Micro-Electromechanical Assemblies Using Nitinol's Shape Memory Properties

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol MEMS Background and Objectives

Nitinol, a unique alloy of nickel and titanium, has emerged as a revolutionary material in the field of Micro-Electromechanical Systems (MEMS) due to its remarkable shape memory properties. This alloy's ability to remember and return to its original shape when heated has opened up new possibilities for creating miniature actuators and sensors with unprecedented capabilities.

The development of Nitinol-based MEMS technology can be traced back to the 1960s when the shape memory effect was first discovered in Nitinol by William J. Buehler and Frederick Wang at the Naval Ordnance Laboratory. However, it wasn't until the 1990s that researchers began to seriously explore its potential in micro-scale applications.

Over the past three decades, the integration of Nitinol into MEMS devices has progressed significantly, driven by the growing demand for smaller, more efficient, and more responsive mechanical systems in various industries. The unique properties of Nitinol, including its high power-to-weight ratio, biocompatibility, and ability to operate in diverse environments, have made it an ideal candidate for MEMS applications.

The primary objective of research on Micro-Electromechanical Assemblies using Nitinol's shape memory properties is to develop innovative, compact, and efficient actuators and sensors that can outperform traditional MEMS devices. These Nitinol-based systems aim to address limitations in current MEMS technology, such as limited force output, restricted motion range, and complex actuation mechanisms.

Researchers are focusing on several key areas to advance Nitinol MEMS technology. These include optimizing the composition and heat treatment of Nitinol to enhance its shape memory effect at the micro-scale, developing novel fabrication techniques to integrate Nitinol into MEMS devices, and creating control systems that can precisely manipulate the shape memory effect for specific applications.

The potential applications for Nitinol MEMS are vast and diverse. In the medical field, researchers are exploring the use of Nitinol-based micro-actuators for minimally invasive surgical tools and implantable devices. In aerospace and robotics, Nitinol MEMS could enable the creation of more adaptive and resilient structures. The automotive industry is investigating Nitinol MEMS for advanced sensor systems and energy-efficient actuators.

As the field progresses, researchers aim to overcome current challenges such as improving the response time of Nitinol actuators, enhancing their energy efficiency, and developing more precise control mechanisms. The ultimate goal is to create a new generation of MEMS devices that can revolutionize various technological domains, from healthcare to aerospace, by harnessing the unique properties of Nitinol.

The development of Nitinol-based MEMS technology can be traced back to the 1960s when the shape memory effect was first discovered in Nitinol by William J. Buehler and Frederick Wang at the Naval Ordnance Laboratory. However, it wasn't until the 1990s that researchers began to seriously explore its potential in micro-scale applications.

Over the past three decades, the integration of Nitinol into MEMS devices has progressed significantly, driven by the growing demand for smaller, more efficient, and more responsive mechanical systems in various industries. The unique properties of Nitinol, including its high power-to-weight ratio, biocompatibility, and ability to operate in diverse environments, have made it an ideal candidate for MEMS applications.

The primary objective of research on Micro-Electromechanical Assemblies using Nitinol's shape memory properties is to develop innovative, compact, and efficient actuators and sensors that can outperform traditional MEMS devices. These Nitinol-based systems aim to address limitations in current MEMS technology, such as limited force output, restricted motion range, and complex actuation mechanisms.

Researchers are focusing on several key areas to advance Nitinol MEMS technology. These include optimizing the composition and heat treatment of Nitinol to enhance its shape memory effect at the micro-scale, developing novel fabrication techniques to integrate Nitinol into MEMS devices, and creating control systems that can precisely manipulate the shape memory effect for specific applications.

The potential applications for Nitinol MEMS are vast and diverse. In the medical field, researchers are exploring the use of Nitinol-based micro-actuators for minimally invasive surgical tools and implantable devices. In aerospace and robotics, Nitinol MEMS could enable the creation of more adaptive and resilient structures. The automotive industry is investigating Nitinol MEMS for advanced sensor systems and energy-efficient actuators.

As the field progresses, researchers aim to overcome current challenges such as improving the response time of Nitinol actuators, enhancing their energy efficiency, and developing more precise control mechanisms. The ultimate goal is to create a new generation of MEMS devices that can revolutionize various technological domains, from healthcare to aerospace, by harnessing the unique properties of Nitinol.

Market Demand Analysis for Nitinol-based MEMS

The market demand for Nitinol-based Micro-Electromechanical Systems (MEMS) has been experiencing significant growth in recent years, driven by the unique properties of Nitinol and the expanding applications of MEMS across various industries. Nitinol, a shape memory alloy, offers exceptional characteristics such as superelasticity and shape memory effect, making it highly suitable for MEMS applications.

In the medical device sector, Nitinol-based MEMS have gained substantial traction. These devices are used in minimally invasive surgeries, cardiovascular stents, orthodontic wires, and actuators for drug delivery systems. The growing emphasis on personalized medicine and the need for smaller, more efficient medical devices have fueled the demand for Nitinol-based MEMS in this sector.

The aerospace and automotive industries have also shown increasing interest in Nitinol-based MEMS. These systems are utilized in sensors, actuators, and adaptive structures, contributing to improved fuel efficiency, enhanced safety features, and overall performance optimization. The push for lighter, more efficient vehicles and aircraft has created a favorable market environment for Nitinol-based MEMS.

Consumer electronics represent another significant market for Nitinol-based MEMS. With the trend towards miniaturization and increased functionality in smartphones, wearables, and other portable devices, Nitinol-based MEMS offer solutions for haptic feedback, microactuators, and energy harvesting components. The growing consumer demand for smart devices with advanced features continues to drive this market segment.

The industrial sector has embraced Nitinol-based MEMS for applications in robotics, automation, and process control. These systems provide precise actuation, sensing capabilities, and adaptive responses in harsh environments, making them valuable in manufacturing, energy production, and environmental monitoring.

Market analysts project a compound annual growth rate (CAGR) for the Nitinol-based MEMS market in the high single digits over the next five years. This growth is attributed to technological advancements, expanding application areas, and increasing adoption across industries. However, challenges such as high production costs and complex manufacturing processes may impact market expansion.

Geographically, North America and Europe currently lead the Nitinol-based MEMS market, owing to their strong presence in medical device manufacturing and aerospace industries. The Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing healthcare expenditure, and the expanding consumer electronics sector in countries like China, Japan, and South Korea.

As research and development efforts continue to unlock new possibilities for Nitinol-based MEMS, the market is poised for further expansion. Emerging applications in areas such as soft robotics, biomedical implants, and energy harvesting devices are expected to create new opportunities and drive market growth in the coming years.

In the medical device sector, Nitinol-based MEMS have gained substantial traction. These devices are used in minimally invasive surgeries, cardiovascular stents, orthodontic wires, and actuators for drug delivery systems. The growing emphasis on personalized medicine and the need for smaller, more efficient medical devices have fueled the demand for Nitinol-based MEMS in this sector.

The aerospace and automotive industries have also shown increasing interest in Nitinol-based MEMS. These systems are utilized in sensors, actuators, and adaptive structures, contributing to improved fuel efficiency, enhanced safety features, and overall performance optimization. The push for lighter, more efficient vehicles and aircraft has created a favorable market environment for Nitinol-based MEMS.

Consumer electronics represent another significant market for Nitinol-based MEMS. With the trend towards miniaturization and increased functionality in smartphones, wearables, and other portable devices, Nitinol-based MEMS offer solutions for haptic feedback, microactuators, and energy harvesting components. The growing consumer demand for smart devices with advanced features continues to drive this market segment.

The industrial sector has embraced Nitinol-based MEMS for applications in robotics, automation, and process control. These systems provide precise actuation, sensing capabilities, and adaptive responses in harsh environments, making them valuable in manufacturing, energy production, and environmental monitoring.

Market analysts project a compound annual growth rate (CAGR) for the Nitinol-based MEMS market in the high single digits over the next five years. This growth is attributed to technological advancements, expanding application areas, and increasing adoption across industries. However, challenges such as high production costs and complex manufacturing processes may impact market expansion.

Geographically, North America and Europe currently lead the Nitinol-based MEMS market, owing to their strong presence in medical device manufacturing and aerospace industries. The Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing healthcare expenditure, and the expanding consumer electronics sector in countries like China, Japan, and South Korea.

As research and development efforts continue to unlock new possibilities for Nitinol-based MEMS, the market is poised for further expansion. Emerging applications in areas such as soft robotics, biomedical implants, and energy harvesting devices are expected to create new opportunities and drive market growth in the coming years.

Current State and Challenges in Nitinol MEMS

The current state of Nitinol-based Micro-Electromechanical Systems (MEMS) represents a significant advancement in the field of smart materials and miniaturized devices. Nitinol, an alloy of nickel and titanium, exhibits unique shape memory and superelastic properties, making it an ideal candidate for MEMS applications. These properties allow Nitinol-based MEMS to perform complex mechanical functions at microscale levels, opening up new possibilities in various industries.

Recent developments have seen Nitinol MEMS being successfully integrated into medical devices, aerospace components, and consumer electronics. In the medical field, Nitinol-based stents and surgical instruments have demonstrated superior performance due to their ability to change shape in response to temperature variations within the human body. Aerospace applications have leveraged Nitinol's high strength-to-weight ratio and fatigue resistance for deployable structures and actuators in satellites and spacecraft.

However, despite these advancements, several challenges persist in the widespread adoption and optimization of Nitinol MEMS. One of the primary obstacles is the complex manufacturing process required to produce Nitinol components at the microscale. Precision control of the alloy composition and heat treatment processes is crucial to achieve the desired shape memory properties, which becomes increasingly difficult at smaller scales.

Another significant challenge lies in the integration of Nitinol elements with other materials and components in MEMS devices. The unique thermal and mechanical properties of Nitinol can lead to compatibility issues with traditional MEMS materials such as silicon and polymers. This necessitates the development of novel fabrication techniques and interface designs to ensure reliable and efficient operation of hybrid Nitinol MEMS.

The control and predictability of Nitinol's shape memory effect in MEMS applications also present ongoing challenges. While the macroscale behavior of Nitinol is well understood, its performance at the microscale can be influenced by factors such as surface effects, grain boundaries, and localized stress concentrations. This variability can impact the reliability and repeatability of Nitinol MEMS devices, particularly in applications requiring precise actuation or sensing capabilities.

Furthermore, the long-term stability and fatigue resistance of Nitinol MEMS under repeated shape memory cycles remain areas of concern. Understanding and mitigating potential degradation mechanisms in microscale Nitinol structures is crucial for ensuring the longevity and reliability of MEMS devices in real-world applications.

Addressing these challenges requires interdisciplinary research efforts combining materials science, mechanical engineering, and microfabrication technologies. Advances in nanoscale characterization techniques and computational modeling are providing new insights into the behavior of Nitinol at the microscale, paving the way for optimized design and fabrication processes. Additionally, ongoing research into alternative shape memory alloys and composite materials may offer solutions to some of the limitations currently faced by Nitinol MEMS.

Recent developments have seen Nitinol MEMS being successfully integrated into medical devices, aerospace components, and consumer electronics. In the medical field, Nitinol-based stents and surgical instruments have demonstrated superior performance due to their ability to change shape in response to temperature variations within the human body. Aerospace applications have leveraged Nitinol's high strength-to-weight ratio and fatigue resistance for deployable structures and actuators in satellites and spacecraft.

However, despite these advancements, several challenges persist in the widespread adoption and optimization of Nitinol MEMS. One of the primary obstacles is the complex manufacturing process required to produce Nitinol components at the microscale. Precision control of the alloy composition and heat treatment processes is crucial to achieve the desired shape memory properties, which becomes increasingly difficult at smaller scales.

Another significant challenge lies in the integration of Nitinol elements with other materials and components in MEMS devices. The unique thermal and mechanical properties of Nitinol can lead to compatibility issues with traditional MEMS materials such as silicon and polymers. This necessitates the development of novel fabrication techniques and interface designs to ensure reliable and efficient operation of hybrid Nitinol MEMS.

The control and predictability of Nitinol's shape memory effect in MEMS applications also present ongoing challenges. While the macroscale behavior of Nitinol is well understood, its performance at the microscale can be influenced by factors such as surface effects, grain boundaries, and localized stress concentrations. This variability can impact the reliability and repeatability of Nitinol MEMS devices, particularly in applications requiring precise actuation or sensing capabilities.

Furthermore, the long-term stability and fatigue resistance of Nitinol MEMS under repeated shape memory cycles remain areas of concern. Understanding and mitigating potential degradation mechanisms in microscale Nitinol structures is crucial for ensuring the longevity and reliability of MEMS devices in real-world applications.

Addressing these challenges requires interdisciplinary research efforts combining materials science, mechanical engineering, and microfabrication technologies. Advances in nanoscale characterization techniques and computational modeling are providing new insights into the behavior of Nitinol at the microscale, paving the way for optimized design and fabrication processes. Additionally, ongoing research into alternative shape memory alloys and composite materials may offer solutions to some of the limitations currently faced by Nitinol MEMS.

Existing Nitinol MEMS Assembly Solutions

01 Shape memory properties in MEMS actuators

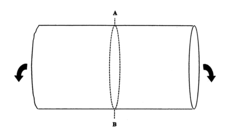

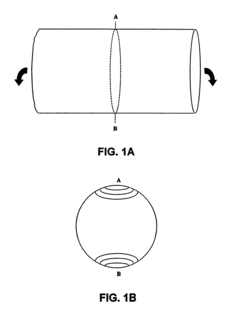

Nitinol's shape memory properties are utilized in micro-electromechanical systems (MEMS) to create actuators. These actuators can change shape or position in response to temperature changes, allowing for precise control and movement in small-scale devices. The unique properties of Nitinol enable the creation of compact and efficient actuators for various MEMS applications.- Shape memory properties in MEMS actuators: Nitinol's shape memory properties are utilized in micro-electromechanical systems (MEMS) to create actuators. These actuators can change shape or position in response to temperature changes, allowing for precise control and movement in small-scale devices. The unique properties of Nitinol enable the creation of compact and efficient actuators for various MEMS applications.

- Nitinol-based microvalves and micropumps: Nitinol's shape memory properties are employed in the development of microvalves and micropumps for MEMS devices. These components can be designed to open, close, or regulate fluid flow in response to temperature changes, making them ideal for microfluidic systems and lab-on-a-chip applications. The use of Nitinol allows for the creation of compact and reliable fluid control mechanisms in microscale devices.

- Nitinol-based micro-switches and relays: The shape memory properties of Nitinol are utilized in the design of micro-switches and relays for MEMS devices. These components can change their electrical connectivity in response to temperature changes, allowing for the creation of temperature-sensitive switches and relays. The use of Nitinol in these applications enables the development of compact and reliable switching mechanisms for various electronic systems.

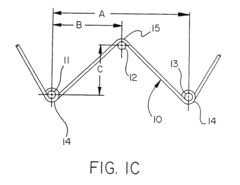

- Nitinol-based micro-grippers and manipulators: Nitinol's shape memory properties are employed in the creation of micro-grippers and manipulators for MEMS devices. These components can change their shape or configuration in response to temperature changes, allowing for precise gripping and manipulation of small objects. The use of Nitinol enables the development of compact and efficient micro-grippers for applications in microsurgery, microassembly, and micromanipulation.

- Integration of Nitinol in MEMS fabrication processes: The integration of Nitinol into MEMS fabrication processes is an important aspect of utilizing its shape memory properties. Techniques for depositing, patterning, and heat-treating Nitinol in microscale devices are developed to ensure proper functionality and reliability. The integration of Nitinol with other materials and structures in MEMS devices is crucial for creating functional and efficient micro-electromechanical assemblies.

02 Nitinol-based microvalves and micropumps

Nitinol's shape memory properties are employed in the development of microvalves and micropumps for MEMS devices. These components can be designed to open, close, or regulate fluid flow in response to temperature changes, making them suitable for microfluidic systems and lab-on-a-chip applications. The use of Nitinol allows for the creation of compact and reliable fluid control mechanisms in microscale devices.Expand Specific Solutions03 Nitinol-based micro-switches and relays

The shape memory properties of Nitinol are utilized in the design of micro-switches and relays for MEMS devices. These components can change their electrical connectivity in response to temperature changes, allowing for the creation of temperature-sensitive switches and relays. The use of Nitinol in these applications enables the development of compact and efficient switching mechanisms for various electronic systems.Expand Specific Solutions04 Nitinol in MEMS-based energy harvesting devices

Nitinol's shape memory properties are employed in the development of MEMS-based energy harvesting devices. These devices can convert thermal energy or mechanical vibrations into electrical energy by utilizing the shape change of Nitinol elements. The unique properties of Nitinol allow for the creation of compact and efficient energy harvesting systems for powering small-scale electronic devices or sensors.Expand Specific Solutions05 Fabrication techniques for Nitinol-based MEMS

Various fabrication techniques are employed to integrate Nitinol into MEMS devices. These techniques include thin film deposition, micromachining, and selective etching processes. The development of these fabrication methods enables the creation of complex Nitinol-based microstructures and their integration with other MEMS components, allowing for the realization of advanced micro-electromechanical assemblies that leverage Nitinol's shape memory properties.Expand Specific Solutions

Key Players in Nitinol MEMS Industry

The research on micro-electromechanical assemblies using Nitinol's shape memory properties is in a nascent stage, with significant potential for growth. The market is relatively small but expanding rapidly, driven by increasing applications in medical devices, aerospace, and robotics. The technology's maturity is still developing, with key players like W. L. Gore & Associates, Boston Scientific Scimed, and Abbott Laboratories leading innovation. Universities such as South China University of Technology and Shandong University are contributing to fundamental research. While the field shows promise, challenges in manufacturing scalability and material cost optimization remain, indicating a competitive landscape poised for further advancements and market expansion.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed advanced Nitinol-based micro-electromechanical assemblies for medical devices. Their technology utilizes Nitinol's shape memory properties to create self-expanding stents and endovascular grafts[1]. These devices can be compressed into a small diameter for minimally invasive delivery, then expand to their pre-programmed shape when deployed in the body. Gore's proprietary surface modification techniques enhance the biocompatibility and durability of Nitinol components[2]. They have also pioneered the use of Nitinol in composite structures, combining it with their ePTFE materials to create devices with unique mechanical properties[3].

Strengths: Expertise in Nitinol processing and surface treatments; integration with proprietary ePTFE materials. Weaknesses: Limited to medical device applications; potential regulatory challenges for novel Nitinol-based devices.

Boston Scientific Scimed, Inc.

Technical Solution: Boston Scientific has developed innovative Nitinol-based micro-electromechanical systems for minimally invasive medical procedures. Their technology focuses on creating complex Nitinol structures with precise shape memory properties for applications such as self-expanding stents and embolic protection devices[4]. They have patented methods for laser-cutting Nitinol tubes to create intricate mesh designs that can be compressed for delivery and expand to predetermined shapes in the body[5]. Boston Scientific has also developed techniques for controlling the transformation temperature of Nitinol components, allowing for precise actuation in physiological conditions[6].

Strengths: Advanced manufacturing techniques for complex Nitinol structures; extensive clinical experience with Nitinol devices. Weaknesses: Primarily focused on cardiovascular applications; potential for material fatigue in long-term implants.

Core Innovations in Nitinol MEMS Technology

Medical device for transcutaneously inserting an insertable element into a body tissue

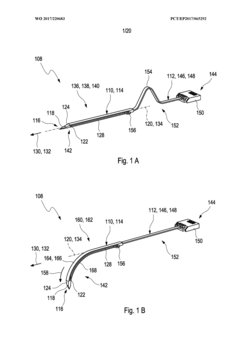

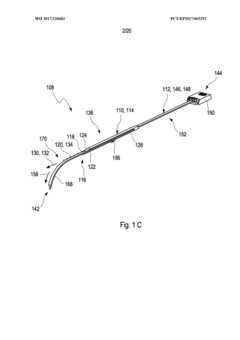

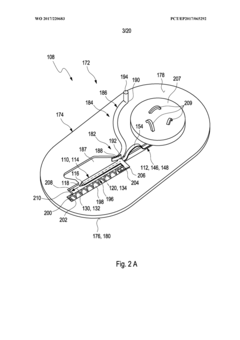

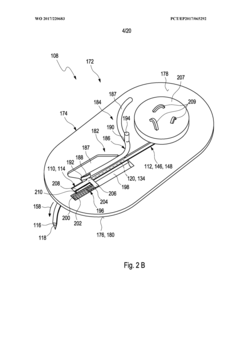

PatentWO2017220683A1

Innovation

- A medical device featuring an insertion cannula made of shape memory alloy, transformable from a straight to an arch shape for easy insertion and removal, integrated with a patch and electronics unit for simplified assembly and operation, reducing the need for additional components and assembly steps.

Method of making shape memory alloy articles with improved fatigue performance

PatentInactiveUS20100319815A1

Innovation

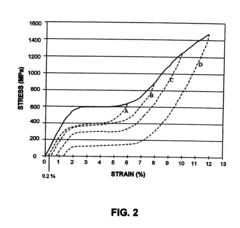

- The method involves controlled pre-straining of shape memory alloy articles, specifically nitinol, to introduce non-recoverable tensile strains greater than 0.20% at targeted surface regions, inducing residual compressive stresses and improving fatigue resistance by maintaining a significant portion within the superelastic material limit, thereby enhancing the fatigue life and safety factor of medical devices.

Biocompatibility and Safety Considerations

The biocompatibility and safety considerations of Nitinol-based micro-electromechanical assemblies are crucial aspects that require thorough examination. Nitinol, an alloy of nickel and titanium, exhibits unique shape memory properties, making it an attractive material for various biomedical applications. However, its use in implantable devices and medical instruments necessitates a comprehensive evaluation of its biological interactions and potential risks.

One of the primary concerns regarding Nitinol's biocompatibility is the presence of nickel, a known allergen and potential carcinogen. While the titanium oxide layer that forms on the surface of Nitinol provides some protection, the long-term effects of nickel release in the body must be carefully assessed. Studies have shown that proper surface treatments and coatings can significantly reduce nickel ion leaching, enhancing the material's biocompatibility.

The mechanical properties of Nitinol, particularly its superelasticity and shape memory effect, also play a role in its safety profile. These characteristics allow for the design of less invasive medical devices and implants that can adapt to the body's natural movements. However, the potential for mechanical failure or unexpected shape changes must be thoroughly evaluated to prevent complications in vivo.

Corrosion resistance is another critical factor in assessing Nitinol's safety for biomedical applications. While Nitinol generally exhibits good corrosion resistance due to its passive oxide layer, the harsh biological environment can potentially lead to degradation over time. Researchers must investigate the long-term stability of Nitinol assemblies under physiological conditions to ensure their durability and prevent the release of harmful corrosion products.

The biocompatibility of Nitinol is also influenced by its surface properties, including roughness, chemistry, and topography. These factors can affect protein adsorption, cell adhesion, and tissue integration. Optimizing surface characteristics through various treatments and modifications can enhance the material's biological performance and reduce the risk of adverse reactions.

Furthermore, the sterilization and cleaning processes for Nitinol-based devices must be carefully considered. Some sterilization methods may alter the material's properties or compromise its surface integrity, potentially affecting both its functionality and biocompatibility. Developing appropriate sterilization protocols that maintain the material's characteristics while ensuring sterility is essential for safe clinical use.

In conclusion, while Nitinol offers promising advantages for micro-electromechanical assemblies in biomedical applications, its safe implementation requires a multifaceted approach to address biocompatibility and safety concerns. Ongoing research and rigorous testing are necessary to fully understand and mitigate potential risks associated with its use in the human body.

One of the primary concerns regarding Nitinol's biocompatibility is the presence of nickel, a known allergen and potential carcinogen. While the titanium oxide layer that forms on the surface of Nitinol provides some protection, the long-term effects of nickel release in the body must be carefully assessed. Studies have shown that proper surface treatments and coatings can significantly reduce nickel ion leaching, enhancing the material's biocompatibility.

The mechanical properties of Nitinol, particularly its superelasticity and shape memory effect, also play a role in its safety profile. These characteristics allow for the design of less invasive medical devices and implants that can adapt to the body's natural movements. However, the potential for mechanical failure or unexpected shape changes must be thoroughly evaluated to prevent complications in vivo.

Corrosion resistance is another critical factor in assessing Nitinol's safety for biomedical applications. While Nitinol generally exhibits good corrosion resistance due to its passive oxide layer, the harsh biological environment can potentially lead to degradation over time. Researchers must investigate the long-term stability of Nitinol assemblies under physiological conditions to ensure their durability and prevent the release of harmful corrosion products.

The biocompatibility of Nitinol is also influenced by its surface properties, including roughness, chemistry, and topography. These factors can affect protein adsorption, cell adhesion, and tissue integration. Optimizing surface characteristics through various treatments and modifications can enhance the material's biological performance and reduce the risk of adverse reactions.

Furthermore, the sterilization and cleaning processes for Nitinol-based devices must be carefully considered. Some sterilization methods may alter the material's properties or compromise its surface integrity, potentially affecting both its functionality and biocompatibility. Developing appropriate sterilization protocols that maintain the material's characteristics while ensuring sterility is essential for safe clinical use.

In conclusion, while Nitinol offers promising advantages for micro-electromechanical assemblies in biomedical applications, its safe implementation requires a multifaceted approach to address biocompatibility and safety concerns. Ongoing research and rigorous testing are necessary to fully understand and mitigate potential risks associated with its use in the human body.

Energy Efficiency in Nitinol-based MEMS

Energy efficiency is a critical consideration in the development and application of Nitinol-based Micro-Electromechanical Systems (MEMS). The unique shape memory properties of Nitinol offer significant advantages in terms of energy conversion and conservation within these miniature devices.

Nitinol's ability to undergo phase transformations between its austenite and martensite states allows for efficient energy storage and release mechanisms. This characteristic enables MEMS devices to perform mechanical work with minimal energy input, potentially reducing overall power consumption in various applications.

The thermal activation of Nitinol's shape memory effect can be optimized to achieve high energy efficiency. By carefully controlling the temperature range and rate of phase transformation, engineers can maximize the work output while minimizing heat loss. This is particularly important in micro-scale devices where thermal management is challenging.

Recent advancements in Nitinol-based MEMS have focused on improving the material's energy density and response time. Researchers have explored various techniques, such as alloying and surface treatments, to enhance the energy conversion efficiency of Nitinol actuators. These improvements have led to more responsive and energy-efficient MEMS devices.

The integration of Nitinol with other smart materials and energy harvesting technologies has shown promise in creating self-powered MEMS. By combining Nitinol's shape memory properties with piezoelectric or thermoelectric elements, it is possible to design systems that can harvest ambient energy to power their operations, further enhancing overall energy efficiency.

Energy recovery strategies have also been implemented in Nitinol-based MEMS to maximize efficiency. By capturing and reusing the energy released during the shape memory effect's reverse transformation, these systems can significantly reduce energy waste and improve overall performance.

The scalability of Nitinol-based MEMS presents both challenges and opportunities for energy efficiency. As devices become smaller, the surface area to volume ratio increases, affecting heat transfer and energy consumption. Researchers are developing novel designs and fabrication techniques to address these scaling effects and maintain high energy efficiency at the micro-scale.

In conclusion, the pursuit of energy efficiency in Nitinol-based MEMS is driving innovation in material science, device design, and energy management strategies. These advancements are crucial for the development of next-generation micro-devices that can operate with minimal power requirements, opening up new possibilities for applications in fields such as biomedical engineering, robotics, and environmental monitoring.

Nitinol's ability to undergo phase transformations between its austenite and martensite states allows for efficient energy storage and release mechanisms. This characteristic enables MEMS devices to perform mechanical work with minimal energy input, potentially reducing overall power consumption in various applications.

The thermal activation of Nitinol's shape memory effect can be optimized to achieve high energy efficiency. By carefully controlling the temperature range and rate of phase transformation, engineers can maximize the work output while minimizing heat loss. This is particularly important in micro-scale devices where thermal management is challenging.

Recent advancements in Nitinol-based MEMS have focused on improving the material's energy density and response time. Researchers have explored various techniques, such as alloying and surface treatments, to enhance the energy conversion efficiency of Nitinol actuators. These improvements have led to more responsive and energy-efficient MEMS devices.

The integration of Nitinol with other smart materials and energy harvesting technologies has shown promise in creating self-powered MEMS. By combining Nitinol's shape memory properties with piezoelectric or thermoelectric elements, it is possible to design systems that can harvest ambient energy to power their operations, further enhancing overall energy efficiency.

Energy recovery strategies have also been implemented in Nitinol-based MEMS to maximize efficiency. By capturing and reusing the energy released during the shape memory effect's reverse transformation, these systems can significantly reduce energy waste and improve overall performance.

The scalability of Nitinol-based MEMS presents both challenges and opportunities for energy efficiency. As devices become smaller, the surface area to volume ratio increases, affecting heat transfer and energy consumption. Researchers are developing novel designs and fabrication techniques to address these scaling effects and maintain high energy efficiency at the micro-scale.

In conclusion, the pursuit of energy efficiency in Nitinol-based MEMS is driving innovation in material science, device design, and energy management strategies. These advancements are crucial for the development of next-generation micro-devices that can operate with minimal power requirements, opening up new possibilities for applications in fields such as biomedical engineering, robotics, and environmental monitoring.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!