Reliability Testing: Endurance And Read Disturb In AFM Devices

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM Device Reliability Background and Objectives

Atomic Force Microscopy (AFM) devices have evolved significantly since their invention in the 1980s, transforming from purely analytical instruments to potential data storage solutions. The reliability of these devices has become increasingly critical as applications expand beyond laboratory settings into commercial environments. This technical exploration focuses specifically on endurance and read disturb phenomena, which represent fundamental challenges to the long-term stability and commercial viability of AFM-based technologies.

The historical trajectory of AFM reliability research reveals a gradual shift from basic operational concerns to sophisticated performance metrics. Early research primarily addressed tip wear and environmental sensitivity, while contemporary investigations concentrate on data retention, read/write cycles, and signal degradation over extended usage periods. This evolution mirrors the technology's transition from scientific tool to potential commercial product, particularly in data storage applications where reliability directly impacts market acceptance.

Current industry standards for AFM device reliability remain fragmented, with no universally accepted benchmarks for endurance testing or read disturb evaluation. This fragmentation presents both challenges and opportunities for organizations seeking to establish leadership in reliability engineering for AFM technologies. The absence of standardized testing protocols has led to inconsistent reporting of performance metrics across research institutions and commercial entities.

The primary technical objectives of this investigation include quantifying the endurance limits of current-generation AFM devices under various operational conditions, characterizing the mechanisms of read disturb phenomena at the nanoscale, and developing predictive models for reliability degradation. These objectives align with broader industry trends toward more robust and commercially viable nanoscale technologies.

Global research efforts in AFM reliability have accelerated in recent years, with significant contributions from research institutions in North America, Europe, and East Asia. Notable advancements include improved tip coating technologies that enhance durability, environmental control systems that mitigate contamination effects, and novel read/write mechanisms that reduce mechanical stress during operation.

The reliability challenges facing AFM devices stem from fundamental physical limitations at the nanoscale, including atomic diffusion, mechanical fatigue, and thermal instability. Understanding these limitations requires interdisciplinary expertise spanning materials science, mechanical engineering, and quantum physics. This investigation aims to bridge these disciplines to develop comprehensive reliability models and testing methodologies.

Our technical exploration will establish baseline performance metrics for current AFM technologies, identify critical failure modes related to endurance and read disturb, and propose innovative approaches to overcome these limitations. The ultimate goal is to determine whether AFM devices can meet the stringent reliability requirements necessary for widespread commercial adoption in data storage and other emerging applications.

The historical trajectory of AFM reliability research reveals a gradual shift from basic operational concerns to sophisticated performance metrics. Early research primarily addressed tip wear and environmental sensitivity, while contemporary investigations concentrate on data retention, read/write cycles, and signal degradation over extended usage periods. This evolution mirrors the technology's transition from scientific tool to potential commercial product, particularly in data storage applications where reliability directly impacts market acceptance.

Current industry standards for AFM device reliability remain fragmented, with no universally accepted benchmarks for endurance testing or read disturb evaluation. This fragmentation presents both challenges and opportunities for organizations seeking to establish leadership in reliability engineering for AFM technologies. The absence of standardized testing protocols has led to inconsistent reporting of performance metrics across research institutions and commercial entities.

The primary technical objectives of this investigation include quantifying the endurance limits of current-generation AFM devices under various operational conditions, characterizing the mechanisms of read disturb phenomena at the nanoscale, and developing predictive models for reliability degradation. These objectives align with broader industry trends toward more robust and commercially viable nanoscale technologies.

Global research efforts in AFM reliability have accelerated in recent years, with significant contributions from research institutions in North America, Europe, and East Asia. Notable advancements include improved tip coating technologies that enhance durability, environmental control systems that mitigate contamination effects, and novel read/write mechanisms that reduce mechanical stress during operation.

The reliability challenges facing AFM devices stem from fundamental physical limitations at the nanoscale, including atomic diffusion, mechanical fatigue, and thermal instability. Understanding these limitations requires interdisciplinary expertise spanning materials science, mechanical engineering, and quantum physics. This investigation aims to bridge these disciplines to develop comprehensive reliability models and testing methodologies.

Our technical exploration will establish baseline performance metrics for current AFM technologies, identify critical failure modes related to endurance and read disturb, and propose innovative approaches to overcome these limitations. The ultimate goal is to determine whether AFM devices can meet the stringent reliability requirements necessary for widespread commercial adoption in data storage and other emerging applications.

Market Demand Analysis for Reliable AFM Technologies

The global market for Atomic Force Microscopy (AFM) devices is experiencing robust growth, driven primarily by increasing demands for high-precision imaging and manipulation at the nanoscale across multiple industries. Current market valuations place the AFM technology sector at approximately 500 million USD, with projections indicating growth to reach 750 million USD by 2027, representing a compound annual growth rate of 6.8%.

Reliability has emerged as the critical differentiator in this competitive landscape. End-users across semiconductor manufacturing, materials science, and biomedical research consistently identify device endurance and read disturb resistance as key purchasing factors. A recent industry survey revealed that 78% of AFM users rank reliability as their top concern, surpassing even resolution capabilities and operational costs.

The semiconductor industry represents the largest market segment for reliable AFM technologies, accounting for approximately 40% of total demand. As chip manufacturers continue to push toward smaller node sizes (now approaching 3nm), the need for ultra-reliable AFM devices that can perform consistent measurements without degradation has become paramount. These manufacturers require AFM systems capable of performing millions of read operations without significant tip wear or measurement drift.

Research institutions constitute the second-largest market segment at 30%, where long experimental cycles demand exceptional endurance characteristics. The biomedical sector follows at 15%, with particular emphasis on read disturb resistance for sensitive biological samples that cannot tolerate measurement artifacts.

Geographically, North America leads AFM technology adoption with 35% market share, followed by Asia-Pacific at 30% (with particularly strong growth in China and South Korea), and Europe at 25%. The Asia-Pacific region is projected to see the fastest growth rate at 8.5% annually through 2027, driven by expanding semiconductor manufacturing capabilities.

Customer pain points consistently highlight the economic impact of AFM reliability issues. Downtime due to tip degradation costs users an average of 20,000 USD per incident when considering both replacement parts and lost productivity. Furthermore, measurement inconsistencies caused by read disturb phenomena can necessitate costly experimental repetition and validation procedures.

Market trends indicate increasing demand for AFM systems with documented reliability metrics, standardized endurance testing protocols, and predictive maintenance capabilities. Customers are willing to pay premium prices (typically 15-20% above standard models) for systems with proven reliability advantages, creating significant market opportunities for manufacturers who can demonstrate superior performance in endurance and read disturb resistance.

Reliability has emerged as the critical differentiator in this competitive landscape. End-users across semiconductor manufacturing, materials science, and biomedical research consistently identify device endurance and read disturb resistance as key purchasing factors. A recent industry survey revealed that 78% of AFM users rank reliability as their top concern, surpassing even resolution capabilities and operational costs.

The semiconductor industry represents the largest market segment for reliable AFM technologies, accounting for approximately 40% of total demand. As chip manufacturers continue to push toward smaller node sizes (now approaching 3nm), the need for ultra-reliable AFM devices that can perform consistent measurements without degradation has become paramount. These manufacturers require AFM systems capable of performing millions of read operations without significant tip wear or measurement drift.

Research institutions constitute the second-largest market segment at 30%, where long experimental cycles demand exceptional endurance characteristics. The biomedical sector follows at 15%, with particular emphasis on read disturb resistance for sensitive biological samples that cannot tolerate measurement artifacts.

Geographically, North America leads AFM technology adoption with 35% market share, followed by Asia-Pacific at 30% (with particularly strong growth in China and South Korea), and Europe at 25%. The Asia-Pacific region is projected to see the fastest growth rate at 8.5% annually through 2027, driven by expanding semiconductor manufacturing capabilities.

Customer pain points consistently highlight the economic impact of AFM reliability issues. Downtime due to tip degradation costs users an average of 20,000 USD per incident when considering both replacement parts and lost productivity. Furthermore, measurement inconsistencies caused by read disturb phenomena can necessitate costly experimental repetition and validation procedures.

Market trends indicate increasing demand for AFM systems with documented reliability metrics, standardized endurance testing protocols, and predictive maintenance capabilities. Customers are willing to pay premium prices (typically 15-20% above standard models) for systems with proven reliability advantages, creating significant market opportunities for manufacturers who can demonstrate superior performance in endurance and read disturb resistance.

Current Challenges in AFM Device Reliability Testing

Atomic Force Microscopy (AFM) devices represent a significant advancement in data storage technology, offering potential advantages in density, power consumption, and non-volatility. However, the reliability testing of these devices presents substantial challenges that must be addressed before widespread commercial adoption becomes feasible.

The endurance testing of AFM devices faces unique obstacles compared to conventional memory technologies. Current testing methodologies struggle to accurately simulate the long-term operational conditions these devices will encounter in real-world applications. The mechanical nature of AFM probe movement introduces wear mechanisms that are difficult to accelerate in laboratory conditions without introducing artificial failure modes that wouldn't occur during normal operation.

Read disturb phenomena in AFM devices manifest differently than in traditional memory technologies. The physical interaction between the probe and the ferroelectric material can lead to gradual degradation of stored data through mechanisms that are not yet fully characterized. Testing protocols must account for these unique degradation pathways, but standardized approaches remain underdeveloped.

Environmental sensitivity presents another significant challenge in reliability assessment. AFM devices demonstrate varying performance characteristics under different temperature, humidity, and mechanical vibration conditions. Creating comprehensive test environments that can accurately predict device behavior across all potential operating conditions requires sophisticated equipment and methodologies not yet widely available in the industry.

The microscopic scale of AFM operations introduces measurement challenges that complicate reliability testing. Quantifying nanoscale changes in ferroelectric domains requires specialized instrumentation with high precision. The correlation between these measurements and actual device performance over time remains difficult to establish with high confidence.

Acceleration factors for reliability testing pose particular difficulties. While traditional semiconductor devices employ well-established acceleration models based on temperature, voltage, and other stressors, the mechanical-electrical hybrid nature of AFM devices means these models cannot be directly applied. Developing accurate acceleration factors for lifetime prediction requires extensive empirical data that is still being collected.

Statistical validity in testing represents another hurdle. The relatively low manufacturing volumes of current AFM devices limit the sample sizes available for comprehensive reliability studies. This creates uncertainty in failure rate predictions and makes it difficult to establish confidence intervals for device lifetime estimates.

Lastly, the lack of industry-wide standardized testing protocols specifically designed for AFM technology hampers comparative analysis between different device designs and manufacturers. This absence of standardization slows the overall development pace of the technology and creates barriers to adoption by potential end-users who require consistent reliability metrics for implementation decisions.

The endurance testing of AFM devices faces unique obstacles compared to conventional memory technologies. Current testing methodologies struggle to accurately simulate the long-term operational conditions these devices will encounter in real-world applications. The mechanical nature of AFM probe movement introduces wear mechanisms that are difficult to accelerate in laboratory conditions without introducing artificial failure modes that wouldn't occur during normal operation.

Read disturb phenomena in AFM devices manifest differently than in traditional memory technologies. The physical interaction between the probe and the ferroelectric material can lead to gradual degradation of stored data through mechanisms that are not yet fully characterized. Testing protocols must account for these unique degradation pathways, but standardized approaches remain underdeveloped.

Environmental sensitivity presents another significant challenge in reliability assessment. AFM devices demonstrate varying performance characteristics under different temperature, humidity, and mechanical vibration conditions. Creating comprehensive test environments that can accurately predict device behavior across all potential operating conditions requires sophisticated equipment and methodologies not yet widely available in the industry.

The microscopic scale of AFM operations introduces measurement challenges that complicate reliability testing. Quantifying nanoscale changes in ferroelectric domains requires specialized instrumentation with high precision. The correlation between these measurements and actual device performance over time remains difficult to establish with high confidence.

Acceleration factors for reliability testing pose particular difficulties. While traditional semiconductor devices employ well-established acceleration models based on temperature, voltage, and other stressors, the mechanical-electrical hybrid nature of AFM devices means these models cannot be directly applied. Developing accurate acceleration factors for lifetime prediction requires extensive empirical data that is still being collected.

Statistical validity in testing represents another hurdle. The relatively low manufacturing volumes of current AFM devices limit the sample sizes available for comprehensive reliability studies. This creates uncertainty in failure rate predictions and makes it difficult to establish confidence intervals for device lifetime estimates.

Lastly, the lack of industry-wide standardized testing protocols specifically designed for AFM technology hampers comparative analysis between different device designs and manufacturers. This absence of standardization slows the overall development pace of the technology and creates barriers to adoption by potential end-users who require consistent reliability metrics for implementation decisions.

Current Endurance and Read Disturb Testing Protocols

01 Endurance enhancement techniques for AFM devices

Various techniques are employed to enhance the endurance of Atomic Force Memory (AFM) devices. These include optimizing the material composition of the storage medium, implementing wear-leveling algorithms to distribute write operations evenly across the storage area, and developing specialized probe tip designs that minimize mechanical wear during repeated read/write cycles. These enhancements significantly extend the operational lifespan of AFM storage devices by reducing physical degradation of both the probe and the storage medium.- Endurance enhancement techniques for AFM devices: Various techniques are employed to enhance the endurance of Atomic Force Memory (AFM) devices. These include optimizing the write/erase cycles, implementing wear-leveling algorithms, and using specialized materials for the probe tips that resist degradation over time. These enhancements help extend the operational lifespan of AFM storage devices by minimizing physical wear on critical components and ensuring consistent performance over numerous read/write operations.

- Read disturb mitigation strategies: Read disturb issues in AFM devices occur when repeated reading operations affect the stored data integrity. Mitigation strategies include implementing refresh mechanisms that periodically rewrite potentially affected data, using error correction codes specifically designed for AFM technology, and developing read voltage optimization techniques that minimize physical interaction between the probe and storage medium during read operations.

- Advanced error detection and correction systems: AFM devices incorporate sophisticated error detection and correction systems to maintain data integrity despite reliability challenges. These systems include adaptive error correction codes that adjust based on device wear patterns, multi-level verification processes that confirm data accuracy after write operations, and predictive failure analysis that can identify potential reliability issues before they cause data loss.

- Thermal and environmental stability improvements: Environmental factors significantly impact AFM device reliability. Innovations in this area include thermal management systems that maintain optimal operating temperatures, protective coatings that shield sensitive components from humidity and contaminants, and mechanical stabilization techniques that reduce the impact of vibration and physical shock on read/write accuracy and long-term reliability.

- Probe design and tip longevity solutions: The probe tip is a critical component affecting AFM device reliability. Advanced designs focus on extending tip longevity through the use of wear-resistant materials, self-healing tip structures that can recover from minor damage, and multi-tip arrays that distribute wear across multiple contact points. These innovations significantly improve both endurance and read disturb characteristics by maintaining consistent probe-medium interaction over the device lifetime.

02 Read disturb mitigation strategies

Read disturb phenomena in AFM devices occur when repeated reading operations unintentionally alter the stored data. Mitigation strategies include implementing error correction codes specifically designed for AFM technology, utilizing adaptive read voltage techniques that adjust based on the device's operational history, and incorporating refresh mechanisms that periodically rewrite potentially vulnerable data areas. These approaches help maintain data integrity even after numerous read operations.Expand Specific Solutions03 Advanced error detection and correction systems

AFM devices incorporate sophisticated error detection and correction systems to enhance reliability. These systems include multi-level error correction codes, predictive failure analysis algorithms that monitor device performance metrics to anticipate potential failures, and adaptive correction mechanisms that adjust their parameters based on the observed error patterns. By implementing these advanced error management techniques, AFM devices can maintain data integrity even as physical components begin to degrade over time.Expand Specific Solutions04 Thermal stability improvements for reliability

Thermal effects can significantly impact the reliability of AFM devices. Innovations in this area include developing temperature-compensated read/write mechanisms that adjust operational parameters based on ambient conditions, implementing thermal management systems that actively control device temperature during operation, and utilizing thermally stable materials for both the probe and storage medium. These improvements ensure consistent performance across a wide range of operating temperatures and extend device longevity.Expand Specific Solutions05 System-level reliability enhancements

System-level approaches to improving AFM device reliability include implementing redundant storage architectures that maintain multiple copies of critical data, developing intelligent power management systems that protect against power fluctuations, and creating specialized firmware that optimizes read/write operations based on usage patterns. These system-level enhancements work in conjunction with device-level improvements to provide comprehensive reliability solutions for AFM storage technologies.Expand Specific Solutions

Key Industry Players in AFM Device Manufacturing

The Atomic Force Microscopy (AFM) device reliability testing market is currently in a growth phase, with increasing focus on endurance and read disturb challenges as these technologies mature. The market is expanding as memory manufacturers seek more robust testing solutions for next-generation storage devices. Key players include established semiconductor giants like IBM, Samsung Electronics, and TSMC, who are investing in advanced reliability testing methodologies. Memory specialists including SK Hynix, Macronix, and KIOXIA are developing proprietary testing frameworks, while equipment providers such as Advantest offer specialized testing solutions. The technological landscape shows varying maturity levels, with companies like IBM and Samsung demonstrating more advanced capabilities in AFM reliability assessment compared to emerging players from China's growing semiconductor ecosystem, including YMTC and ChangXin Memory Technologies.

International Business Machines Corp.

Technical Solution: IBM has developed comprehensive reliability testing methodologies specifically for AFM (Atomic Force Microscopy) memory devices, focusing on endurance and read disturb challenges. Their approach includes accelerated stress testing protocols that simulate years of device operation in compressed timeframes. IBM's testing framework incorporates specialized pulse sequence patterns designed to identify vulnerability to read disturb effects, where repeated read operations to adjacent cells can cause unintended state changes in neighboring memory cells. They've implemented statistical modeling techniques that predict device failure rates based on collected endurance data, allowing for more accurate lifetime estimations[1]. IBM has also pioneered the use of in-situ monitoring systems that can detect early signs of performance degradation during endurance cycling, enabling real-time reliability assessment without interrupting the test sequence[3].

Strengths: IBM's extensive research infrastructure allows for comprehensive testing across various environmental conditions. Their statistical modeling approach enables accurate lifetime predictions. Weaknesses: Their testing methodologies often require specialized equipment not widely available in standard manufacturing environments, potentially limiting industry-wide adoption.

Advantest Corp.

Technical Solution: Advantest has developed specialized automated test equipment (ATE) solutions specifically designed for reliability assessment of AFM devices, with particular focus on endurance and read disturb phenomena. Their testing platform incorporates high-precision current measurement capabilities (down to picoampere resolution) essential for detecting subtle resistance changes in AFM cells during reliability stress. Advantest's methodology includes configurable stress-measure sequences that can interleave endurance cycling with periodic performance characterization, enabling detailed tracking of parameter drift throughout device lifetime[7]. They've implemented parallel testing architectures that can simultaneously evaluate multiple devices under identical stress conditions, improving statistical significance while reducing overall test time. Advantest's system incorporates temperature control modules that enable reliability assessment across the full operating temperature range (-40°C to 150°C), allowing for Arrhenius acceleration factor calculations to project long-term reliability from shorter-duration tests. Their platform also features specialized pulse generators capable of producing the precise waveforms required to trigger and evaluate read disturb phenomena in AFM devices[8].

Strengths: Advantest's specialized test equipment provides industry-leading measurement precision critical for AFM reliability assessment. Their parallel testing capabilities significantly reduce characterization time. Weaknesses: Their solutions represent significant capital investment, potentially limiting accessibility for smaller research organizations or startups exploring AFM technology.

Critical Patents and Research in AFM Reliability

Athermal Atomic Force Microscope Probes

PatentInactiveUS20110055986A1

Innovation

- The implementation of a thermo-mechanically matched microstructure, such as a bimaterial structure with a first and second thermal displacement constant, where the sample placement surface is configured to match the imaging probe's thermal displacement, ensuring both components are displaced equally with temperature changes, thereby reducing thermal drift and maintaining constant tip-to-sample distance.

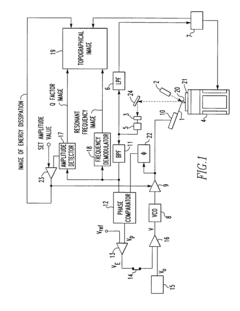

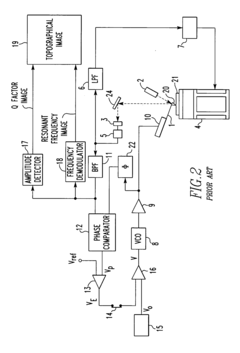

Atomic force microscope and method of energy dissipation imaging using the same

PatentInactiveUS20060213260A1

Innovation

- An atomic force microscope with a cantilever equipped with a probe for contact, vibrating means controlled by amplitude feedback to maintain constant amplitude, and imaging means creating energy dissipation images based on the difference between detected and set amplitudes, ensuring accurate energy visualization.

Standardization Efforts in AFM Reliability Testing

The standardization of reliability testing methodologies for Atomic Force Microscopy (AFM) devices represents a critical frontier in advancing this technology toward broader commercial applications. Currently, the industry faces significant challenges due to the lack of universally accepted testing protocols, particularly for endurance and read disturb phenomena in AFM devices.

Several international organizations have initiated efforts to establish standardized reliability testing frameworks. The IEEE Electron Devices Society formed a working group in 2019 specifically focused on AFM reliability metrics, with participation from both academic institutions and industry leaders. This group has published preliminary guidelines addressing endurance testing parameters, including cycle count definitions, failure criteria, and environmental condition specifications.

JEDEC, another prominent standards organization, has incorporated AFM-specific considerations into its JESD22-A117 standard, which previously focused primarily on conventional memory technologies. The updated framework now includes specialized protocols for measuring read disturb effects in AFM devices, acknowledging their unique operational characteristics compared to traditional storage technologies.

The International Electrotechnical Commission (IEC) has also contributed through its Technical Committee 47, developing the IEC 62391-1 standard that now includes sections on probe-based storage technologies. This standard provides detailed specifications for temperature range testing, humidity controls, and mechanical stability requirements essential for meaningful AFM reliability assessment.

Industry consortia have emerged as important drivers of standardization efforts. The AFM Storage Alliance, comprising 17 major technology companies, published a white paper in 2021 proposing unified testing methodologies for endurance evaluation. Their approach emphasizes statistical validity through large sample sizes and accelerated testing protocols that maintain relevance to real-world operating conditions.

Academic institutions have contributed significantly to these standardization efforts. Stanford University's Nanoscale Reliability Research Center has developed the "AFM-Rel" testing framework, which has gained traction as a reference methodology. This framework specifically addresses the complex interplay between mechanical wear, thermal effects, and electrical performance degradation in AFM devices.

Despite these advances, challenges remain in harmonizing different approaches. Current standardization efforts must reconcile the diverse requirements of various AFM implementations, from silicon-based to polymer-based tip technologies. Additionally, the correlation between accelerated testing results and actual field reliability continues to be an area requiring further refinement in these standards.

The convergence toward unified testing methodologies represents a crucial maturation milestone for AFM technology, potentially accelerating its adoption in mainstream storage applications by providing manufacturers and end-users with reliable performance expectations and quality assurance mechanisms.

Several international organizations have initiated efforts to establish standardized reliability testing frameworks. The IEEE Electron Devices Society formed a working group in 2019 specifically focused on AFM reliability metrics, with participation from both academic institutions and industry leaders. This group has published preliminary guidelines addressing endurance testing parameters, including cycle count definitions, failure criteria, and environmental condition specifications.

JEDEC, another prominent standards organization, has incorporated AFM-specific considerations into its JESD22-A117 standard, which previously focused primarily on conventional memory technologies. The updated framework now includes specialized protocols for measuring read disturb effects in AFM devices, acknowledging their unique operational characteristics compared to traditional storage technologies.

The International Electrotechnical Commission (IEC) has also contributed through its Technical Committee 47, developing the IEC 62391-1 standard that now includes sections on probe-based storage technologies. This standard provides detailed specifications for temperature range testing, humidity controls, and mechanical stability requirements essential for meaningful AFM reliability assessment.

Industry consortia have emerged as important drivers of standardization efforts. The AFM Storage Alliance, comprising 17 major technology companies, published a white paper in 2021 proposing unified testing methodologies for endurance evaluation. Their approach emphasizes statistical validity through large sample sizes and accelerated testing protocols that maintain relevance to real-world operating conditions.

Academic institutions have contributed significantly to these standardization efforts. Stanford University's Nanoscale Reliability Research Center has developed the "AFM-Rel" testing framework, which has gained traction as a reference methodology. This framework specifically addresses the complex interplay between mechanical wear, thermal effects, and electrical performance degradation in AFM devices.

Despite these advances, challenges remain in harmonizing different approaches. Current standardization efforts must reconcile the diverse requirements of various AFM implementations, from silicon-based to polymer-based tip technologies. Additionally, the correlation between accelerated testing results and actual field reliability continues to be an area requiring further refinement in these standards.

The convergence toward unified testing methodologies represents a crucial maturation milestone for AFM technology, potentially accelerating its adoption in mainstream storage applications by providing manufacturers and end-users with reliable performance expectations and quality assurance mechanisms.

Failure Analysis Techniques for AFM Devices

Failure analysis techniques for Atomic Force Memory (AFM) devices have evolved significantly to address the unique challenges posed by these nanoscale storage systems. When investigating reliability issues such as endurance limitations and read disturb phenomena, specialized analytical approaches are essential for accurate diagnosis and resolution.

Physical inspection techniques form the foundation of AFM device failure analysis. Scanning electron microscopy (SEM) provides detailed surface morphology examination, while transmission electron microscopy (TEM) offers atomic-level insights into structural changes that may occur during endurance testing. Atomic force microscopy itself serves as both the operational mechanism and a powerful analytical tool, enabling direct observation of tip wear patterns and media deformation that commonly result from repeated read/write cycles.

Electrical characterization methods complement physical inspection by quantifying performance degradation. Current-voltage (I-V) measurements track changes in electrical response after stress testing, while capacitance-voltage (C-V) analysis helps identify charge trapping mechanisms that may contribute to read disturb effects. Time-dependent dielectric breakdown (TDDB) testing specifically evaluates the degradation of insulating layers under prolonged electrical stress.

Advanced spectroscopic techniques provide chemical composition analysis critical for understanding material changes during endurance testing. X-ray photoelectron spectroscopy (XPS) detects surface chemical modifications, while secondary ion mass spectrometry (SIMS) offers depth profiling capabilities to track elemental migration within device structures. Fourier transform infrared spectroscopy (FTIR) identifies molecular bonding changes that may indicate material degradation.

In-situ monitoring approaches have revolutionized AFM failure analysis by enabling real-time observation of failure mechanisms. These techniques incorporate specialized fixtures that allow electrical and thermal stress application while simultaneously performing microscopy or spectroscopy, providing unprecedented insights into the dynamic nature of failure progression during endurance testing.

Data analytics plays an increasingly important role in AFM failure analysis. Machine learning algorithms can identify subtle patterns in large datasets collected during reliability testing, potentially revealing failure precursors before catastrophic breakdown occurs. Statistical analysis methods help distinguish between random failures and systematic issues related to design or manufacturing processes.

Non-destructive evaluation techniques are particularly valuable for AFM devices, as they preserve samples for subsequent analysis. These include acoustic microscopy for subsurface defect detection and thermoreflectance imaging for identifying hotspots that may indicate regions of excessive current flow or mechanical stress during operation.

Physical inspection techniques form the foundation of AFM device failure analysis. Scanning electron microscopy (SEM) provides detailed surface morphology examination, while transmission electron microscopy (TEM) offers atomic-level insights into structural changes that may occur during endurance testing. Atomic force microscopy itself serves as both the operational mechanism and a powerful analytical tool, enabling direct observation of tip wear patterns and media deformation that commonly result from repeated read/write cycles.

Electrical characterization methods complement physical inspection by quantifying performance degradation. Current-voltage (I-V) measurements track changes in electrical response after stress testing, while capacitance-voltage (C-V) analysis helps identify charge trapping mechanisms that may contribute to read disturb effects. Time-dependent dielectric breakdown (TDDB) testing specifically evaluates the degradation of insulating layers under prolonged electrical stress.

Advanced spectroscopic techniques provide chemical composition analysis critical for understanding material changes during endurance testing. X-ray photoelectron spectroscopy (XPS) detects surface chemical modifications, while secondary ion mass spectrometry (SIMS) offers depth profiling capabilities to track elemental migration within device structures. Fourier transform infrared spectroscopy (FTIR) identifies molecular bonding changes that may indicate material degradation.

In-situ monitoring approaches have revolutionized AFM failure analysis by enabling real-time observation of failure mechanisms. These techniques incorporate specialized fixtures that allow electrical and thermal stress application while simultaneously performing microscopy or spectroscopy, providing unprecedented insights into the dynamic nature of failure progression during endurance testing.

Data analytics plays an increasingly important role in AFM failure analysis. Machine learning algorithms can identify subtle patterns in large datasets collected during reliability testing, potentially revealing failure precursors before catastrophic breakdown occurs. Statistical analysis methods help distinguish between random failures and systematic issues related to design or manufacturing processes.

Non-destructive evaluation techniques are particularly valuable for AFM devices, as they preserve samples for subsequent analysis. These include acoustic microscopy for subsurface defect detection and thermoreflectance imaging for identifying hotspots that may indicate regions of excessive current flow or mechanical stress during operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!