Predicting Phase Formation Using CALPHAD For PBF-LB Process Design

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CALPHAD Background and PBF-LB Integration Goals

CALPHAD (CALculation of PHAse Diagrams) methodology has evolved significantly since its inception in the 1970s, transforming from a specialized academic tool to an essential industrial resource for materials design and process optimization. This computational thermodynamics approach enables the prediction of phase equilibria and transformations in multi-component systems by minimizing Gibbs free energy. The methodology has matured through decades of database development, with extensive experimental validation across numerous alloy systems.

In recent years, CALPHAD has become increasingly relevant to advanced manufacturing processes, particularly in the rapidly evolving field of additive manufacturing (AM). Powder Bed Fusion-Laser Beam (PBF-LB), as one of the most widely adopted metal AM technologies, presents unique challenges related to rapid solidification, non-equilibrium phase formation, and complex thermal histories that traditional manufacturing processes do not encounter.

The integration of CALPHAD with PBF-LB process design represents a critical technological frontier. Conventional manufacturing processes typically operate closer to equilibrium conditions, whereas PBF-LB involves extreme cooling rates (10^3-10^6 K/s), steep thermal gradients, and repeated thermal cycling. These conditions lead to microstructural features and phase distributions that deviate significantly from equilibrium predictions, creating a gap between traditional CALPHAD capabilities and AM requirements.

The technological trajectory shows increasing sophistication in CALPHAD models to account for non-equilibrium phenomena. Early models focused primarily on equilibrium thermodynamics, while contemporary approaches incorporate kinetic considerations, diffusion models, and nucleation theory to better represent the rapid solidification conditions characteristic of PBF-LB processes.

The primary technical goal of integrating CALPHAD with PBF-LB is to develop predictive capabilities that can accurately forecast phase formation under the extreme processing conditions of laser-based additive manufacturing. This includes predicting metastable phases, segregation phenomena, and microstructural evolution during the build process and subsequent heat treatments.

Secondary objectives include optimizing process parameters (laser power, scan speed, hatch spacing) based on material-specific thermodynamic and kinetic properties, reducing the empirical trial-and-error approach currently dominating the field. Additionally, there is significant interest in using CALPHAD to design novel alloy compositions specifically tailored for PBF-LB processing, with improved printability, reduced cracking susceptibility, and enhanced mechanical properties.

The ultimate technological ambition is to establish a comprehensive computational framework that seamlessly integrates thermodynamic predictions with process simulation, enabling digital twins of the manufacturing process that can predict final part properties based on material composition and processing parameters.

In recent years, CALPHAD has become increasingly relevant to advanced manufacturing processes, particularly in the rapidly evolving field of additive manufacturing (AM). Powder Bed Fusion-Laser Beam (PBF-LB), as one of the most widely adopted metal AM technologies, presents unique challenges related to rapid solidification, non-equilibrium phase formation, and complex thermal histories that traditional manufacturing processes do not encounter.

The integration of CALPHAD with PBF-LB process design represents a critical technological frontier. Conventional manufacturing processes typically operate closer to equilibrium conditions, whereas PBF-LB involves extreme cooling rates (10^3-10^6 K/s), steep thermal gradients, and repeated thermal cycling. These conditions lead to microstructural features and phase distributions that deviate significantly from equilibrium predictions, creating a gap between traditional CALPHAD capabilities and AM requirements.

The technological trajectory shows increasing sophistication in CALPHAD models to account for non-equilibrium phenomena. Early models focused primarily on equilibrium thermodynamics, while contemporary approaches incorporate kinetic considerations, diffusion models, and nucleation theory to better represent the rapid solidification conditions characteristic of PBF-LB processes.

The primary technical goal of integrating CALPHAD with PBF-LB is to develop predictive capabilities that can accurately forecast phase formation under the extreme processing conditions of laser-based additive manufacturing. This includes predicting metastable phases, segregation phenomena, and microstructural evolution during the build process and subsequent heat treatments.

Secondary objectives include optimizing process parameters (laser power, scan speed, hatch spacing) based on material-specific thermodynamic and kinetic properties, reducing the empirical trial-and-error approach currently dominating the field. Additionally, there is significant interest in using CALPHAD to design novel alloy compositions specifically tailored for PBF-LB processing, with improved printability, reduced cracking susceptibility, and enhanced mechanical properties.

The ultimate technological ambition is to establish a comprehensive computational framework that seamlessly integrates thermodynamic predictions with process simulation, enabling digital twins of the manufacturing process that can predict final part properties based on material composition and processing parameters.

Market Analysis for CALPHAD in Additive Manufacturing

The CALPHAD (CALculation of PHAse Diagrams) methodology market within additive manufacturing is experiencing significant growth, driven by the increasing adoption of metal 3D printing technologies, particularly Powder Bed Fusion-Laser Beam (PBF-LB) processes. The global market for simulation software in additive manufacturing was valued at approximately $600 million in 2022 and is projected to grow at a CAGR of 15-18% through 2028, with CALPHAD-based solutions representing a rapidly expanding segment.

Manufacturing industries, especially aerospace, automotive, and medical device sectors, are demonstrating heightened demand for computational tools that can accurately predict material behavior during the PBF-LB process. This demand stems from the critical need to reduce the costly trial-and-error approach traditionally used in developing new alloys and process parameters for additive manufacturing.

The market for CALPHAD in additive manufacturing is segmented by end-user industries, with aerospace leading adoption at 35% market share, followed by medical (25%), automotive (20%), and other industrial applications (20%). Geographically, North America dominates with 40% market share, followed by Europe (30%), Asia-Pacific (25%), and rest of the world (5%).

Key market drivers include the increasing complexity of alloy systems being developed specifically for additive manufacturing, stringent quality requirements in critical applications, and the push toward digital manufacturing workflows. The ability of CALPHAD to predict phase formation during rapid solidification conditions typical in PBF-LB processes provides significant value by reducing development cycles and material waste.

Market restraints include the high cost of comprehensive CALPHAD databases, the specialized expertise required to effectively utilize these tools, and the need for experimental validation of computational predictions. Additionally, the accuracy limitations when modeling non-equilibrium conditions present in PBF-LB processes remain a challenge that software providers are actively addressing.

The market shows a clear trend toward integration of CALPHAD with machine learning approaches to improve predictive capabilities for complex multi-component alloy systems. Cloud-based deployment models are gaining traction, allowing smaller manufacturers to access sophisticated simulation capabilities without significant upfront investment in software and computing infrastructure.

Customer feedback indicates strong return on investment for organizations implementing CALPHAD-based solutions, with reported development time reductions of 30-50% for new material qualifications in PBF-LB processes and corresponding cost savings in experimental validation requirements.

Manufacturing industries, especially aerospace, automotive, and medical device sectors, are demonstrating heightened demand for computational tools that can accurately predict material behavior during the PBF-LB process. This demand stems from the critical need to reduce the costly trial-and-error approach traditionally used in developing new alloys and process parameters for additive manufacturing.

The market for CALPHAD in additive manufacturing is segmented by end-user industries, with aerospace leading adoption at 35% market share, followed by medical (25%), automotive (20%), and other industrial applications (20%). Geographically, North America dominates with 40% market share, followed by Europe (30%), Asia-Pacific (25%), and rest of the world (5%).

Key market drivers include the increasing complexity of alloy systems being developed specifically for additive manufacturing, stringent quality requirements in critical applications, and the push toward digital manufacturing workflows. The ability of CALPHAD to predict phase formation during rapid solidification conditions typical in PBF-LB processes provides significant value by reducing development cycles and material waste.

Market restraints include the high cost of comprehensive CALPHAD databases, the specialized expertise required to effectively utilize these tools, and the need for experimental validation of computational predictions. Additionally, the accuracy limitations when modeling non-equilibrium conditions present in PBF-LB processes remain a challenge that software providers are actively addressing.

The market shows a clear trend toward integration of CALPHAD with machine learning approaches to improve predictive capabilities for complex multi-component alloy systems. Cloud-based deployment models are gaining traction, allowing smaller manufacturers to access sophisticated simulation capabilities without significant upfront investment in software and computing infrastructure.

Customer feedback indicates strong return on investment for organizations implementing CALPHAD-based solutions, with reported development time reductions of 30-50% for new material qualifications in PBF-LB processes and corresponding cost savings in experimental validation requirements.

Current Challenges in Phase Prediction for PBF-LB

Despite significant advancements in computational methods for phase prediction in Powder Bed Fusion-Laser Beam (PBF-LB) processes, several critical challenges persist that limit the accuracy and applicability of CALPHAD (CALculation of PHAse Diagrams) approaches. The extreme thermal conditions characteristic of PBF-LB processes—including rapid heating rates exceeding 10^6 K/s, cooling rates of 10^3-10^8 K/s, and steep thermal gradients—create non-equilibrium conditions that traditional CALPHAD models struggle to accurately represent.

The inherent assumptions of thermodynamic equilibrium in standard CALPHAD databases present a fundamental limitation when applied to additive manufacturing processes. These databases, primarily developed for conventional manufacturing methods, fail to capture the metastable phases and unique microstructures that form under the extreme conditions of PBF-LB processing. This discrepancy leads to significant prediction errors when attempting to model phase formation in additively manufactured components.

Kinetic considerations represent another major challenge. The rapid solidification inherent to PBF-LB processes often results in solute trapping, extended solid solubility, and the formation of metastable phases that cannot be predicted using equilibrium-based approaches. Current kinetic models integrated with CALPHAD frameworks remain insufficient for capturing these phenomena accurately across diverse material systems.

The multi-scale nature of the PBF-LB process further complicates phase prediction efforts. Phenomena occurring at the microscale (e.g., dendrite formation) and nanoscale (e.g., precipitate nucleation) significantly influence macroscale properties, yet integrating these different scale models remains computationally prohibitive and methodologically challenging.

Experimental validation of CALPHAD predictions for PBF-LB processes presents additional difficulties. The complex thermal history experienced by different regions within a single build makes it challenging to correlate specific processing conditions with observed microstructures. Furthermore, the limited availability of in-situ characterization techniques capable of capturing phase transformations at relevant time scales restricts the development and validation of more accurate models.

Material-specific challenges also exist, particularly for high-performance alloys commonly used in PBF-LB applications. Many advanced alloys contain multiple elements with complex interactions, requiring higher-order thermodynamic descriptions that are often unavailable or incomplete in existing CALPHAD databases. This is especially problematic for novel alloy compositions specifically designed for additive manufacturing.

Computational efficiency remains a significant barrier to implementing sophisticated phase prediction models in practical PBF-LB process design. The integration of CALPHAD with finite element thermal models and kinetic simulations creates substantial computational demands that limit their application in industrial settings where rapid iteration and optimization are required.

The inherent assumptions of thermodynamic equilibrium in standard CALPHAD databases present a fundamental limitation when applied to additive manufacturing processes. These databases, primarily developed for conventional manufacturing methods, fail to capture the metastable phases and unique microstructures that form under the extreme conditions of PBF-LB processing. This discrepancy leads to significant prediction errors when attempting to model phase formation in additively manufactured components.

Kinetic considerations represent another major challenge. The rapid solidification inherent to PBF-LB processes often results in solute trapping, extended solid solubility, and the formation of metastable phases that cannot be predicted using equilibrium-based approaches. Current kinetic models integrated with CALPHAD frameworks remain insufficient for capturing these phenomena accurately across diverse material systems.

The multi-scale nature of the PBF-LB process further complicates phase prediction efforts. Phenomena occurring at the microscale (e.g., dendrite formation) and nanoscale (e.g., precipitate nucleation) significantly influence macroscale properties, yet integrating these different scale models remains computationally prohibitive and methodologically challenging.

Experimental validation of CALPHAD predictions for PBF-LB processes presents additional difficulties. The complex thermal history experienced by different regions within a single build makes it challenging to correlate specific processing conditions with observed microstructures. Furthermore, the limited availability of in-situ characterization techniques capable of capturing phase transformations at relevant time scales restricts the development and validation of more accurate models.

Material-specific challenges also exist, particularly for high-performance alloys commonly used in PBF-LB applications. Many advanced alloys contain multiple elements with complex interactions, requiring higher-order thermodynamic descriptions that are often unavailable or incomplete in existing CALPHAD databases. This is especially problematic for novel alloy compositions specifically designed for additive manufacturing.

Computational efficiency remains a significant barrier to implementing sophisticated phase prediction models in practical PBF-LB process design. The integration of CALPHAD with finite element thermal models and kinetic simulations creates substantial computational demands that limit their application in industrial settings where rapid iteration and optimization are required.

Existing CALPHAD Implementation for PBF-LB Processes

01 CALPHAD methodology for phase diagram prediction

The CALPHAD (CALculation of PHAse Diagrams) methodology is used to predict phase diagrams and phase formation in various material systems. This computational approach combines thermodynamic principles with experimental data to model phase equilibria and transformations. The method enables researchers to predict stable phases, phase boundaries, and transformation temperatures in complex alloy systems without extensive experimental work.- CALPHAD methodology for alloy design and phase prediction: The CALPHAD (CALculation of PHAse Diagrams) methodology is used for predicting phase formation in alloy systems. This computational approach combines thermodynamic principles with experimental data to create models that predict phase equilibria and transformations. The methodology enables researchers to design new alloys with specific properties by predicting phase stability across different compositions and temperatures, reducing the need for extensive experimental work.

- Thermodynamic database development for CALPHAD modeling: Development of comprehensive thermodynamic databases is crucial for accurate CALPHAD modeling. These databases contain parameters describing Gibbs energy functions for various phases in multicomponent systems. The quality of phase formation predictions depends heavily on the accuracy and completeness of these databases, which are continuously refined by incorporating new experimental data and first-principles calculations to improve prediction reliability for complex material systems.

- Integration of CALPHAD with machine learning and AI: Modern CALPHAD approaches increasingly integrate machine learning and artificial intelligence techniques to enhance phase prediction capabilities. These computational methods help identify patterns in complex thermodynamic data, accelerate parameter optimization, and improve predictions for systems with limited experimental data. The combination of traditional CALPHAD methodologies with advanced AI algorithms enables more accurate phase formation predictions and accelerates materials discovery processes.

- Kinetic modeling and non-equilibrium phase prediction: Beyond equilibrium thermodynamics, advanced CALPHAD implementations incorporate kinetic modeling to predict non-equilibrium phase formation. These approaches account for diffusion processes, nucleation barriers, and growth kinetics to simulate real-world phase transformations. By considering both thermodynamic driving forces and kinetic limitations, these models can predict metastable phases and transformation pathways that occur during material processing and service conditions.

- Experimental validation and refinement of CALPHAD predictions: Experimental validation is essential for refining CALPHAD phase formation predictions. This involves comparing computational predictions with experimental observations from techniques such as X-ray diffraction, electron microscopy, and thermal analysis. The discrepancies between predicted and observed phase formations are used to refine thermodynamic models and parameters, creating an iterative improvement process that enhances the accuracy and reliability of CALPHAD-based phase predictions for materials design.

02 Alloy design and optimization using CALPHAD

CALPHAD techniques are applied to design and optimize new alloy compositions with desired properties. By calculating phase stability and predicting microstructural evolution, researchers can develop alloys with specific characteristics for various applications. This approach reduces the need for trial-and-error experimentation and accelerates materials development by providing insights into phase formation and stability across different compositions and processing conditions.Expand Specific Solutions03 Integration of CALPHAD with machine learning and AI

Modern CALPHAD approaches incorporate machine learning and artificial intelligence to enhance phase prediction capabilities. These hybrid methods combine traditional thermodynamic modeling with data-driven approaches to improve accuracy and computational efficiency. Machine learning algorithms can identify patterns in experimental data and thermodynamic parameters, leading to more reliable predictions of phase formation in complex material systems.Expand Specific Solutions04 Multi-component system modeling and high-entropy alloys

CALPHAD methods are particularly valuable for modeling phase formation in multi-component systems and high-entropy alloys. These complex materials, containing multiple principal elements in near-equiatomic proportions, present significant challenges for traditional experimental approaches. CALPHAD enables researchers to navigate vast compositional spaces efficiently, predicting stable phases and guiding experimental efforts toward promising compositions.Expand Specific Solutions05 Experimental validation and database development for CALPHAD

The accuracy of CALPHAD predictions depends on comprehensive thermodynamic databases developed through systematic experimental validation. Researchers use various experimental techniques to verify calculated phase diagrams and refine thermodynamic parameters. This iterative process of prediction, validation, and database refinement continuously improves the reliability of CALPHAD methods for phase formation prediction across different material systems.Expand Specific Solutions

Leading Organizations in CALPHAD and PBF-LB Research

The Predicting Phase Formation Using CALPHAD for PBF-LB Process Design market is in an early growth stage, with increasing adoption across aerospace, defense, and advanced manufacturing sectors. The global market size is estimated at $150-200 million, expected to grow at 15-20% annually as additive manufacturing expands. Technology maturity varies significantly among key players: RTX Corp., Siemens Energy, and Lawrence Livermore National Laboratory lead with advanced implementation, while academic institutions like MIT, Carnegie Mellon, and Central South University drive fundamental research. Companies like 3D Systems and Divergent Technologies are commercializing applications, with EWI and Fraunhofer bridging research-industry gaps. The integration of CALPHAD with machine learning represents the emerging frontier in this field.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Laboratory has developed ALE3D-CALPHAD, an integrated computational framework that combines CALPHAD thermodynamics with high-fidelity process modeling for PBF-LB applications. Their approach utilizes massively parallel computing resources to simulate the complex thermal history and resultant phase formation during laser powder bed fusion processes. LLNL's methodology incorporates multi-physics modeling that accounts for powder packing, laser-material interactions, fluid dynamics of the melt pool, and subsequent rapid solidification[7]. Their CALPHAD implementation has been enhanced with kinetic models that predict non-equilibrium phase formation under extreme cooling rates (10^5-10^7 K/s) typical in PBF-LB processes. LLNL has also developed specialized databases for additively manufactured materials that include metastable phases and defect structures not typically found in conventional processing routes. Their system enables process parameter optimization through predictive modeling of microstructural features including grain size, texture, segregation patterns, and precipitate distributions across complex geometries[8].

Strengths: Unparalleled computational capabilities allowing for high-resolution simulations; strong fundamental science foundation; extensive validation through advanced characterization techniques. Weaknesses: Solutions often require supercomputing resources limiting accessibility; complex implementation pathway for industrial adoption; primarily focused on materials relevant to national security applications.

Massachusetts Institute of Technology

Technical Solution: MIT has developed an advanced CALPHAD-based approach for predicting phase formation in PBF-LB (Powder Bed Fusion-Laser Beam) additive manufacturing processes. Their methodology integrates computational thermodynamics with process-specific parameters to create accurate phase diagrams that account for rapid solidification conditions unique to laser-based AM. MIT's approach incorporates thermal gradient and cooling rate models derived from finite element simulations to modify traditional CALPHAD databases, enabling prediction of non-equilibrium phases that form during the extreme thermal cycles of PBF-LB processes[1]. They've also developed machine learning algorithms that enhance CALPHAD predictions by incorporating empirical data from actual builds, creating a feedback loop that continuously improves prediction accuracy[3]. Their system includes specialized software tools that simulate the microstructural evolution during solidification, accounting for laser parameters, scan strategies, and powder characteristics.

Strengths: Superior integration of computational thermodynamics with process-specific parameters; robust machine learning enhancement for continuous improvement; comprehensive consideration of non-equilibrium conditions. Weaknesses: Requires extensive computational resources; relies on accurate input data that may not be available for novel alloy systems; model validation still requires significant experimental work.

Critical Thermodynamic Models for Phase Formation

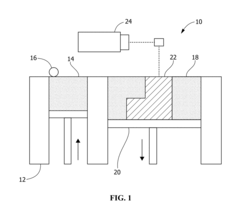

Laser-stirred powder bed fusion

PatentActiveUS20180290209A1

Innovation

- The implementation of laser stirring in the L-PBF process, using oscillatory paths such as circular or elliptical paths for the laser beam to fuse material layers, which helps in reducing cracking and porosity by breaking up dendritic microstructures and optimizing heat input, travel speed, and thermal response.

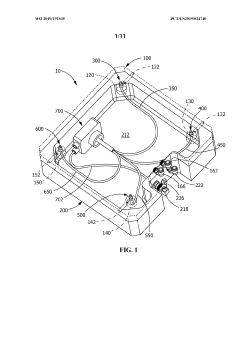

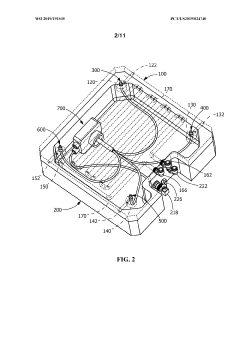

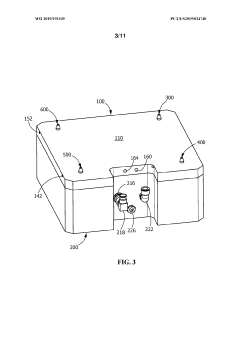

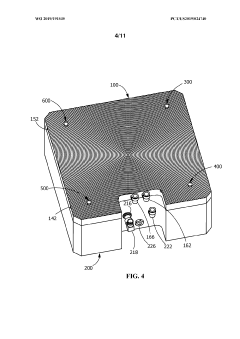

Laser beam profiling system for use in laser powder bed fusion manufacturing

PatentWO2019191535A1

Innovation

- A portable testing apparatus is introduced, featuring a support with pin-hole defining structures and fiber optic cables that capture and convert laser light into electrical signals, allowing for the analysis of laser beam quality through a data acquisition device and algorithm, enabling precise characterization of the non-stationary laser beam across multiple passes.

Material Database Requirements for Accurate Predictions

Accurate phase formation prediction using CALPHAD for PBF-LB processes requires comprehensive and high-quality material databases. These databases must contain thermodynamic and kinetic parameters that accurately represent the complex metallurgical phenomena occurring during rapid solidification and subsequent thermal cycles characteristic of laser-based additive manufacturing.

The foundation of reliable CALPHAD predictions lies in thermodynamic databases that include Gibbs free energy descriptions for all relevant phases across the entire composition and temperature ranges encountered in the process. For PBF-LB specifically, databases must extend to temperatures well above typical melting points (often exceeding 2000°C) and cover cooling rates of 10^3-10^6 K/s. Conventional databases developed for equilibrium conditions often lack sufficient data in these extreme regions, leading to extrapolation errors.

Mobility databases containing diffusion coefficients and atomic mobilities are equally critical, as they govern the kinetic aspects of phase transformations during rapid solidification. These parameters must account for temperature-dependent behavior across all composition ranges relevant to the alloy system being processed. The databases should incorporate experimentally validated diffusion data obtained under conditions that approximate the non-equilibrium nature of PBF-LB processes.

Surface tension and viscosity data represent another essential component, as these properties significantly influence melt pool dynamics, wetting behavior, and ultimately microstructure development. Databases must include temperature and composition-dependent surface properties, particularly for multi-component systems where minor alloying elements can dramatically alter interfacial energies.

Metastable phase information is particularly crucial for PBF-LB processes. Databases must contain thermodynamic descriptions of metastable phases that may form during rapid solidification but are absent under equilibrium conditions. This includes data on amorphous structures, supersaturated solid solutions, and non-equilibrium intermetallic compounds commonly observed in additively manufactured materials.

Validation against experimental data specific to rapid solidification conditions is essential for database reliability. Databases should be continuously refined using experimental results from techniques like differential scanning calorimetry under varying cooling rates, in-situ X-ray diffraction during laser processing, and microstructural characterization of additively manufactured samples. This validation process ensures that predictions remain accurate across the extreme processing conditions characteristic of PBF-LB manufacturing.

The foundation of reliable CALPHAD predictions lies in thermodynamic databases that include Gibbs free energy descriptions for all relevant phases across the entire composition and temperature ranges encountered in the process. For PBF-LB specifically, databases must extend to temperatures well above typical melting points (often exceeding 2000°C) and cover cooling rates of 10^3-10^6 K/s. Conventional databases developed for equilibrium conditions often lack sufficient data in these extreme regions, leading to extrapolation errors.

Mobility databases containing diffusion coefficients and atomic mobilities are equally critical, as they govern the kinetic aspects of phase transformations during rapid solidification. These parameters must account for temperature-dependent behavior across all composition ranges relevant to the alloy system being processed. The databases should incorporate experimentally validated diffusion data obtained under conditions that approximate the non-equilibrium nature of PBF-LB processes.

Surface tension and viscosity data represent another essential component, as these properties significantly influence melt pool dynamics, wetting behavior, and ultimately microstructure development. Databases must include temperature and composition-dependent surface properties, particularly for multi-component systems where minor alloying elements can dramatically alter interfacial energies.

Metastable phase information is particularly crucial for PBF-LB processes. Databases must contain thermodynamic descriptions of metastable phases that may form during rapid solidification but are absent under equilibrium conditions. This includes data on amorphous structures, supersaturated solid solutions, and non-equilibrium intermetallic compounds commonly observed in additively manufactured materials.

Validation against experimental data specific to rapid solidification conditions is essential for database reliability. Databases should be continuously refined using experimental results from techniques like differential scanning calorimetry under varying cooling rates, in-situ X-ray diffraction during laser processing, and microstructural characterization of additively manufactured samples. This validation process ensures that predictions remain accurate across the extreme processing conditions characteristic of PBF-LB manufacturing.

Process Parameter Optimization Using CALPHAD Models

Process parameter optimization using CALPHAD models represents a significant advancement in the field of Powder Bed Fusion-Laser Beam (PBF-LB) additive manufacturing. By integrating thermodynamic calculations with process parameters, manufacturers can achieve more precise control over material properties and microstructure development during the printing process.

CALPHAD (CALculation of PHAse Diagrams) methodology provides a robust framework for predicting phase equilibria and transformations under various processing conditions. When applied to PBF-LB processes, these models can simulate the rapid heating and cooling cycles characteristic of laser-material interactions, offering insights into solidification pathways and potential defect formation mechanisms.

The optimization process typically begins with the establishment of a comprehensive thermodynamic database for the alloy system of interest. This database incorporates Gibbs energy descriptions for all relevant phases, allowing for accurate predictions of phase stability across a wide range of temperatures and compositions. For PBF-LB applications, these databases must be extended to account for metastable phases that may form under rapid solidification conditions.

Process parameters such as laser power, scan speed, hatch spacing, and layer thickness can be systematically varied within the CALPHAD framework to predict resulting thermal histories and corresponding microstructural evolution. By coupling CALPHAD calculations with heat transfer models, researchers can establish correlations between process parameters and key quality indicators such as porosity, residual stress, and mechanical properties.

Machine learning algorithms have recently enhanced the efficiency of CALPHAD-based parameter optimization. These approaches can identify complex, non-linear relationships between process variables and desired material outcomes, significantly reducing the experimental iterations required to achieve optimal processing windows. Neural networks trained on CALPHAD-generated datasets have demonstrated particular promise in predicting phase formation across diverse parameter spaces.

Real-time monitoring systems integrated with CALPHAD models represent the cutting edge of process parameter optimization. These systems can detect deviations from predicted thermal conditions during printing and implement corrective adjustments to maintain consistent material quality. Such closed-loop control mechanisms are especially valuable for processing challenging materials with narrow processing windows.

Economic benefits of CALPHAD-driven parameter optimization include reduced material waste, decreased development time, and improved part reliability. By frontloading the optimization process with computational predictions, manufacturers can minimize costly trial-and-error approaches while accelerating the qualification of new materials for PBF-LB applications.

CALPHAD (CALculation of PHAse Diagrams) methodology provides a robust framework for predicting phase equilibria and transformations under various processing conditions. When applied to PBF-LB processes, these models can simulate the rapid heating and cooling cycles characteristic of laser-material interactions, offering insights into solidification pathways and potential defect formation mechanisms.

The optimization process typically begins with the establishment of a comprehensive thermodynamic database for the alloy system of interest. This database incorporates Gibbs energy descriptions for all relevant phases, allowing for accurate predictions of phase stability across a wide range of temperatures and compositions. For PBF-LB applications, these databases must be extended to account for metastable phases that may form under rapid solidification conditions.

Process parameters such as laser power, scan speed, hatch spacing, and layer thickness can be systematically varied within the CALPHAD framework to predict resulting thermal histories and corresponding microstructural evolution. By coupling CALPHAD calculations with heat transfer models, researchers can establish correlations between process parameters and key quality indicators such as porosity, residual stress, and mechanical properties.

Machine learning algorithms have recently enhanced the efficiency of CALPHAD-based parameter optimization. These approaches can identify complex, non-linear relationships between process variables and desired material outcomes, significantly reducing the experimental iterations required to achieve optimal processing windows. Neural networks trained on CALPHAD-generated datasets have demonstrated particular promise in predicting phase formation across diverse parameter spaces.

Real-time monitoring systems integrated with CALPHAD models represent the cutting edge of process parameter optimization. These systems can detect deviations from predicted thermal conditions during printing and implement corrective adjustments to maintain consistent material quality. Such closed-loop control mechanisms are especially valuable for processing challenging materials with narrow processing windows.

Economic benefits of CALPHAD-driven parameter optimization include reduced material waste, decreased development time, and improved part reliability. By frontloading the optimization process with computational predictions, manufacturers can minimize costly trial-and-error approaches while accelerating the qualification of new materials for PBF-LB applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!