Testing Standards And Metrics For AFM Device Performance

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM Technology Background and Objectives

Atomic Force Microscopy (AFM) has evolved significantly since its invention in 1986 by Gerd Binnig, Calvin Quate, and Christoph Gerber. This revolutionary scanning probe microscopy technique enables the visualization and measurement of surface topography at the nanoscale by detecting forces between a sharp probe and sample surface. Over the past four decades, AFM technology has transformed from a purely academic research tool into an essential instrument across multiple industries including semiconductor manufacturing, materials science, and biological research.

The evolution of AFM technology has been characterized by continuous improvements in resolution, scanning speed, and functionality. Early AFM systems operated primarily in contact mode with limited resolution and slow scanning speeds. Modern systems now incorporate multiple operational modes including tapping mode, non-contact mode, and various specialized techniques that can measure not only topography but also mechanical, electrical, magnetic, and thermal properties of samples.

Despite these advancements, the AFM industry faces significant challenges related to standardization and performance metrics. Unlike optical microscopy or electron microscopy, AFM lacks universally accepted testing standards and performance metrics, making it difficult for users to objectively compare instruments from different manufacturers or even evaluate the performance of a single instrument over time.

The primary objective of this technical research is to comprehensively examine the current landscape of testing standards and metrics for AFM device performance. This investigation aims to identify existing standardization efforts, evaluate their effectiveness, and propose potential frameworks for establishing industry-wide performance metrics that can be universally adopted.

A critical aspect of this research involves understanding how AFM performance is currently quantified across different application domains. Parameters such as spatial resolution, force sensitivity, scanning speed, noise levels, and measurement reproducibility are essential metrics, but their relative importance varies depending on the specific application. For instance, high-speed scanning capabilities may be crucial for industrial quality control applications, while ultimate force sensitivity might be more important for biological research.

The research will also explore emerging trends in AFM technology, including the integration of artificial intelligence for data processing, automated operation protocols, and hybrid systems that combine AFM with complementary techniques. These developments are reshaping performance expectations and necessitate new approaches to performance evaluation.

By establishing clear testing standards and metrics for AFM device performance, this research aims to facilitate more transparent comparison between instruments, accelerate technology development through benchmarking, and ultimately enhance the reliability and reproducibility of AFM measurements across scientific and industrial applications.

The evolution of AFM technology has been characterized by continuous improvements in resolution, scanning speed, and functionality. Early AFM systems operated primarily in contact mode with limited resolution and slow scanning speeds. Modern systems now incorporate multiple operational modes including tapping mode, non-contact mode, and various specialized techniques that can measure not only topography but also mechanical, electrical, magnetic, and thermal properties of samples.

Despite these advancements, the AFM industry faces significant challenges related to standardization and performance metrics. Unlike optical microscopy or electron microscopy, AFM lacks universally accepted testing standards and performance metrics, making it difficult for users to objectively compare instruments from different manufacturers or even evaluate the performance of a single instrument over time.

The primary objective of this technical research is to comprehensively examine the current landscape of testing standards and metrics for AFM device performance. This investigation aims to identify existing standardization efforts, evaluate their effectiveness, and propose potential frameworks for establishing industry-wide performance metrics that can be universally adopted.

A critical aspect of this research involves understanding how AFM performance is currently quantified across different application domains. Parameters such as spatial resolution, force sensitivity, scanning speed, noise levels, and measurement reproducibility are essential metrics, but their relative importance varies depending on the specific application. For instance, high-speed scanning capabilities may be crucial for industrial quality control applications, while ultimate force sensitivity might be more important for biological research.

The research will also explore emerging trends in AFM technology, including the integration of artificial intelligence for data processing, automated operation protocols, and hybrid systems that combine AFM with complementary techniques. These developments are reshaping performance expectations and necessitate new approaches to performance evaluation.

By establishing clear testing standards and metrics for AFM device performance, this research aims to facilitate more transparent comparison between instruments, accelerate technology development through benchmarking, and ultimately enhance the reliability and reproducibility of AFM measurements across scientific and industrial applications.

Market Demand Analysis for AFM Testing Standards

The global market for Atomic Force Microscopy (AFM) testing standards has experienced significant growth in recent years, driven primarily by increasing demand for nanoscale measurement precision across multiple industries. Current market analysis indicates that the AFM instrumentation market is valued at approximately $500 million globally, with a compound annual growth rate of 6.8% projected through 2028. This growth trajectory underscores the critical importance of standardized testing protocols and performance metrics.

The semiconductor industry represents the largest market segment demanding rigorous AFM testing standards, accounting for nearly 35% of the total market share. As semiconductor manufacturers continue to push toward smaller node sizes, the need for precise, reproducible AFM measurements becomes increasingly crucial for quality control and process optimization. Industry reports highlight that over 80% of leading semiconductor manufacturers have expressed concerns about inconsistencies in AFM measurement results across different instruments and laboratories.

Materials science research institutions constitute the second-largest market segment, representing approximately 28% of demand for standardized AFM testing. The reproducibility crisis in materials characterization has prompted calls for more robust standardization, with a recent survey of 150 research institutions revealing that 73% consider current AFM calibration and measurement standards inadequate for cutting-edge research applications.

Life sciences and pharmaceutical companies have emerged as the fastest-growing segment, with demand for AFM testing standards increasing at 9.2% annually. This surge is primarily driven by applications in drug delivery systems, biomaterial characterization, and cellular imaging, where quantitative measurements at the nanoscale directly impact product development and regulatory approval processes.

Geographically, North America leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the most rapid growth, particularly in China, South Korea, and Singapore, where significant investments in nanotechnology research infrastructure are creating new demand centers for standardized AFM testing protocols.

Customer pain points consistently identified across market segments include: lack of traceability to international measurement standards, poor inter-laboratory reproducibility, insufficient calibration protocols for specialized applications, and absence of application-specific performance metrics. A comprehensive industry survey conducted in 2022 revealed that 67% of AFM users consider standardization their most significant challenge when comparing results across different instruments or research groups.

The market analysis clearly indicates that establishing robust testing standards and performance metrics for AFM devices represents not only a technical necessity but also a significant commercial opportunity, with potential to unlock greater adoption of AFM technology across emerging application areas.

The semiconductor industry represents the largest market segment demanding rigorous AFM testing standards, accounting for nearly 35% of the total market share. As semiconductor manufacturers continue to push toward smaller node sizes, the need for precise, reproducible AFM measurements becomes increasingly crucial for quality control and process optimization. Industry reports highlight that over 80% of leading semiconductor manufacturers have expressed concerns about inconsistencies in AFM measurement results across different instruments and laboratories.

Materials science research institutions constitute the second-largest market segment, representing approximately 28% of demand for standardized AFM testing. The reproducibility crisis in materials characterization has prompted calls for more robust standardization, with a recent survey of 150 research institutions revealing that 73% consider current AFM calibration and measurement standards inadequate for cutting-edge research applications.

Life sciences and pharmaceutical companies have emerged as the fastest-growing segment, with demand for AFM testing standards increasing at 9.2% annually. This surge is primarily driven by applications in drug delivery systems, biomaterial characterization, and cellular imaging, where quantitative measurements at the nanoscale directly impact product development and regulatory approval processes.

Geographically, North America leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the most rapid growth, particularly in China, South Korea, and Singapore, where significant investments in nanotechnology research infrastructure are creating new demand centers for standardized AFM testing protocols.

Customer pain points consistently identified across market segments include: lack of traceability to international measurement standards, poor inter-laboratory reproducibility, insufficient calibration protocols for specialized applications, and absence of application-specific performance metrics. A comprehensive industry survey conducted in 2022 revealed that 67% of AFM users consider standardization their most significant challenge when comparing results across different instruments or research groups.

The market analysis clearly indicates that establishing robust testing standards and performance metrics for AFM devices represents not only a technical necessity but also a significant commercial opportunity, with potential to unlock greater adoption of AFM technology across emerging application areas.

Current State and Challenges in AFM Performance Metrics

Atomic Force Microscopy (AFM) has evolved significantly since its invention in 1986, becoming an essential tool for nanoscale imaging and characterization across multiple scientific disciplines. However, the field currently faces a critical challenge: the lack of standardized performance metrics and testing protocols. This inconsistency creates significant barriers to comparing instruments from different manufacturers, validating research results, and establishing reliable quality control measures.

Globally, AFM technology development shows geographic concentration in North America, Europe, and East Asia, with each region adopting slightly different approaches to performance evaluation. The United States and Germany lead in establishing preliminary standards, while Japan excels in precision engineering aspects of AFM instrumentation. China has rapidly expanded its AFM manufacturing capabilities but often follows divergent quality assessment frameworks.

The primary technical challenges in AFM performance metrics center around five key areas. First, probe characterization remains inconsistent, with variations in tip geometry, spring constant calibration, and resonance properties significantly affecting measurement outcomes. Second, environmental control parameters such as vibration isolation, acoustic shielding, and thermal stability lack standardized reporting formats, making cross-laboratory comparisons difficult.

Third, the field struggles with signal processing standardization, as different manufacturers implement proprietary algorithms for noise reduction, feedback control, and image processing that fundamentally alter the final data presentation. Fourth, resolution claims often lack verification through standardized test samples, with manufacturers using different reference materials and measurement conditions to showcase their instruments' capabilities.

Perhaps most challenging is the absence of application-specific performance metrics. AFM applications span from materials science to biological imaging, each requiring different optimization parameters. The performance metrics relevant for high-speed scanning may differ substantially from those critical for force spectroscopy or electrical characterization modes.

Recent international efforts through ISO technical committees have begun addressing these challenges, particularly through the development of the ISO/TC 201 standards for surface chemical analysis. However, implementation remains fragmented, with many laboratories continuing to rely on internally developed validation protocols rather than adopting emerging standards.

The economic implications of these challenges are substantial. The lack of standardization increases development costs, complicates procurement decisions for end-users, and creates market inefficiencies where technical superiority cannot be objectively demonstrated. Additionally, the reproducibility crisis affecting scientific research is exacerbated by inconsistent AFM performance reporting, potentially undermining confidence in nanoscale characterization data across disciplines.

Globally, AFM technology development shows geographic concentration in North America, Europe, and East Asia, with each region adopting slightly different approaches to performance evaluation. The United States and Germany lead in establishing preliminary standards, while Japan excels in precision engineering aspects of AFM instrumentation. China has rapidly expanded its AFM manufacturing capabilities but often follows divergent quality assessment frameworks.

The primary technical challenges in AFM performance metrics center around five key areas. First, probe characterization remains inconsistent, with variations in tip geometry, spring constant calibration, and resonance properties significantly affecting measurement outcomes. Second, environmental control parameters such as vibration isolation, acoustic shielding, and thermal stability lack standardized reporting formats, making cross-laboratory comparisons difficult.

Third, the field struggles with signal processing standardization, as different manufacturers implement proprietary algorithms for noise reduction, feedback control, and image processing that fundamentally alter the final data presentation. Fourth, resolution claims often lack verification through standardized test samples, with manufacturers using different reference materials and measurement conditions to showcase their instruments' capabilities.

Perhaps most challenging is the absence of application-specific performance metrics. AFM applications span from materials science to biological imaging, each requiring different optimization parameters. The performance metrics relevant for high-speed scanning may differ substantially from those critical for force spectroscopy or electrical characterization modes.

Recent international efforts through ISO technical committees have begun addressing these challenges, particularly through the development of the ISO/TC 201 standards for surface chemical analysis. However, implementation remains fragmented, with many laboratories continuing to rely on internally developed validation protocols rather than adopting emerging standards.

The economic implications of these challenges are substantial. The lack of standardization increases development costs, complicates procurement decisions for end-users, and creates market inefficiencies where technical superiority cannot be objectively demonstrated. Additionally, the reproducibility crisis affecting scientific research is exacerbated by inconsistent AFM performance reporting, potentially undermining confidence in nanoscale characterization data across disciplines.

Existing AFM Performance Evaluation Solutions

01 Probe design and optimization for AFM performance

The design and optimization of AFM probes significantly impacts device performance. Advanced probe designs incorporate specialized materials and geometries to enhance sensitivity, durability, and measurement accuracy. Innovations include multi-functional probes capable of simultaneous measurements, temperature-resistant probes for thermal applications, and probes with optimized tip shapes for specific sample interactions. These design improvements allow for higher resolution imaging, reduced noise, and more reliable measurements across various operating conditions.- Probe design and optimization for AFM: The design and optimization of probes are crucial for AFM device performance. Advanced probe designs incorporate specialized materials and geometries to enhance sensitivity and resolution. Innovations include cantilevers with optimized spring constants, tip shapes engineered for specific applications, and probes with integrated functionalities. These design improvements allow for more accurate measurements of surface topography and mechanical properties at the nanoscale.

- Feedback control systems for AFM performance enhancement: Sophisticated feedback control systems are essential for improving AFM device performance. These systems continuously monitor and adjust the probe-sample interaction forces to maintain optimal imaging conditions. Advanced algorithms process signals in real-time to compensate for thermal drift, vibration, and other environmental factors. Implementation of digital signal processing techniques and adaptive control mechanisms significantly enhances measurement stability, accuracy, and reproducibility across various operating conditions.

- Environmental control for improved AFM measurements: Environmental control systems significantly impact AFM device performance. Temperature stabilization, vibration isolation, and acoustic shielding are critical for high-resolution imaging. Humidity and atmospheric composition control enables more consistent measurements, especially for samples sensitive to environmental conditions. Advanced AFM systems incorporate integrated environmental chambers that maintain stable conditions throughout the measurement process, resulting in higher precision and reproducibility of nanoscale characterization.

- High-speed and dynamic AFM technologies: High-speed AFM technologies enable real-time observation of dynamic processes at the nanoscale. These systems incorporate faster scanning mechanisms, optimized cantilevers with higher resonance frequencies, and advanced data acquisition systems. Innovations in actuator design and signal processing allow for rapid image acquisition while maintaining resolution. Dynamic AFM modes provide insights into time-dependent phenomena and mechanical properties of samples, expanding the application range of atomic force microscopy in materials science and biology.

- Integration of AFM with complementary analytical techniques: Integration of AFM with complementary analytical techniques enhances overall device performance and expands measurement capabilities. Combined systems may incorporate optical microscopy, Raman spectroscopy, or electrical measurement capabilities alongside AFM functionality. These hybrid instruments enable simultaneous acquisition of topographical, chemical, and physical property data from the same sample region. Correlative approaches provide more comprehensive characterization of complex materials and biological systems at the nanoscale.

02 Vibration isolation and noise reduction systems

Vibration isolation and noise reduction systems are critical for enhancing AFM device performance. These systems employ various technologies including active and passive damping mechanisms, acoustic isolation chambers, and advanced signal processing algorithms to minimize environmental disturbances. By reducing mechanical vibrations, acoustic noise, and electromagnetic interference, these systems enable more stable tip-sample interactions, resulting in higher resolution imaging and more accurate force measurements, particularly for nanoscale applications requiring atomic-level precision.Expand Specific Solutions03 Feedback control and signal processing improvements

Advanced feedback control systems and signal processing techniques significantly enhance AFM performance. These improvements include real-time adaptive control algorithms, digital signal processing for noise filtering, and high-speed data acquisition systems. By optimizing the feedback loop response and implementing sophisticated signal analysis methods, these technologies enable faster scanning speeds, improved tracking of surface features, and enhanced measurement precision. These advancements are particularly valuable for dynamic mode operations and for imaging biological samples or other delicate materials.Expand Specific Solutions04 Integration of multiple measurement capabilities

Modern AFM devices incorporate multiple measurement capabilities within a single instrument to enhance versatility and performance. These integrated systems combine traditional topographical imaging with additional functionalities such as electrical conductivity measurement, thermal analysis, magnetic force detection, and chemical characterization. By enabling simultaneous multi-parameter measurements, these advanced AFM systems provide more comprehensive sample analysis, reduce measurement time, and allow for correlation between different physical properties at the nanoscale level.Expand Specific Solutions05 Environmental control systems for AFM operation

Environmental control systems significantly improve AFM device performance by maintaining optimal operating conditions. These systems regulate temperature, humidity, atmospheric composition, and pressure during measurements. Advanced environmental chambers allow for in-situ experiments under controlled gas environments, liquid immersion, or variable temperatures. By minimizing thermal drift, reducing sample contamination, and enabling measurements in native sample environments, these systems enhance measurement stability, reproducibility, and applicability to a wider range of materials and research questions.Expand Specific Solutions

Key Industry Players in AFM Device Manufacturing

The AFM device performance testing standards and metrics market is in a growth phase, characterized by increasing demand for standardized measurement protocols across research and industrial applications. The market size is expanding due to rising adoption in semiconductor, materials science, and nanotechnology sectors, projected to reach significant value in the coming years. Regarding technical maturity, established players like Bruker Nano and Oxford Instruments Asylum Research lead with comprehensive testing solutions, while DENSO, Agilent Technologies, and KIOXIA contribute industry-specific innovations. Academic institutions including Kanazawa University, Northwestern University, and Wuhan University are advancing fundamental research, while research organizations like Industrial Technology Research Institute and Naval Research Laboratory bridge the gap between theoretical standards and practical implementation.

Bruker Nano, Inc.

Technical Solution: Bruker Nano has developed comprehensive testing standards and metrics for AFM device performance through their PeakForce Tapping technology. This proprietary technology enables simultaneous acquisition of multiple material properties while protecting both tip and sample. Their standardized approach includes calibration protocols that ensure consistent force measurements across different instruments and operators. Bruker's testing framework incorporates automated probe calibration, drift correction algorithms, and real-time feedback systems that maintain measurement accuracy even during environmental fluctuations. Their metrics system quantifies AFM performance through resolution parameters (both lateral and vertical), force sensitivity measurements, and noise floor characterization across different operational modes. Bruker has established industry benchmarks for thermal stability (< 0.2 nm/°C drift) and vibration isolation performance that have become de facto standards in the field.

Strengths: Industry-leading calibration protocols that ensure measurement reproducibility across instruments; comprehensive performance metrics that address both hardware capabilities and application-specific requirements. Weaknesses: Proprietary nature of some testing standards limits universal adoption; relatively high cost of implementation for smaller research facilities.

Oxford Instruments Asylum Research, Inc.

Technical Solution: Oxford Instruments Asylum Research has pioneered the development of standardized AFM performance metrics through their Cypher and Jupiter AFM systems. Their approach focuses on quantifiable performance parameters including noise floor measurements (< 25 pm in typical imaging conditions), drift rates (< 0.2 nm/min), and closed-loop positioning accuracy. Their testing standards incorporate environmental control parameters, establishing performance benchmarks under varying temperature, humidity, and atmospheric conditions. Asylum Research has developed the GetReal™ automated probe calibration system that standardizes cantilever spring constant calibration, reducing operator variability and enabling consistent force measurements across different instruments. Their performance metrics framework includes standardized test samples with known topographical features that allow for objective comparison between different AFM systems and operational modes. Additionally, they've established protocols for measuring and reporting tip-sample interaction forces, resonance quality factors, and bandwidth limitations in dynamic AFM modes.

Strengths: Exceptional noise floor performance metrics that enable atomic-resolution imaging; automated calibration systems that reduce operator-dependent variability. Weaknesses: Some performance metrics are optimized for specific research applications rather than general industrial use; limited standardization across different manufacturer platforms.

Critical Technical Standards for AFM Measurement Accuracy

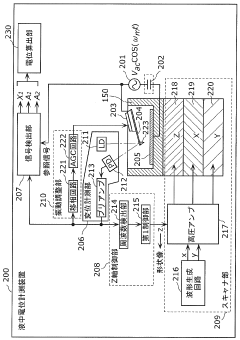

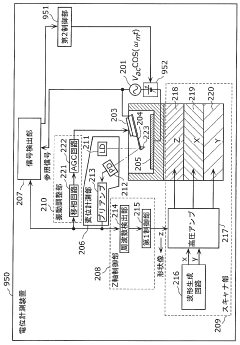

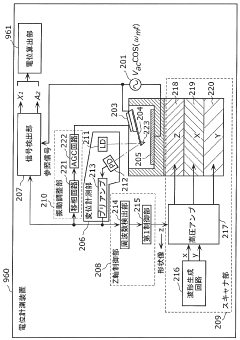

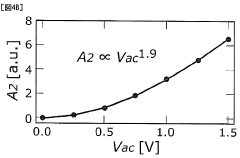

Device for measuring in-liquid electric potential, and atomic force microscope

PatentWO2012060033A1

Innovation

- A liquid potential measuring device using an AFM with an AC bias voltage of 10 kHz or higher, a capacitor to remove DC components, and a signal detection unit to output specific frequency components, allowing for accurate surface potential measurement by suppressing electrochemical reactions and ion rearrangement.

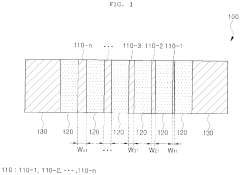

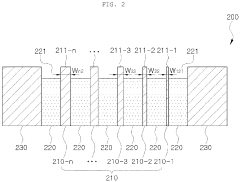

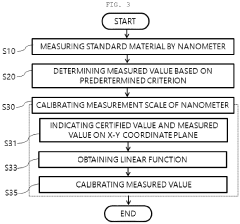

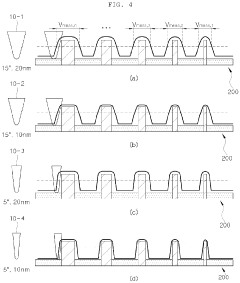

Method for calibrating NANO measurement scale and standard material used therein

PatentPendingEP4016090A1

Innovation

- A method involving a standard material with a series of nanostructures of certified values of different sizes, alternately stacked with intermediate layers, is used to calibrate the microscope measurement scale by measuring widths and determining deviations, allowing for linear fitting and calibration of measured values to align with certified values.

International Standardization Efforts for AFM Devices

The standardization of Atomic Force Microscopy (AFM) has evolved significantly over the past three decades, with several international bodies taking leading roles in establishing uniform testing protocols and performance metrics. The International Organization for Standardization (ISO) has been at the forefront through its Technical Committee 201 (ISO/TC 201), specifically focusing on surface chemical analysis, which includes AFM methodologies. This committee has published several standards, including ISO 11775 and ISO 18115, which provide terminology and operational guidelines for AFM devices.

The American Society for Testing and Materials (ASTM) has also contributed substantially through its Committee E42 on Surface Analysis, developing standards like ASTM E2382 for calibration of AFM Z-axis measurements. These standards have been crucial for ensuring measurement consistency across different laboratories and instrument manufacturers.

In Europe, the European Committee for Standardization (CEN) has worked in conjunction with ISO to adopt harmonized standards, particularly important for AFM manufacturers seeking compliance with European market regulations. The European Metrology Research Programme (EMRP) has funded projects specifically aimed at developing traceable measurement capabilities for nanoscale dimensions using AFM.

The Asia-Pacific region has seen increasing participation in standardization efforts, with the Japan Industrial Standards Committee (JISC) and the China National Institute of Standardization (CNIS) developing complementary standards that address specific regional manufacturing considerations while maintaining compatibility with international frameworks.

Recent collaborative initiatives have focused on developing reference materials and calibration artifacts specifically designed for AFM performance verification. The International Bureau of Weights and Measures (BIPM) has coordinated international comparisons of AFM measurements to establish traceability to the SI unit system, essential for quantitative analysis across borders.

A significant trend in current standardization efforts is the move toward application-specific standards rather than generic AFM protocols. This includes specialized standards for biological samples, semiconductor metrology, and nanomaterial characterization, recognizing that different applications require tailored approaches to measurement and data interpretation.

The integration of digital data formats and metadata standards has also become a priority, with initiatives like the FAIR (Findable, Accessible, Interoperable, Reusable) principles being incorporated into AFM data management standards, facilitating more effective data sharing and analysis across the global scientific community.

The American Society for Testing and Materials (ASTM) has also contributed substantially through its Committee E42 on Surface Analysis, developing standards like ASTM E2382 for calibration of AFM Z-axis measurements. These standards have been crucial for ensuring measurement consistency across different laboratories and instrument manufacturers.

In Europe, the European Committee for Standardization (CEN) has worked in conjunction with ISO to adopt harmonized standards, particularly important for AFM manufacturers seeking compliance with European market regulations. The European Metrology Research Programme (EMRP) has funded projects specifically aimed at developing traceable measurement capabilities for nanoscale dimensions using AFM.

The Asia-Pacific region has seen increasing participation in standardization efforts, with the Japan Industrial Standards Committee (JISC) and the China National Institute of Standardization (CNIS) developing complementary standards that address specific regional manufacturing considerations while maintaining compatibility with international frameworks.

Recent collaborative initiatives have focused on developing reference materials and calibration artifacts specifically designed for AFM performance verification. The International Bureau of Weights and Measures (BIPM) has coordinated international comparisons of AFM measurements to establish traceability to the SI unit system, essential for quantitative analysis across borders.

A significant trend in current standardization efforts is the move toward application-specific standards rather than generic AFM protocols. This includes specialized standards for biological samples, semiconductor metrology, and nanomaterial characterization, recognizing that different applications require tailored approaches to measurement and data interpretation.

The integration of digital data formats and metadata standards has also become a priority, with initiatives like the FAIR (Findable, Accessible, Interoperable, Reusable) principles being incorporated into AFM data management standards, facilitating more effective data sharing and analysis across the global scientific community.

Cross-Industry Applications of AFM Testing Metrics

Atomic Force Microscopy (AFM) testing metrics have transcended their original scientific research applications to become integral tools across diverse industries. In the semiconductor sector, AFM metrics provide critical nanoscale measurements for quality control in chip manufacturing, with resolution parameters and force calibration standards enabling precise evaluation of surface topography and material properties. These metrics have become essential benchmarks for production processes where nanometer-level precision directly impacts device performance and reliability.

The biomedical field has adapted AFM testing metrics for characterizing biomaterials, cellular structures, and pharmaceutical compounds. Specialized metrics for measuring biomechanical properties, such as cell elasticity and adhesion forces, have been standardized to ensure consistency in medical device development and drug delivery systems. The healthcare industry increasingly relies on these quantifiable measurements to validate biocompatibility and functionality of implantable devices.

Materials science and manufacturing industries employ AFM metrics as quality assurance tools for surface roughness analysis, coating uniformity assessment, and defect identification. Standardized roughness parameters (Ra, Rq) and hardness measurements provide comparable data across production facilities worldwide, facilitating global supply chain quality management. These metrics have been incorporated into international manufacturing standards, creating common reference points for material performance evaluation.

The energy sector utilizes AFM testing metrics for characterizing advanced materials in battery technology, solar cells, and fuel cells. Conductivity mapping and nanomechanical property measurements help optimize energy storage and conversion efficiency. Specialized metrics for evaluating degradation mechanisms have become particularly valuable for predicting service life and performance stability of energy components under various environmental conditions.

In environmental monitoring, AFM metrics provide standardized approaches for analyzing particulate matter, microplastics, and contaminants at nanoscale levels. Quantitative parameters for particle size distribution, surface charge, and aggregation behavior enable meaningful comparisons between different environmental samples and monitoring locations. These applications demonstrate how AFM testing metrics have evolved from laboratory curiosities to essential industrial tools with cross-disciplinary impact.

The aerospace and automotive industries have adopted AFM metrics for evaluating high-performance coatings, composite materials, and tribological interfaces. Standardized wear resistance measurements and surface texture parameters help predict component durability under extreme conditions, translating microscopic properties into macroscopic performance predictions for critical safety systems.

The biomedical field has adapted AFM testing metrics for characterizing biomaterials, cellular structures, and pharmaceutical compounds. Specialized metrics for measuring biomechanical properties, such as cell elasticity and adhesion forces, have been standardized to ensure consistency in medical device development and drug delivery systems. The healthcare industry increasingly relies on these quantifiable measurements to validate biocompatibility and functionality of implantable devices.

Materials science and manufacturing industries employ AFM metrics as quality assurance tools for surface roughness analysis, coating uniformity assessment, and defect identification. Standardized roughness parameters (Ra, Rq) and hardness measurements provide comparable data across production facilities worldwide, facilitating global supply chain quality management. These metrics have been incorporated into international manufacturing standards, creating common reference points for material performance evaluation.

The energy sector utilizes AFM testing metrics for characterizing advanced materials in battery technology, solar cells, and fuel cells. Conductivity mapping and nanomechanical property measurements help optimize energy storage and conversion efficiency. Specialized metrics for evaluating degradation mechanisms have become particularly valuable for predicting service life and performance stability of energy components under various environmental conditions.

In environmental monitoring, AFM metrics provide standardized approaches for analyzing particulate matter, microplastics, and contaminants at nanoscale levels. Quantitative parameters for particle size distribution, surface charge, and aggregation behavior enable meaningful comparisons between different environmental samples and monitoring locations. These applications demonstrate how AFM testing metrics have evolved from laboratory curiosities to essential industrial tools with cross-disciplinary impact.

The aerospace and automotive industries have adopted AFM metrics for evaluating high-performance coatings, composite materials, and tribological interfaces. Standardized wear resistance measurements and surface texture parameters help predict component durability under extreme conditions, translating microscopic properties into macroscopic performance predictions for critical safety systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!