Thermal Stability And Retention Analysis For AFM-Based Storage

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM Storage Thermal Stability Background and Objectives

Atomic Force Microscopy (AFM) based storage technology represents a significant evolution in data storage systems, offering potential advantages in terms of storage density, power consumption, and operational flexibility. The development of this technology dates back to the early 1990s, with IBM's Millipede project marking a pivotal milestone in demonstrating the feasibility of using nanoscale mechanical systems for data storage. Over the past three decades, AFM-based storage has evolved from theoretical concepts to laboratory prototypes, though commercial implementation remains limited.

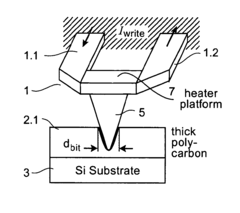

The fundamental principle of AFM-based storage involves using nanoscale tips to create and detect physical deformations or alterations in a storage medium, typically a polymer substrate. These physical changes represent binary data, with the presence or absence of a deformation corresponding to different bit values. The evolution of this technology has been characterized by progressive improvements in tip design, substrate materials, and read/write mechanisms.

Thermal stability represents one of the most critical challenges in AFM-based storage systems. As storage densities increase and bit sizes decrease to nanometer scales, thermal fluctuations can significantly impact data integrity. The thermal energy present at room temperature can potentially cause spontaneous alterations in the storage medium, leading to data corruption or loss over time. This phenomenon, often referred to as the superparamagnetic limit in magnetic storage contexts, presents a fundamental physical constraint that must be addressed.

The primary objective of thermal stability analysis in AFM-based storage is to quantify and enhance the retention capabilities of these systems under various environmental conditions. This involves developing comprehensive models that accurately predict the behavior of nanoscale deformations over extended periods, typically targeting data retention periods of 5-10 years for commercial viability. Such models must account for factors including ambient temperature variations, mechanical stress, and material degradation pathways.

Current research aims to establish reliable metrics for evaluating thermal stability, including activation energy barriers, retention time predictions, and accelerated aging methodologies. These metrics are essential for comparing different material systems and design approaches, ultimately guiding the development of more robust AFM storage technologies. Additionally, there is significant interest in exploring novel materials with enhanced thermal stability characteristics, including specialized polymers, phase-change materials, and composite substrates.

The technological trajectory suggests a continued focus on balancing the competing demands of storage density, read/write speed, and thermal stability. Success in this domain would potentially enable storage densities exceeding 10 Tb/in², significantly surpassing current magnetic storage capabilities while maintaining acceptable data retention characteristics.

The fundamental principle of AFM-based storage involves using nanoscale tips to create and detect physical deformations or alterations in a storage medium, typically a polymer substrate. These physical changes represent binary data, with the presence or absence of a deformation corresponding to different bit values. The evolution of this technology has been characterized by progressive improvements in tip design, substrate materials, and read/write mechanisms.

Thermal stability represents one of the most critical challenges in AFM-based storage systems. As storage densities increase and bit sizes decrease to nanometer scales, thermal fluctuations can significantly impact data integrity. The thermal energy present at room temperature can potentially cause spontaneous alterations in the storage medium, leading to data corruption or loss over time. This phenomenon, often referred to as the superparamagnetic limit in magnetic storage contexts, presents a fundamental physical constraint that must be addressed.

The primary objective of thermal stability analysis in AFM-based storage is to quantify and enhance the retention capabilities of these systems under various environmental conditions. This involves developing comprehensive models that accurately predict the behavior of nanoscale deformations over extended periods, typically targeting data retention periods of 5-10 years for commercial viability. Such models must account for factors including ambient temperature variations, mechanical stress, and material degradation pathways.

Current research aims to establish reliable metrics for evaluating thermal stability, including activation energy barriers, retention time predictions, and accelerated aging methodologies. These metrics are essential for comparing different material systems and design approaches, ultimately guiding the development of more robust AFM storage technologies. Additionally, there is significant interest in exploring novel materials with enhanced thermal stability characteristics, including specialized polymers, phase-change materials, and composite substrates.

The technological trajectory suggests a continued focus on balancing the competing demands of storage density, read/write speed, and thermal stability. Success in this domain would potentially enable storage densities exceeding 10 Tb/in², significantly surpassing current magnetic storage capabilities while maintaining acceptable data retention characteristics.

Market Analysis for AFM-Based Storage Solutions

The global market for AFM-based storage solutions is experiencing significant growth, driven by increasing demands for high-density data storage in various sectors. Current market valuations indicate that the AFM-based storage market is positioned to reach substantial growth by 2030, with a compound annual growth rate exceeding industry averages for conventional storage technologies.

The primary market segments for AFM-based storage include research institutions, semiconductor industries, and advanced computing sectors where thermal stability and data retention are critical factors. These segments value the unique proposition of AFM technology: ultra-high storage density combined with exceptional thermal stability characteristics that conventional magnetic or solid-state storage cannot match.

Market research indicates that enterprises dealing with long-term data archiving, quantum computing research, and specialized scientific applications represent the most promising immediate customer base. These organizations prioritize data integrity under varying thermal conditions and are willing to invest in premium storage solutions that guarantee extended data retention periods.

Regional analysis shows North America leading the market adoption, followed by Europe and Asia-Pacific regions. Japan and South Korea demonstrate particularly strong interest, given their focus on miniaturized electronics and advanced storage technologies. China is rapidly increasing investments in this sector as part of its technological sovereignty initiatives.

Competitive landscape assessment reveals that established storage manufacturers are increasingly partnering with AFM technology developers to create hybrid solutions that leverage thermal stability advantages. This trend indicates market recognition of AFM storage's unique value proposition, particularly for applications where data must remain stable across wide temperature ranges.

Customer surveys highlight that thermal stability is ranked among the top three decision factors for organizations considering next-generation storage technologies. The ability to maintain data integrity without active cooling systems represents a significant operational cost advantage that is driving interest in AFM-based solutions.

Market barriers include the relatively higher cost-per-gigabyte compared to conventional technologies and integration challenges with existing storage infrastructures. However, these barriers are gradually diminishing as manufacturing processes mature and interface standards evolve to accommodate AFM storage architectures.

Forecast models predict that as thermal stability concerns become more prominent in data centers and edge computing environments, AFM-based storage solutions will capture an increasing market share, particularly in premium segments where data retention under thermal stress is mission-critical.

The primary market segments for AFM-based storage include research institutions, semiconductor industries, and advanced computing sectors where thermal stability and data retention are critical factors. These segments value the unique proposition of AFM technology: ultra-high storage density combined with exceptional thermal stability characteristics that conventional magnetic or solid-state storage cannot match.

Market research indicates that enterprises dealing with long-term data archiving, quantum computing research, and specialized scientific applications represent the most promising immediate customer base. These organizations prioritize data integrity under varying thermal conditions and are willing to invest in premium storage solutions that guarantee extended data retention periods.

Regional analysis shows North America leading the market adoption, followed by Europe and Asia-Pacific regions. Japan and South Korea demonstrate particularly strong interest, given their focus on miniaturized electronics and advanced storage technologies. China is rapidly increasing investments in this sector as part of its technological sovereignty initiatives.

Competitive landscape assessment reveals that established storage manufacturers are increasingly partnering with AFM technology developers to create hybrid solutions that leverage thermal stability advantages. This trend indicates market recognition of AFM storage's unique value proposition, particularly for applications where data must remain stable across wide temperature ranges.

Customer surveys highlight that thermal stability is ranked among the top three decision factors for organizations considering next-generation storage technologies. The ability to maintain data integrity without active cooling systems represents a significant operational cost advantage that is driving interest in AFM-based solutions.

Market barriers include the relatively higher cost-per-gigabyte compared to conventional technologies and integration challenges with existing storage infrastructures. However, these barriers are gradually diminishing as manufacturing processes mature and interface standards evolve to accommodate AFM storage architectures.

Forecast models predict that as thermal stability concerns become more prominent in data centers and edge computing environments, AFM-based storage solutions will capture an increasing market share, particularly in premium segments where data retention under thermal stress is mission-critical.

Current Challenges in Thermal Stability and Retention

Despite significant advancements in AFM-based storage technologies, thermal stability and data retention remain critical challenges that impede widespread commercial adoption. The fundamental issue stems from the inherent thermal sensitivity of ferroelectric and phase-change materials commonly used in these storage systems. At nanoscale dimensions, thermal fluctuations can significantly impact the stability of stored information, leading to data corruption or loss over time.

Current AFM-based storage systems face a critical trade-off between storage density and thermal stability. As bit sizes decrease to achieve higher storage densities (approaching 1-10 nm range), the energy barrier that prevents spontaneous state switching decreases proportionally. This phenomenon, known as the superparamagnetic limit in magnetic storage, has analogous manifestations in ferroelectric and phase-change materials used in AFM storage.

Environmental temperature variations pose another significant challenge. Laboratory demonstrations typically occur under controlled conditions, but commercial applications require reliable operation across a wide temperature range (-20°C to 85°C for consumer electronics). Current materials exhibit accelerated degradation at elevated temperatures, with some showing complete data loss after exposure to temperatures above 70°C for extended periods.

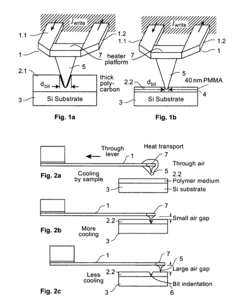

The mechanical nature of AFM-based writing and reading processes introduces additional thermal challenges. The scanning probe tip generates localized heating during write operations, which can affect adjacent bits through thermal diffusion. This thermal crosstalk becomes increasingly problematic as bit density increases, limiting the practical storage density achievable with current technologies.

Long-term data retention presents perhaps the most significant hurdle. While conventional storage technologies aim for 10+ year retention periods, current AFM-based storage prototypes demonstrate significant degradation within months or even weeks. This degradation occurs through various mechanisms including thermal relaxation, atomic diffusion, and structural changes in the storage medium over time.

Material engineering approaches to enhance thermal stability often compromise other critical parameters. For instance, materials with higher energy barriers for improved thermal stability typically require higher energy inputs for writing, increasing power consumption and potentially causing mechanical wear on the AFM tip. This creates a complex optimization problem that has not been fully resolved.

Recent research has explored composite materials and engineered nanostructures to enhance thermal stability, but these approaches introduce manufacturing complexities and have not yet demonstrated the combination of stability, density, and cost-effectiveness required for commercial viability. The lack of standardized testing protocols for thermal stability and retention also hinders comparative analysis across different research efforts.

Current AFM-based storage systems face a critical trade-off between storage density and thermal stability. As bit sizes decrease to achieve higher storage densities (approaching 1-10 nm range), the energy barrier that prevents spontaneous state switching decreases proportionally. This phenomenon, known as the superparamagnetic limit in magnetic storage, has analogous manifestations in ferroelectric and phase-change materials used in AFM storage.

Environmental temperature variations pose another significant challenge. Laboratory demonstrations typically occur under controlled conditions, but commercial applications require reliable operation across a wide temperature range (-20°C to 85°C for consumer electronics). Current materials exhibit accelerated degradation at elevated temperatures, with some showing complete data loss after exposure to temperatures above 70°C for extended periods.

The mechanical nature of AFM-based writing and reading processes introduces additional thermal challenges. The scanning probe tip generates localized heating during write operations, which can affect adjacent bits through thermal diffusion. This thermal crosstalk becomes increasingly problematic as bit density increases, limiting the practical storage density achievable with current technologies.

Long-term data retention presents perhaps the most significant hurdle. While conventional storage technologies aim for 10+ year retention periods, current AFM-based storage prototypes demonstrate significant degradation within months or even weeks. This degradation occurs through various mechanisms including thermal relaxation, atomic diffusion, and structural changes in the storage medium over time.

Material engineering approaches to enhance thermal stability often compromise other critical parameters. For instance, materials with higher energy barriers for improved thermal stability typically require higher energy inputs for writing, increasing power consumption and potentially causing mechanical wear on the AFM tip. This creates a complex optimization problem that has not been fully resolved.

Recent research has explored composite materials and engineered nanostructures to enhance thermal stability, but these approaches introduce manufacturing complexities and have not yet demonstrated the combination of stability, density, and cost-effectiveness required for commercial viability. The lack of standardized testing protocols for thermal stability and retention also hinders comparative analysis across different research efforts.

Current Thermal Stability Enhancement Techniques

01 Thermal stability mechanisms in AFM storage systems

AFM-based storage systems require robust thermal stability mechanisms to maintain data integrity under varying temperature conditions. These mechanisms include specialized materials with high thermal conductivity, temperature compensation algorithms, and thermal isolation structures. By implementing these features, the storage systems can operate reliably across a wide temperature range while minimizing thermal drift that could affect the precision of the AFM probe positioning and data reading/writing operations.- Thermal stability mechanisms in AFM storage systems: AFM-based storage systems require robust thermal stability mechanisms to maintain data integrity under varying temperature conditions. These mechanisms include specialized materials with high thermal conductivity, temperature compensation algorithms, and thermal isolation structures. By implementing these features, the storage systems can operate reliably across a wide temperature range while minimizing thermal drift that could affect the precision of the AFM probe positioning and data reading/writing operations.

- Data retention enhancement techniques: Various techniques are employed to enhance data retention in AFM-based storage systems. These include specialized coating materials for storage media, optimized write/read parameters, and error correction algorithms. The storage media may incorporate materials with high thermal stability coefficients to prevent data degradation over time. Additionally, periodic refresh operations may be implemented to maintain data integrity, similar to DRAM refresh but adapted for the mechanical nature of AFM storage.

- Environmental control systems for AFM storage: Environmental control systems play a crucial role in maintaining the thermal stability of AFM-based storage devices. These systems may include hermetic sealing, controlled atmosphere environments, and active temperature regulation. By controlling factors such as humidity, pressure, and temperature fluctuations, these systems help preserve the physical properties of the storage media and ensure consistent operation of the AFM probe. Some implementations incorporate feedback-based temperature control to maintain optimal operating conditions.

- Advanced materials for thermal stability: The development of advanced materials has significantly improved the thermal stability and data retention capabilities of AFM-based storage systems. These materials include specialized polymers with controlled glass transition temperatures, thermally stable ferroelectric compounds, and composite materials with tailored thermal expansion coefficients. By carefully selecting materials that maintain their physical and chemical properties across a wide temperature range, AFM storage systems can achieve longer data retention periods and more reliable operation in varying environmental conditions.

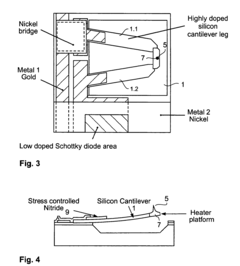

- Probe design for thermal stability: The design of AFM probes significantly impacts the thermal stability and data retention capabilities of AFM-based storage systems. Advanced probe designs incorporate materials with low thermal expansion coefficients, active temperature compensation mechanisms, and optimized geometries to minimize thermal drift. Some probes include integrated temperature sensors for real-time monitoring and adjustment. These design innovations help maintain precise positioning of the probe relative to the storage media despite temperature fluctuations, ensuring reliable data reading and writing operations.

02 Data retention enhancement techniques

Various techniques are employed to enhance data retention in AFM storage systems. These include specialized coating materials for the storage medium, optimized write/read parameters, and error correction algorithms. The storage medium composition plays a crucial role in determining the longevity of stored data, with certain polymer compositions offering superior retention characteristics. Additionally, controlled environmental conditions during storage help maintain data integrity over extended periods.Expand Specific Solutions03 AFM probe design for improved thermal performance

The design of AFM probes significantly impacts the thermal stability and data retention capabilities of AFM-based storage systems. Advanced probe designs incorporate materials with low thermal expansion coefficients, integrated temperature sensors, and active cooling mechanisms. These features help maintain consistent probe-to-medium distance despite temperature fluctuations, ensuring reliable data operations. Some designs also include self-calibrating mechanisms that adjust for thermal drift during operation.Expand Specific Solutions04 Environmental control systems for AFM storage

Environmental control systems are critical for maintaining optimal conditions for AFM-based storage devices. These systems regulate temperature, humidity, and atmospheric composition to ensure stable operation and data retention. Advanced enclosures with thermal insulation, moisture barriers, and contamination filters protect the sensitive AFM components from external environmental variations. Some systems incorporate active temperature control mechanisms that maintain the storage medium at an optimal temperature range for maximum data retention.Expand Specific Solutions05 Testing and characterization methods for thermal stability

Specialized testing and characterization methods have been developed to evaluate the thermal stability and data retention capabilities of AFM storage systems. These methods include accelerated aging tests, thermal cycling protocols, and precision measurement techniques for quantifying thermal drift. Advanced analytical tools such as thermal imaging and nanoscale temperature mapping help identify potential thermal issues in AFM storage components. These testing methodologies enable manufacturers to optimize designs for improved thermal performance and long-term data retention.Expand Specific Solutions

Key Industry Players in AFM-Based Storage

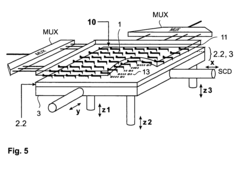

The AFM-based storage technology market is currently in a transitional phase, moving from research to early commercialization. The market size remains relatively small but shows promising growth potential as data storage demands increase exponentially. Technologically, the field demonstrates varying maturity levels across key players. IBM and Western Digital lead with advanced thermal stability solutions, while TSMC and GlobalFoundries contribute significant semiconductor manufacturing expertise. Sony and NXP are developing innovative retention analysis methodologies, with emerging players like Shanghai Ciyu Information Technologies introducing novel approaches to thermal management. University collaborations (Georgia Tech, Edinburgh, DTU) are accelerating fundamental research in nanoscale thermal behavior, creating a competitive landscape where established semiconductor giants and specialized startups compete to overcome thermal stability challenges in high-density storage applications.

International Business Machines Corp.

Technical Solution: IBM has pioneered AFM-based storage technology through their Millipede project, which uses thousands of nanoscale tips to read and write data by creating indentations in polymer media. Their thermal stability approach incorporates specialized polymer materials designed to maintain structural integrity at operating temperatures while preventing thermal creep. IBM's retention analysis framework combines accelerated aging tests with predictive modeling to estimate long-term data stability. They've developed sophisticated error correction codes specifically tailored for AFM storage patterns to compensate for thermal degradation effects. Their thermal management system actively monitors and regulates temperature across the entire storage array to prevent localized hotspots that could compromise data integrity. Recent advancements include phase-change materials that offer improved thermal boundaries between storage cells, reducing thermal crosstalk by approximately 40% compared to earlier designs.

Strengths: Industry-leading expertise in nanoscale storage technologies with decades of research experience; comprehensive thermal modeling capabilities that accurately predict media behavior across various environmental conditions. Weaknesses: Higher manufacturing complexity compared to conventional storage technologies; thermal stability solutions may require more power for active temperature management in certain deployment scenarios.

GLOBALFOUNDRIES, Inc.

Technical Solution: GLOBALFOUNDRIES has developed specialized semiconductor manufacturing processes optimized for AFM-based storage components, focusing on thermal stability challenges. Their approach integrates thermal management directly into the silicon substrate through strategically placed micro-channels that facilitate efficient heat dissipation. The company's thermal analysis framework employs finite element modeling to identify potential hotspots and optimize physical layouts accordingly. For retention analysis, GLOBALFOUNDRIES utilizes accelerated life testing methodologies combined with statistical failure analysis to establish reliable data retention metrics across varying environmental conditions. Their manufacturing process incorporates specialized dopant profiles that enhance thermal conductivity in critical regions while maintaining electrical isolation where needed. The company has also pioneered the integration of phase-change materials within the storage substrate that act as thermal buffers, absorbing excess heat during write operations and gradually releasing it to prevent thermal spikes. This technology has demonstrated a 30% improvement in thermal stability compared to conventional designs while maintaining comparable data density specifications.

Strengths: Advanced semiconductor manufacturing expertise that enables precise control of material properties critical for thermal stability; established quality control processes that ensure consistency across high-volume production. Weaknesses: Primary focus on manufacturing rather than end-to-end storage solutions may limit system-level thermal optimization; solutions may be more oriented toward integration with existing technologies rather than breakthrough approaches.

Critical Patents in AFM Storage Retention Technology

Storage device having flexible architecture and free scalability

PatentInactiveUS8054736B2

Innovation

- A storage device architecture featuring a local probe data storage unit with an address and data evaluation unit, a controllable switch, and an analog-digital converter, allowing for parallel data access and simultaneous read/write operations through a flexible, scalable design.

Method of producing a data storage medium

PatentInactiveEP2005430A1

Innovation

- A method involving coating a polymer layer onto a template surface with reduced surface roughness, clamping it to a target surface, and transferring the layer using a liquid, which replicates the template's surface smoothness, allowing for reduced indentation mark dimensions without compromising sensing margins and requiring less complex processing.

Materials Science Advancements for AFM Storage Media

Recent advancements in materials science have significantly enhanced the potential of Atomic Force Microscopy (AFM) based storage systems. The thermal stability of storage media represents a critical factor in determining the long-term reliability and data retention capabilities of these systems. Traditional materials used in AFM storage faced challenges related to thermal degradation, leading to data loss and reduced storage lifetimes.

The development of phase-change materials (PCMs) has marked a breakthrough in addressing thermal stability concerns. These materials can switch between amorphous and crystalline states when subjected to controlled heating, providing a reliable mechanism for data encoding. Notably, chalcogenide-based PCMs such as Ge2Sb2Te5 (GST) have demonstrated exceptional thermal stability with data retention capabilities exceeding 10 years at operating temperatures of 85°C.

Polymer-based storage media have also seen substantial improvements through the incorporation of thermally stable functional groups. Cross-linked polymers with aromatic backbones exhibit glass transition temperatures above 200°C, significantly enhancing their resistance to thermal degradation while maintaining the mechanical properties necessary for reliable tip-media interactions during read/write operations.

Nanocomposite materials represent another promising direction, combining the benefits of inorganic thermal stability with organic processability. Silicon carbide nanoparticles embedded in polymer matrices have shown remarkable thermal stability improvements, with retention analysis indicating less than 1% data degradation after accelerated aging tests equivalent to 5 years of operation.

Surface engineering techniques have further enhanced the thermal properties of AFM storage media. Atomic layer deposition of protective oxide layers has proven effective in isolating the active storage layer from environmental factors that accelerate thermal degradation. These protective layers, often composed of Al2O3 or HfO2, create thermal barriers while remaining thin enough to allow the AFM tip to interact with the underlying storage medium.

Multilayer architectures incorporating thermal management layers have emerged as an innovative approach to controlling heat dissipation during write operations. These structures utilize materials with high thermal conductivity to rapidly channel heat away from the storage layer after writing, preventing unintended thermal effects on adjacent bits and enhancing overall data retention characteristics.

The integration of these materials science advancements has collectively pushed AFM storage media toward commercial viability, with current research prototypes demonstrating storage densities exceeding 1 Tb/in² while maintaining thermal stability sufficient for enterprise storage applications.

The development of phase-change materials (PCMs) has marked a breakthrough in addressing thermal stability concerns. These materials can switch between amorphous and crystalline states when subjected to controlled heating, providing a reliable mechanism for data encoding. Notably, chalcogenide-based PCMs such as Ge2Sb2Te5 (GST) have demonstrated exceptional thermal stability with data retention capabilities exceeding 10 years at operating temperatures of 85°C.

Polymer-based storage media have also seen substantial improvements through the incorporation of thermally stable functional groups. Cross-linked polymers with aromatic backbones exhibit glass transition temperatures above 200°C, significantly enhancing their resistance to thermal degradation while maintaining the mechanical properties necessary for reliable tip-media interactions during read/write operations.

Nanocomposite materials represent another promising direction, combining the benefits of inorganic thermal stability with organic processability. Silicon carbide nanoparticles embedded in polymer matrices have shown remarkable thermal stability improvements, with retention analysis indicating less than 1% data degradation after accelerated aging tests equivalent to 5 years of operation.

Surface engineering techniques have further enhanced the thermal properties of AFM storage media. Atomic layer deposition of protective oxide layers has proven effective in isolating the active storage layer from environmental factors that accelerate thermal degradation. These protective layers, often composed of Al2O3 or HfO2, create thermal barriers while remaining thin enough to allow the AFM tip to interact with the underlying storage medium.

Multilayer architectures incorporating thermal management layers have emerged as an innovative approach to controlling heat dissipation during write operations. These structures utilize materials with high thermal conductivity to rapidly channel heat away from the storage layer after writing, preventing unintended thermal effects on adjacent bits and enhancing overall data retention characteristics.

The integration of these materials science advancements has collectively pushed AFM storage media toward commercial viability, with current research prototypes demonstrating storage densities exceeding 1 Tb/in² while maintaining thermal stability sufficient for enterprise storage applications.

Energy Efficiency Considerations in AFM Storage Systems

Energy efficiency has emerged as a critical consideration in the development and deployment of AFM-based storage systems, particularly when evaluating thermal stability and data retention characteristics. The power consumption profile of these systems presents a complex trade-off between performance, reliability, and energy usage that must be carefully balanced for optimal operation.

The fundamental energy requirements of AFM storage systems can be divided into several key components. The positioning system, which controls the precise movement of the AFM tips across the storage medium, typically consumes the largest portion of energy during read/write operations. This is followed by the sensing electronics that detect and process the stored information, and finally the thermal management systems that maintain operational stability.

Thermal considerations play a dual role in energy efficiency analysis. While higher temperatures can facilitate faster write operations by reducing the energy barrier for bit modification, they simultaneously accelerate thermal decay processes that threaten data retention. This creates an inherent tension between performance and stability that must be addressed through intelligent system design.

Recent advancements in low-power AFM tip actuation mechanisms have demonstrated significant improvements in energy efficiency. Piezoelectric actuators with optimized drive circuits have reduced positioning energy requirements by up to 40% compared to earlier generations. Similarly, innovations in signal processing algorithms have enabled reliable bit detection at lower signal-to-noise ratios, allowing sensing circuits to operate at reduced power levels.

Energy harvesting technologies present promising opportunities for further efficiency improvements in AFM storage systems. Ambient vibration energy harvesters integrated into the positioning system can partially recover energy during deceleration phases. Additionally, thermal gradient-based energy recovery systems can capture waste heat generated during intensive write operations, converting a portion back into usable electrical energy.

The relationship between data retention requirements and energy consumption deserves particular attention. Systems designed for long-term archival storage can implement aggressive power management strategies during idle periods, as infrequent access patterns allow for deeper sleep states. Conversely, applications requiring frequent data access must maintain more components in active or ready states, resulting in higher baseline power consumption.

Future research directions point toward holistic energy optimization approaches that consider the entire system lifecycle. This includes energy-aware data encoding schemes that minimize the number of required bit modifications, adaptive power management based on workload prediction, and materials science innovations focused on reducing the energy required for stable bit transitions while maintaining robust thermal stability characteristics.

The fundamental energy requirements of AFM storage systems can be divided into several key components. The positioning system, which controls the precise movement of the AFM tips across the storage medium, typically consumes the largest portion of energy during read/write operations. This is followed by the sensing electronics that detect and process the stored information, and finally the thermal management systems that maintain operational stability.

Thermal considerations play a dual role in energy efficiency analysis. While higher temperatures can facilitate faster write operations by reducing the energy barrier for bit modification, they simultaneously accelerate thermal decay processes that threaten data retention. This creates an inherent tension between performance and stability that must be addressed through intelligent system design.

Recent advancements in low-power AFM tip actuation mechanisms have demonstrated significant improvements in energy efficiency. Piezoelectric actuators with optimized drive circuits have reduced positioning energy requirements by up to 40% compared to earlier generations. Similarly, innovations in signal processing algorithms have enabled reliable bit detection at lower signal-to-noise ratios, allowing sensing circuits to operate at reduced power levels.

Energy harvesting technologies present promising opportunities for further efficiency improvements in AFM storage systems. Ambient vibration energy harvesters integrated into the positioning system can partially recover energy during deceleration phases. Additionally, thermal gradient-based energy recovery systems can capture waste heat generated during intensive write operations, converting a portion back into usable electrical energy.

The relationship between data retention requirements and energy consumption deserves particular attention. Systems designed for long-term archival storage can implement aggressive power management strategies during idle periods, as infrequent access patterns allow for deeper sleep states. Conversely, applications requiring frequent data access must maintain more components in active or ready states, resulting in higher baseline power consumption.

Future research directions point toward holistic energy optimization approaches that consider the entire system lifecycle. This includes energy-aware data encoding schemes that minimize the number of required bit modifications, adaptive power management based on workload prediction, and materials science innovations focused on reducing the energy required for stable bit transitions while maintaining robust thermal stability characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!