Nitinol in High-Durability Sports Equipment Enhancement

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol in Sports Tech: Background and Objectives

Nitinol, an alloy of nickel and titanium, has emerged as a revolutionary material in the field of sports equipment enhancement. This shape memory alloy, discovered in the early 1960s, has gained significant attention due to its unique properties that make it ideal for high-durability applications. The evolution of Nitinol technology in sports equipment has been driven by the increasing demand for lightweight, durable, and high-performance gear across various athletic disciplines.

The primary objective of researching Nitinol in high-durability sports equipment enhancement is to leverage its exceptional characteristics to create innovative solutions that can withstand extreme conditions and improve athletic performance. These properties include superelasticity, shape memory effect, and high fatigue resistance, which offer substantial advantages over traditional materials used in sports equipment manufacturing.

The development of Nitinol-enhanced sports equipment has followed a trajectory of continuous improvement and diversification. Initially, the material found applications in golf club shafts and tennis racket strings, where its ability to absorb shock and maintain shape proved beneficial. As research progressed, the scope of Nitinol's use expanded to include more demanding sports such as winter sports equipment, cycling components, and protective gear for high-impact activities.

One of the key trends driving the evolution of Nitinol in sports technology is the pursuit of customization and adaptability. Researchers and manufacturers are exploring ways to create equipment that can adjust to individual athletes' needs or changing environmental conditions. This trend aligns with the broader movement towards personalized sports equipment and the integration of smart technologies in athletic gear.

The technical goals for Nitinol in sports equipment enhancement are multifaceted. Researchers aim to optimize the material's composition and processing techniques to enhance its already impressive properties further. This includes improving its fatigue life, increasing its temperature range for shape memory effects, and developing more efficient methods for incorporating Nitinol into complex equipment designs.

Another significant objective is to overcome the challenges associated with Nitinol's implementation in mass-produced sports equipment. These challenges include high production costs, complex manufacturing processes, and the need for specialized knowledge in working with the material. Addressing these issues is crucial for wider adoption of Nitinol-enhanced equipment across various sports and price points.

As the field progresses, there is a growing focus on combining Nitinol with other advanced materials and technologies. This includes exploring hybrid materials that incorporate Nitinol with carbon fiber composites or integrating Nitinol components with electronic sensors for smart equipment applications. These developments aim to create synergistic effects that can push the boundaries of equipment performance and durability even further.

The primary objective of researching Nitinol in high-durability sports equipment enhancement is to leverage its exceptional characteristics to create innovative solutions that can withstand extreme conditions and improve athletic performance. These properties include superelasticity, shape memory effect, and high fatigue resistance, which offer substantial advantages over traditional materials used in sports equipment manufacturing.

The development of Nitinol-enhanced sports equipment has followed a trajectory of continuous improvement and diversification. Initially, the material found applications in golf club shafts and tennis racket strings, where its ability to absorb shock and maintain shape proved beneficial. As research progressed, the scope of Nitinol's use expanded to include more demanding sports such as winter sports equipment, cycling components, and protective gear for high-impact activities.

One of the key trends driving the evolution of Nitinol in sports technology is the pursuit of customization and adaptability. Researchers and manufacturers are exploring ways to create equipment that can adjust to individual athletes' needs or changing environmental conditions. This trend aligns with the broader movement towards personalized sports equipment and the integration of smart technologies in athletic gear.

The technical goals for Nitinol in sports equipment enhancement are multifaceted. Researchers aim to optimize the material's composition and processing techniques to enhance its already impressive properties further. This includes improving its fatigue life, increasing its temperature range for shape memory effects, and developing more efficient methods for incorporating Nitinol into complex equipment designs.

Another significant objective is to overcome the challenges associated with Nitinol's implementation in mass-produced sports equipment. These challenges include high production costs, complex manufacturing processes, and the need for specialized knowledge in working with the material. Addressing these issues is crucial for wider adoption of Nitinol-enhanced equipment across various sports and price points.

As the field progresses, there is a growing focus on combining Nitinol with other advanced materials and technologies. This includes exploring hybrid materials that incorporate Nitinol with carbon fiber composites or integrating Nitinol components with electronic sensors for smart equipment applications. These developments aim to create synergistic effects that can push the boundaries of equipment performance and durability even further.

Market Analysis for Durable Sports Equipment

The market for durable sports equipment has been experiencing significant growth in recent years, driven by increasing consumer demand for high-performance, long-lasting products. This trend is particularly evident in the context of Nitinol-enhanced sports equipment, which offers superior durability and performance characteristics.

The global sports equipment market is projected to reach a substantial value in the coming years, with a notable portion attributed to durable and high-performance gear. Nitinol, a nickel-titanium alloy known for its shape memory and superelastic properties, is emerging as a game-changing material in this sector. Its ability to withstand repeated stress and strain without permanent deformation makes it ideal for applications in sports equipment that require high durability and resilience.

Consumer preferences are shifting towards products that offer longevity and consistent performance, even under extreme conditions. This shift is partly driven by environmental concerns, as durable equipment reduces the need for frequent replacements, aligning with sustainability goals. Additionally, professional and amateur athletes alike are seeking equipment that can withstand intense training and competition, leading to increased demand for Nitinol-enhanced products.

The market for Nitinol in sports equipment spans various categories, including but not limited to tennis rackets, golf clubs, bicycle frames, and protective gear. Each of these segments presents unique opportunities for Nitinol application, with varying market sizes and growth potentials. For instance, the tennis equipment market, where Nitinol can significantly enhance racket performance, is showing steady growth globally.

Geographically, North America and Europe currently lead in the adoption of high-durability sports equipment, including Nitinol-enhanced products. However, rapidly growing markets in Asia-Pacific, particularly in countries like China and India, are expected to drive significant future growth. The increasing popularity of sports and rising disposable incomes in these regions contribute to the expanding market for premium, durable sports equipment.

Key market drivers include technological advancements in material science, growing health and fitness awareness, and the rising popularity of extreme sports. These factors collectively contribute to a robust demand for sports equipment that can offer superior performance and longevity. The integration of Nitinol in sports equipment aligns perfectly with these market trends, positioning it as a material of choice for manufacturers looking to differentiate their products in a competitive landscape.

However, challenges exist in the form of high production costs associated with Nitinol and the need for specialized manufacturing processes. These factors can impact product pricing and market penetration, particularly in price-sensitive segments. Despite these challenges, the long-term benefits of Nitinol-enhanced equipment, including reduced replacement frequency and improved performance, are expected to drive continued market growth and innovation in the durable sports equipment sector.

The global sports equipment market is projected to reach a substantial value in the coming years, with a notable portion attributed to durable and high-performance gear. Nitinol, a nickel-titanium alloy known for its shape memory and superelastic properties, is emerging as a game-changing material in this sector. Its ability to withstand repeated stress and strain without permanent deformation makes it ideal for applications in sports equipment that require high durability and resilience.

Consumer preferences are shifting towards products that offer longevity and consistent performance, even under extreme conditions. This shift is partly driven by environmental concerns, as durable equipment reduces the need for frequent replacements, aligning with sustainability goals. Additionally, professional and amateur athletes alike are seeking equipment that can withstand intense training and competition, leading to increased demand for Nitinol-enhanced products.

The market for Nitinol in sports equipment spans various categories, including but not limited to tennis rackets, golf clubs, bicycle frames, and protective gear. Each of these segments presents unique opportunities for Nitinol application, with varying market sizes and growth potentials. For instance, the tennis equipment market, where Nitinol can significantly enhance racket performance, is showing steady growth globally.

Geographically, North America and Europe currently lead in the adoption of high-durability sports equipment, including Nitinol-enhanced products. However, rapidly growing markets in Asia-Pacific, particularly in countries like China and India, are expected to drive significant future growth. The increasing popularity of sports and rising disposable incomes in these regions contribute to the expanding market for premium, durable sports equipment.

Key market drivers include technological advancements in material science, growing health and fitness awareness, and the rising popularity of extreme sports. These factors collectively contribute to a robust demand for sports equipment that can offer superior performance and longevity. The integration of Nitinol in sports equipment aligns perfectly with these market trends, positioning it as a material of choice for manufacturers looking to differentiate their products in a competitive landscape.

However, challenges exist in the form of high production costs associated with Nitinol and the need for specialized manufacturing processes. These factors can impact product pricing and market penetration, particularly in price-sensitive segments. Despite these challenges, the long-term benefits of Nitinol-enhanced equipment, including reduced replacement frequency and improved performance, are expected to drive continued market growth and innovation in the durable sports equipment sector.

Nitinol Properties and Current Challenges

Nitinol, an alloy of nickel and titanium, possesses unique properties that make it highly suitable for use in high-durability sports equipment. Its most notable characteristic is its shape memory effect, allowing it to return to a predetermined shape when heated. This property, combined with its superelasticity, enables Nitinol to withstand significant deformation without permanent damage, making it ideal for applications requiring repeated stress and strain.

The current state of Nitinol technology in sports equipment is promising, with applications ranging from golf club shafts to tennis racket strings. However, several challenges persist in fully harnessing its potential. One primary issue is the complex manufacturing process required to produce Nitinol components with consistent properties. The alloy's behavior is highly sensitive to its composition and heat treatment, necessitating precise control during production.

Another significant challenge lies in optimizing Nitinol's performance across a wide range of temperatures. While its shape memory effect is advantageous, ensuring consistent behavior in varying environmental conditions remains a hurdle. This is particularly crucial for outdoor sports equipment that may be subjected to extreme temperature fluctuations.

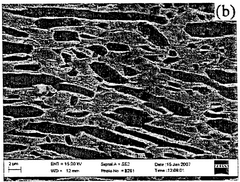

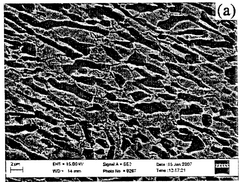

Durability and fatigue resistance, while generally superior to many conventional materials, still present areas for improvement. Prolonged cyclic loading can lead to microstructural changes in Nitinol, potentially affecting its long-term performance. Researchers are actively working on enhancing these properties through alloying additions and advanced heat treatment processes.

Cost remains a significant barrier to widespread adoption in sports equipment. The raw materials and specialized manufacturing processes required for Nitinol production result in higher costs compared to traditional materials like steel or aluminum. This limits its use to high-end products and specialized applications where its unique properties justify the expense.

Biocompatibility is another aspect under scrutiny, particularly for equipment that comes into direct contact with the athlete's skin. While Nitinol is generally considered biocompatible, concerns about nickel release and potential allergic reactions persist, necessitating further research and development of protective coatings or alternative compositions.

The integration of Nitinol with other materials in composite structures presents both opportunities and challenges. Leveraging Nitinol's properties in combination with carbon fiber or other advanced materials could lead to revolutionary sports equipment designs. However, ensuring proper bonding and preventing galvanic corrosion at material interfaces remain technical hurdles to overcome.

The current state of Nitinol technology in sports equipment is promising, with applications ranging from golf club shafts to tennis racket strings. However, several challenges persist in fully harnessing its potential. One primary issue is the complex manufacturing process required to produce Nitinol components with consistent properties. The alloy's behavior is highly sensitive to its composition and heat treatment, necessitating precise control during production.

Another significant challenge lies in optimizing Nitinol's performance across a wide range of temperatures. While its shape memory effect is advantageous, ensuring consistent behavior in varying environmental conditions remains a hurdle. This is particularly crucial for outdoor sports equipment that may be subjected to extreme temperature fluctuations.

Durability and fatigue resistance, while generally superior to many conventional materials, still present areas for improvement. Prolonged cyclic loading can lead to microstructural changes in Nitinol, potentially affecting its long-term performance. Researchers are actively working on enhancing these properties through alloying additions and advanced heat treatment processes.

Cost remains a significant barrier to widespread adoption in sports equipment. The raw materials and specialized manufacturing processes required for Nitinol production result in higher costs compared to traditional materials like steel or aluminum. This limits its use to high-end products and specialized applications where its unique properties justify the expense.

Biocompatibility is another aspect under scrutiny, particularly for equipment that comes into direct contact with the athlete's skin. While Nitinol is generally considered biocompatible, concerns about nickel release and potential allergic reactions persist, necessitating further research and development of protective coatings or alternative compositions.

The integration of Nitinol with other materials in composite structures presents both opportunities and challenges. Leveraging Nitinol's properties in combination with carbon fiber or other advanced materials could lead to revolutionary sports equipment designs. However, ensuring proper bonding and preventing galvanic corrosion at material interfaces remain technical hurdles to overcome.

Current Nitinol Applications in Sports Equipment

01 Heat treatment for improved durability

Heat treatment processes can be applied to Nitinol to enhance its durability and mechanical properties. These treatments can include annealing, shape setting, and aging, which help optimize the material's microstructure and phase transformation characteristics. Proper heat treatment can lead to improved fatigue resistance, corrosion resistance, and overall longevity of Nitinol components.- Heat treatment for improved durability: Heat treatment processes can be applied to Nitinol to enhance its durability and mechanical properties. These treatments can include annealing, aging, and shape-setting, which help optimize the material's microstructure and shape memory characteristics. Proper heat treatment can lead to increased fatigue resistance and overall longevity of Nitinol components.

- Surface modification techniques: Various surface modification techniques can be employed to improve the durability of Nitinol. These may include electropolishing, passivation, or coating applications. Such treatments can enhance corrosion resistance, reduce surface defects, and improve biocompatibility, ultimately leading to increased durability in various applications.

- Composition optimization: Adjusting the composition of Nitinol alloys can significantly impact their durability. Fine-tuning the ratio of nickel to titanium, as well as incorporating small amounts of other elements, can lead to improved mechanical properties, corrosion resistance, and fatigue life. This optimization can result in Nitinol materials tailored for specific applications with enhanced durability.

- Design considerations for durability: Proper design of Nitinol components is crucial for maximizing durability. This includes considerations such as stress distribution, fatigue-resistant geometries, and minimizing stress concentrations. Optimized designs can significantly extend the lifespan of Nitinol devices and structures, particularly in applications subject to cyclic loading or extreme conditions.

- Testing and quality control methods: Implementing rigorous testing and quality control methods is essential for ensuring the durability of Nitinol products. This may involve fatigue testing, corrosion resistance evaluations, and microstructural analysis. Advanced testing techniques can help identify potential weaknesses and validate the long-term performance of Nitinol components in various environments and applications.

02 Surface modification techniques

Various surface modification techniques can be employed to enhance the durability of Nitinol. These may include electropolishing, passivation, or the application of protective coatings. Such treatments can improve corrosion resistance, reduce surface defects, and enhance biocompatibility, ultimately leading to increased durability and performance of Nitinol devices.Expand Specific Solutions03 Optimized alloy composition

The durability of Nitinol can be improved by optimizing its alloy composition. This may involve adjusting the nickel-titanium ratio or adding small amounts of tertiary elements. Careful control of the alloy composition can lead to enhanced mechanical properties, improved phase transformation characteristics, and increased resistance to fatigue and corrosion.Expand Specific Solutions04 Design considerations for durability

Proper design considerations can significantly impact the durability of Nitinol components. This includes optimizing geometries to minimize stress concentrations, selecting appropriate dimensions and cross-sections, and considering the specific loading conditions and environmental factors the component will face. Thoughtful design can help maximize the inherent properties of Nitinol and extend the lifespan of devices made from this material.Expand Specific Solutions05 Testing and quality control methods

Implementing rigorous testing and quality control methods is crucial for ensuring the durability of Nitinol components. This may include fatigue testing, corrosion testing, and microstructural analysis. Advanced characterization techniques can be used to assess material properties and identify potential failure modes. Establishing comprehensive quality control protocols helps maintain consistency and reliability in Nitinol production and application.Expand Specific Solutions

Key Players in Nitinol-Enhanced Sports Gear

The research on Nitinol in high-durability sports equipment enhancement is in a growth phase, with increasing market potential due to the material's unique properties. The global shape memory alloy market, which includes Nitinol, is expected to expand significantly in the coming years. Technologically, while Nitinol has been used in various industries, its application in sports equipment is still evolving. Companies like W. L. Gore & Associates and Abbott Laboratories are at the forefront of Nitinol research and development, with academic institutions such as South China University of Technology and Jilin University contributing to the advancement of Nitinol technology. The competitive landscape is diverse, with both established players and emerging startups exploring innovative applications of Nitinol in sports equipment.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has pioneered the use of Nitinol in high-performance textiles and outdoor equipment. Their research focuses on incorporating Nitinol wires into fabric structures to create smart, responsive garments and gear. They've developed a proprietary weaving technique that integrates ultra-fine Nitinol filaments into breathable, waterproof membranes, enhancing the durability and functionality of outdoor apparel[4]. For sports equipment, Gore has created Nitinol-reinforced composite materials that offer exceptional strength-to-weight ratios, ideal for applications in cycling, skiing, and climbing gear[5]. Their most recent innovation involves a self-adjusting insulation system using Nitinol actuators that respond to temperature changes, optimizing thermal regulation in extreme environments[6].

Strengths: Extensive experience in material science, established presence in outdoor and performance markets. Weaknesses: Limited to specific niche markets, potentially high product costs.

Verispellis Skis & Snowboards, Inc.

Technical Solution: Verispellis has focused its research on integrating Nitinol into high-performance winter sports equipment. Their flagship technology involves embedding Nitinol wires throughout the core of skis and snowboards. These wires can be electrically activated to change the flex and stiffness of the equipment in real-time, allowing athletes to adapt to varying snow conditions instantly[7]. They've also developed a Nitinol-based edge technology that uses the material's shape memory properties to maintain a sharp edge even after repeated use, significantly extending the lifespan of their products[8]. Verispellis is currently exploring the use of Nitinol in bindings and boot systems to create adaptive fit and release mechanisms that enhance both performance and safety[9].

Strengths: Highly specialized in winter sports applications, innovative use of Nitinol's unique properties. Weaknesses: Limited market scope, high development and production costs.

Innovative Nitinol-Based Technologies for Sports

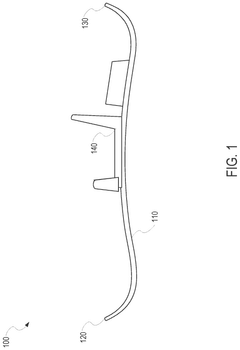

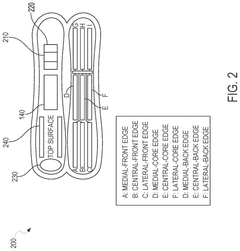

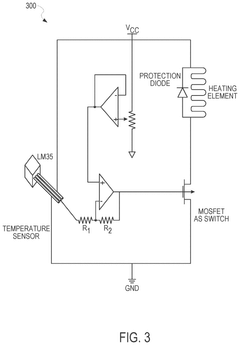

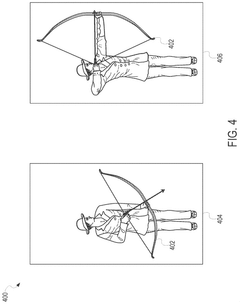

Digitally controlled variable stiffness sporting equipment

PatentActiveUS12129537B2

Innovation

- Integration of nitinol components treated with specific thermal processes to create a digitally controlled variable stiffness system, allowing athletes to adjust the stiffness of equipment through a control unit and heating elements, enabling phase shifts between softer and more rigid states.

Titanium alloy for using in sport goods and manufacturing method thereof

PatentInactiveTW200839017A

Innovation

- Unique composition of titanium alloy with specific percentages of various elements to achieve high tensile strength and extension strength.

- Thermal treatment process to optimize the mechanical properties of the alloy for sports equipment use.

- Versatility of the alloy for use in various sports goods such as golf club heads and bicycles.

Environmental Impact of Nitinol in Sports Gear

The environmental impact of Nitinol in sports gear is a crucial consideration as the material gains popularity in high-durability equipment. Nitinol, an alloy of nickel and titanium, offers unique properties that make it ideal for sports applications, but its production and disposal processes raise important environmental concerns.

The manufacturing of Nitinol involves energy-intensive processes, contributing to carbon emissions. The extraction and refining of nickel and titanium, the primary components of Nitinol, require significant energy inputs and can lead to habitat disruption and water pollution if not properly managed. However, the long lifespan of Nitinol-enhanced sports equipment may offset some of these initial environmental costs by reducing the need for frequent replacements.

Durability is a key factor in the environmental assessment of Nitinol-based sports gear. The material's shape memory and superelastic properties allow for equipment that can withstand repeated stress and strain, potentially lasting much longer than traditional alternatives. This increased longevity can lead to a reduction in waste generation and resource consumption associated with the production and disposal of sports equipment.

The recyclability of Nitinol presents both challenges and opportunities. While the alloy itself is recyclable, the complex composites often used in sports equipment can make separation and recovery difficult. Developing efficient recycling processes for Nitinol-containing products is crucial to minimize their end-of-life environmental impact. Some manufacturers are exploring design-for-disassembly approaches to facilitate easier recycling of Nitinol components.

Water pollution is another concern, particularly in aquatic sports applications. The potential leaching of nickel from Nitinol equipment into water bodies could have adverse effects on aquatic ecosystems. However, studies have shown that properly treated Nitinol surfaces can significantly reduce nickel release, mitigating this risk.

The use of Nitinol in sports gear may also indirectly contribute to environmental conservation. For instance, in activities like rock climbing, more durable equipment can reduce the need for fixed anchors, minimizing damage to natural rock formations. Similarly, in water sports, longer-lasting gear may decrease the likelihood of equipment failure and subsequent pollution from lost or abandoned items.

As the adoption of Nitinol in sports equipment grows, it is essential to conduct comprehensive life cycle assessments to fully understand its environmental implications. These assessments should consider raw material extraction, manufacturing processes, use phase durability, and end-of-life management. Such analyses can guide manufacturers in optimizing the environmental performance of Nitinol-enhanced sports gear and inform consumers about the ecological footprint of their equipment choices.

The manufacturing of Nitinol involves energy-intensive processes, contributing to carbon emissions. The extraction and refining of nickel and titanium, the primary components of Nitinol, require significant energy inputs and can lead to habitat disruption and water pollution if not properly managed. However, the long lifespan of Nitinol-enhanced sports equipment may offset some of these initial environmental costs by reducing the need for frequent replacements.

Durability is a key factor in the environmental assessment of Nitinol-based sports gear. The material's shape memory and superelastic properties allow for equipment that can withstand repeated stress and strain, potentially lasting much longer than traditional alternatives. This increased longevity can lead to a reduction in waste generation and resource consumption associated with the production and disposal of sports equipment.

The recyclability of Nitinol presents both challenges and opportunities. While the alloy itself is recyclable, the complex composites often used in sports equipment can make separation and recovery difficult. Developing efficient recycling processes for Nitinol-containing products is crucial to minimize their end-of-life environmental impact. Some manufacturers are exploring design-for-disassembly approaches to facilitate easier recycling of Nitinol components.

Water pollution is another concern, particularly in aquatic sports applications. The potential leaching of nickel from Nitinol equipment into water bodies could have adverse effects on aquatic ecosystems. However, studies have shown that properly treated Nitinol surfaces can significantly reduce nickel release, mitigating this risk.

The use of Nitinol in sports gear may also indirectly contribute to environmental conservation. For instance, in activities like rock climbing, more durable equipment can reduce the need for fixed anchors, minimizing damage to natural rock formations. Similarly, in water sports, longer-lasting gear may decrease the likelihood of equipment failure and subsequent pollution from lost or abandoned items.

As the adoption of Nitinol in sports equipment grows, it is essential to conduct comprehensive life cycle assessments to fully understand its environmental implications. These assessments should consider raw material extraction, manufacturing processes, use phase durability, and end-of-life management. Such analyses can guide manufacturers in optimizing the environmental performance of Nitinol-enhanced sports gear and inform consumers about the ecological footprint of their equipment choices.

Safety Standards for Nitinol-Enhanced Equipment

The integration of Nitinol in high-durability sports equipment necessitates rigorous safety standards to ensure user protection and product reliability. These standards encompass various aspects of equipment design, manufacturing, and testing processes. One crucial area of focus is the thermal treatment of Nitinol components, which significantly influences their mechanical properties and performance. Strict guidelines are established for heat treatment procedures, including temperature control, duration, and cooling rates, to achieve optimal shape memory and superelastic characteristics while maintaining structural integrity.

Material composition standards are another critical element, specifying acceptable ranges for nickel and titanium content, as well as permissible levels of impurities. These standards aim to minimize the risk of allergic reactions and ensure consistent material properties across different batches. Additionally, stringent requirements are set for surface finish and coating processes to prevent material degradation and enhance biocompatibility, particularly for equipment in direct contact with the user's skin.

Mechanical testing protocols form a substantial part of safety standards for Nitinol-enhanced sports equipment. These include fatigue testing to simulate repeated stress cycles, impact resistance tests to evaluate performance under sudden loads, and corrosion resistance assessments to ensure longevity in various environmental conditions. Specific test parameters and acceptance criteria are defined based on the intended application and usage patterns of the equipment.

Quality control measures are integral to safety standards, encompassing both manufacturing processes and final product inspection. Non-destructive testing methods, such as X-ray diffraction and ultrasonic scanning, are employed to detect internal defects or inconsistencies in Nitinol components. Statistical process control techniques are implemented to monitor and maintain consistent quality throughout production runs.

Environmental and user safety considerations are also addressed in these standards. Guidelines are established for the safe disposal or recycling of Nitinol-containing equipment at the end of its lifecycle. Moreover, standards specify requirements for user manuals and product labeling, ensuring that consumers are adequately informed about proper usage, maintenance, and potential risks associated with Nitinol-enhanced equipment.

Compliance with these safety standards is typically verified through a combination of manufacturer self-certification and third-party testing. Regulatory bodies in different regions may have specific requirements or adaptations of these standards, necessitating a comprehensive approach to ensure global market access for Nitinol-enhanced sports equipment.

Material composition standards are another critical element, specifying acceptable ranges for nickel and titanium content, as well as permissible levels of impurities. These standards aim to minimize the risk of allergic reactions and ensure consistent material properties across different batches. Additionally, stringent requirements are set for surface finish and coating processes to prevent material degradation and enhance biocompatibility, particularly for equipment in direct contact with the user's skin.

Mechanical testing protocols form a substantial part of safety standards for Nitinol-enhanced sports equipment. These include fatigue testing to simulate repeated stress cycles, impact resistance tests to evaluate performance under sudden loads, and corrosion resistance assessments to ensure longevity in various environmental conditions. Specific test parameters and acceptance criteria are defined based on the intended application and usage patterns of the equipment.

Quality control measures are integral to safety standards, encompassing both manufacturing processes and final product inspection. Non-destructive testing methods, such as X-ray diffraction and ultrasonic scanning, are employed to detect internal defects or inconsistencies in Nitinol components. Statistical process control techniques are implemented to monitor and maintain consistent quality throughout production runs.

Environmental and user safety considerations are also addressed in these standards. Guidelines are established for the safe disposal or recycling of Nitinol-containing equipment at the end of its lifecycle. Moreover, standards specify requirements for user manuals and product labeling, ensuring that consumers are adequately informed about proper usage, maintenance, and potential risks associated with Nitinol-enhanced equipment.

Compliance with these safety standards is typically verified through a combination of manufacturer self-certification and third-party testing. Regulatory bodies in different regions may have specific requirements or adaptations of these standards, necessitating a comprehensive approach to ensure global market access for Nitinol-enhanced sports equipment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!