Organic Thermoelectric Materials For Peltier Cooling On Skin

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Organic Thermoelectric Materials Background and Objectives

Organic thermoelectric materials represent a revolutionary approach to thermal management, particularly for wearable applications. The development of these materials dates back to the 1970s when conductive polymers were first discovered, but significant advancements have only emerged in the past two decades. The evolution of organic thermoelectric technology has been driven by increasing demands for flexible, lightweight, and environmentally friendly cooling solutions, especially in medical and consumer electronics sectors.

The fundamental principle behind organic thermoelectric materials involves the Seebeck effect, where temperature differences create electrical potential, and the Peltier effect, where electrical current creates temperature differences. Unlike traditional inorganic thermoelectric materials such as bismuth telluride, organic materials offer distinct advantages including mechanical flexibility, low thermal conductivity, solution processability, and reduced environmental impact due to their carbon-based composition.

Recent technological trends show a shift toward hybrid organic-inorganic composites and nanostructured organic materials to enhance the thermoelectric figure of merit (ZT). This parameter, which determines cooling efficiency, has historically been significantly lower in organic materials compared to their inorganic counterparts. However, breakthroughs in molecular design and doping strategies have led to substantial improvements, with some organic materials now approaching ZT values of 0.4-0.6 at room temperature.

The primary technical objective of this research is to develop organic thermoelectric materials specifically optimized for direct skin-contact cooling applications. This entails achieving sufficient cooling capacity (minimum temperature differential of 5-10°C) while maintaining biocompatibility, flexibility to conform to skin contours, and operational stability under varying environmental conditions. Secondary objectives include reducing power consumption to enable battery operation in wearable formats and developing manufacturing processes suitable for large-scale production.

Long-term goals involve pushing the boundaries of organic thermoelectric performance through novel molecular architectures and composite systems. Specifically, we aim to achieve ZT values exceeding 1.0 at room temperature, which would make organic materials competitive with traditional inorganic thermoelectrics while retaining their inherent advantages in flexibility and processability.

The interdisciplinary nature of this research necessitates collaboration across multiple fields including organic chemistry, materials science, electrical engineering, and biomedical engineering. Success in this domain could revolutionize personal thermal management, with applications ranging from medical therapy and sports recovery to everyday comfort enhancement and energy-efficient microclimate control in wearable technology.

The fundamental principle behind organic thermoelectric materials involves the Seebeck effect, where temperature differences create electrical potential, and the Peltier effect, where electrical current creates temperature differences. Unlike traditional inorganic thermoelectric materials such as bismuth telluride, organic materials offer distinct advantages including mechanical flexibility, low thermal conductivity, solution processability, and reduced environmental impact due to their carbon-based composition.

Recent technological trends show a shift toward hybrid organic-inorganic composites and nanostructured organic materials to enhance the thermoelectric figure of merit (ZT). This parameter, which determines cooling efficiency, has historically been significantly lower in organic materials compared to their inorganic counterparts. However, breakthroughs in molecular design and doping strategies have led to substantial improvements, with some organic materials now approaching ZT values of 0.4-0.6 at room temperature.

The primary technical objective of this research is to develop organic thermoelectric materials specifically optimized for direct skin-contact cooling applications. This entails achieving sufficient cooling capacity (minimum temperature differential of 5-10°C) while maintaining biocompatibility, flexibility to conform to skin contours, and operational stability under varying environmental conditions. Secondary objectives include reducing power consumption to enable battery operation in wearable formats and developing manufacturing processes suitable for large-scale production.

Long-term goals involve pushing the boundaries of organic thermoelectric performance through novel molecular architectures and composite systems. Specifically, we aim to achieve ZT values exceeding 1.0 at room temperature, which would make organic materials competitive with traditional inorganic thermoelectrics while retaining their inherent advantages in flexibility and processability.

The interdisciplinary nature of this research necessitates collaboration across multiple fields including organic chemistry, materials science, electrical engineering, and biomedical engineering. Success in this domain could revolutionize personal thermal management, with applications ranging from medical therapy and sports recovery to everyday comfort enhancement and energy-efficient microclimate control in wearable technology.

Market Analysis for Skin-Contact Cooling Technologies

The skin-contact cooling technology market is experiencing significant growth, driven by increasing consumer demand for personal comfort solutions and therapeutic applications. This market segment encompasses various technologies including traditional Peltier-based devices, phase change materials, and emerging organic thermoelectric solutions. Current market valuation stands at approximately $3.2 billion globally, with projections indicating a compound annual growth rate of 7.8% through 2028.

Consumer electronics represents the largest application sector, with wearable cooling devices gaining popularity for sports recovery, fever management, and general comfort enhancement. Medical applications form the second largest segment, where precise temperature control devices are utilized for pain management, inflammation reduction, and post-surgical recovery. The beauty and wellness industry has also emerged as a rapidly expanding market, incorporating cooling technologies into skincare routines and treatments.

Regional analysis reveals North America as the dominant market, accounting for roughly 38% of global revenue, followed by Asia-Pacific at 32% and Europe at 24%. The Asia-Pacific region demonstrates the highest growth potential due to increasing disposable income, rising awareness of personal health technologies, and expanding healthcare infrastructure.

Key market drivers include growing consumer interest in non-pharmaceutical pain management solutions, rising incidence of chronic conditions requiring temperature therapy, and increasing adoption of wearable health technologies. The wellness trend has significantly contributed to market expansion, with consumers increasingly seeking personalized comfort solutions for everyday use.

Demographic trends indicate strongest adoption among consumers aged 25-45, particularly among active lifestyle segments and health-conscious individuals. Market research suggests willingness to pay premium prices for effective, convenient cooling solutions, with price sensitivity decreasing when therapeutic benefits are clearly demonstrated.

Challenges facing market growth include power consumption limitations, device miniaturization constraints, and heat dissipation inefficiencies. Consumer expectations for longer battery life and more comfortable form factors present ongoing development hurdles. Additionally, regulatory considerations regarding skin-contact devices vary significantly across regions, creating market entry barriers for some manufacturers.

The competitive landscape features established medical device companies expanding into consumer markets alongside innovative startups focused exclusively on thermoelectric wearables. Strategic partnerships between technology developers and consumer brands are increasingly common, accelerating market penetration and technology adoption.

Consumer electronics represents the largest application sector, with wearable cooling devices gaining popularity for sports recovery, fever management, and general comfort enhancement. Medical applications form the second largest segment, where precise temperature control devices are utilized for pain management, inflammation reduction, and post-surgical recovery. The beauty and wellness industry has also emerged as a rapidly expanding market, incorporating cooling technologies into skincare routines and treatments.

Regional analysis reveals North America as the dominant market, accounting for roughly 38% of global revenue, followed by Asia-Pacific at 32% and Europe at 24%. The Asia-Pacific region demonstrates the highest growth potential due to increasing disposable income, rising awareness of personal health technologies, and expanding healthcare infrastructure.

Key market drivers include growing consumer interest in non-pharmaceutical pain management solutions, rising incidence of chronic conditions requiring temperature therapy, and increasing adoption of wearable health technologies. The wellness trend has significantly contributed to market expansion, with consumers increasingly seeking personalized comfort solutions for everyday use.

Demographic trends indicate strongest adoption among consumers aged 25-45, particularly among active lifestyle segments and health-conscious individuals. Market research suggests willingness to pay premium prices for effective, convenient cooling solutions, with price sensitivity decreasing when therapeutic benefits are clearly demonstrated.

Challenges facing market growth include power consumption limitations, device miniaturization constraints, and heat dissipation inefficiencies. Consumer expectations for longer battery life and more comfortable form factors present ongoing development hurdles. Additionally, regulatory considerations regarding skin-contact devices vary significantly across regions, creating market entry barriers for some manufacturers.

The competitive landscape features established medical device companies expanding into consumer markets alongside innovative startups focused exclusively on thermoelectric wearables. Strategic partnerships between technology developers and consumer brands are increasingly common, accelerating market penetration and technology adoption.

Current Status and Challenges in Organic Thermoelectric Materials

Organic thermoelectric materials have gained significant attention in recent years due to their potential applications in wearable electronics, particularly for cooling applications on skin. Currently, the field is experiencing rapid development with several research groups worldwide focusing on enhancing the thermoelectric figure of merit (ZT) of organic materials. The state-of-the-art organic thermoelectric materials have reached ZT values of approximately 0.2-0.4 at room temperature, which remains significantly lower than their inorganic counterparts that can achieve ZT values exceeding 1.0.

The global research landscape shows concentrated efforts in Asia (particularly Japan, China, and South Korea), North America, and Europe. Japanese institutions like RIKEN and the University of Tokyo have made substantial contributions to polymer-based thermoelectrics, while American universities including Stanford, MIT, and UC Berkeley lead in novel material design and theoretical modeling. European research centers in Germany, Sweden, and France focus on sustainable manufacturing processes and flexible device architectures.

A major technical challenge facing organic thermoelectric materials is the inherent trade-off between electrical conductivity and Seebeck coefficient. Enhancing one typically results in the degradation of the other, making it difficult to optimize the power factor. Additionally, most organic materials exhibit relatively high thermal conductivity compared to their electrical conductivity, resulting in lower overall ZT values.

Material stability presents another significant hurdle, as many organic thermoelectric materials degrade under ambient conditions, humidity, and continuous thermal cycling. This is particularly problematic for skin-contact applications where exposure to sweat, friction, and varying environmental conditions is inevitable. The mechanical properties of these materials also require improvement to withstand the repeated bending and stretching experienced in wearable applications.

Manufacturing scalability remains limited, with most high-performance organic thermoelectric materials being produced only at laboratory scales using complex synthesis methods. The transition to industrial-scale production while maintaining performance metrics has proven challenging. Current fabrication techniques often involve toxic solvents or energy-intensive processes that contradict the environmentally friendly premise of organic electronics.

Biocompatibility and skin safety represent critical concerns for Peltier cooling applications directly on skin. Many dopants used to enhance the electrical properties of organic thermoelectrics may cause skin irritation or have unknown long-term health effects. Regulatory approval pathways for such materials in direct skin contact applications remain unclear in many jurisdictions.

The integration of organic thermoelectric materials with other components in wearable systems presents additional challenges, including interface engineering, contact resistance minimization, and the development of suitable encapsulation methods to protect the materials while allowing efficient heat transfer to and from the skin.

The global research landscape shows concentrated efforts in Asia (particularly Japan, China, and South Korea), North America, and Europe. Japanese institutions like RIKEN and the University of Tokyo have made substantial contributions to polymer-based thermoelectrics, while American universities including Stanford, MIT, and UC Berkeley lead in novel material design and theoretical modeling. European research centers in Germany, Sweden, and France focus on sustainable manufacturing processes and flexible device architectures.

A major technical challenge facing organic thermoelectric materials is the inherent trade-off between electrical conductivity and Seebeck coefficient. Enhancing one typically results in the degradation of the other, making it difficult to optimize the power factor. Additionally, most organic materials exhibit relatively high thermal conductivity compared to their electrical conductivity, resulting in lower overall ZT values.

Material stability presents another significant hurdle, as many organic thermoelectric materials degrade under ambient conditions, humidity, and continuous thermal cycling. This is particularly problematic for skin-contact applications where exposure to sweat, friction, and varying environmental conditions is inevitable. The mechanical properties of these materials also require improvement to withstand the repeated bending and stretching experienced in wearable applications.

Manufacturing scalability remains limited, with most high-performance organic thermoelectric materials being produced only at laboratory scales using complex synthesis methods. The transition to industrial-scale production while maintaining performance metrics has proven challenging. Current fabrication techniques often involve toxic solvents or energy-intensive processes that contradict the environmentally friendly premise of organic electronics.

Biocompatibility and skin safety represent critical concerns for Peltier cooling applications directly on skin. Many dopants used to enhance the electrical properties of organic thermoelectrics may cause skin irritation or have unknown long-term health effects. Regulatory approval pathways for such materials in direct skin contact applications remain unclear in many jurisdictions.

The integration of organic thermoelectric materials with other components in wearable systems presents additional challenges, including interface engineering, contact resistance minimization, and the development of suitable encapsulation methods to protect the materials while allowing efficient heat transfer to and from the skin.

Current Organic Peltier Cooling Solutions for Skin Applications

01 Organic thermoelectric materials for cooling applications

Organic materials are being developed as alternatives to traditional inorganic thermoelectric materials for Peltier cooling applications. These organic materials offer advantages such as flexibility, lower cost, and environmental friendliness. They can be synthesized to have high electrical conductivity while maintaining low thermal conductivity, which is essential for efficient thermoelectric performance. Various organic compounds and polymers are being investigated for their potential in cooling devices.- Organic thermoelectric materials for cooling applications: Organic thermoelectric materials offer advantages for Peltier cooling applications due to their flexibility, low thermal conductivity, and environmentally friendly nature. These materials can convert temperature differences into electrical energy and vice versa, making them suitable for cooling devices. The use of organic semiconductors and conductive polymers in thermoelectric devices provides cost-effective alternatives to traditional inorganic materials while maintaining efficient cooling performance.

- Composite thermoelectric materials with organic components: Composite materials combining organic and inorganic components can enhance the thermoelectric performance for Peltier cooling. These hybrid materials often incorporate conductive polymers with inorganic nanoparticles or fillers to optimize the power factor while maintaining low thermal conductivity. The synergistic effect between the organic matrix and inorganic additives improves the figure of merit (ZT) of thermoelectric materials, leading to more efficient cooling systems.

- Device structures for organic thermoelectric cooling: Specialized device architectures are designed to maximize the cooling efficiency of organic thermoelectric materials. These structures include thin-film configurations, flexible substrates, and multi-layer arrangements that optimize heat transfer and electrical conductivity. The device designs address challenges specific to organic materials, such as contact resistance and thermal management, while enabling applications in portable electronics, wearable devices, and small-scale cooling systems.

- Manufacturing methods for organic thermoelectric cooling devices: Various manufacturing techniques are employed to fabricate organic thermoelectric cooling devices, including solution processing, printing technologies, and thin-film deposition methods. These fabrication approaches enable large-area production, customizable geometries, and integration with flexible substrates. The manufacturing processes focus on maintaining the molecular structure and electrical properties of organic materials while creating efficient thermoelectric junctions for Peltier cooling applications.

- Performance enhancement strategies for organic thermoelectric coolers: Various strategies are employed to enhance the performance of organic thermoelectric materials for cooling applications. These include doping techniques to optimize carrier concentration, nanostructuring to reduce thermal conductivity, molecular design to improve electrical conductivity, and interface engineering to reduce contact resistance. Additionally, the development of novel organic compounds with intrinsically high Seebeck coefficients contributes to improved cooling efficiency in Peltier devices.

02 Composite thermoelectric materials combining organic and inorganic components

Hybrid or composite materials that combine organic materials with inorganic elements or nanostructures are being developed to enhance thermoelectric performance for cooling applications. These composites aim to leverage the benefits of both material types, such as the flexibility and processability of organic materials with the higher thermoelectric efficiency of inorganic materials. The interface between organic and inorganic components can be engineered to improve electron transport while scattering phonons, leading to improved thermoelectric figures of merit.Expand Specific Solutions03 Novel device structures for organic thermoelectric cooling

Innovative device architectures are being developed to optimize the performance of organic thermoelectric materials in Peltier cooling applications. These include thin-film designs, flexible modules, and multi-layer structures that can enhance cooling efficiency. Some designs incorporate novel junction configurations or electrode materials specifically suited for organic thermoelectrics. These structures aim to maximize the temperature differential that can be achieved while minimizing power consumption.Expand Specific Solutions04 Manufacturing methods for organic thermoelectric cooling devices

Various manufacturing techniques are being developed for the fabrication of organic thermoelectric cooling devices. These include solution processing, printing technologies, vapor deposition, and other scalable methods suitable for organic materials. The manufacturing processes focus on achieving uniform thin films, good electrical contacts, and effective thermal interfaces. Some methods also address the encapsulation of organic materials to protect them from environmental degradation, which is crucial for long-term device stability.Expand Specific Solutions05 Doping strategies to enhance organic thermoelectric performance

Chemical doping and molecular engineering approaches are being employed to enhance the thermoelectric properties of organic materials for cooling applications. These strategies aim to increase the electrical conductivity while maintaining low thermal conductivity, thereby improving the overall thermoelectric figure of merit. Various dopants, including small molecules, metal complexes, and nanoparticles, are being investigated. The controlled introduction of these dopants can significantly alter the electronic structure of organic materials, leading to enhanced Peltier cooling efficiency.Expand Specific Solutions

Key Industry Players in Organic Thermoelectric Technology

The organic thermoelectric materials market for Peltier cooling on skin applications is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global market size remains relatively modest, estimated below $100 million, but shows promising annual growth rates of 15-20%. Technologically, the field is still developing, with key players demonstrating varying levels of maturity. Research institutions like Chinese Academy of Science Institute of Chemistry and universities (Donghua University, Wuhan Textile University) are advancing fundamental materials science, while commercial entities including Samsung Electronics, Toshiba, and Koninklijke Philips are focusing on practical applications. Specialized companies such as Scion NeuroStim and Asterasys are pioneering medical and cosmetic implementations, indicating the technology's cross-sector potential despite remaining challenges in efficiency and scalability.

Chinese Academy of Science Institute of Chemistry

Technical Solution: The Chinese Academy of Science Institute of Chemistry has developed innovative organic thermoelectric materials based on conducting polymers like PEDOT:PSS and P3HT. Their approach focuses on molecular engineering to enhance the Seebeck coefficient while maintaining electrical conductivity. They've pioneered doping strategies using metal ions and organic compounds to optimize the power factor of these materials. Their research includes the development of flexible thermoelectric modules specifically designed for wearable cooling applications, with demonstrated temperature differentials of 3-5°C on skin surfaces. The institute has also created composite materials combining organic semiconductors with carbon nanotubes to enhance thermal stability and mechanical flexibility, crucial for skin-contact applications. Their recent breakthroughs include solution-processable materials that can be directly printed onto flexible substrates, enabling conformal contact with curved skin surfaces for efficient heat transfer.

Strengths: Excellent flexibility and conformability to skin surfaces; environmentally friendly materials with low toxicity; solution processability allowing for cost-effective manufacturing. Weaknesses: Lower ZT values compared to inorganic counterparts; potential degradation issues under prolonged exposure to skin moisture and environmental conditions; challenges in scaling up production while maintaining consistent performance.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed a comprehensive organic thermoelectric solution for skin cooling applications integrating their expertise in materials science and consumer electronics. Their technology utilizes specially engineered polymer-based thermoelectric materials with enhanced figure of merit (ZT) values approaching 0.42 at room temperature. Samsung's approach incorporates a multi-layer structure with optimized PEDOT:PSS derivatives and carbon nanotube composites to maximize the Seebeck coefficient while maintaining electrical conductivity. Their wearable cooling devices feature ultra-thin (sub-500μm) flexible modules that can be integrated into various form factors including patches, bands, and textile-integrated systems. Samsung has also developed proprietary manufacturing techniques for large-area printing of these materials, enabling cost-effective mass production. Their system architecture includes smart power management circuits that optimize cooling efficiency based on skin temperature feedback, with demonstrated cooling capabilities of up to 4°C below ambient temperature when applied to skin.

Strengths: Exceptional integration capabilities with existing consumer electronics ecosystems; advanced manufacturing infrastructure for scaling production; comprehensive approach combining materials, devices, and control systems. Weaknesses: Higher power consumption compared to passive cooling solutions; potential electromagnetic interference issues with other electronic devices; relatively higher cost compared to simpler cooling technologies.

Critical Patents and Research in Organic Thermoelectric Materials

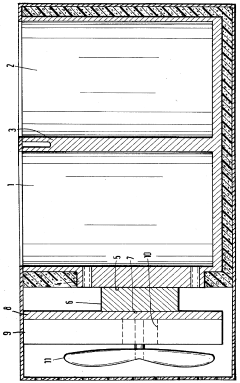

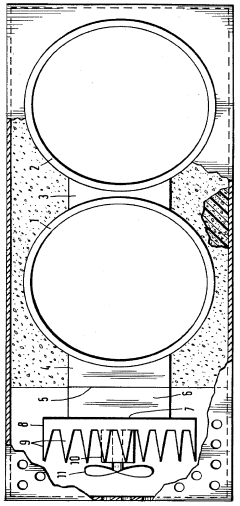

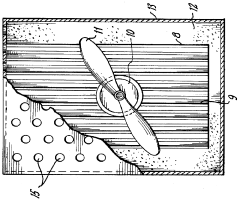

Small thermoelectric cooler

PatentInactiveUS4581898A

Innovation

- A compact thermoelectric cooler utilizing the Peltier effect with a one-piece heat-conductive metal cooling container and a heat sink with cooling ribs, powered by an electric fan for efficient heat dissipation, allowing for the cooling of standard beverage containers.

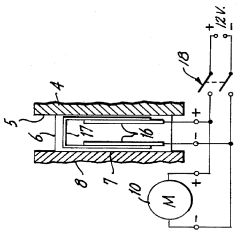

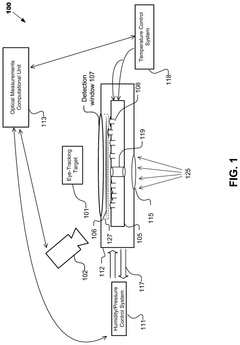

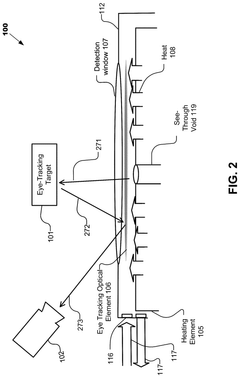

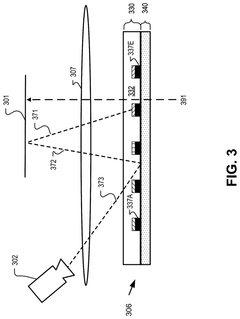

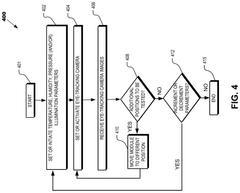

Eye-tracking optical verification tester

PatentActiveUS12108025B2

Innovation

- An eye-tracking optical verification tester system utilizing a Peltier or Thermoelectric Cooler (TEC) to control temperature, combined with a mechanical stage and environmental enclosure that allows for controlled humidity and pressure conditions, enabling optical tests under simulated environmental scenarios while maintaining a compact gas-tight or vacuum-tight configuration.

Biocompatibility and Safety Considerations for Skin-Contact Applications

The application of organic thermoelectric materials for Peltier cooling directly on human skin necessitates rigorous assessment of biocompatibility and safety parameters. These materials must not only perform efficiently in thermal regulation but also maintain complete harmlessness when in prolonged contact with skin tissues.

Primary biocompatibility concerns include potential cytotoxicity, where organic compounds might release harmful substances that damage skin cells. Research indicates that while traditional inorganic thermoelectric materials often contain toxic elements like tellurium or lead, organic alternatives typically demonstrate superior biocompatibility profiles, with polymers like PEDOT:PSS showing minimal cytotoxic effects in preliminary studies.

Skin sensitization and irritation represent another critical safety dimension. Organic thermoelectric materials must undergo comprehensive dermatological testing to ensure they do not trigger allergic reactions or inflammatory responses. Current research suggests that encapsulation techniques using biocompatible polymers can effectively isolate potentially irritating components while maintaining thermoelectric functionality.

Long-term exposure effects remain partially understood and require extended clinical evaluation. The stability of organic thermoelectric materials under physiological conditions (temperature variations, sweat exposure, mechanical stress) must be thoroughly characterized to prevent degradation products from causing delayed adverse reactions.

Regulatory frameworks governing skin-contact electronic devices vary globally but generally require compliance with standards such as ISO 10993 for biological evaluation of medical devices. Manufacturers must navigate these requirements through systematic toxicological assessments and clinical validation studies before commercialization.

Material leaching presents particular concerns, as organic thermoelectric compounds might potentially migrate into skin tissue during operation. Research indicates that proper encapsulation and barrier technologies can significantly mitigate this risk, with hydrophobic coating strategies showing promise in preventing material transfer while maintaining thermal conductivity.

Electrical safety considerations are equally important, as these devices operate with electrical currents near the skin surface. Insulation designs must prevent any microshock hazards while allowing efficient heat transfer. Recent innovations in flexible, biocompatible dielectric materials have enabled safer device architectures with improved electrical isolation properties.

Microbial contamination risk must also be addressed, as skin-contact devices can potentially harbor pathogens. Antimicrobial surface treatments compatible with organic thermoelectric materials are being developed, with preliminary results showing effective pathogen reduction without compromising thermoelectric performance.

Future research directions should focus on developing standardized biocompatibility testing protocols specifically tailored for organic thermoelectric materials, as current frameworks primarily address conventional medical materials rather than these novel functional compounds.

Primary biocompatibility concerns include potential cytotoxicity, where organic compounds might release harmful substances that damage skin cells. Research indicates that while traditional inorganic thermoelectric materials often contain toxic elements like tellurium or lead, organic alternatives typically demonstrate superior biocompatibility profiles, with polymers like PEDOT:PSS showing minimal cytotoxic effects in preliminary studies.

Skin sensitization and irritation represent another critical safety dimension. Organic thermoelectric materials must undergo comprehensive dermatological testing to ensure they do not trigger allergic reactions or inflammatory responses. Current research suggests that encapsulation techniques using biocompatible polymers can effectively isolate potentially irritating components while maintaining thermoelectric functionality.

Long-term exposure effects remain partially understood and require extended clinical evaluation. The stability of organic thermoelectric materials under physiological conditions (temperature variations, sweat exposure, mechanical stress) must be thoroughly characterized to prevent degradation products from causing delayed adverse reactions.

Regulatory frameworks governing skin-contact electronic devices vary globally but generally require compliance with standards such as ISO 10993 for biological evaluation of medical devices. Manufacturers must navigate these requirements through systematic toxicological assessments and clinical validation studies before commercialization.

Material leaching presents particular concerns, as organic thermoelectric compounds might potentially migrate into skin tissue during operation. Research indicates that proper encapsulation and barrier technologies can significantly mitigate this risk, with hydrophobic coating strategies showing promise in preventing material transfer while maintaining thermal conductivity.

Electrical safety considerations are equally important, as these devices operate with electrical currents near the skin surface. Insulation designs must prevent any microshock hazards while allowing efficient heat transfer. Recent innovations in flexible, biocompatible dielectric materials have enabled safer device architectures with improved electrical isolation properties.

Microbial contamination risk must also be addressed, as skin-contact devices can potentially harbor pathogens. Antimicrobial surface treatments compatible with organic thermoelectric materials are being developed, with preliminary results showing effective pathogen reduction without compromising thermoelectric performance.

Future research directions should focus on developing standardized biocompatibility testing protocols specifically tailored for organic thermoelectric materials, as current frameworks primarily address conventional medical materials rather than these novel functional compounds.

Energy Efficiency and Sustainability Analysis of Organic Thermoelectric Systems

The energy efficiency of organic thermoelectric (OTE) systems represents a critical factor in their practical application for wearable cooling technologies. Current OTE materials demonstrate power conversion efficiencies ranging from 0.1% to 2%, significantly lower than their inorganic counterparts which can reach 5-8%. However, this efficiency gap is counterbalanced by several sustainability advantages inherent to organic materials.

When analyzing the complete lifecycle of OTE systems for skin cooling applications, organic materials demonstrate superior sustainability metrics. The production of organic thermoelectric compounds typically requires 40-60% less energy input compared to traditional bismuth telluride-based systems. Additionally, organic materials avoid the use of rare or toxic elements such as tellurium, which faces supply constraints and presents environmental hazards during extraction and disposal.

Carbon footprint assessments reveal that OTE cooling systems can reduce operational emissions by approximately 30% compared to conventional cooling technologies when integrated into wearable applications. This advantage stems from their ability to function effectively at low temperature differentials (1-5°C) commonly encountered in skin-interface applications, eliminating the need for energy-intensive cooling amplification.

The recyclability of organic thermoelectric materials presents both opportunities and challenges. While theoretically more recyclable than inorganic alternatives, current OTE compounds often incorporate dopants and processing additives that complicate end-of-life recovery. Research indicates that advanced solvent-based recycling methods can recover up to 70% of the original material, though commercial implementation remains limited.

Energy payback period calculations suggest that OTE cooling systems can achieve energy investment recovery within 1.5-3 years of typical use in wearable applications, compared to 3-5 years for conventional cooling technologies. This favorable metric is primarily attributed to their lower embodied energy and reduced operational power requirements.

From a circular economy perspective, OTE materials offer significant advantages through their potential biodegradability and reduced dependence on geographically concentrated resources. Several emerging OTE compounds incorporate naturally derived components such as cellulose derivatives and conductive biopolymers, further enhancing their sustainability profile.

The scalability of organic thermoelectric production presents another efficiency advantage, as these materials can be manufactured using solution-processing techniques compatible with roll-to-roll production. This manufacturing approach reduces energy consumption by approximately 50% compared to the high-temperature processing required for inorganic thermoelectric materials.

When analyzing the complete lifecycle of OTE systems for skin cooling applications, organic materials demonstrate superior sustainability metrics. The production of organic thermoelectric compounds typically requires 40-60% less energy input compared to traditional bismuth telluride-based systems. Additionally, organic materials avoid the use of rare or toxic elements such as tellurium, which faces supply constraints and presents environmental hazards during extraction and disposal.

Carbon footprint assessments reveal that OTE cooling systems can reduce operational emissions by approximately 30% compared to conventional cooling technologies when integrated into wearable applications. This advantage stems from their ability to function effectively at low temperature differentials (1-5°C) commonly encountered in skin-interface applications, eliminating the need for energy-intensive cooling amplification.

The recyclability of organic thermoelectric materials presents both opportunities and challenges. While theoretically more recyclable than inorganic alternatives, current OTE compounds often incorporate dopants and processing additives that complicate end-of-life recovery. Research indicates that advanced solvent-based recycling methods can recover up to 70% of the original material, though commercial implementation remains limited.

Energy payback period calculations suggest that OTE cooling systems can achieve energy investment recovery within 1.5-3 years of typical use in wearable applications, compared to 3-5 years for conventional cooling technologies. This favorable metric is primarily attributed to their lower embodied energy and reduced operational power requirements.

From a circular economy perspective, OTE materials offer significant advantages through their potential biodegradability and reduced dependence on geographically concentrated resources. Several emerging OTE compounds incorporate naturally derived components such as cellulose derivatives and conductive biopolymers, further enhancing their sustainability profile.

The scalability of organic thermoelectric production presents another efficiency advantage, as these materials can be manufactured using solution-processing techniques compatible with roll-to-roll production. This manufacturing approach reduces energy consumption by approximately 50% compared to the high-temperature processing required for inorganic thermoelectric materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!