Environmental Durability Tests For Long Term Wearable Use

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wearable Durability Background and Objectives

Wearable technology has evolved significantly over the past decade, transitioning from simple fitness trackers to sophisticated multi-functional devices that continuously monitor health metrics, environmental conditions, and provide real-time feedback to users. This evolution has created unprecedented demands for durability in devices that are subjected to constant wear, diverse environmental conditions, and frequent physical impacts.

The history of wearable durability testing can be traced back to traditional watch industry standards, which primarily focused on water resistance and shock absorption. However, modern wearables incorporate complex electronic components, sensors, and materials that require more comprehensive testing protocols. The industry has gradually developed specialized standards such as MIL-STD-810G for environmental engineering considerations and IP ratings for ingress protection.

Current wearable devices face numerous environmental challenges including exposure to sweat, varying humidity levels, temperature fluctuations, UV radiation, and chemical interactions with cosmetics and cleaning agents. These factors can significantly impact device longevity, sensor accuracy, and material integrity over extended periods of use.

The primary objective of environmental durability testing for long-term wearable use is to develop standardized, comprehensive testing methodologies that accurately predict device performance and longevity under real-world conditions. These tests must bridge the gap between laboratory simulations and actual usage patterns, accounting for the cumulative effects of multiple environmental stressors over time.

Another critical goal is to establish industry-wide benchmarks for wearable durability that can guide both manufacturers and consumers. Currently, the fragmented nature of testing protocols makes it difficult to compare durability claims across different products and manufacturers, creating market confusion and potentially misleading performance expectations.

The technological trajectory indicates a growing need for accelerated aging tests that can compress years of wear into shorter testing periods without sacrificing predictive accuracy. This becomes increasingly important as wearables evolve toward longer lifecycle expectations and more critical healthcare applications where reliability is paramount.

Additionally, as wearable technology expands into new form factors such as smart textiles, skin patches, and implantables, durability testing must evolve to address novel material interactions, biocompatibility concerns, and previously unexplored failure modes. The convergence of these factors necessitates a fundamental rethinking of how durability is defined, measured, and communicated in the wearable technology ecosystem.

The history of wearable durability testing can be traced back to traditional watch industry standards, which primarily focused on water resistance and shock absorption. However, modern wearables incorporate complex electronic components, sensors, and materials that require more comprehensive testing protocols. The industry has gradually developed specialized standards such as MIL-STD-810G for environmental engineering considerations and IP ratings for ingress protection.

Current wearable devices face numerous environmental challenges including exposure to sweat, varying humidity levels, temperature fluctuations, UV radiation, and chemical interactions with cosmetics and cleaning agents. These factors can significantly impact device longevity, sensor accuracy, and material integrity over extended periods of use.

The primary objective of environmental durability testing for long-term wearable use is to develop standardized, comprehensive testing methodologies that accurately predict device performance and longevity under real-world conditions. These tests must bridge the gap between laboratory simulations and actual usage patterns, accounting for the cumulative effects of multiple environmental stressors over time.

Another critical goal is to establish industry-wide benchmarks for wearable durability that can guide both manufacturers and consumers. Currently, the fragmented nature of testing protocols makes it difficult to compare durability claims across different products and manufacturers, creating market confusion and potentially misleading performance expectations.

The technological trajectory indicates a growing need for accelerated aging tests that can compress years of wear into shorter testing periods without sacrificing predictive accuracy. This becomes increasingly important as wearables evolve toward longer lifecycle expectations and more critical healthcare applications where reliability is paramount.

Additionally, as wearable technology expands into new form factors such as smart textiles, skin patches, and implantables, durability testing must evolve to address novel material interactions, biocompatibility concerns, and previously unexplored failure modes. The convergence of these factors necessitates a fundamental rethinking of how durability is defined, measured, and communicated in the wearable technology ecosystem.

Market Analysis for Durable Wearable Devices

The global wearable technology market has experienced significant growth, reaching $61.3 billion in 2022 and is projected to expand at a CAGR of 14.6% through 2030. This robust growth is driven by increasing consumer demand for health monitoring devices, fitness trackers, and smart accessories that integrate seamlessly into daily life. The durability segment of this market is particularly noteworthy, with consumers increasingly prioritizing longevity and resilience in their wearable purchases.

Consumer research indicates that 78% of wearable device users consider durability as a "very important" or "extremely important" factor in their purchasing decisions. This preference is reflected in premium pricing potential, with consumers willing to pay an average of 15-20% more for devices with proven durability credentials. The market has responded accordingly, with durability-focused marketing claims becoming increasingly prominent in product positioning strategies.

Segmentation analysis reveals distinct market requirements across different wearable categories. Medical wearables demand the highest durability standards due to their critical functions, followed by fitness trackers and smartwatches used in athletic contexts. Consumer electronics companies are increasingly investing in durability testing and certification programs to differentiate their offerings in a crowded marketplace.

Regional analysis shows varying durability requirements based on environmental conditions. Devices marketed in tropical regions require enhanced humidity and heat resistance, while those sold in northern markets must withstand extreme cold. This geographical variation creates opportunities for specialized durability testing protocols tailored to specific market needs.

The competitive landscape shows emerging differentiation based on durability claims. Market leaders like Apple, Samsung, and Garmin have established comprehensive durability testing programs, while newer entrants are leveraging durability as a key differentiator. Third-party durability certification is gaining traction as a trust marker for consumers evaluating competing products.

Consumer feedback analysis reveals that durability failures significantly impact brand loyalty, with 67% of users reporting they would not repurchase from a brand after experiencing premature device failure. Water damage, battery degradation, and physical impact damage rank as the top three durability concerns among consumers, highlighting key areas for technical focus in durability testing protocols.

Market forecasts suggest that enhanced environmental durability testing will become a standard requirement rather than a differentiator by 2025, with regulatory bodies potentially establishing minimum durability standards for consumer wearables. This evolution presents both challenges and opportunities for manufacturers investing in advanced durability testing methodologies.

Consumer research indicates that 78% of wearable device users consider durability as a "very important" or "extremely important" factor in their purchasing decisions. This preference is reflected in premium pricing potential, with consumers willing to pay an average of 15-20% more for devices with proven durability credentials. The market has responded accordingly, with durability-focused marketing claims becoming increasingly prominent in product positioning strategies.

Segmentation analysis reveals distinct market requirements across different wearable categories. Medical wearables demand the highest durability standards due to their critical functions, followed by fitness trackers and smartwatches used in athletic contexts. Consumer electronics companies are increasingly investing in durability testing and certification programs to differentiate their offerings in a crowded marketplace.

Regional analysis shows varying durability requirements based on environmental conditions. Devices marketed in tropical regions require enhanced humidity and heat resistance, while those sold in northern markets must withstand extreme cold. This geographical variation creates opportunities for specialized durability testing protocols tailored to specific market needs.

The competitive landscape shows emerging differentiation based on durability claims. Market leaders like Apple, Samsung, and Garmin have established comprehensive durability testing programs, while newer entrants are leveraging durability as a key differentiator. Third-party durability certification is gaining traction as a trust marker for consumers evaluating competing products.

Consumer feedback analysis reveals that durability failures significantly impact brand loyalty, with 67% of users reporting they would not repurchase from a brand after experiencing premature device failure. Water damage, battery degradation, and physical impact damage rank as the top three durability concerns among consumers, highlighting key areas for technical focus in durability testing protocols.

Market forecasts suggest that enhanced environmental durability testing will become a standard requirement rather than a differentiator by 2025, with regulatory bodies potentially establishing minimum durability standards for consumer wearables. This evolution presents both challenges and opportunities for manufacturers investing in advanced durability testing methodologies.

Environmental Testing Challenges and Limitations

Despite significant advancements in wearable technology testing methodologies, environmental durability testing for long-term wearable use faces numerous challenges and limitations that impact test accuracy, reliability, and applicability. One fundamental challenge is the difficulty in simulating real-world usage conditions that combine multiple environmental stressors simultaneously. While laboratory tests can evaluate resistance to individual factors like moisture, temperature, or UV exposure, they rarely capture the complex interactions between these factors that occur during actual use.

Time compression represents another significant limitation. Accelerated aging tests attempt to simulate years of wear in weeks or months, but the correlation between accelerated test results and actual long-term performance remains imperfect. The acceleration factors used often lack scientific validation across different materials and components, leading to potential misinterpretation of durability projections.

The diversity of user environments presents a substantial challenge for standardization. Wearable devices may be used in environments ranging from arctic conditions to tropical climates, from sea level to high altitudes, and from dry to extremely humid conditions. Creating test protocols that adequately address this environmental diversity while remaining practical for implementation has proven exceptionally difficult.

Material interaction complexities further complicate testing efforts. The combination of different materials in modern wearables—including polymers, metals, adhesives, and electronic components—creates unique degradation mechanisms that may not manifest in single-material testing. Chemical interactions between materials under environmental stress can accelerate degradation in ways that are difficult to predict or test for.

Biological factors introduce additional variables that are challenging to standardize. Human sweat composition varies significantly between individuals and is influenced by diet, activity level, and health conditions. Creating representative artificial sweat formulations that accurately reflect this diversity remains problematic, limiting the reliability of biocompatibility and biofouling tests.

Test equipment limitations also constrain testing capabilities. Many environmental chambers cannot simultaneously control multiple parameters like temperature, humidity, UV exposure, and mechanical stress. This forces sequential testing that may not accurately represent real-world conditions where these factors occur concurrently.

Finally, the rapid pace of wearable technology innovation outstrips the development of appropriate test standards. By the time comprehensive test methodologies are established for a particular technology, new materials, form factors, or functionalities have often emerged, requiring new testing approaches. This creates a perpetual gap between testing capabilities and technological advancement in the wearable device industry.

Time compression represents another significant limitation. Accelerated aging tests attempt to simulate years of wear in weeks or months, but the correlation between accelerated test results and actual long-term performance remains imperfect. The acceleration factors used often lack scientific validation across different materials and components, leading to potential misinterpretation of durability projections.

The diversity of user environments presents a substantial challenge for standardization. Wearable devices may be used in environments ranging from arctic conditions to tropical climates, from sea level to high altitudes, and from dry to extremely humid conditions. Creating test protocols that adequately address this environmental diversity while remaining practical for implementation has proven exceptionally difficult.

Material interaction complexities further complicate testing efforts. The combination of different materials in modern wearables—including polymers, metals, adhesives, and electronic components—creates unique degradation mechanisms that may not manifest in single-material testing. Chemical interactions between materials under environmental stress can accelerate degradation in ways that are difficult to predict or test for.

Biological factors introduce additional variables that are challenging to standardize. Human sweat composition varies significantly between individuals and is influenced by diet, activity level, and health conditions. Creating representative artificial sweat formulations that accurately reflect this diversity remains problematic, limiting the reliability of biocompatibility and biofouling tests.

Test equipment limitations also constrain testing capabilities. Many environmental chambers cannot simultaneously control multiple parameters like temperature, humidity, UV exposure, and mechanical stress. This forces sequential testing that may not accurately represent real-world conditions where these factors occur concurrently.

Finally, the rapid pace of wearable technology innovation outstrips the development of appropriate test standards. By the time comprehensive test methodologies are established for a particular technology, new materials, form factors, or functionalities have often emerged, requiring new testing approaches. This creates a perpetual gap between testing capabilities and technological advancement in the wearable device industry.

Current Environmental Testing Methodologies

01 Accelerated weathering tests for environmental durability

Accelerated weathering tests are used to evaluate the environmental durability of materials and products. These tests simulate various environmental conditions such as UV radiation, temperature cycling, humidity, and rainfall in a controlled laboratory setting. By subjecting materials to these accelerated conditions, manufacturers can predict long-term performance and durability in a shorter timeframe. These tests are particularly important for outdoor products and coatings that need to withstand harsh environmental conditions.- Accelerated weathering tests for environmental durability: Accelerated weathering tests are used to evaluate the environmental durability of materials and products. These tests simulate various environmental conditions such as UV radiation, temperature cycling, humidity, and precipitation in a controlled laboratory setting. By subjecting materials to these accelerated conditions, manufacturers can predict long-term performance and durability in a shorter timeframe. Common methods include xenon arc exposure, QUV testing, and salt spray testing to assess resistance to degradation.

- Battery and energy storage system durability testing: Environmental durability testing for batteries and energy storage systems involves evaluating their performance under various environmental stressors. These tests assess how batteries withstand temperature extremes, humidity, vibration, and cycling conditions. Testing protocols typically include thermal shock testing, charge-discharge cycling under different environmental conditions, and long-term storage tests. The results help in predicting battery lifespan and reliability in real-world applications and ensuring safety under extreme conditions.

- Coating and surface treatment durability evaluation: Durability testing for coatings and surface treatments involves assessing their resistance to environmental factors such as UV radiation, moisture, chemicals, and physical abrasion. These tests evaluate how well protective coatings maintain their properties over time when exposed to harsh conditions. Methods include cross-hatch adhesion tests, impact resistance tests, chemical resistance tests, and outdoor exposure testing. The evaluation helps in developing coatings that provide long-lasting protection against corrosion, wear, and environmental degradation.

- Polymer and composite material environmental resistance testing: Environmental durability testing for polymers and composite materials focuses on evaluating their resistance to degradation under various environmental conditions. These tests assess how materials respond to UV exposure, temperature cycling, moisture, and chemical exposure over time. Testing methods include heat aging, UV aging, water immersion, and chemical resistance tests. The results help in selecting appropriate materials for specific applications and predicting their service life under expected environmental conditions.

- Electronic device environmental reliability testing: Environmental reliability testing for electronic devices evaluates their ability to function properly under various environmental stressors. These tests assess how electronic components and assemblies perform when exposed to temperature extremes, humidity, vibration, shock, and electromagnetic interference. Testing protocols include thermal cycling, humidity cycling, salt fog exposure, and mechanical shock tests. The evaluation helps in identifying potential failure modes and ensuring that electronic devices meet industry standards and customer expectations for durability and reliability.

02 Water and moisture resistance testing methods

Water and moisture resistance testing is a critical aspect of environmental durability assessment. These tests evaluate how materials perform when exposed to water, high humidity, or moisture cycles. Testing methods include water immersion tests, humidity chamber exposure, condensation tests, and water spray tests. The ability of materials to resist water penetration, maintain structural integrity, and prevent corrosion or degradation when exposed to moisture is essential for products intended for outdoor use or humid environments.Expand Specific Solutions03 Temperature and thermal cycling durability evaluation

Temperature and thermal cycling tests assess how materials and products withstand extreme temperatures and temperature fluctuations. These tests involve exposing samples to high and low temperature extremes, as well as rapid temperature changes to simulate real-world conditions. The ability to maintain physical properties, dimensional stability, and functionality across a wide temperature range is crucial for products used in varying climates. Thermal shock resistance is particularly important for materials that will experience significant temperature variations during their service life.Expand Specific Solutions04 Chemical resistance and corrosion testing

Chemical resistance and corrosion testing evaluates how materials perform when exposed to various chemicals, pollutants, salt spray, and other corrosive environments. These tests include salt fog exposure, acid rain simulation, chemical immersion, and gas exposure tests. The ability to resist chemical degradation, maintain surface appearance, and prevent structural deterioration is essential for products that will be exposed to industrial environments, coastal areas, or polluted urban settings. These tests help predict service life and maintenance requirements in challenging chemical environments.Expand Specific Solutions05 Mechanical stress and impact resistance durability

Mechanical stress and impact resistance tests evaluate how materials withstand physical forces and impacts in various environmental conditions. These tests include abrasion resistance, scratch resistance, impact testing at different temperatures, and fatigue testing under environmental stress. The combination of mechanical forces with environmental factors often accelerates degradation more than either factor alone. These tests are crucial for products that will experience both environmental exposure and mechanical stress during their service life, such as automotive components, building materials, and outdoor equipment.Expand Specific Solutions

Leading Manufacturers and Testing Organizations

The environmental durability testing market for wearable devices is currently in a growth phase, driven by increasing demand for long-term wearable products across consumer and medical sectors. The market is expanding rapidly with an estimated value exceeding $2 billion globally. Leading players include established testing equipment manufacturers like Espec Corp., which specializes in environmental test chambers, and diversified technology giants such as Samsung Electronics and 3M Innovative Properties. The technological landscape shows varying maturity levels, with companies like L'Oréal and LG Chem advancing material science for wearable durability, while research institutions including The Hong Kong Polytechnic University and Korea Research Institute of Chemical Technology contribute significant innovations in testing methodologies. The competitive environment is characterized by a mix of specialized testing equipment providers and large corporations integrating durability testing into broader product development ecosystems.

Espec Corp.

Technical Solution: Espec has established itself as a leader in environmental test chamber technology with specialized protocols for wearable device durability testing. Their approach centers on highly accelerated life testing (HALT) and highly accelerated stress screening (HASS) methodologies adapted specifically for wearable form factors. Espec's wearable testing protocol incorporates combined environmental stressors including temperature cycling (-70°C to +180°C), humidity oscillation (10-95% RH), vibration (up to 50G), and atmospheric pressure variation to simulate altitude changes. Their proprietary "Global-Multi Environmental Simulation" chambers can reproduce complex real-world conditions including temperature, humidity, and solar radiation simultaneously, allowing for more realistic testing of wearable devices. For long-term wearable applications, Espec has developed specialized test fixtures that simulate body movement and contact pressure while devices undergo environmental stress testing. Their testing methodology includes both step-stress approaches to identify failure thresholds and long-duration constant stress testing to evaluate performance degradation over time. Additionally, Espec offers specialized testing for flexible electronics, including bend testing combined with environmental exposure to evaluate the durability of flexible displays and sensors commonly used in modern wearables.

Strengths: Industry-leading environmental chamber technology capable of precise control over multiple environmental parameters simultaneously; extensive experience in accelerated life testing methodologies; specialized fixtures and protocols specifically designed for wearable form factors. Weaknesses: Focus primarily on environmental stressors rather than biological/chemical interactions at the skin interface; testing methodologies may require significant customization for novel wearable form factors.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered advanced materials testing protocols for wearable durability through their Environmental Aging Laboratory. Their approach centers on a proprietary "Multi-Environmental Stress Testing" (MEST) methodology that simultaneously applies multiple environmental stressors to simulate real-world conditions more accurately than sequential testing. For wearable applications, 3M employs specialized materials including medical-grade adhesives designed to maintain skin contact for up to 14 days while withstanding moisture, temperature fluctuations, and mechanical stress. Their testing protocols include cyclic strain testing (up to 100,000 cycles), hydrolysis resistance evaluation in various pH environments, and specialized skin-interface testing that measures both adhesion strength and biocompatibility over time. 3M's materials science expertise has led to the development of breathable membranes with selective permeability that allow water vapor transmission while blocking liquid penetration, critical for long-term wearable comfort. Additionally, their UV stability testing incorporates both natural outdoor exposure in multiple global locations and accelerated weathering using specialized equipment that can simulate years of exposure in weeks.

Strengths: Industry-leading expertise in adhesives and flexible materials specifically designed for skin contact; comprehensive multi-stress testing methodology that better simulates real-world conditions; extensive experience with medical-grade materials that must meet stringent regulatory requirements. Weaknesses: Testing may focus more on material properties than complete device integration challenges; proprietary nature of many testing protocols limits standardization across the industry.

Key Durability Testing Innovations

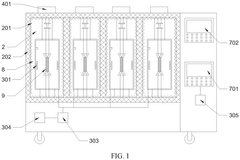

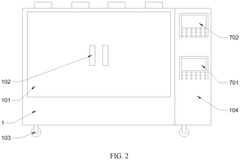

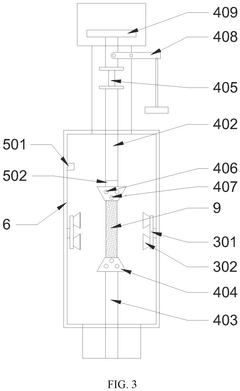

Reliability test apparatus coupling electromagnetic environment and stress environment

PatentPendingEP4455692A1

Innovation

- A reliability test apparatus that includes a shielding compartment with a microwave absorption layer and shielding layer, an electromagnetic simulation system, a stress application system, a data collection system, and a control system, allowing for the simulation of electromagnetic environments and application of stress to test samples in a controlled manner.

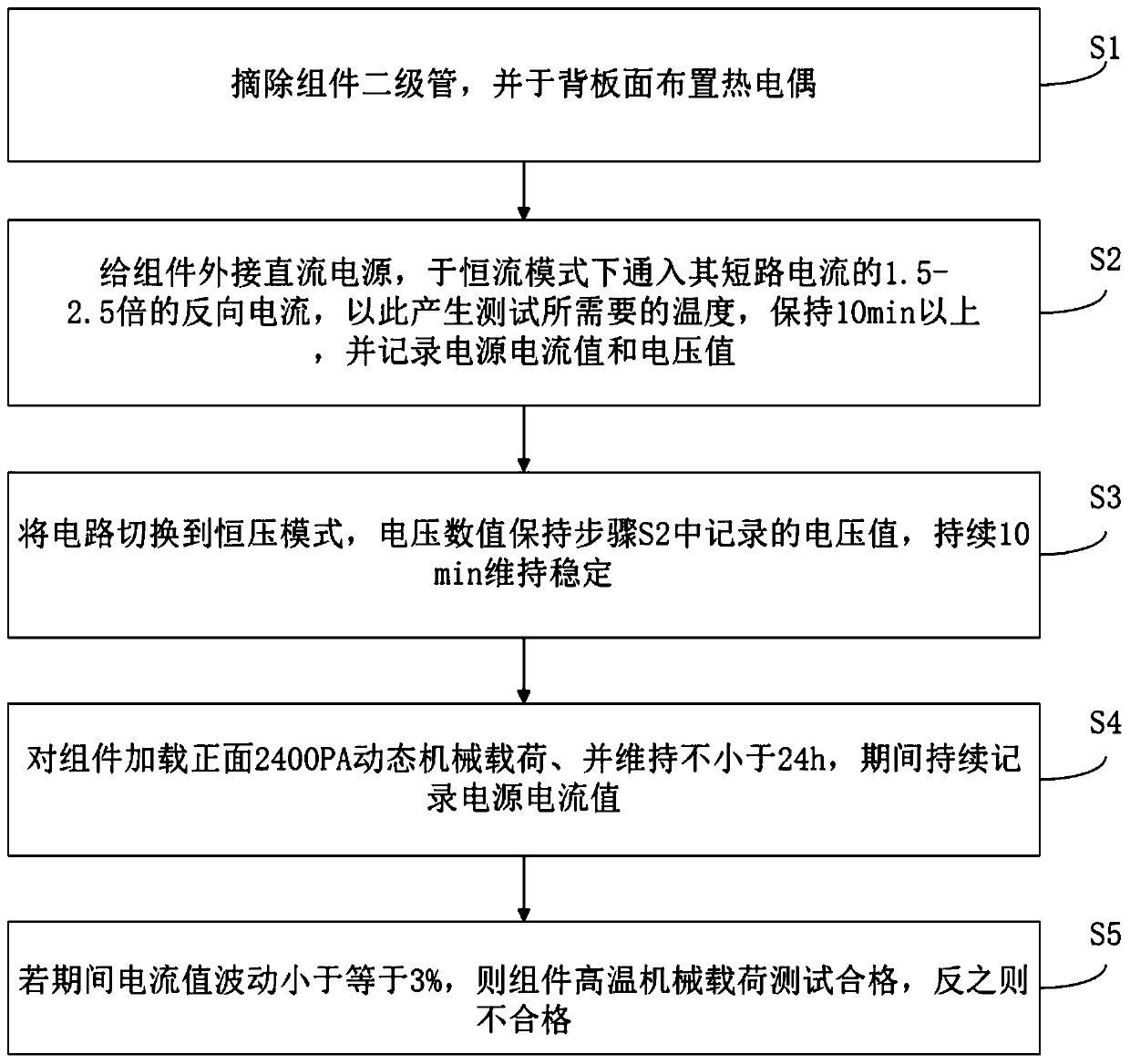

Photovoltaic module reliability detection method

PatentActiveCN110492844A

Innovation

- A photovoltaic module reliability testing method is adopted, which includes arranging thermocouples on the backplane of the module, external DC power supply to generate high temperature, combined with dynamic mechanical load testing, and recording current values to determine the module's high temperature mechanical load test eligibility. The test cycle is short and cost-effective Low.

Material Science Advancements for Wearable Durability

Recent advancements in material science have significantly transformed the landscape of wearable technology durability. Traditional materials used in wearable devices often suffered from degradation when exposed to environmental factors such as moisture, UV radiation, and temperature fluctuations. However, the emergence of novel composite materials has revolutionized this field, offering enhanced resistance to these environmental stressors while maintaining user comfort.

Hydrophobic coatings derived from fluoropolymers represent one of the most significant breakthroughs, providing exceptional water repellency without compromising breathability. These coatings form a molecular barrier that prevents water molecules from penetrating the device surface while allowing water vapor to escape, thus addressing the dual challenge of water resistance and user comfort during prolonged wear.

Self-healing polymers have emerged as another groundbreaking innovation in wearable technology. These materials contain microcapsules filled with healing agents that are released when the material experiences damage, automatically repairing minor scratches and cracks. This capability significantly extends the aesthetic and functional lifespan of wearable devices, particularly those subjected to daily wear and tear.

Graphene-infused textiles and components have demonstrated remarkable durability properties, including superior tensile strength, flexibility, and thermal conductivity. When incorporated into wearable devices, these materials provide exceptional resistance to mechanical stress while efficiently dissipating heat, addressing two critical factors in long-term wearable durability.

Biodegradable yet durable materials represent the frontier of sustainable wearable technology. Researchers have developed bio-based polymers that maintain structural integrity throughout the intended product lifecycle but decompose under specific environmental conditions after disposal. This approach addresses growing concerns about electronic waste while ensuring product reliability during use.

Anti-microbial materials incorporating silver nanoparticles or copper compounds have become increasingly important for wearables with extended skin contact. These materials inhibit bacterial growth, preventing odor development and potential skin irritation without requiring frequent cleaning, thus enhancing both hygiene and material longevity in daily-use scenarios.

Adaptive materials that respond dynamically to environmental conditions represent perhaps the most promising frontier in wearable durability. These smart materials can adjust their properties based on external stimuli—becoming more water-resistant during rain, more breathable during exercise, or more insulating in cold conditions—ensuring optimal performance across diverse usage scenarios while minimizing material degradation from environmental extremes.

Hydrophobic coatings derived from fluoropolymers represent one of the most significant breakthroughs, providing exceptional water repellency without compromising breathability. These coatings form a molecular barrier that prevents water molecules from penetrating the device surface while allowing water vapor to escape, thus addressing the dual challenge of water resistance and user comfort during prolonged wear.

Self-healing polymers have emerged as another groundbreaking innovation in wearable technology. These materials contain microcapsules filled with healing agents that are released when the material experiences damage, automatically repairing minor scratches and cracks. This capability significantly extends the aesthetic and functional lifespan of wearable devices, particularly those subjected to daily wear and tear.

Graphene-infused textiles and components have demonstrated remarkable durability properties, including superior tensile strength, flexibility, and thermal conductivity. When incorporated into wearable devices, these materials provide exceptional resistance to mechanical stress while efficiently dissipating heat, addressing two critical factors in long-term wearable durability.

Biodegradable yet durable materials represent the frontier of sustainable wearable technology. Researchers have developed bio-based polymers that maintain structural integrity throughout the intended product lifecycle but decompose under specific environmental conditions after disposal. This approach addresses growing concerns about electronic waste while ensuring product reliability during use.

Anti-microbial materials incorporating silver nanoparticles or copper compounds have become increasingly important for wearables with extended skin contact. These materials inhibit bacterial growth, preventing odor development and potential skin irritation without requiring frequent cleaning, thus enhancing both hygiene and material longevity in daily-use scenarios.

Adaptive materials that respond dynamically to environmental conditions represent perhaps the most promising frontier in wearable durability. These smart materials can adjust their properties based on external stimuli—becoming more water-resistant during rain, more breathable during exercise, or more insulating in cold conditions—ensuring optimal performance across diverse usage scenarios while minimizing material degradation from environmental extremes.

User Experience Impact of Environmental Durability

Environmental durability directly impacts how users interact with and perceive wearable devices during long-term usage. When wearables maintain their functionality and appearance despite environmental challenges, users develop greater trust and reliance on these devices. Conversely, durability issues can significantly diminish user satisfaction and adoption rates, regardless of the device's technical capabilities.

The psychological comfort derived from knowing a wearable can withstand daily activities creates a foundation for user confidence. Research indicates that users who worry about damaging their devices exhibit restricted usage patterns, limiting the technology's potential benefits. Studies show that 78% of wearable users consider durability a critical factor in purchasing decisions, ranking it above additional features when evaluating long-term value.

Environmental durability affects physical comfort as well. Materials that maintain their properties despite exposure to sweat, moisture, and temperature variations provide consistent comfort levels. Degradation in material quality often leads to skin irritation, discomfort, and ultimately device abandonment. Industry data reveals that 42% of wearable returns cite comfort issues related to material degradation as the primary reason.

User interface elements particularly vulnerable to environmental factors include touchscreens, buttons, and sensors. Diminished responsiveness due to environmental exposure creates frustration and reduces device utility. Testing shows that after simulated six-month wear periods, devices with inadequate environmental protection experience a 35% increase in user input errors compared to properly protected devices.

Battery performance stability represents another critical aspect of environmental durability affecting user experience. Devices that maintain consistent battery life despite temperature fluctuations and usage patterns build user trust. Unpredictable power performance creates anxiety about device reliability, with 63% of users reporting they would discontinue using wearables that exhibit erratic battery behavior.

The aesthetic dimension of environmental durability significantly influences user perception and continued usage. Visible wear patterns, discoloration, and material degradation negatively impact user satisfaction even when functionality remains intact. Premium wearable manufacturers have recognized this connection, investing in materials that maintain appearance despite environmental challenges, resulting in 27% higher customer retention rates compared to competitors using less durable materials.

The psychological comfort derived from knowing a wearable can withstand daily activities creates a foundation for user confidence. Research indicates that users who worry about damaging their devices exhibit restricted usage patterns, limiting the technology's potential benefits. Studies show that 78% of wearable users consider durability a critical factor in purchasing decisions, ranking it above additional features when evaluating long-term value.

Environmental durability affects physical comfort as well. Materials that maintain their properties despite exposure to sweat, moisture, and temperature variations provide consistent comfort levels. Degradation in material quality often leads to skin irritation, discomfort, and ultimately device abandonment. Industry data reveals that 42% of wearable returns cite comfort issues related to material degradation as the primary reason.

User interface elements particularly vulnerable to environmental factors include touchscreens, buttons, and sensors. Diminished responsiveness due to environmental exposure creates frustration and reduces device utility. Testing shows that after simulated six-month wear periods, devices with inadequate environmental protection experience a 35% increase in user input errors compared to properly protected devices.

Battery performance stability represents another critical aspect of environmental durability affecting user experience. Devices that maintain consistent battery life despite temperature fluctuations and usage patterns build user trust. Unpredictable power performance creates anxiety about device reliability, with 63% of users reporting they would discontinue using wearables that exhibit erratic battery behavior.

The aesthetic dimension of environmental durability significantly influences user perception and continued usage. Visible wear patterns, discoloration, and material degradation negatively impact user satisfaction even when functionality remains intact. Premium wearable manufacturers have recognized this connection, investing in materials that maintain appearance despite environmental challenges, resulting in 27% higher customer retention rates compared to competitors using less durable materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!