Polyurethane Sealants: Future Applications and Trends

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Sealant Evolution

Polyurethane sealants have undergone significant evolution since their introduction in the 1960s. Initially developed as a more flexible alternative to traditional sealants, PU sealants quickly gained popularity due to their superior adhesion, elasticity, and durability. The early formulations were primarily focused on construction applications, offering improved weatherproofing and joint sealing capabilities.

As the technology progressed through the 1970s and 1980s, manufacturers began to refine PU sealant formulations to enhance specific properties. This period saw the development of low-modulus sealants for expansion joints and high-modulus variants for structural glazing applications. The introduction of moisture-curing systems in the 1980s marked a significant advancement, allowing for easier application and faster curing times.

The 1990s brought about a shift towards more environmentally friendly formulations. Manufacturers began to reduce volatile organic compounds (VOCs) in response to growing environmental concerns and stricter regulations. This led to the development of low-VOC and solvent-free PU sealants, which maintained performance while minimizing environmental impact.

The turn of the millennium saw a focus on improving the longevity and UV resistance of PU sealants. Advanced polymer technologies were incorporated to enhance weatherability and color stability, particularly important for exposed applications in construction and automotive industries. Additionally, the introduction of hybrid sealants, combining polyurethane with other polymers like silicone, offered new performance characteristics and expanded application possibilities.

In recent years, the evolution of PU sealants has been driven by the demand for multi-functional products. Modern formulations often incorporate additional properties such as fire resistance, sound insulation, and even self-healing capabilities. The advent of smart materials has also influenced PU sealant development, with research into sealants that can respond to environmental stimuli or indicate when maintenance is required.

The latest trend in PU sealant evolution is the push towards sustainability and bio-based materials. Researchers are exploring the use of renewable resources in sealant production, aiming to reduce the carbon footprint while maintaining or improving performance characteristics. This includes the development of bio-based polyols and isocyanates, key components in PU sealant formulations.

Looking ahead, the evolution of PU sealants is likely to continue focusing on enhanced sustainability, improved durability, and expanded functionality. Emerging technologies such as nanotechnology and advanced polymer science are expected to play a crucial role in shaping the next generation of PU sealants, potentially offering unprecedented levels of performance and versatility.

As the technology progressed through the 1970s and 1980s, manufacturers began to refine PU sealant formulations to enhance specific properties. This period saw the development of low-modulus sealants for expansion joints and high-modulus variants for structural glazing applications. The introduction of moisture-curing systems in the 1980s marked a significant advancement, allowing for easier application and faster curing times.

The 1990s brought about a shift towards more environmentally friendly formulations. Manufacturers began to reduce volatile organic compounds (VOCs) in response to growing environmental concerns and stricter regulations. This led to the development of low-VOC and solvent-free PU sealants, which maintained performance while minimizing environmental impact.

The turn of the millennium saw a focus on improving the longevity and UV resistance of PU sealants. Advanced polymer technologies were incorporated to enhance weatherability and color stability, particularly important for exposed applications in construction and automotive industries. Additionally, the introduction of hybrid sealants, combining polyurethane with other polymers like silicone, offered new performance characteristics and expanded application possibilities.

In recent years, the evolution of PU sealants has been driven by the demand for multi-functional products. Modern formulations often incorporate additional properties such as fire resistance, sound insulation, and even self-healing capabilities. The advent of smart materials has also influenced PU sealant development, with research into sealants that can respond to environmental stimuli or indicate when maintenance is required.

The latest trend in PU sealant evolution is the push towards sustainability and bio-based materials. Researchers are exploring the use of renewable resources in sealant production, aiming to reduce the carbon footprint while maintaining or improving performance characteristics. This includes the development of bio-based polyols and isocyanates, key components in PU sealant formulations.

Looking ahead, the evolution of PU sealants is likely to continue focusing on enhanced sustainability, improved durability, and expanded functionality. Emerging technologies such as nanotechnology and advanced polymer science are expected to play a crucial role in shaping the next generation of PU sealants, potentially offering unprecedented levels of performance and versatility.

Market Demand Analysis

The global market for polyurethane sealants has been experiencing steady growth, driven by increasing demand across various industries. The construction sector remains the primary consumer of these versatile materials, with applications ranging from building facades and window installations to flooring and roofing systems. As urbanization continues to accelerate worldwide, the need for efficient and durable sealing solutions in both residential and commercial construction projects is expected to fuel market expansion.

In the automotive industry, polyurethane sealants are gaining traction due to their superior bonding properties and resistance to environmental factors. With the trend towards lightweight vehicle construction and improved fuel efficiency, these sealants are increasingly used in body assembly, windshield bonding, and underbody coating applications. The growing electric vehicle market also presents new opportunities for polyurethane sealants in battery sealing and thermal management systems.

The aerospace sector is another key driver of market demand, particularly in the commercial aircraft segment. Polyurethane sealants are essential for maintaining cabin pressurization, preventing fuel leaks, and ensuring overall structural integrity. As air travel continues to grow globally, the demand for these specialized sealants is projected to increase correspondingly.

In the marine industry, polyurethane sealants are valued for their excellent water resistance and durability in harsh environments. Applications include deck sealing, hull bonding, and underwater hull protection. The expansion of shipbuilding activities, particularly in emerging economies, is expected to contribute to market growth in this sector.

The packaging industry is also adopting polyurethane sealants for flexible packaging applications, driven by the need for improved barrier properties and extended shelf life of products. This trend is particularly evident in the food and beverage sector, where maintaining product freshness and preventing contamination are paramount.

Emerging applications in the electronics industry, such as the sealing of mobile devices and wearable technology, are opening up new avenues for market expansion. The increasing focus on miniaturization and water resistance in consumer electronics is driving demand for high-performance, low-viscosity polyurethane sealants.

Geographically, Asia-Pacific is expected to be the fastest-growing market for polyurethane sealants, fueled by rapid industrialization, infrastructure development, and increasing automotive production in countries like China and India. North America and Europe remain significant markets, with demand driven by renovation activities and stringent building energy efficiency regulations.

In the automotive industry, polyurethane sealants are gaining traction due to their superior bonding properties and resistance to environmental factors. With the trend towards lightweight vehicle construction and improved fuel efficiency, these sealants are increasingly used in body assembly, windshield bonding, and underbody coating applications. The growing electric vehicle market also presents new opportunities for polyurethane sealants in battery sealing and thermal management systems.

The aerospace sector is another key driver of market demand, particularly in the commercial aircraft segment. Polyurethane sealants are essential for maintaining cabin pressurization, preventing fuel leaks, and ensuring overall structural integrity. As air travel continues to grow globally, the demand for these specialized sealants is projected to increase correspondingly.

In the marine industry, polyurethane sealants are valued for their excellent water resistance and durability in harsh environments. Applications include deck sealing, hull bonding, and underwater hull protection. The expansion of shipbuilding activities, particularly in emerging economies, is expected to contribute to market growth in this sector.

The packaging industry is also adopting polyurethane sealants for flexible packaging applications, driven by the need for improved barrier properties and extended shelf life of products. This trend is particularly evident in the food and beverage sector, where maintaining product freshness and preventing contamination are paramount.

Emerging applications in the electronics industry, such as the sealing of mobile devices and wearable technology, are opening up new avenues for market expansion. The increasing focus on miniaturization and water resistance in consumer electronics is driving demand for high-performance, low-viscosity polyurethane sealants.

Geographically, Asia-Pacific is expected to be the fastest-growing market for polyurethane sealants, fueled by rapid industrialization, infrastructure development, and increasing automotive production in countries like China and India. North America and Europe remain significant markets, with demand driven by renovation activities and stringent building energy efficiency regulations.

Technical Challenges

Polyurethane sealants face several technical challenges that hinder their widespread adoption and limit their performance in various applications. One of the primary issues is the balance between flexibility and strength. While these sealants need to be flexible to accommodate movement in joints and substrates, they also require sufficient strength to maintain their structural integrity. Achieving the optimal balance between these properties remains a significant challenge for manufacturers.

Another critical challenge is the long-term durability of polyurethane sealants, particularly in harsh environmental conditions. Exposure to UV radiation, extreme temperatures, and moisture can lead to degradation of the sealant's properties over time. This degradation can result in reduced adhesion, discoloration, and loss of elasticity, ultimately compromising the sealant's effectiveness and longevity.

The curing process of polyurethane sealants presents additional technical hurdles. Ensuring consistent and complete curing across various environmental conditions and substrate types is crucial for optimal performance. Factors such as humidity, temperature, and substrate porosity can significantly impact the curing process, leading to potential issues with adhesion and overall sealant integrity.

Adhesion to a wide range of substrates remains a persistent challenge for polyurethane sealants. While they generally exhibit good adhesion to many materials, achieving strong and durable bonds with certain substrates, such as plastics or coated metals, can be problematic. Developing formulations that provide excellent adhesion across diverse substrates without compromising other performance characteristics is an ongoing area of research and development.

Environmental and health concerns also pose significant challenges for the polyurethane sealant industry. The presence of volatile organic compounds (VOCs) and isocyanates in some formulations has raised concerns about indoor air quality and potential health risks. Developing low-VOC and isocyanate-free formulations that maintain the desirable properties of traditional polyurethane sealants is a major focus for manufacturers and researchers.

The compatibility of polyurethane sealants with other construction materials and coatings is another area of technical challenge. Ensuring that the sealants do not react adversely with adjacent materials or compromise the performance of coatings and finishes is crucial for their successful integration into complex building systems and industrial applications.

Lastly, the development of smart and responsive polyurethane sealants presents new technical challenges. Incorporating features such as self-healing properties, temperature-responsive behavior, or enhanced fire resistance requires innovative approaches to material design and formulation. Overcoming these challenges could lead to significant advancements in the functionality and performance of polyurethane sealants across various industries.

Another critical challenge is the long-term durability of polyurethane sealants, particularly in harsh environmental conditions. Exposure to UV radiation, extreme temperatures, and moisture can lead to degradation of the sealant's properties over time. This degradation can result in reduced adhesion, discoloration, and loss of elasticity, ultimately compromising the sealant's effectiveness and longevity.

The curing process of polyurethane sealants presents additional technical hurdles. Ensuring consistent and complete curing across various environmental conditions and substrate types is crucial for optimal performance. Factors such as humidity, temperature, and substrate porosity can significantly impact the curing process, leading to potential issues with adhesion and overall sealant integrity.

Adhesion to a wide range of substrates remains a persistent challenge for polyurethane sealants. While they generally exhibit good adhesion to many materials, achieving strong and durable bonds with certain substrates, such as plastics or coated metals, can be problematic. Developing formulations that provide excellent adhesion across diverse substrates without compromising other performance characteristics is an ongoing area of research and development.

Environmental and health concerns also pose significant challenges for the polyurethane sealant industry. The presence of volatile organic compounds (VOCs) and isocyanates in some formulations has raised concerns about indoor air quality and potential health risks. Developing low-VOC and isocyanate-free formulations that maintain the desirable properties of traditional polyurethane sealants is a major focus for manufacturers and researchers.

The compatibility of polyurethane sealants with other construction materials and coatings is another area of technical challenge. Ensuring that the sealants do not react adversely with adjacent materials or compromise the performance of coatings and finishes is crucial for their successful integration into complex building systems and industrial applications.

Lastly, the development of smart and responsive polyurethane sealants presents new technical challenges. Incorporating features such as self-healing properties, temperature-responsive behavior, or enhanced fire resistance requires innovative approaches to material design and formulation. Overcoming these challenges could lead to significant advancements in the functionality and performance of polyurethane sealants across various industries.

Current PU Solutions

01 Composition of polyurethane sealants

Polyurethane sealants are typically composed of polyurethane polymers, additives, and curing agents. The specific composition can be tailored to achieve desired properties such as flexibility, adhesion, and durability. Various formulations may include different types of polyols, isocyanates, and other components to optimize performance for specific applications.- Composition of polyurethane sealants: Polyurethane sealants are typically composed of polyurethane polymers, additives, and curing agents. The composition can be adjusted to achieve specific properties such as flexibility, adhesion, and durability. Various formulations may include different types of polyols, isocyanates, and other components to tailor the sealant's performance for different applications.

- Moisture-curing polyurethane sealants: Moisture-curing polyurethane sealants react with atmospheric moisture to form a durable, flexible seal. These sealants are particularly useful in construction and automotive applications where exposure to environmental conditions is expected. The curing process can be controlled by adjusting the formulation and environmental conditions during application.

- Polyurethane sealants with enhanced properties: Researchers have developed polyurethane sealants with enhanced properties such as improved chemical resistance, UV stability, and thermal performance. These advancements are achieved through the incorporation of specific additives, modifying the polymer structure, or using hybrid systems that combine polyurethane with other materials like silicone or epoxy.

- Application methods for polyurethane sealants: Various application methods have been developed for polyurethane sealants, including gun-applied systems, self-leveling formulations, and sprayable versions. These methods are designed to improve ease of use, ensure consistent application, and enhance the overall performance of the sealant in different environments and substrates.

- Environmental considerations in polyurethane sealants: Recent developments in polyurethane sealant technology have focused on reducing environmental impact. This includes the development of low-VOC formulations, bio-based polyurethanes, and sealants with improved recyclability or biodegradability. These innovations aim to meet increasingly stringent environmental regulations while maintaining the high performance expected from polyurethane sealants.

02 Moisture-curing polyurethane sealants

Moisture-curing polyurethane sealants are designed to cure upon exposure to atmospheric moisture. These sealants typically contain isocyanate-terminated prepolymers that react with water to form a crosslinked polymer network. This type of sealant is particularly useful in applications where traditional heat or chemical curing methods are impractical.Expand Specific Solutions03 Two-component polyurethane sealants

Two-component polyurethane sealants consist of separate polyol and isocyanate components that are mixed just before application. This system allows for rapid curing and provides excellent control over the curing process. These sealants are often used in applications requiring fast setting times and high performance properties.Expand Specific Solutions04 Polyurethane sealants with enhanced properties

Researchers have developed polyurethane sealants with enhanced properties such as improved chemical resistance, weatherability, and adhesion. These advancements are achieved through the incorporation of specific additives, modifying the polymer structure, or introducing new curing mechanisms. Such improvements expand the range of applications for polyurethane sealants in various industries.Expand Specific Solutions05 Application methods for polyurethane sealants

Various application methods have been developed for polyurethane sealants, including gun-applied systems, brush-on techniques, and spray applications. These methods are designed to improve ease of use, ensure proper coverage, and optimize the performance of the sealant in different environments and substrates. Some applications may require specialized equipment or techniques to achieve the desired results.Expand Specific Solutions

Industry Leaders

The polyurethane sealants market is in a growth phase, driven by increasing demand in construction and automotive industries. The global market size is projected to expand significantly, with key players like Sika Technology AG, Dow Global Technologies LLC, and BASF Corp. leading innovation. The technology is mature but evolving, with companies such as Henkel AG & Co. KGaA and Covestro Deutschland AG focusing on developing eco-friendly and high-performance formulations. Emerging players like Beijing Oriental Yuhong Waterproof Technology Co., Ltd. and Hangzhou Zhijiang Silicone Chemicals Co. Ltd. are contributing to market diversification and regional expansion, particularly in Asia. Future trends indicate a shift towards sustainable, low-VOC products and smart sealants with enhanced durability and functionality.

Sika Technology AG

Technical Solution: Sika has developed advanced polyurethane sealants with enhanced durability and flexibility. Their technology focuses on improving adhesion to various substrates, including concrete, metal, and plastics. Sika's sealants incorporate moisture-curing mechanisms that allow for faster curing times and improved resistance to environmental factors. They have also developed low-VOC formulations to meet stringent environmental regulations. Sika's research extends to self-healing polyurethane sealants that can repair minor damages autonomously, potentially extending the lifespan of sealed joints.

Strengths: Excellent adhesion properties, fast curing times, and environmental compliance. Weaknesses: May be more expensive than traditional sealants, and some formulations might require specific application conditions.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered silylated polyurethane technology for sealants, combining the benefits of polyurethane and silicone chemistries. This hybrid approach results in sealants with improved weatherability, UV resistance, and paintability. Dow's sealants also feature advanced polymer crosslinking that enhances elasticity and durability. They have developed sealants with low modulus and high movement capability, making them suitable for expansion joints in construction. Additionally, Dow has invested in bio-based polyurethane sealants, utilizing renewable resources to reduce environmental impact.

Strengths: High performance in extreme weather conditions, excellent elasticity, and eco-friendly options. Weaknesses: Higher cost compared to conventional polyurethane sealants, and potential limitations in certain chemical exposure scenarios.

Key PU Technologies

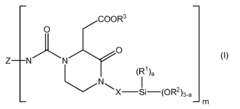

Alkoxysilane-group modified polyurethanes and low modulus sealants formed therefrom

PatentWO2016137746A1

Innovation

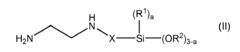

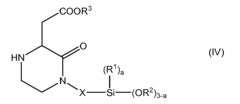

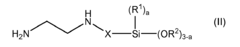

- Development of alkoxysilane-group modified polyurethanes formed from a polyoxyalkylene polyol with a molecular weight of at least 18,000 g/mole and a compound of the formula ONC— Y— Si— (X)3, where X represents alkoxy radicals and Y is a difunctional organic radical, with a weight average molar ratio of isocyanate groups to hydroxyl groups less than 0.80:1, and optionally including up to 15% inert plasticizer, to create sealants with reduced plasticizer content.

Silane-terminated polyurethane polymers

PatentInactiveEP2221331A1

Innovation

- Development of new silane-terminated polyurethane polymers with improved properties, including odorlessness and enhanced storage stability, achieved through specific polymer formulations and reaction processes involving aminosilanes and maleic or fumaric acid diesters, allowing a broader range of raw materials and eliminating isocyanate groups for better toxicological profiles.

Environmental Impact

The environmental impact of polyurethane sealants has become a critical consideration in their future applications and trends. As the construction and automotive industries continue to expand, the demand for these versatile materials is expected to grow. However, this growth must be balanced with increasing environmental concerns and regulations.

One of the primary environmental challenges associated with polyurethane sealants is their production process. Traditional manufacturing methods often involve the use of volatile organic compounds (VOCs) and isocyanates, which can contribute to air pollution and pose health risks to workers and end-users. To address this issue, manufacturers are developing low-VOC and VOC-free formulations that maintain the performance characteristics of conventional sealants while reducing harmful emissions.

The disposal of polyurethane sealants at the end of their lifecycle presents another environmental concern. Many of these products are not biodegradable and can persist in landfills for extended periods. To mitigate this impact, researchers are exploring bio-based alternatives and recyclable formulations. These innovations aim to create more sustainable sealant options that can be easily reprocessed or naturally decompose without leaving harmful residues in the environment.

Energy efficiency is a key factor in reducing the environmental footprint of polyurethane sealants. Advanced formulations are being developed to enhance the insulating properties of these materials, contributing to improved energy performance in buildings and vehicles. By minimizing heat transfer and air leakage, these high-performance sealants can significantly reduce energy consumption and associated greenhouse gas emissions over the lifetime of the structures they protect.

Water conservation is another area where polyurethane sealants are making a positive environmental impact. Improved water-resistant formulations are being used to prevent leaks and water damage in various applications, from roofing to plumbing. By extending the lifespan of structures and reducing the need for repairs and replacements, these sealants help conserve resources and minimize waste generation.

The trend towards green building certifications, such as LEED, is driving the development of eco-friendly polyurethane sealants. Manufacturers are focusing on creating products that meet stringent environmental standards, including low emissions, recycled content, and responsible sourcing of raw materials. This shift is not only beneficial for the environment but also aligns with the growing consumer demand for sustainable construction materials.

As the industry moves forward, life cycle assessments (LCAs) are becoming increasingly important in evaluating the overall environmental impact of polyurethane sealants. These comprehensive analyses consider all stages of a product's life, from raw material extraction to disposal, providing valuable insights for further improvements in sustainability. The results of these assessments are guiding research and development efforts towards more environmentally friendly solutions in the polyurethane sealant sector.

One of the primary environmental challenges associated with polyurethane sealants is their production process. Traditional manufacturing methods often involve the use of volatile organic compounds (VOCs) and isocyanates, which can contribute to air pollution and pose health risks to workers and end-users. To address this issue, manufacturers are developing low-VOC and VOC-free formulations that maintain the performance characteristics of conventional sealants while reducing harmful emissions.

The disposal of polyurethane sealants at the end of their lifecycle presents another environmental concern. Many of these products are not biodegradable and can persist in landfills for extended periods. To mitigate this impact, researchers are exploring bio-based alternatives and recyclable formulations. These innovations aim to create more sustainable sealant options that can be easily reprocessed or naturally decompose without leaving harmful residues in the environment.

Energy efficiency is a key factor in reducing the environmental footprint of polyurethane sealants. Advanced formulations are being developed to enhance the insulating properties of these materials, contributing to improved energy performance in buildings and vehicles. By minimizing heat transfer and air leakage, these high-performance sealants can significantly reduce energy consumption and associated greenhouse gas emissions over the lifetime of the structures they protect.

Water conservation is another area where polyurethane sealants are making a positive environmental impact. Improved water-resistant formulations are being used to prevent leaks and water damage in various applications, from roofing to plumbing. By extending the lifespan of structures and reducing the need for repairs and replacements, these sealants help conserve resources and minimize waste generation.

The trend towards green building certifications, such as LEED, is driving the development of eco-friendly polyurethane sealants. Manufacturers are focusing on creating products that meet stringent environmental standards, including low emissions, recycled content, and responsible sourcing of raw materials. This shift is not only beneficial for the environment but also aligns with the growing consumer demand for sustainable construction materials.

As the industry moves forward, life cycle assessments (LCAs) are becoming increasingly important in evaluating the overall environmental impact of polyurethane sealants. These comprehensive analyses consider all stages of a product's life, from raw material extraction to disposal, providing valuable insights for further improvements in sustainability. The results of these assessments are guiding research and development efforts towards more environmentally friendly solutions in the polyurethane sealant sector.

Regulatory Landscape

The regulatory landscape for polyurethane sealants is evolving rapidly, driven by increasing environmental concerns and health considerations. Globally, there is a growing trend towards stricter regulations on volatile organic compounds (VOCs) emissions, which directly impacts the formulation and application of polyurethane sealants. In the United States, the Environmental Protection Agency (EPA) has set stringent limits on VOC content in architectural sealants, prompting manufacturers to develop low-VOC and zero-VOC formulations.

The European Union, through its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, has imposed comprehensive requirements on the chemical components used in polyurethane sealants. This has led to the phasing out of certain hazardous substances and the promotion of safer alternatives. Additionally, the EU's Construction Products Regulation (CPR) mandates CE marking for sealants used in construction, ensuring compliance with harmonized technical specifications.

In Asia, countries like China and Japan are also tightening their regulatory frameworks. China's new VOC regulations for adhesives and sealants, implemented in 2020, have set maximum limits for VOC content, pushing manufacturers to reformulate their products. Japan's Building Standard Law has specific requirements for the fire resistance and durability of sealants used in construction.

The automotive industry, a significant consumer of polyurethane sealants, faces its own set of regulations. In the United States, the Corporate Average Fuel Economy (CAFE) standards indirectly influence sealant formulations by driving the demand for lighter materials and improved fuel efficiency. This has led to the development of specialized polyurethane sealants that contribute to weight reduction and enhanced aerodynamics in vehicles.

Sustainability and circular economy principles are increasingly shaping regulatory approaches. The EU's Circular Economy Action Plan, for instance, emphasizes the need for products that are easier to recycle and reuse. This is likely to impact future regulations on polyurethane sealants, potentially requiring manufacturers to consider end-of-life scenarios and recyclability in their product designs.

Occupational health and safety regulations also play a crucial role in shaping the polyurethane sealants industry. Many countries have implemented strict guidelines for the handling and application of these materials, particularly concerning isocyanates, a key component in polyurethane chemistry. These regulations often mandate proper personal protective equipment and ventilation systems in workplaces where sealants are applied.

As global awareness of environmental and health issues continues to grow, it is anticipated that regulatory frameworks will become increasingly stringent and harmonized across different regions. This evolving landscape presents both challenges and opportunities for the polyurethane sealants industry, driving innovation in product formulations and application technologies to meet future regulatory requirements.

The European Union, through its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, has imposed comprehensive requirements on the chemical components used in polyurethane sealants. This has led to the phasing out of certain hazardous substances and the promotion of safer alternatives. Additionally, the EU's Construction Products Regulation (CPR) mandates CE marking for sealants used in construction, ensuring compliance with harmonized technical specifications.

In Asia, countries like China and Japan are also tightening their regulatory frameworks. China's new VOC regulations for adhesives and sealants, implemented in 2020, have set maximum limits for VOC content, pushing manufacturers to reformulate their products. Japan's Building Standard Law has specific requirements for the fire resistance and durability of sealants used in construction.

The automotive industry, a significant consumer of polyurethane sealants, faces its own set of regulations. In the United States, the Corporate Average Fuel Economy (CAFE) standards indirectly influence sealant formulations by driving the demand for lighter materials and improved fuel efficiency. This has led to the development of specialized polyurethane sealants that contribute to weight reduction and enhanced aerodynamics in vehicles.

Sustainability and circular economy principles are increasingly shaping regulatory approaches. The EU's Circular Economy Action Plan, for instance, emphasizes the need for products that are easier to recycle and reuse. This is likely to impact future regulations on polyurethane sealants, potentially requiring manufacturers to consider end-of-life scenarios and recyclability in their product designs.

Occupational health and safety regulations also play a crucial role in shaping the polyurethane sealants industry. Many countries have implemented strict guidelines for the handling and application of these materials, particularly concerning isocyanates, a key component in polyurethane chemistry. These regulations often mandate proper personal protective equipment and ventilation systems in workplaces where sealants are applied.

As global awareness of environmental and health issues continues to grow, it is anticipated that regulatory frameworks will become increasingly stringent and harmonized across different regions. This evolving landscape presents both challenges and opportunities for the polyurethane sealants industry, driving innovation in product formulations and application technologies to meet future regulatory requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!