improved biodegradability and reduced toxicity. This includes the use of bio-based polyols and isocyanates, as well as the incorporation of enzymatically degradable segments in the polymer structure.

Current PU Biomedical Solutions

01 Polyurethane synthesis and composition

This category focuses on the synthesis and composition of polyurethane materials. It includes various methods for producing polyurethane with specific properties, such as improved durability, flexibility, or chemical resistance. The synthesis may involve different types of isocyanates, polyols, and additives to achieve desired characteristics.- Polyurethane synthesis and composition: This category focuses on the development of new polyurethane compositions and synthesis methods. It includes innovations in the formulation of polyurethane precursors, catalysts, and additives to achieve specific properties or improve manufacturing processes. These advancements aim to enhance the performance, durability, and versatility of polyurethane materials for various applications.

- Polyurethane coatings and films: This area covers innovations in polyurethane-based coatings and films. It includes developments in formulations for improved adhesion, weather resistance, and durability. The research also encompasses techniques for applying polyurethane coatings to various substrates and creating specialized films for specific industrial or consumer applications.

- Polyurethane foams and insulation: This category focuses on advancements in polyurethane foam technology, particularly for insulation applications. It includes innovations in foam formulations, blowing agents, and processing techniques to improve thermal insulation properties, fire resistance, and environmental sustainability. The research also covers the development of specialized foams for acoustic insulation and structural applications.

- Polyurethane in textile and fiber applications: This area encompasses the use of polyurethane in textile and fiber-related applications. It includes innovations in polyurethane-based fibers, coatings for fabrics, and adhesives for textile lamination. The research focuses on improving the elasticity, durability, and comfort of textiles, as well as developing water-resistant and breathable materials for various industries.

- Polyurethane in medical and biocompatible applications: This category covers the development of polyurethane materials for medical and biocompatible applications. It includes innovations in biocompatible polyurethane formulations, drug delivery systems, and tissue engineering scaffolds. The research focuses on improving the biocompatibility, biodegradability, and functionality of polyurethane materials for use in medical devices, implants, and regenerative medicine.

02 Polyurethane applications in coatings and adhesives

This category covers the use of polyurethane in coatings and adhesives. It includes formulations for various applications such as automotive coatings, industrial adhesives, and protective finishes. The focus is on developing polyurethane-based products with enhanced adhesion, durability, and resistance to environmental factors.Expand Specific Solutions03 Polyurethane foam technology

This category encompasses innovations in polyurethane foam technology. It includes methods for producing various types of foam, such as flexible, rigid, or spray foams, with specific properties like improved insulation, fire resistance, or biodegradability. The focus is on optimizing foam formulations and manufacturing processes.Expand Specific Solutions04 Polyurethane in textile and fiber applications

This category focuses on the use of polyurethane in textile and fiber applications. It includes methods for incorporating polyurethane into fabrics, fibers, and other textile materials to enhance properties such as elasticity, moisture-wicking, or durability. The innovations may cover spinning techniques, coating processes, or composite material development.Expand Specific Solutions05 Sustainable and bio-based polyurethane

This category addresses the development of sustainable and bio-based polyurethane materials. It includes innovations in using renewable resources, such as plant-based polyols, to replace petroleum-based components in polyurethane production. The focus is on creating environmentally friendly alternatives while maintaining or improving material performance.Expand Specific Solutions

Key PU Biomedical Players

The polyurethane market in biomedical applications is experiencing rapid growth, driven by increasing demand for advanced medical devices and tissue engineering solutions. The industry is in a phase of innovation and expansion, with a projected market size reaching billions of dollars globally. Technological maturity varies across applications, with companies like Medtronic, Inc. and PolyNovo Biomaterials Pty Ltd. leading in medical device development. Academic institutions such as Sichuan University and The Children's Hospital of Philadelphia are advancing research in tissue engineering and biocompatibility. Emerging players like Bezwada Biomedical LLC and Vysera Biomedical Ltd. are focusing on novel polyurethane formulations for specific biomedical applications, indicating a competitive and diverse landscape with significant potential for further advancements.

Medtronic, Inc.

Technical Solution: Medtronic has developed a novel polyurethane-based drug delivery system for controlled release of therapeutic agents in biomedical applications. Their technology involves creating microspheres or nanoparticles from biodegradable polyurethane, which can encapsulate various drugs or bioactive molecules. These particles are designed to degrade slowly in the body, releasing the encapsulated agents over an extended period. This system allows for targeted and sustained drug delivery, potentially improving treatment efficacy and reducing side effects in various medical conditions.

Strengths: Controlled and sustained drug release, biodegradability, versatility in encapsulating different therapeutic agents. Weaknesses: Potential for initial burst release, complexity in manufacturing process, need for extensive in vivo testing for each drug-polymer combination.

PolyNovo Biomaterials Pty Ltd.

Technical Solution: PolyNovo has pioneered the development of NovoSorb, a novel biodegradable polyurethane polymer for tissue engineering and regenerative medicine applications. NovoSorb is designed as a porous scaffold that can be tailored to specific tissue requirements. The polymer's unique chemistry allows for controlled degradation rates and mechanical properties, making it suitable for various applications such as dermal regeneration, bone void filling, and soft tissue repair. PolyNovo's technology also includes the ability to incorporate bioactive molecules into the polymer matrix, enhancing tissue regeneration and integration.

Strengths: Customizable degradation rates and mechanical properties, biocompatibility, versatility in tissue engineering applications. Weaknesses: Limited long-term clinical data for some applications, potential challenges in scaling up production for diverse medical needs.

Innovative PU Biomaterials

Polyurethanes for medical implantation

PatentInactiveEP2010589A2

Innovation

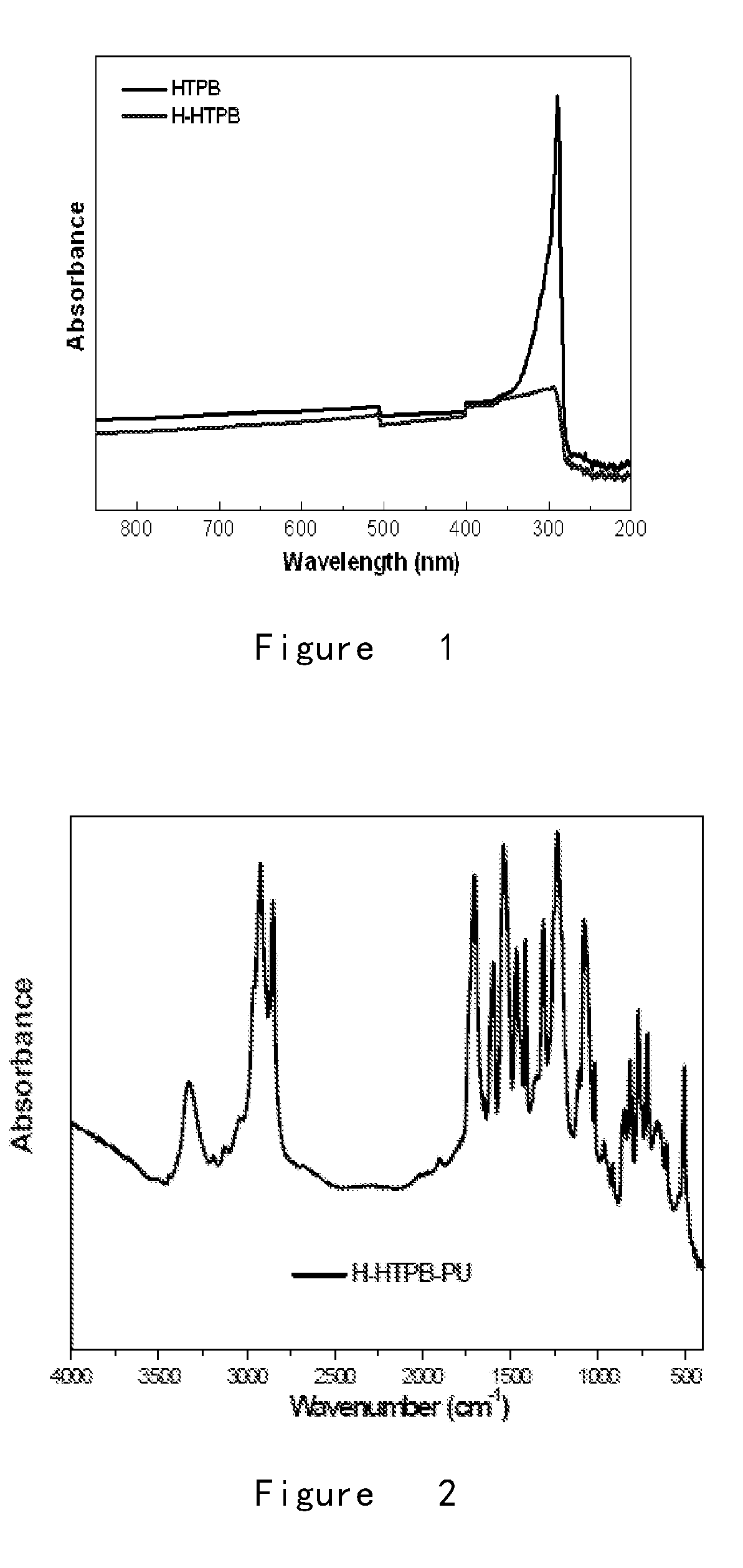

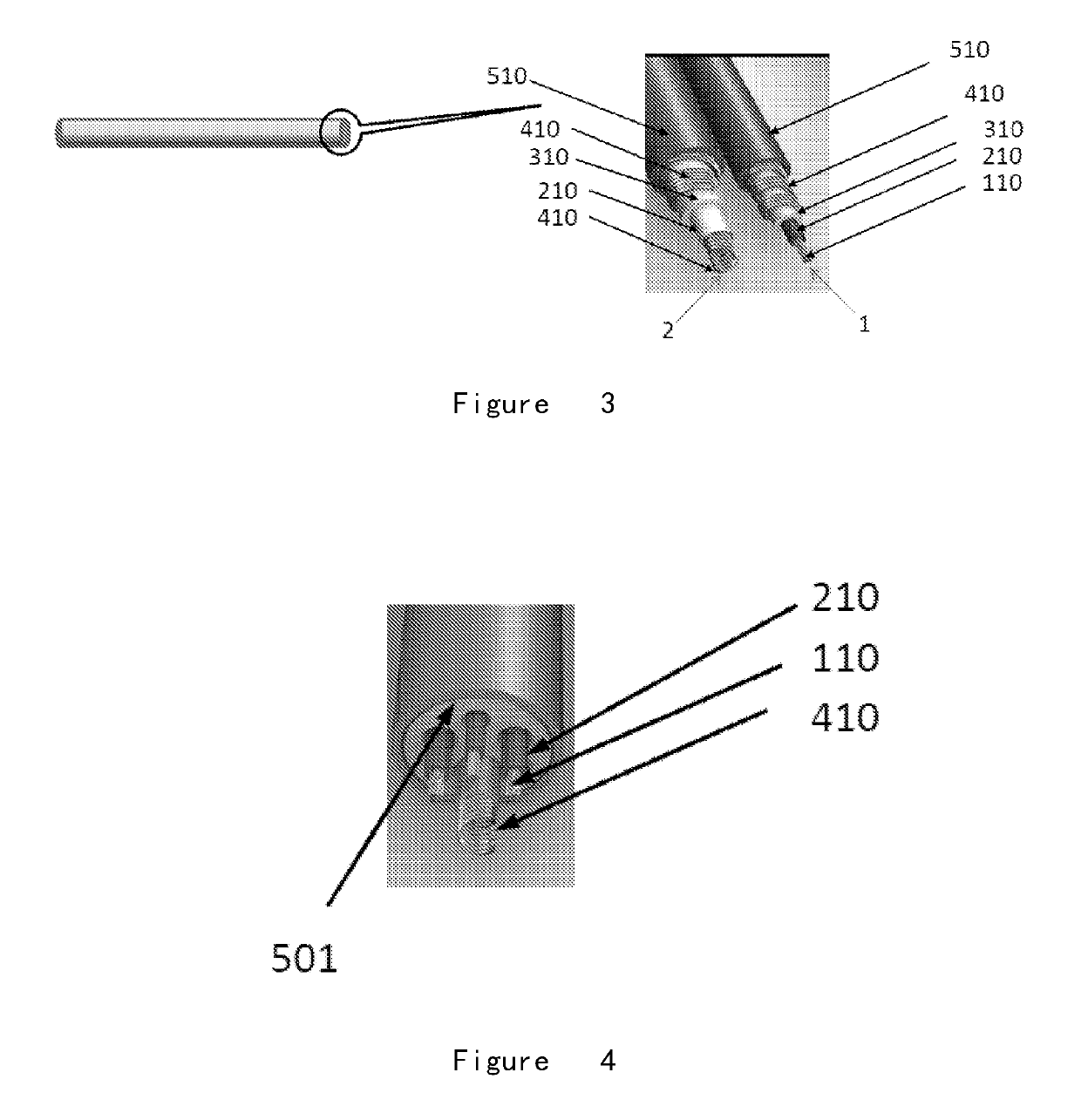

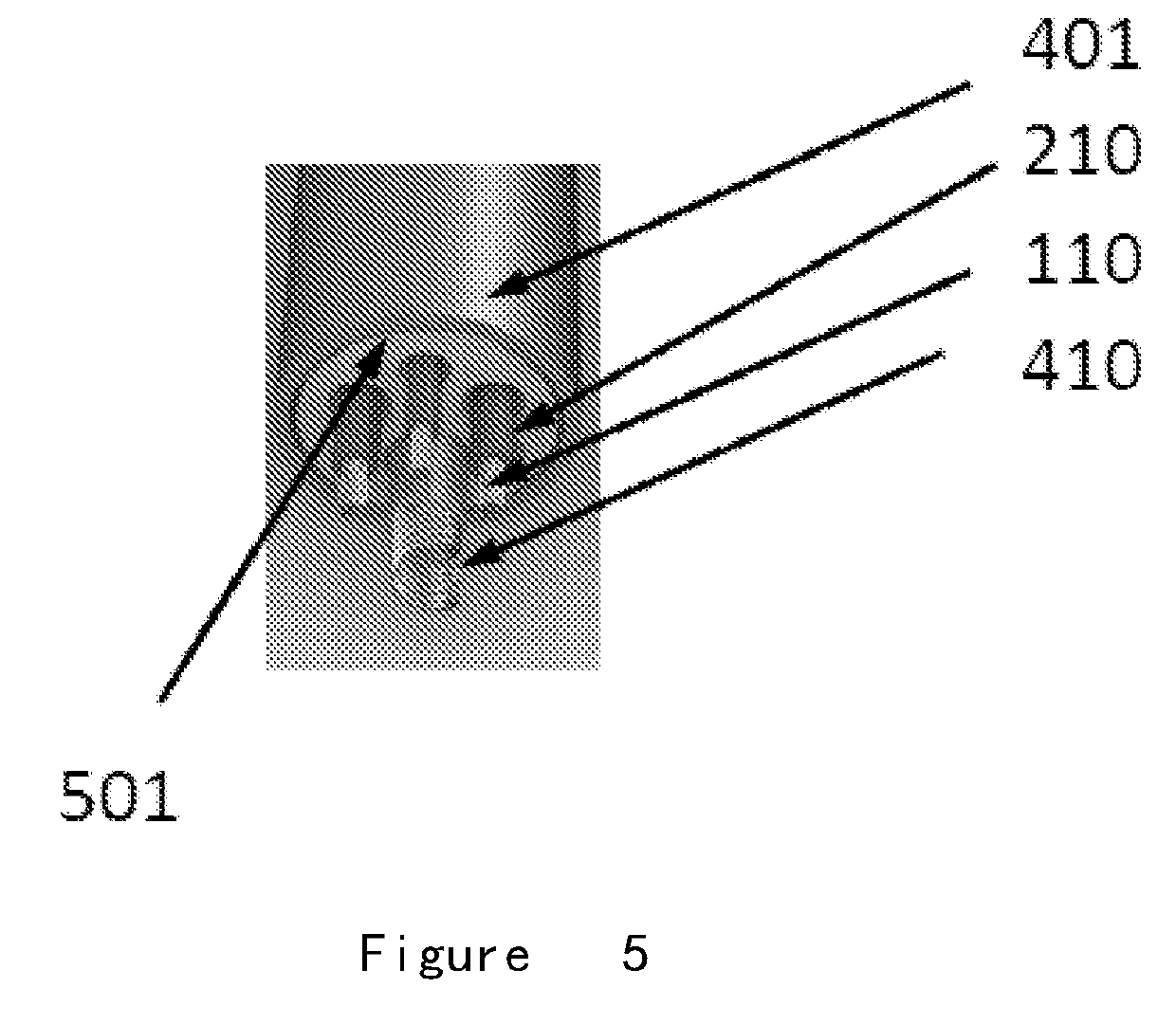

- A polyurethane material with a phenol-based silicone soft segment and a methylene diphenyl diisocyanate hard segment, where the soft segment does not include polycarbonate, and is enhanced with chain extenders and bioactive compounds to improve biostability and physical properties, such as increased UV absorption and reduced crystallinity.

Medical device, method for preparation thereof, and use thereof

PatentActiveUS20190111186A1

Innovation

- A method involving the production of polyolefin polyurethane using hydrogenated polyolefin diols and microwave heating to create a material with improved resistance to oxidation and hydrolysis, characterized by specific molecular weights, elongation, and mechanical properties suitable for biomedical applications.

PU Biomedical Regulations

The regulatory landscape for polyurethane (PU) in biomedical applications is complex and evolving, reflecting the material's increasing importance in healthcare. Regulatory bodies worldwide have established stringent guidelines to ensure the safety and efficacy of PU-based medical devices and implants.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of PU in biomedical applications. The FDA classifies medical devices containing PU based on their intended use and risk level. Class I devices, such as wound dressings, undergo general controls, while Class II devices, like catheters, require special controls and premarket notification. Class III devices, including certain implants, necessitate premarket approval.

The European Union employs the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) to govern PU-based medical products. These regulations emphasize rigorous clinical evaluation, post-market surveillance, and traceability throughout the product lifecycle. Manufacturers must obtain CE marking to demonstrate compliance with essential requirements for safety and performance.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) regulates PU-containing medical devices. The Japanese regulatory system categorizes devices into general medical devices, controlled medical devices, and specially controlled medical devices, with increasing levels of scrutiny for higher-risk products.

Globally, the International Organization for Standardization (ISO) provides standards relevant to PU in biomedical applications. ISO 10993 series, for instance, outlines biological evaluation of medical devices, including tests for cytotoxicity, sensitization, and hemocompatibility, which are crucial for PU-based products.

Regulatory bodies are increasingly focusing on the long-term safety of PU implants, particularly concerning degradation products and potential leaching of chemicals. This has led to more stringent requirements for biocompatibility testing and long-term performance evaluation.

Environmental concerns have also influenced regulations, with growing emphasis on sustainable production and disposal of PU-based medical products. Some jurisdictions are implementing regulations to promote the use of bio-based polyurethanes and environmentally friendly manufacturing processes.

As nanotechnology advances in PU formulations for biomedical applications, regulatory frameworks are adapting to address potential risks associated with nanoparticles. This includes additional safety assessments and specific guidelines for nanomaterial-containing medical devices.

The regulatory landscape continues to evolve, with ongoing efforts to harmonize international standards and regulations. This aims to streamline the approval process for PU-based medical products while maintaining high safety standards across global markets.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of PU in biomedical applications. The FDA classifies medical devices containing PU based on their intended use and risk level. Class I devices, such as wound dressings, undergo general controls, while Class II devices, like catheters, require special controls and premarket notification. Class III devices, including certain implants, necessitate premarket approval.

The European Union employs the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) to govern PU-based medical products. These regulations emphasize rigorous clinical evaluation, post-market surveillance, and traceability throughout the product lifecycle. Manufacturers must obtain CE marking to demonstrate compliance with essential requirements for safety and performance.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) regulates PU-containing medical devices. The Japanese regulatory system categorizes devices into general medical devices, controlled medical devices, and specially controlled medical devices, with increasing levels of scrutiny for higher-risk products.

Globally, the International Organization for Standardization (ISO) provides standards relevant to PU in biomedical applications. ISO 10993 series, for instance, outlines biological evaluation of medical devices, including tests for cytotoxicity, sensitization, and hemocompatibility, which are crucial for PU-based products.

Regulatory bodies are increasingly focusing on the long-term safety of PU implants, particularly concerning degradation products and potential leaching of chemicals. This has led to more stringent requirements for biocompatibility testing and long-term performance evaluation.

Environmental concerns have also influenced regulations, with growing emphasis on sustainable production and disposal of PU-based medical products. Some jurisdictions are implementing regulations to promote the use of bio-based polyurethanes and environmentally friendly manufacturing processes.

As nanotechnology advances in PU formulations for biomedical applications, regulatory frameworks are adapting to address potential risks associated with nanoparticles. This includes additional safety assessments and specific guidelines for nanomaterial-containing medical devices.

The regulatory landscape continues to evolve, with ongoing efforts to harmonize international standards and regulations. This aims to streamline the approval process for PU-based medical products while maintaining high safety standards across global markets.

PU Sustainability in Biomedicine

The sustainability of polyurethane (PU) in biomedical applications has become a critical focus in recent years, driven by increasing environmental concerns and the need for more eco-friendly materials in healthcare. As PU continues to play a significant role in various biomedical devices and implants, researchers and manufacturers are exploring innovative approaches to enhance its sustainability throughout its lifecycle.

One key aspect of PU sustainability in biomedicine is the development of bio-based polyurethanes. These materials are derived from renewable resources such as vegetable oils, lignin, and cellulose, reducing reliance on petroleum-based feedstocks. Bio-based PUs not only offer a more sustainable alternative but also often exhibit improved biocompatibility and biodegradability, making them particularly attractive for tissue engineering and drug delivery applications.

Another important consideration is the end-of-life management of PU-based medical devices. Traditional PUs can persist in the environment for extended periods, contributing to plastic pollution. To address this issue, researchers are developing biodegradable PU formulations that can break down into non-toxic components after their intended use. This approach not only reduces environmental impact but also opens up new possibilities for temporary implants and scaffolds in regenerative medicine.

The recyclability of PU in biomedical applications is also gaining attention. While recycling medical-grade materials presents unique challenges due to stringent hygiene and safety requirements, advancements in chemical recycling technologies are showing promise. These methods can break down PU into its constituent monomers, which can then be purified and reused in new medical-grade materials, creating a more circular economy in healthcare.

Reducing the environmental footprint of PU production processes is another crucial aspect of sustainability. Manufacturers are adopting greener synthesis methods, such as using water-based systems instead of solvent-based ones, and implementing more energy-efficient production techniques. These efforts not only decrease the environmental impact but also often result in purer materials with enhanced performance characteristics.

The longevity and durability of PU-based medical devices also contribute to their sustainability profile. By improving the material's resistance to degradation and wear, manufacturers can extend the lifespan of devices, reducing the need for frequent replacements and minimizing waste generation. This is particularly relevant for long-term implants and prosthetics, where material stability is crucial for patient safety and comfort.

As the healthcare industry increasingly prioritizes sustainability, the development of PU materials that align with these goals will be essential. The ongoing research and innovation in this field are not only enhancing the environmental credentials of PU but also expanding its potential applications in biomedicine, promising a future where advanced healthcare solutions and environmental responsibility go hand in hand.

One key aspect of PU sustainability in biomedicine is the development of bio-based polyurethanes. These materials are derived from renewable resources such as vegetable oils, lignin, and cellulose, reducing reliance on petroleum-based feedstocks. Bio-based PUs not only offer a more sustainable alternative but also often exhibit improved biocompatibility and biodegradability, making them particularly attractive for tissue engineering and drug delivery applications.

Another important consideration is the end-of-life management of PU-based medical devices. Traditional PUs can persist in the environment for extended periods, contributing to plastic pollution. To address this issue, researchers are developing biodegradable PU formulations that can break down into non-toxic components after their intended use. This approach not only reduces environmental impact but also opens up new possibilities for temporary implants and scaffolds in regenerative medicine.

The recyclability of PU in biomedical applications is also gaining attention. While recycling medical-grade materials presents unique challenges due to stringent hygiene and safety requirements, advancements in chemical recycling technologies are showing promise. These methods can break down PU into its constituent monomers, which can then be purified and reused in new medical-grade materials, creating a more circular economy in healthcare.

Reducing the environmental footprint of PU production processes is another crucial aspect of sustainability. Manufacturers are adopting greener synthesis methods, such as using water-based systems instead of solvent-based ones, and implementing more energy-efficient production techniques. These efforts not only decrease the environmental impact but also often result in purer materials with enhanced performance characteristics.

The longevity and durability of PU-based medical devices also contribute to their sustainability profile. By improving the material's resistance to degradation and wear, manufacturers can extend the lifespan of devices, reducing the need for frequent replacements and minimizing waste generation. This is particularly relevant for long-term implants and prosthetics, where material stability is crucial for patient safety and comfort.

As the healthcare industry increasingly prioritizes sustainability, the development of PU materials that align with these goals will be essential. The ongoing research and innovation in this field are not only enhancing the environmental credentials of PU but also expanding its potential applications in biomedicine, promising a future where advanced healthcare solutions and environmental responsibility go hand in hand.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!