Protecting Biodiversity with PLA Material Adoption

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Material Evolution and Biodiversity Goals

Polylactic acid (PLA) has emerged as a promising biodegradable material with the potential to significantly impact biodiversity conservation efforts. The evolution of PLA technology has been closely intertwined with the growing global focus on environmental sustainability and biodiversity protection. Initially developed as a biodegradable alternative to traditional plastics, PLA has undergone substantial improvements in its properties and production processes over the past few decades.

The primary goal of adopting PLA materials in the context of biodiversity protection is to reduce the accumulation of non-biodegradable plastics in natural ecosystems. Plastic pollution has been identified as a major threat to biodiversity, particularly in marine environments. By replacing conventional plastics with PLA in various applications, the aim is to minimize the long-term impact of human-made materials on flora and fauna.

PLA's evolution has been driven by the need to enhance its mechanical properties, thermal stability, and biodegradability. Early iterations of PLA were limited in their applications due to brittleness and low heat resistance. However, ongoing research and development have led to significant improvements, expanding PLA's potential uses across multiple industries. This progress aligns with the broader goal of creating sustainable materials that can effectively replace petroleum-based plastics without compromising performance or functionality.

Another crucial aspect of PLA's development in relation to biodiversity goals is the focus on sustainable sourcing of raw materials. PLA is derived from renewable resources, primarily corn starch or sugarcane. The agricultural practices involved in producing these feedstocks have become an important consideration in ensuring that PLA production does not inadvertently harm biodiversity through land-use changes or intensive farming methods.

Recent advancements in PLA technology have also aimed at improving its end-of-life characteristics. While PLA is biodegradable, the conditions required for its decomposition are not always present in natural environments. Research efforts are now directed towards developing PLA variants that can biodegrade more readily in diverse ecosystems, including marine environments, to further reduce the material's potential impact on biodiversity.

The evolution of PLA is also closely tied to the development of circular economy models. The goal is not only to create a biodegradable material but also to establish efficient recycling and composting systems that can process PLA products at the end of their lifecycle. This holistic approach aims to minimize waste and resource consumption, ultimately supporting biodiversity conservation efforts by reducing the overall environmental footprint of material production and disposal.

The primary goal of adopting PLA materials in the context of biodiversity protection is to reduce the accumulation of non-biodegradable plastics in natural ecosystems. Plastic pollution has been identified as a major threat to biodiversity, particularly in marine environments. By replacing conventional plastics with PLA in various applications, the aim is to minimize the long-term impact of human-made materials on flora and fauna.

PLA's evolution has been driven by the need to enhance its mechanical properties, thermal stability, and biodegradability. Early iterations of PLA were limited in their applications due to brittleness and low heat resistance. However, ongoing research and development have led to significant improvements, expanding PLA's potential uses across multiple industries. This progress aligns with the broader goal of creating sustainable materials that can effectively replace petroleum-based plastics without compromising performance or functionality.

Another crucial aspect of PLA's development in relation to biodiversity goals is the focus on sustainable sourcing of raw materials. PLA is derived from renewable resources, primarily corn starch or sugarcane. The agricultural practices involved in producing these feedstocks have become an important consideration in ensuring that PLA production does not inadvertently harm biodiversity through land-use changes or intensive farming methods.

Recent advancements in PLA technology have also aimed at improving its end-of-life characteristics. While PLA is biodegradable, the conditions required for its decomposition are not always present in natural environments. Research efforts are now directed towards developing PLA variants that can biodegrade more readily in diverse ecosystems, including marine environments, to further reduce the material's potential impact on biodiversity.

The evolution of PLA is also closely tied to the development of circular economy models. The goal is not only to create a biodegradable material but also to establish efficient recycling and composting systems that can process PLA products at the end of their lifecycle. This holistic approach aims to minimize waste and resource consumption, ultimately supporting biodiversity conservation efforts by reducing the overall environmental footprint of material production and disposal.

Market Demand for Eco-friendly Plastics

The market demand for eco-friendly plastics has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations on plastic waste. PLA (Polylactic Acid), as a biodegradable and renewable alternative to traditional petroleum-based plastics, has gained significant attention in this context. The global bioplastics market, which includes PLA, is projected to grow at a compound annual growth rate of over 15% from 2021 to 2026.

Consumer awareness and preference for sustainable products have been key factors in driving this demand. A survey conducted by Nielsen in 2019 found that 73% of global consumers would change their consumption habits to reduce their environmental impact. This shift in consumer behavior has led many companies to adopt eco-friendly packaging solutions, with PLA being a popular choice due to its versatility and biodegradability.

The packaging industry has been the largest consumer of PLA, accounting for approximately 60% of its total market share. Food packaging, in particular, has seen a significant uptake of PLA materials due to their food-safe properties and compostability. The beverage industry has also shown interest in PLA for bottle production, although challenges in recycling infrastructure have limited widespread adoption.

In the textile industry, PLA fibers are gaining traction as a sustainable alternative to synthetic fibers. The apparel sector has shown increasing interest in PLA-based fabrics for their breathability and moisture-wicking properties. This trend is expected to continue as more fashion brands commit to sustainability goals and seek alternatives to petroleum-based synthetic fibers.

The medical and pharmaceutical sectors have also contributed to the growing demand for PLA. Its biocompatibility and biodegradability make it an excellent material for medical implants, drug delivery systems, and tissue engineering scaffolds. The COVID-19 pandemic has further highlighted the importance of biodegradable materials in healthcare, potentially accelerating the adoption of PLA in this sector.

Despite the positive market outlook, challenges remain in scaling up PLA production to meet increasing demand. The cost of PLA production is still higher than that of conventional plastics, which can be a barrier to widespread adoption, especially in price-sensitive markets. Additionally, the limited availability of industrial composting facilities in many regions poses a challenge to the proper disposal and biodegradation of PLA products.

As governments worldwide implement stricter regulations on single-use plastics and promote circular economy initiatives, the demand for eco-friendly alternatives like PLA is expected to surge. This regulatory push, combined with growing consumer awareness and corporate sustainability commitments, is likely to drive significant market growth for PLA and other biodegradable plastics in the coming years.

Consumer awareness and preference for sustainable products have been key factors in driving this demand. A survey conducted by Nielsen in 2019 found that 73% of global consumers would change their consumption habits to reduce their environmental impact. This shift in consumer behavior has led many companies to adopt eco-friendly packaging solutions, with PLA being a popular choice due to its versatility and biodegradability.

The packaging industry has been the largest consumer of PLA, accounting for approximately 60% of its total market share. Food packaging, in particular, has seen a significant uptake of PLA materials due to their food-safe properties and compostability. The beverage industry has also shown interest in PLA for bottle production, although challenges in recycling infrastructure have limited widespread adoption.

In the textile industry, PLA fibers are gaining traction as a sustainable alternative to synthetic fibers. The apparel sector has shown increasing interest in PLA-based fabrics for their breathability and moisture-wicking properties. This trend is expected to continue as more fashion brands commit to sustainability goals and seek alternatives to petroleum-based synthetic fibers.

The medical and pharmaceutical sectors have also contributed to the growing demand for PLA. Its biocompatibility and biodegradability make it an excellent material for medical implants, drug delivery systems, and tissue engineering scaffolds. The COVID-19 pandemic has further highlighted the importance of biodegradable materials in healthcare, potentially accelerating the adoption of PLA in this sector.

Despite the positive market outlook, challenges remain in scaling up PLA production to meet increasing demand. The cost of PLA production is still higher than that of conventional plastics, which can be a barrier to widespread adoption, especially in price-sensitive markets. Additionally, the limited availability of industrial composting facilities in many regions poses a challenge to the proper disposal and biodegradation of PLA products.

As governments worldwide implement stricter regulations on single-use plastics and promote circular economy initiatives, the demand for eco-friendly alternatives like PLA is expected to surge. This regulatory push, combined with growing consumer awareness and corporate sustainability commitments, is likely to drive significant market growth for PLA and other biodegradable plastics in the coming years.

PLA Technology Status and Challenges

Polylactic acid (PLA) has emerged as a promising biodegradable material with potential to address environmental concerns. However, its widespread adoption for protecting biodiversity faces several technological challenges. Currently, PLA production relies heavily on corn and other food crops, raising concerns about competition with food supplies. This dependency on agricultural feedstocks limits scalability and increases production costs.

The mechanical properties of PLA, while suitable for many applications, still fall short in areas requiring high heat resistance or impact strength. This restricts its use in certain industries where traditional plastics excel. Efforts to enhance PLA's performance through blending with other polymers or adding reinforcing agents have shown promise but often compromise its biodegradability.

Another significant challenge lies in PLA's end-of-life management. While theoretically biodegradable, PLA requires specific conditions for efficient decomposition, which are not always available in natural environments or standard composting facilities. This discrepancy between theoretical biodegradability and practical decomposition rates in various ecosystems poses a challenge for its positioning as an eco-friendly alternative.

The recycling of PLA presents additional hurdles. Current recycling infrastructure is not optimized for PLA, and mixing it with conventional plastics can contaminate recycling streams. Developing efficient sorting and recycling processes for PLA is crucial for its long-term sustainability but remains a technological challenge.

From a manufacturing perspective, PLA processing requires careful control of temperature and moisture levels, which can be more demanding than traditional plastic processing. This necessitates modifications to existing manufacturing equipment and processes, potentially increasing production costs and complexity.

Geographically, PLA technology development is concentrated in North America, Europe, and parts of Asia, particularly Japan and China. This concentration has led to disparities in access to PLA technology and its benefits across different regions, potentially limiting its global impact on biodiversity protection.

Recent advancements in PLA technology have focused on improving its thermal stability, enhancing its mechanical properties, and developing more efficient production methods. Researchers are exploring alternative feedstocks, such as agricultural waste and algae, to reduce reliance on food crops. Additionally, efforts are underway to develop PLA variants that can biodegrade more readily in diverse environments, addressing the end-of-life challenges.

The mechanical properties of PLA, while suitable for many applications, still fall short in areas requiring high heat resistance or impact strength. This restricts its use in certain industries where traditional plastics excel. Efforts to enhance PLA's performance through blending with other polymers or adding reinforcing agents have shown promise but often compromise its biodegradability.

Another significant challenge lies in PLA's end-of-life management. While theoretically biodegradable, PLA requires specific conditions for efficient decomposition, which are not always available in natural environments or standard composting facilities. This discrepancy between theoretical biodegradability and practical decomposition rates in various ecosystems poses a challenge for its positioning as an eco-friendly alternative.

The recycling of PLA presents additional hurdles. Current recycling infrastructure is not optimized for PLA, and mixing it with conventional plastics can contaminate recycling streams. Developing efficient sorting and recycling processes for PLA is crucial for its long-term sustainability but remains a technological challenge.

From a manufacturing perspective, PLA processing requires careful control of temperature and moisture levels, which can be more demanding than traditional plastic processing. This necessitates modifications to existing manufacturing equipment and processes, potentially increasing production costs and complexity.

Geographically, PLA technology development is concentrated in North America, Europe, and parts of Asia, particularly Japan and China. This concentration has led to disparities in access to PLA technology and its benefits across different regions, potentially limiting its global impact on biodiversity protection.

Recent advancements in PLA technology have focused on improving its thermal stability, enhancing its mechanical properties, and developing more efficient production methods. Researchers are exploring alternative feedstocks, such as agricultural waste and algae, to reduce reliance on food crops. Additionally, efforts are underway to develop PLA variants that can biodegrade more readily in diverse environments, addressing the end-of-life challenges.

Current PLA Biodegradation Solutions

01 Biodegradable PLA composites for environmental protection

Development of biodegradable PLA composites that incorporate natural fibers or other eco-friendly materials. These composites are designed to break down naturally in the environment, reducing plastic pollution and supporting biodiversity. The materials often have improved mechanical properties and can be used in various applications, including packaging and consumer goods.- Biodegradable PLA composites for environmental protection: Development of biodegradable PLA composites that incorporate natural fibers or other eco-friendly materials. These composites are designed to break down naturally in the environment, reducing plastic pollution and supporting biodiversity. The materials often have improved mechanical properties and can be used in various applications, including packaging and consumer goods.

- PLA-based materials for agricultural applications: Creation of PLA-based materials specifically for agricultural use, such as mulch films, seed coatings, and controlled-release fertilizer capsules. These materials are designed to degrade safely in soil, reducing plastic accumulation in farmlands and supporting soil health and biodiversity. They can also enhance crop growth while minimizing environmental impact.

- PLA blends with enhanced biodegradability: Development of PLA blends that incorporate other biodegradable polymers or additives to enhance the material's overall biodegradability. These blends are engineered to break down more quickly and completely in various environmental conditions, reducing the persistence of plastic waste in ecosystems and supporting biodiversity conservation.

- PLA-based materials for marine biodiversity protection: Creation of PLA-based materials specifically designed for marine applications, such as fishing gear, aquaculture equipment, and marine packaging. These materials are engineered to degrade safely in marine environments, reducing plastic pollution in oceans and protecting marine biodiversity. They often incorporate additives that accelerate breakdown in seawater.

- PLA modifications for improved environmental compatibility: Development of modified PLA materials with enhanced environmental compatibility. These modifications can include the incorporation of natural antioxidants, UV stabilizers, or other additives that improve the material's resistance to degradation during use while ensuring complete biodegradation at end-of-life. This approach aims to balance product performance with biodiversity protection.

02 PLA-based materials for agricultural applications

Creation of PLA-based materials specifically for agricultural use, such as mulch films, seed coatings, and controlled-release fertilizer capsules. These materials are designed to degrade safely in soil, reducing plastic accumulation in farmlands and supporting soil health and biodiversity. They can also enhance crop yields while minimizing environmental impact.Expand Specific Solutions03 PLA blends with enhanced biodegradability

Development of PLA blends that incorporate other biodegradable polymers or additives to enhance the material's overall biodegradability. These blends are engineered to decompose more rapidly under various environmental conditions, reducing the persistence of plastic waste in ecosystems and supporting biodiversity conservation efforts.Expand Specific Solutions04 PLA-based materials for marine biodiversity protection

Creation of PLA-based materials specifically designed for marine applications, such as fishing gear, aquaculture equipment, and marine packaging. These materials are engineered to degrade safely in marine environments, reducing the impact of plastic pollution on marine ecosystems and protecting marine biodiversity.Expand Specific Solutions05 PLA modifications for improved environmental compatibility

Development of modified PLA materials with enhanced environmental compatibility. These modifications may include the incorporation of natural antioxidants, UV stabilizers, or other additives that improve the material's resistance to degradation during use while maintaining its biodegradability at end-of-life. This approach aims to balance the material's functional properties with its environmental impact.Expand Specific Solutions

Key Players in PLA Industry

The adoption of PLA materials for biodiversity protection is in its growth phase, with an expanding market driven by increasing environmental concerns. The global biodiversity crisis has accelerated research and development in this field, leading to a market expected to reach significant scale in the coming years. Technologically, PLA materials are advancing rapidly, with companies like Toray Plastics (America), Inc., Sichuan University, and Mitsubishi Gas Chemical Co., Inc. at the forefront of innovation. These players, along with others like Avantium Knowledge Centre BV and Stora Enso Oyj, are pushing the boundaries of PLA material applications, improving biodegradability, and enhancing performance characteristics to make them more suitable for various biodiversity protection initiatives.

Sulapac Oy

Technical Solution: Sulapac Oy has developed a biodegradable material made from wood chips and natural binders. This innovative material is designed to replace traditional plastics in various applications, including packaging and consumer goods. The company's technology allows for the creation of fully biodegradable products that maintain the functionality and aesthetics of conventional plastics while decomposing naturally in the environment without leaving harmful microplastics behind. Sulapac's material can be processed using existing plastic manufacturing equipment, making it a practical solution for companies looking to transition to more sustainable packaging options.

Strengths: Fully biodegradable, maintains functionality of traditional plastics, compatible with existing manufacturing processes. Weaknesses: May have higher production costs compared to conventional plastics, limited track record in long-term applications.

Arctic Biomaterials Oy

Technical Solution: Arctic Biomaterials Oy specializes in developing and producing biodegradable PLA (Polylactic Acid) compounds and biocomposites. Their technology focuses on enhancing the properties of PLA through the addition of natural fibers and minerals, creating materials with improved mechanical and thermal characteristics. The company's products are designed to be compostable and can be used in various applications, including packaging, consumer goods, and industrial components. Arctic Biomaterials' solutions aim to provide a sustainable alternative to petroleum-based plastics while maintaining high performance standards.

Strengths: Enhanced PLA properties, wide range of applications, compostable end products. Weaknesses: May require specific composting conditions for optimal biodegradation, potentially higher costs compared to traditional plastics.

Innovations in PLA Biodegradability

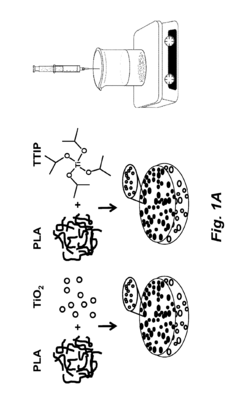

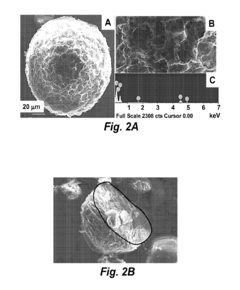

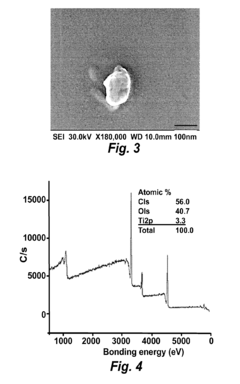

Biodegradable photocatalytic nanocomposite microsponges of polyactic acid

PatentActiveUS20140102991A1

Innovation

- The development of hybrid microparticles incorporating photocatalytically active titanium dioxide nanoparticles within a porous PLA matrix, formed through a method involving sol-gel synthesis and methanol mineralization, allowing for efficient photocatalytic degradation of organic compounds under mild conditions.

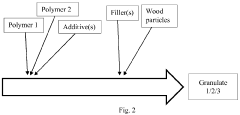

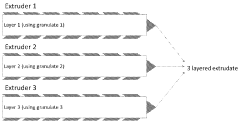

Flexible multi-layer composite material

PatentWO2024013432A1

Innovation

- A multi-layer composite material is developed using biopolymer layers with distinct properties, including a grease barrier, oxygen barrier, and moisture-resistant layers, incorporating hydrophilic natural fibers to enhance degradation and mechanical properties, suitable for extrusion and food/cosmetic contact.

Environmental Impact Assessment

The adoption of PLA (Polylactic Acid) materials as a biodegradable alternative to conventional plastics has significant implications for biodiversity protection. This environmental impact assessment evaluates the potential effects of widespread PLA adoption on ecosystems and species diversity.

PLA production primarily utilizes renewable resources such as corn, sugarcane, or cassava starch. This shift from petroleum-based plastics reduces dependency on fossil fuels and decreases greenhouse gas emissions associated with plastic manufacturing. The reduced carbon footprint contributes to mitigating climate change, which is a major threat to global biodiversity.

The biodegradability of PLA materials offers substantial benefits for marine and terrestrial ecosystems. Unlike traditional plastics that persist in the environment for centuries, PLA can decompose within months to years under proper conditions. This characteristic significantly reduces the risk of long-term accumulation of plastic waste in natural habitats, potentially decreasing the incidence of wildlife entanglement and ingestion of plastic debris.

However, the environmental impact of PLA is not entirely benign. Large-scale production of PLA feedstocks may lead to increased agricultural land use, potentially resulting in habitat loss or fragmentation if not managed sustainably. This could negatively affect local biodiversity, particularly in regions where natural ecosystems are converted to cropland for PLA production.

The decomposition of PLA in natural environments requires specific conditions, including high temperatures and humidity. In many ecosystems, these conditions may not be met, leading to slower degradation rates than expected. This could result in temporary accumulation of PLA waste in certain environments, albeit for shorter periods compared to conventional plastics.

PLA's impact on soil ecosystems during degradation is an area requiring further research. While biodegradation is generally considered beneficial, the breakdown of PLA may temporarily alter soil pH or microbial communities. Understanding these effects is crucial for assessing the long-term impact on soil biodiversity and ecosystem functions.

The transition to PLA materials may indirectly benefit biodiversity through reduced pollution from plastic production processes. Traditional plastic manufacturing often involves the release of toxic chemicals and microplastics into the environment. PLA production generally has a lower toxicity profile, potentially reducing harmful impacts on sensitive species and ecosystems.

In conclusion, while PLA adoption offers promising benefits for biodiversity protection through reduced pollution and waste accumulation, careful management of production practices and end-of-life disposal is essential to maximize its positive environmental impact and minimize potential negative consequences on ecosystems.

PLA production primarily utilizes renewable resources such as corn, sugarcane, or cassava starch. This shift from petroleum-based plastics reduces dependency on fossil fuels and decreases greenhouse gas emissions associated with plastic manufacturing. The reduced carbon footprint contributes to mitigating climate change, which is a major threat to global biodiversity.

The biodegradability of PLA materials offers substantial benefits for marine and terrestrial ecosystems. Unlike traditional plastics that persist in the environment for centuries, PLA can decompose within months to years under proper conditions. This characteristic significantly reduces the risk of long-term accumulation of plastic waste in natural habitats, potentially decreasing the incidence of wildlife entanglement and ingestion of plastic debris.

However, the environmental impact of PLA is not entirely benign. Large-scale production of PLA feedstocks may lead to increased agricultural land use, potentially resulting in habitat loss or fragmentation if not managed sustainably. This could negatively affect local biodiversity, particularly in regions where natural ecosystems are converted to cropland for PLA production.

The decomposition of PLA in natural environments requires specific conditions, including high temperatures and humidity. In many ecosystems, these conditions may not be met, leading to slower degradation rates than expected. This could result in temporary accumulation of PLA waste in certain environments, albeit for shorter periods compared to conventional plastics.

PLA's impact on soil ecosystems during degradation is an area requiring further research. While biodegradation is generally considered beneficial, the breakdown of PLA may temporarily alter soil pH or microbial communities. Understanding these effects is crucial for assessing the long-term impact on soil biodiversity and ecosystem functions.

The transition to PLA materials may indirectly benefit biodiversity through reduced pollution from plastic production processes. Traditional plastic manufacturing often involves the release of toxic chemicals and microplastics into the environment. PLA production generally has a lower toxicity profile, potentially reducing harmful impacts on sensitive species and ecosystems.

In conclusion, while PLA adoption offers promising benefits for biodiversity protection through reduced pollution and waste accumulation, careful management of production practices and end-of-life disposal is essential to maximize its positive environmental impact and minimize potential negative consequences on ecosystems.

Policy Framework for Bioplastics

The development of a comprehensive policy framework for bioplastics is crucial for promoting the adoption of PLA materials and protecting biodiversity. This framework should address various aspects of bioplastic production, use, and disposal to ensure sustainable practices and minimize environmental impact.

One key element of the policy framework is the establishment of clear standards and certification processes for bioplastics. These standards should define what qualifies as a bioplastic, including criteria for biodegradability, compostability, and renewable content. Certification programs can help consumers and businesses identify genuine bioplastic products, promoting transparency and trust in the market.

Incentive programs play a vital role in encouraging the adoption of PLA and other bioplastics. Governments can implement tax breaks, subsidies, or grants for companies that invest in bioplastic research, production, or use. These incentives can help offset the initially higher costs associated with bioplastic materials and accelerate their market penetration.

Regulations on single-use plastics should be updated to include provisions for bioplastic alternatives. While bans on conventional single-use plastics are becoming more common, policies should also address the proper use and disposal of bioplastic alternatives to prevent unintended consequences, such as improper disposal or contamination of recycling streams.

Extended Producer Responsibility (EPR) schemes should be adapted to include bioplastics. These policies can ensure that manufacturers take responsibility for the entire lifecycle of their products, including proper disposal or recycling. EPR schemes can incentivize the use of more sustainable materials and improve the overall management of bioplastic waste.

Investment in infrastructure for bioplastic recycling and composting is essential. Policies should support the development of specialized facilities capable of processing bioplastics, ensuring that these materials are properly managed at the end of their life cycle. This may include funding for research into new recycling technologies specifically designed for bioplastics.

Education and awareness campaigns should be incorporated into the policy framework. These initiatives can inform consumers about the benefits and proper disposal of bioplastics, as well as their role in protecting biodiversity. Clear labeling requirements for bioplastic products can support these educational efforts.

Finally, the policy framework should include provisions for ongoing research and development in the field of bioplastics. This can involve funding for academic institutions and private sector collaborations to improve the performance, cost-effectiveness, and environmental impact of bioplastic materials like PLA.

One key element of the policy framework is the establishment of clear standards and certification processes for bioplastics. These standards should define what qualifies as a bioplastic, including criteria for biodegradability, compostability, and renewable content. Certification programs can help consumers and businesses identify genuine bioplastic products, promoting transparency and trust in the market.

Incentive programs play a vital role in encouraging the adoption of PLA and other bioplastics. Governments can implement tax breaks, subsidies, or grants for companies that invest in bioplastic research, production, or use. These incentives can help offset the initially higher costs associated with bioplastic materials and accelerate their market penetration.

Regulations on single-use plastics should be updated to include provisions for bioplastic alternatives. While bans on conventional single-use plastics are becoming more common, policies should also address the proper use and disposal of bioplastic alternatives to prevent unintended consequences, such as improper disposal or contamination of recycling streams.

Extended Producer Responsibility (EPR) schemes should be adapted to include bioplastics. These policies can ensure that manufacturers take responsibility for the entire lifecycle of their products, including proper disposal or recycling. EPR schemes can incentivize the use of more sustainable materials and improve the overall management of bioplastic waste.

Investment in infrastructure for bioplastic recycling and composting is essential. Policies should support the development of specialized facilities capable of processing bioplastics, ensuring that these materials are properly managed at the end of their life cycle. This may include funding for research into new recycling technologies specifically designed for bioplastics.

Education and awareness campaigns should be incorporated into the policy framework. These initiatives can inform consumers about the benefits and proper disposal of bioplastics, as well as their role in protecting biodiversity. Clear labeling requirements for bioplastic products can support these educational efforts.

Finally, the policy framework should include provisions for ongoing research and development in the field of bioplastics. This can involve funding for academic institutions and private sector collaborations to improve the performance, cost-effectiveness, and environmental impact of bioplastic materials like PLA.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!