Quantify Lithium Mine Water Consumption Per Kilogram of Lithium Output

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Mining Water Consumption Background and Objectives

Lithium has emerged as a critical resource in the global transition towards sustainable energy systems, primarily due to its essential role in rechargeable batteries for electric vehicles and renewable energy storage. The historical development of lithium extraction technologies has evolved from traditional hard rock mining to increasingly sophisticated brine extraction methods, with water consumption becoming a central concern in this evolution. Current industry trends indicate a significant expansion of lithium production capacity worldwide, with projections suggesting a potential tripling of global output by 2030 to meet escalating demand.

Water usage in lithium mining operations varies dramatically depending on the extraction method employed. Brine-based extraction, predominantly used in the "Lithium Triangle" of South America, requires substantial water resources in water-scarce regions, creating a critical sustainability challenge. Hard rock mining operations, while less water-intensive per unit area, still consume significant volumes in processing and refining stages. The industry's water footprint has become increasingly scrutinized as production scales up to meet clean energy demands.

The primary objective of quantifying water consumption per kilogram of lithium output is to establish standardized metrics that enable meaningful comparison across different extraction technologies and operational contexts. This quantification aims to provide transparency in an area where reporting has historically been inconsistent and often opaque, hampering efforts to assess and improve the sustainability of lithium supply chains.

Secondary objectives include identifying water efficiency benchmarks for the industry, supporting the development of more sustainable extraction technologies, and informing regulatory frameworks that balance resource development with environmental protection. By establishing clear water consumption metrics, stakeholders can better evaluate the true environmental costs associated with lithium production.

The technical challenges in accurate quantification stem from the complexity of lithium operations, where water is used across multiple processes including extraction, processing, and waste management. Additionally, the distinction between consumptive and non-consumptive water use, as well as considerations of water quality degradation, further complicate measurement efforts. Regional variations in climate, geology, and regulatory requirements also influence water consumption patterns, necessitating context-specific analysis.

This technical investigation seeks to develop a comprehensive methodology for water consumption quantification that accounts for these complexities while providing actionable insights for industry, policymakers, and environmental stakeholders in the rapidly evolving lithium sector.

Water usage in lithium mining operations varies dramatically depending on the extraction method employed. Brine-based extraction, predominantly used in the "Lithium Triangle" of South America, requires substantial water resources in water-scarce regions, creating a critical sustainability challenge. Hard rock mining operations, while less water-intensive per unit area, still consume significant volumes in processing and refining stages. The industry's water footprint has become increasingly scrutinized as production scales up to meet clean energy demands.

The primary objective of quantifying water consumption per kilogram of lithium output is to establish standardized metrics that enable meaningful comparison across different extraction technologies and operational contexts. This quantification aims to provide transparency in an area where reporting has historically been inconsistent and often opaque, hampering efforts to assess and improve the sustainability of lithium supply chains.

Secondary objectives include identifying water efficiency benchmarks for the industry, supporting the development of more sustainable extraction technologies, and informing regulatory frameworks that balance resource development with environmental protection. By establishing clear water consumption metrics, stakeholders can better evaluate the true environmental costs associated with lithium production.

The technical challenges in accurate quantification stem from the complexity of lithium operations, where water is used across multiple processes including extraction, processing, and waste management. Additionally, the distinction between consumptive and non-consumptive water use, as well as considerations of water quality degradation, further complicate measurement efforts. Regional variations in climate, geology, and regulatory requirements also influence water consumption patterns, necessitating context-specific analysis.

This technical investigation seeks to develop a comprehensive methodology for water consumption quantification that accounts for these complexities while providing actionable insights for industry, policymakers, and environmental stakeholders in the rapidly evolving lithium sector.

Global Market Demand for Sustainable Lithium Production

The global lithium market has witnessed unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. This surge has intensified focus on sustainable lithium extraction methods, with water consumption emerging as a critical environmental concern. Market analysts project the global lithium demand to reach 1.5 million metric tons of lithium carbonate equivalent (LCE) by 2030, representing a threefold increase from 2022 levels.

Automotive manufacturers and battery producers are increasingly prioritizing sustainably sourced lithium in their supply chains. Major automakers including Tesla, Volkswagen, and BMW have publicly committed to reducing the environmental footprint of their battery materials, creating significant market pull for water-efficient lithium production. This shift is evidenced by premium pricing for responsibly sourced lithium, with some buyers willing to pay 10-15% above market rates for materials with verified lower water impacts.

Investment trends further highlight this market evolution, with venture capital funding for sustainable lithium technologies exceeding $2 billion in 2022 alone. Direct lithium extraction (DLE) companies, which typically offer reduced water consumption compared to traditional evaporation methods, have attracted particular interest from both strategic and financial investors.

Regulatory pressures are simultaneously reshaping market dynamics. The European Union's Battery Regulation includes provisions for carbon footprint declarations and responsible sourcing, while similar frameworks are emerging in North America and Asia. These regulations increasingly incorporate water usage metrics as sustainability indicators, creating market advantages for producers with lower water intensity ratios.

Consumer awareness regarding battery supply chain sustainability has also reached unprecedented levels. End-user surveys indicate that 68% of potential EV buyers consider environmental impacts of battery production in their purchasing decisions, with water usage in water-stressed regions ranking among top concerns.

The geographical distribution of demand for sustainable lithium production shows notable regional variations. European markets demonstrate the strongest preference for water-efficient lithium, followed by North American and premium Asian markets. This regional differentiation is creating specialized market segments within the broader lithium supply chain.

Energy storage applications beyond automotive uses are emerging as another significant demand driver for sustainable lithium. Grid-scale storage projects increasingly incorporate environmental criteria in procurement specifications, expanding the market for water-efficient lithium beyond the transportation sector.

Automotive manufacturers and battery producers are increasingly prioritizing sustainably sourced lithium in their supply chains. Major automakers including Tesla, Volkswagen, and BMW have publicly committed to reducing the environmental footprint of their battery materials, creating significant market pull for water-efficient lithium production. This shift is evidenced by premium pricing for responsibly sourced lithium, with some buyers willing to pay 10-15% above market rates for materials with verified lower water impacts.

Investment trends further highlight this market evolution, with venture capital funding for sustainable lithium technologies exceeding $2 billion in 2022 alone. Direct lithium extraction (DLE) companies, which typically offer reduced water consumption compared to traditional evaporation methods, have attracted particular interest from both strategic and financial investors.

Regulatory pressures are simultaneously reshaping market dynamics. The European Union's Battery Regulation includes provisions for carbon footprint declarations and responsible sourcing, while similar frameworks are emerging in North America and Asia. These regulations increasingly incorporate water usage metrics as sustainability indicators, creating market advantages for producers with lower water intensity ratios.

Consumer awareness regarding battery supply chain sustainability has also reached unprecedented levels. End-user surveys indicate that 68% of potential EV buyers consider environmental impacts of battery production in their purchasing decisions, with water usage in water-stressed regions ranking among top concerns.

The geographical distribution of demand for sustainable lithium production shows notable regional variations. European markets demonstrate the strongest preference for water-efficient lithium, followed by North American and premium Asian markets. This regional differentiation is creating specialized market segments within the broader lithium supply chain.

Energy storage applications beyond automotive uses are emerging as another significant demand driver for sustainable lithium. Grid-scale storage projects increasingly incorporate environmental criteria in procurement specifications, expanding the market for water-efficient lithium beyond the transportation sector.

Current Water Usage Challenges in Lithium Extraction

The lithium extraction industry faces significant water management challenges, particularly in water-stressed regions where many lithium operations are located. Current extraction methods, especially in the "Lithium Triangle" of Argentina, Bolivia, and Chile, rely heavily on evaporation processes that consume between 500,000 to 2 million liters of water per ton of lithium carbonate produced. This intensive water usage occurs in regions where water is already scarce, creating competition with local communities and agriculture.

Traditional brine extraction methods pump lithium-rich brine from underground reservoirs to evaporation ponds, where it remains exposed for 12-18 months. During this period, substantial water loss occurs through evaporation, with estimates suggesting that producing one ton of lithium requires approximately 2,000 tons of water to evaporate. This ratio represents one of the highest water consumption rates in mining industries globally.

Hard-rock lithium mining, while less water-intensive than brine operations, still requires significant water volumes for ore processing, dust suppression, and slurry transport. Australian spodumene operations typically consume 170-510 cubic meters of water per ton of lithium carbonate equivalent (LCE), presenting different but still substantial water management challenges.

Quantification difficulties compound these challenges, as standardized methodologies for measuring water consumption across different extraction technologies and geographical contexts are lacking. Companies report water usage using varied metrics and boundaries, making direct comparisons problematic. Some operations include only direct consumption while others incorporate broader watershed impacts, creating inconsistent data sets.

Water quality degradation represents another critical dimension, as extraction processes can contaminate local water supplies with chemicals used in processing or through disruption of the natural hydrological balance. In the Atacama Desert, evidence suggests that lithium mining has contributed to declining water tables and increased salinity in freshwater aquifers, affecting local ecosystems and communities.

Climate change further exacerbates these challenges by increasing water scarcity in already arid regions. Projections indicate that many lithium-producing regions will experience more severe drought conditions in coming decades, potentially constraining production capacity and intensifying conflicts over water resources.

Regulatory frameworks governing water usage in lithium extraction vary significantly across jurisdictions, creating an uneven landscape of compliance requirements. While Chile has implemented stricter water permits and monitoring systems, other regions lack robust oversight, resulting in inadequate protection of water resources and inconsistent industry practices.

Traditional brine extraction methods pump lithium-rich brine from underground reservoirs to evaporation ponds, where it remains exposed for 12-18 months. During this period, substantial water loss occurs through evaporation, with estimates suggesting that producing one ton of lithium requires approximately 2,000 tons of water to evaporate. This ratio represents one of the highest water consumption rates in mining industries globally.

Hard-rock lithium mining, while less water-intensive than brine operations, still requires significant water volumes for ore processing, dust suppression, and slurry transport. Australian spodumene operations typically consume 170-510 cubic meters of water per ton of lithium carbonate equivalent (LCE), presenting different but still substantial water management challenges.

Quantification difficulties compound these challenges, as standardized methodologies for measuring water consumption across different extraction technologies and geographical contexts are lacking. Companies report water usage using varied metrics and boundaries, making direct comparisons problematic. Some operations include only direct consumption while others incorporate broader watershed impacts, creating inconsistent data sets.

Water quality degradation represents another critical dimension, as extraction processes can contaminate local water supplies with chemicals used in processing or through disruption of the natural hydrological balance. In the Atacama Desert, evidence suggests that lithium mining has contributed to declining water tables and increased salinity in freshwater aquifers, affecting local ecosystems and communities.

Climate change further exacerbates these challenges by increasing water scarcity in already arid regions. Projections indicate that many lithium-producing regions will experience more severe drought conditions in coming decades, potentially constraining production capacity and intensifying conflicts over water resources.

Regulatory frameworks governing water usage in lithium extraction vary significantly across jurisdictions, creating an uneven landscape of compliance requirements. While Chile has implemented stricter water permits and monitoring systems, other regions lack robust oversight, resulting in inadequate protection of water resources and inconsistent industry practices.

Existing Water Consumption Measurement Methodologies

01 Water reduction technologies in lithium extraction

Various technologies have been developed to reduce water consumption in lithium mining operations. These include closed-loop water systems, advanced filtration methods, and water recycling processes that minimize freshwater requirements. These technologies help address the significant water challenges in lithium-rich regions, many of which are located in arid environments where water resources are already scarce.- Water reduction technologies in lithium extraction: Various technologies have been developed to reduce water consumption in lithium mining operations. These include closed-loop water systems, advanced filtration methods, and water recycling processes that minimize freshwater requirements. Such technologies help address the significant water challenges in lithium-rich regions, many of which are located in arid environments where water resources are already scarce.

- Direct lithium extraction methods with lower water footprint: Novel direct lithium extraction (DLE) methods have been developed that significantly reduce water consumption compared to traditional evaporation pond techniques. These methods include adsorption-based technologies, ion exchange processes, and selective membrane systems that can extract lithium from brines with minimal water loss. DLE technologies can reduce water usage by up to 90% while also accelerating the extraction timeline from months to days.

- Water management systems for brine operations: Specialized water management systems have been designed specifically for lithium brine operations. These systems include advanced monitoring technologies, evaporation control methods, and integrated water balance approaches that optimize water usage throughout the extraction process. Such systems help mining operations maintain compliance with environmental regulations while ensuring operational efficiency.

- Wastewater treatment and reuse in lithium processing: Innovative wastewater treatment technologies have been developed for lithium processing facilities to enable water reuse and reduce overall consumption. These include advanced filtration systems, chemical treatment processes, and biological remediation methods that remove contaminants and allow water to be recycled back into the extraction process. Such technologies help minimize the environmental impact of lithium mining while conserving valuable water resources.

- Alternative lithium sources with lower water requirements: Research has focused on identifying and developing alternative lithium sources that require less water for extraction. These include hard rock mining, geothermal brines, and clay deposits that can be processed using methods with significantly lower water intensity than traditional brine evaporation. By diversifying lithium sources, the industry can reduce its overall water footprint while meeting growing demand for lithium batteries.

02 Direct lithium extraction (DLE) methods

Direct lithium extraction methods offer alternatives to traditional evaporation ponds, significantly reducing water consumption. These innovative approaches use selective adsorption materials, ion exchange resins, or membrane technologies to extract lithium from brines with minimal water loss. DLE methods can reduce water usage by up to 90% compared to conventional evaporation techniques while also accelerating the extraction process.Expand Specific Solutions03 Brine management and recycling systems

Advanced brine management systems focus on efficient handling and recycling of process water in lithium operations. These systems include specialized treatment processes that allow for the separation of valuable minerals while enabling water reuse. By implementing sophisticated brine recycling technologies, mining operations can significantly reduce their freshwater intake and minimize environmental impact in water-sensitive areas.Expand Specific Solutions04 Water-efficient lithium processing techniques

Innovative processing techniques have been developed specifically to address water consumption concerns in lithium production. These include dry processing methods, advanced concentration techniques, and water-efficient leaching processes. By optimizing these processing steps, lithium producers can maintain production efficiency while substantially reducing their water footprint throughout the extraction and refinement stages.Expand Specific Solutions05 Monitoring and management systems for water usage

Sophisticated monitoring and management systems have been implemented to track and optimize water usage in lithium mining operations. These systems employ sensors, data analytics, and automation to provide real-time information on water consumption patterns. By identifying inefficiencies and implementing targeted improvements, these management approaches enable mining companies to establish sustainable water practices while meeting production targets.Expand Specific Solutions

Major Lithium Producers and Industry Landscape

The lithium mining water consumption landscape is currently in a growth phase, with the market expanding rapidly due to increasing demand for lithium-ion batteries in electric vehicles and energy storage systems. Water consumption efficiency represents a critical competitive factor in this maturing industry. Companies like Lilac Solutions, Energy Exploration Technologies (EnergyX), and Pure Lithium are pioneering direct lithium extraction technologies that significantly reduce water usage compared to traditional evaporation methods. Research institutions including KAUST, Korea Institute of Geoscience & Mineral Resources, and Qinghai Institute of Salt Lakes are advancing scientific understanding of water-efficient extraction processes. Established players such as POSCO Holdings, Eramet, and BASF are investing in sustainable lithium production technologies to address growing environmental concerns while meeting escalating global demand.

Eramet SA

Technical Solution: Eramet has developed an innovative direct lithium extraction (DLE) process specifically designed to minimize water consumption in lithium mining operations. Their proprietary technology combines selective adsorption materials with an advanced water management system that significantly reduces freshwater requirements. According to their technical documentation, Eramet's process consumes approximately 60-80 cubic meters of water per ton of lithium carbonate equivalent (LCE) produced, representing a reduction of up to 90% compared to traditional evaporation pond methods. The company has implemented this technology at their Centenario-Ratones project in Argentina, where water scarcity is a critical concern. Their system incorporates a multi-stage water recovery process that can recycle up to 85% of process water, further reducing the environmental footprint. Eramet's approach also includes comprehensive water monitoring throughout the extraction process, with real-time data analytics to optimize water usage based on production demands and environmental conditions. The company reports that their technology can achieve lithium recovery rates of over 85% while maintaining consistent water efficiency metrics across seasonal variations.

Strengths: Significantly reduced water footprint compared to conventional methods; high water recycling efficiency; adaptable to challenging environmental conditions; integrated monitoring systems for optimization. Weaknesses: Higher initial capital investment compared to traditional methods; requires specialized technical expertise for operation; energy requirements for the extraction and water recycling processes may be substantial.

Qinghai Institute of Salt Lakes, Chinese Academy of Sciences

Technical Solution: The Qinghai Institute of Salt Lakes has developed an advanced membrane filtration system specifically designed for lithium extraction from salt lake brines. Their technology utilizes a multi-stage reverse osmosis process combined with selective adsorption materials that can efficiently separate lithium from other salt components while minimizing water consumption. The institute has implemented a closed-loop water recycling system that can recover up to 85% of process water, significantly reducing freshwater requirements. Their research indicates that their optimized process requires approximately 200-250 cubic meters of water per ton of lithium carbonate equivalent (LCE) produced, which represents a substantial improvement over traditional evaporation pond methods that can use 500-2,000 cubic meters per ton. The institute has also developed specialized monitoring systems to track water usage throughout the extraction process, allowing for real-time adjustments to maximize efficiency.

Strengths: Significantly reduced water consumption compared to traditional methods; high water recycling rate; real-time monitoring capabilities for process optimization. Weaknesses: Still requires substantial initial water investment; technology may be region-specific to salt lake conditions in Qinghai; implementation costs can be high for the advanced filtration and monitoring systems.

Critical Water Efficiency Technologies and Patents

Lithium purification and conversion

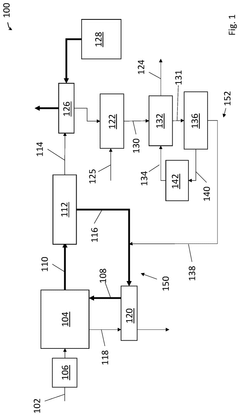

PatentPendingUS20230088458A1

Innovation

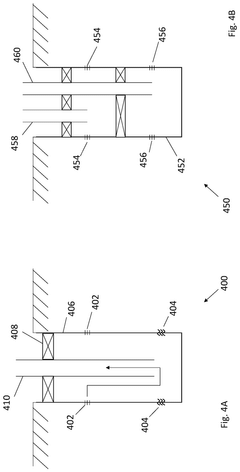

- The method involves an adsorption/desorption process using a lithium-selective medium to extract lithium from brine, followed by membrane separations in a counter-current format to concentrate lithium, and subsequent conversion stages to produce high-purity lithium products.

Lithium recovery thermal management

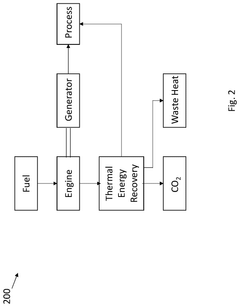

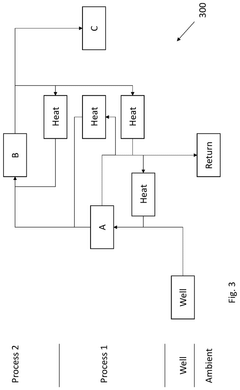

PatentActiveUS20240336490A1

Innovation

- A method involving a sorption/desorption process using ion withdrawal and thermal energy recovery, where lithium is extracted from brine sources using modular, dynamically scalable energy sources, including electric heaters and heat exchangers, to minimize energy use and environmental impact by optimizing energy coupling and thermal management.

Environmental Impact Assessment Framework

The Environmental Impact Assessment Framework for lithium mining water consumption quantification must establish a comprehensive methodology that accounts for all water-related impacts throughout the extraction process. This framework should begin with a clear boundary definition that specifies which operations are included in the assessment, from exploration to processing and refining stages.

Water consumption metrics should be standardized across different extraction methods, particularly distinguishing between traditional evaporative ponds and direct lithium extraction (DLE) technologies. The framework must incorporate water quality parameters alongside quantity measurements, as the degradation of water quality represents a significant environmental impact even when water is returned to the environment.

Temporal considerations are essential within the assessment framework, accounting for seasonal variations in water availability and consumption patterns. Many lithium-rich regions experience significant dry seasons that can exacerbate water scarcity issues, making time-specific measurements crucial for accurate impact evaluation.

Geographic contextualization forms another critical component, as water consumption impacts vary dramatically depending on the local hydrological conditions. A cubic meter of water consumed in Chile's Atacama Desert carries significantly different environmental implications than the same volume used in areas with abundant water resources. The framework should incorporate water stress indices for the mining regions to properly weight the impact of consumption.

Life cycle assessment principles should be integrated to capture indirect water consumption throughout the supply chain, including energy production for mining operations and transportation of materials. This comprehensive approach prevents impact shifting and ensures all water-related environmental costs are properly accounted for.

Stakeholder engagement protocols must be established within the framework, particularly concerning indigenous communities and other water users who may be affected by mining operations. Transparent reporting mechanisms should be developed to communicate water consumption data to all relevant parties, including local communities, regulatory bodies, and downstream battery manufacturers.

The framework should also establish clear thresholds for acceptable water consumption rates based on local ecosystem requirements and competing water needs, providing a scientific basis for sustainable extraction limits. These thresholds must be adaptable to changing climate conditions, acknowledging that water availability projections may shift significantly over the operational lifetime of lithium mining projects.

Water consumption metrics should be standardized across different extraction methods, particularly distinguishing between traditional evaporative ponds and direct lithium extraction (DLE) technologies. The framework must incorporate water quality parameters alongside quantity measurements, as the degradation of water quality represents a significant environmental impact even when water is returned to the environment.

Temporal considerations are essential within the assessment framework, accounting for seasonal variations in water availability and consumption patterns. Many lithium-rich regions experience significant dry seasons that can exacerbate water scarcity issues, making time-specific measurements crucial for accurate impact evaluation.

Geographic contextualization forms another critical component, as water consumption impacts vary dramatically depending on the local hydrological conditions. A cubic meter of water consumed in Chile's Atacama Desert carries significantly different environmental implications than the same volume used in areas with abundant water resources. The framework should incorporate water stress indices for the mining regions to properly weight the impact of consumption.

Life cycle assessment principles should be integrated to capture indirect water consumption throughout the supply chain, including energy production for mining operations and transportation of materials. This comprehensive approach prevents impact shifting and ensures all water-related environmental costs are properly accounted for.

Stakeholder engagement protocols must be established within the framework, particularly concerning indigenous communities and other water users who may be affected by mining operations. Transparent reporting mechanisms should be developed to communicate water consumption data to all relevant parties, including local communities, regulatory bodies, and downstream battery manufacturers.

The framework should also establish clear thresholds for acceptable water consumption rates based on local ecosystem requirements and competing water needs, providing a scientific basis for sustainable extraction limits. These thresholds must be adaptable to changing climate conditions, acknowledging that water availability projections may shift significantly over the operational lifetime of lithium mining projects.

Regulatory Compliance and Water Rights Considerations

Lithium mining operations are subject to a complex web of regulatory frameworks governing water usage, which vary significantly across different jurisdictions. In major lithium-producing regions such as Chile, Argentina, and Australia, specific regulations dictate permissible extraction volumes, monitoring requirements, and environmental impact assessments related to water consumption. Companies must navigate these regulations to maintain operational licenses and avoid costly penalties or production shutdowns.

Water rights allocation systems present another critical consideration for lithium producers. In the water-scarce Lithium Triangle of South America, water rights are increasingly contested between mining operations, agricultural activities, and indigenous communities. The legal frameworks governing these rights often predate the lithium boom, creating regulatory uncertainty and potential for conflict. In Chile, for example, the Water Code separates water rights from land ownership, allowing them to be traded as commodities, which has significant implications for lithium operations.

Environmental compliance standards are becoming increasingly stringent worldwide, with particular focus on water-intensive industries. Lithium producers must demonstrate adherence to discharge limits, groundwater protection measures, and ecosystem conservation requirements. Many jurisdictions now require regular reporting of water consumption metrics per unit of production, aligning with the quantification focus of this technical research.

International standards and certification schemes are emerging as important factors in lithium supply chains. Initiatives such as the Initiative for Responsible Mining Assurance (IRMA) and the International Council on Mining and Metals (ICMM) Water Stewardship Framework establish benchmarks for responsible water management. Compliance with these voluntary standards is increasingly demanded by downstream customers seeking to demonstrate environmental responsibility in their supply chains.

The regulatory landscape is rapidly evolving in response to growing water scarcity concerns. Several jurisdictions are implementing or considering water consumption caps, progressive taxation based on water intensity, and mandatory efficiency improvements. Forward-looking lithium producers are proactively engaging with regulatory developments, participating in policy consultations, and implementing water management systems that exceed current compliance requirements to mitigate future regulatory risks.

Stakeholder engagement requirements represent another significant compliance consideration. Many regulatory frameworks now mandate consultation with local communities regarding water usage, particularly where indigenous rights are concerned. Failure to adequately address community concerns can result in project delays, legal challenges, and reputational damage that extends beyond regulatory penalties.

Water rights allocation systems present another critical consideration for lithium producers. In the water-scarce Lithium Triangle of South America, water rights are increasingly contested between mining operations, agricultural activities, and indigenous communities. The legal frameworks governing these rights often predate the lithium boom, creating regulatory uncertainty and potential for conflict. In Chile, for example, the Water Code separates water rights from land ownership, allowing them to be traded as commodities, which has significant implications for lithium operations.

Environmental compliance standards are becoming increasingly stringent worldwide, with particular focus on water-intensive industries. Lithium producers must demonstrate adherence to discharge limits, groundwater protection measures, and ecosystem conservation requirements. Many jurisdictions now require regular reporting of water consumption metrics per unit of production, aligning with the quantification focus of this technical research.

International standards and certification schemes are emerging as important factors in lithium supply chains. Initiatives such as the Initiative for Responsible Mining Assurance (IRMA) and the International Council on Mining and Metals (ICMM) Water Stewardship Framework establish benchmarks for responsible water management. Compliance with these voluntary standards is increasingly demanded by downstream customers seeking to demonstrate environmental responsibility in their supply chains.

The regulatory landscape is rapidly evolving in response to growing water scarcity concerns. Several jurisdictions are implementing or considering water consumption caps, progressive taxation based on water intensity, and mandatory efficiency improvements. Forward-looking lithium producers are proactively engaging with regulatory developments, participating in policy consultations, and implementing water management systems that exceed current compliance requirements to mitigate future regulatory risks.

Stakeholder engagement requirements represent another significant compliance consideration. Many regulatory frameworks now mandate consultation with local communities regarding water usage, particularly where indigenous rights are concerned. Failure to adequately address community concerns can result in project delays, legal challenges, and reputational damage that extends beyond regulatory penalties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!