Ammonium hydroxide use in cosmetics formulation

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide in Cosmetics: Background and Objectives

Ammonium hydroxide, a compound of nitrogen and hydrogen in water, has been a subject of interest in the cosmetics industry for decades. Its use in cosmetic formulations dates back to the early 20th century, with applications ranging from hair dyes to skin care products. The evolution of this chemical's role in cosmetics has been shaped by advancements in chemistry, changing consumer preferences, and regulatory developments.

Initially, ammonium hydroxide found its primary use in hair coloring products, where it served as an alkalizing agent to open the hair cuticle and facilitate dye penetration. Over time, its applications expanded to include various cosmetic formulations, including skin care products, where it acts as a pH adjuster and buffering agent. The ability of ammonium hydroxide to maintain the stability and effectiveness of cosmetic formulations has made it a valuable ingredient in the industry.

The cosmetics sector has witnessed significant technological advancements in recent years, driving the need for innovative formulation techniques. In this context, the role of ammonium hydroxide has evolved, with researchers exploring its potential in new applications and seeking to optimize its use in existing products. The primary objective of current research efforts is to enhance the efficacy and safety of cosmetic formulations containing ammonium hydroxide while addressing potential concerns related to its use.

One key area of focus is the development of more precise and controlled methods for incorporating ammonium hydroxide into cosmetic formulations. This includes investigating optimal concentration levels, exploring synergistic effects with other ingredients, and assessing its impact on product stability and shelf life. Researchers are also examining ways to mitigate potential irritation or sensitization issues associated with ammonium hydroxide, particularly in products designed for sensitive skin.

Another important aspect of ongoing research is the exploration of alternative or complementary ingredients that can work in conjunction with ammonium hydroxide to improve overall product performance. This involves studying the interactions between ammonium hydroxide and various cosmetic ingredients, such as emollients, humectants, and active compounds, to create more effective and multifunctional formulations.

As the cosmetics industry continues to evolve, driven by consumer demand for safer, more natural, and environmentally friendly products, research on ammonium hydroxide usage is also adapting to these trends. Scientists are investigating potential bio-based alternatives and exploring ways to minimize the environmental impact of ammonium hydroxide production and use in cosmetics. This aligns with the broader industry goal of developing more sustainable and eco-friendly formulations.

Initially, ammonium hydroxide found its primary use in hair coloring products, where it served as an alkalizing agent to open the hair cuticle and facilitate dye penetration. Over time, its applications expanded to include various cosmetic formulations, including skin care products, where it acts as a pH adjuster and buffering agent. The ability of ammonium hydroxide to maintain the stability and effectiveness of cosmetic formulations has made it a valuable ingredient in the industry.

The cosmetics sector has witnessed significant technological advancements in recent years, driving the need for innovative formulation techniques. In this context, the role of ammonium hydroxide has evolved, with researchers exploring its potential in new applications and seeking to optimize its use in existing products. The primary objective of current research efforts is to enhance the efficacy and safety of cosmetic formulations containing ammonium hydroxide while addressing potential concerns related to its use.

One key area of focus is the development of more precise and controlled methods for incorporating ammonium hydroxide into cosmetic formulations. This includes investigating optimal concentration levels, exploring synergistic effects with other ingredients, and assessing its impact on product stability and shelf life. Researchers are also examining ways to mitigate potential irritation or sensitization issues associated with ammonium hydroxide, particularly in products designed for sensitive skin.

Another important aspect of ongoing research is the exploration of alternative or complementary ingredients that can work in conjunction with ammonium hydroxide to improve overall product performance. This involves studying the interactions between ammonium hydroxide and various cosmetic ingredients, such as emollients, humectants, and active compounds, to create more effective and multifunctional formulations.

As the cosmetics industry continues to evolve, driven by consumer demand for safer, more natural, and environmentally friendly products, research on ammonium hydroxide usage is also adapting to these trends. Scientists are investigating potential bio-based alternatives and exploring ways to minimize the environmental impact of ammonium hydroxide production and use in cosmetics. This aligns with the broader industry goal of developing more sustainable and eco-friendly formulations.

Market Analysis for Ammonium Hydroxide-based Cosmetics

The global market for ammonium hydroxide-based cosmetics has been experiencing steady growth in recent years, driven by increasing consumer demand for effective and multifunctional beauty products. This segment of the cosmetics industry is expected to continue its upward trajectory, with a projected compound annual growth rate (CAGR) of 5.8% from 2021 to 2026.

The rising popularity of ammonium hydroxide in cosmetic formulations can be attributed to its versatile properties. As a pH adjuster and buffering agent, it plays a crucial role in maintaining the stability and efficacy of various cosmetic products. Additionally, its ability to act as a neutralizer in hair dyes and bleaching agents has significantly contributed to its widespread adoption in the hair care sector.

The skincare segment represents the largest market share for ammonium hydroxide-based cosmetics, accounting for approximately 40% of the total market value. This is primarily due to the increasing demand for anti-aging products and the growing awareness of skin health among consumers. Hair care products follow closely, with a market share of around 35%, driven by the rising popularity of hair coloring and treatment products.

Geographically, North America and Europe dominate the market, collectively accounting for over 60% of the global market share. This can be attributed to the presence of established cosmetic manufacturers, advanced research and development facilities, and high consumer spending on personal care products in these regions. However, the Asia-Pacific region is expected to witness the fastest growth, with a CAGR of 7.2% during the forecast period, driven by the increasing disposable income and changing lifestyle preferences in countries like China and India.

Key market players in the ammonium hydroxide-based cosmetics industry include L'Oréal, Unilever, Procter & Gamble, and Estée Lauder. These companies are investing heavily in research and development to innovate new formulations and expand their product portfolios. Moreover, there is a growing trend towards the development of natural and organic cosmetic products, which is expected to create new opportunities for ammonium hydroxide alternatives in the coming years.

Consumer awareness regarding the safety and environmental impact of cosmetic ingredients is also shaping the market dynamics. While ammonium hydroxide is generally recognized as safe for use in cosmetics by regulatory bodies, there is an increasing demand for transparency in ingredient labeling and formulation processes. This trend is likely to influence product development strategies and marketing approaches in the industry.

The rising popularity of ammonium hydroxide in cosmetic formulations can be attributed to its versatile properties. As a pH adjuster and buffering agent, it plays a crucial role in maintaining the stability and efficacy of various cosmetic products. Additionally, its ability to act as a neutralizer in hair dyes and bleaching agents has significantly contributed to its widespread adoption in the hair care sector.

The skincare segment represents the largest market share for ammonium hydroxide-based cosmetics, accounting for approximately 40% of the total market value. This is primarily due to the increasing demand for anti-aging products and the growing awareness of skin health among consumers. Hair care products follow closely, with a market share of around 35%, driven by the rising popularity of hair coloring and treatment products.

Geographically, North America and Europe dominate the market, collectively accounting for over 60% of the global market share. This can be attributed to the presence of established cosmetic manufacturers, advanced research and development facilities, and high consumer spending on personal care products in these regions. However, the Asia-Pacific region is expected to witness the fastest growth, with a CAGR of 7.2% during the forecast period, driven by the increasing disposable income and changing lifestyle preferences in countries like China and India.

Key market players in the ammonium hydroxide-based cosmetics industry include L'Oréal, Unilever, Procter & Gamble, and Estée Lauder. These companies are investing heavily in research and development to innovate new formulations and expand their product portfolios. Moreover, there is a growing trend towards the development of natural and organic cosmetic products, which is expected to create new opportunities for ammonium hydroxide alternatives in the coming years.

Consumer awareness regarding the safety and environmental impact of cosmetic ingredients is also shaping the market dynamics. While ammonium hydroxide is generally recognized as safe for use in cosmetics by regulatory bodies, there is an increasing demand for transparency in ingredient labeling and formulation processes. This trend is likely to influence product development strategies and marketing approaches in the industry.

Current Applications and Challenges in Cosmetic Formulations

Ammonium hydroxide has found widespread use in cosmetic formulations due to its versatile properties. As a pH adjuster, it plays a crucial role in maintaining the stability and effectiveness of various cosmetic products. In hair care, ammonium hydroxide is commonly used in hair dyes and bleaching agents, where it helps to open the hair cuticle, allowing for better penetration of colorants or lightening agents. This application has revolutionized the hair coloring industry, enabling more vibrant and longer-lasting results.

In skincare products, ammonium hydroxide serves as a buffering agent, helping to control the pH levels of formulations. This is particularly important in products like facial cleansers and toners, where maintaining the skin's natural pH balance is essential for optimal skin health. Additionally, its alkaline nature makes it useful in certain exfoliating products, where it can help to soften the skin and facilitate the removal of dead skin cells.

Despite its widespread use, the application of ammonium hydroxide in cosmetics faces several challenges. One of the primary concerns is its potential for skin irritation, especially in higher concentrations. Formulators must carefully balance the concentration of ammonium hydroxide to achieve the desired pH adjustment without compromising skin safety. This challenge is particularly pronounced in products intended for sensitive skin or those designed for frequent use.

Another significant challenge lies in the volatile nature of ammonium hydroxide. Its tendency to evaporate can lead to changes in product pH over time, potentially affecting the stability and efficacy of the formulation. This necessitates careful consideration in packaging and storage solutions to maintain product integrity throughout its shelf life.

The strong odor associated with ammonium hydroxide presents another hurdle for cosmetic formulators. Masking this odor without compromising the product's performance or introducing additional irritants requires sophisticated fragrance technology and formulation expertise. This challenge is particularly relevant in leave-on products where consumer acceptance is closely tied to sensory attributes.

Regulatory compliance poses an ongoing challenge in the use of ammonium hydroxide in cosmetics. Different regions have varying regulations regarding its permissible concentrations and usage in specific product categories. Formulators must navigate these regulatory landscapes while ensuring product efficacy and safety, often necessitating the development of region-specific formulations.

As the cosmetics industry moves towards more natural and sustainable solutions, there is growing pressure to find alternatives to synthetic pH adjusters like ammonium hydroxide. This trend challenges formulators to explore plant-based or biotechnology-derived alternatives that can match the performance of ammonium hydroxide without compromising on product stability or efficacy.

In skincare products, ammonium hydroxide serves as a buffering agent, helping to control the pH levels of formulations. This is particularly important in products like facial cleansers and toners, where maintaining the skin's natural pH balance is essential for optimal skin health. Additionally, its alkaline nature makes it useful in certain exfoliating products, where it can help to soften the skin and facilitate the removal of dead skin cells.

Despite its widespread use, the application of ammonium hydroxide in cosmetics faces several challenges. One of the primary concerns is its potential for skin irritation, especially in higher concentrations. Formulators must carefully balance the concentration of ammonium hydroxide to achieve the desired pH adjustment without compromising skin safety. This challenge is particularly pronounced in products intended for sensitive skin or those designed for frequent use.

Another significant challenge lies in the volatile nature of ammonium hydroxide. Its tendency to evaporate can lead to changes in product pH over time, potentially affecting the stability and efficacy of the formulation. This necessitates careful consideration in packaging and storage solutions to maintain product integrity throughout its shelf life.

The strong odor associated with ammonium hydroxide presents another hurdle for cosmetic formulators. Masking this odor without compromising the product's performance or introducing additional irritants requires sophisticated fragrance technology and formulation expertise. This challenge is particularly relevant in leave-on products where consumer acceptance is closely tied to sensory attributes.

Regulatory compliance poses an ongoing challenge in the use of ammonium hydroxide in cosmetics. Different regions have varying regulations regarding its permissible concentrations and usage in specific product categories. Formulators must navigate these regulatory landscapes while ensuring product efficacy and safety, often necessitating the development of region-specific formulations.

As the cosmetics industry moves towards more natural and sustainable solutions, there is growing pressure to find alternatives to synthetic pH adjusters like ammonium hydroxide. This trend challenges formulators to explore plant-based or biotechnology-derived alternatives that can match the performance of ammonium hydroxide without compromising on product stability or efficacy.

Existing Formulation Techniques with Ammonium Hydroxide

01 Use of ammonium hydroxide in chemical processes

Ammonium hydroxide is widely used in various chemical processes as a reactant, catalyst, or pH adjuster. It plays a crucial role in the synthesis of organic compounds, production of fertilizers, and treatment of industrial waste. Its alkaline properties make it useful for neutralizing acids and controlling pH levels in different applications.- Use in chemical processes: Ammonium hydroxide is widely used in various chemical processes as a reactant, catalyst, or pH regulator. It plays a crucial role in the synthesis of organic compounds, production of fertilizers, and treatment of industrial waste. Its alkaline properties make it suitable for neutralizing acids and controlling pH levels in different applications.

- Application in cleaning and surface treatment: Ammonium hydroxide is utilized in cleaning formulations and surface treatment processes. It is effective in removing grease, oils, and other contaminants from various surfaces. In the semiconductor industry, it is used for etching and cleaning silicon wafers. Additionally, it finds applications in the textile industry for fabric treatment and in the leather industry for dehairing hides.

- Role in environmental remediation: Ammonium hydroxide is employed in environmental remediation processes, particularly in air pollution control. It is used in flue gas treatment systems to neutralize acidic components and remove sulfur dioxide. In water treatment, it helps in adjusting pH levels and removing heavy metals. Its ability to react with and neutralize various pollutants makes it valuable in environmental protection applications.

- Use in personal care and cosmetic products: Ammonium hydroxide finds applications in personal care and cosmetic products. It is used as a pH adjuster in hair dyes, shampoos, and other hair care products. In some cosmetic formulations, it acts as a buffering agent or helps in adjusting the viscosity of the product. Its alkaline nature also makes it useful in certain depilatory creams and hair relaxers.

- Application in food processing: Ammonium hydroxide has specific applications in food processing. It is used as a leavening agent in baked goods, helping to create a lighter texture. In some countries, it is approved as a food additive for pH control. It also finds use in the production of certain types of caramel coloring. However, its use in food applications is regulated and limited to specific concentrations due to safety considerations.

02 Application in hair coloring and bleaching

Ammonium hydroxide is commonly used in hair coloring and bleaching products. It helps to open the hair cuticle, allowing the dye or bleaching agent to penetrate the hair shaft more effectively. This results in more vibrant and longer-lasting hair color or a more efficient lightening process.Expand Specific Solutions03 Role in cleaning and household products

Ammonium hydroxide is an effective cleaning agent used in various household and industrial cleaning products. Its alkaline nature helps to dissolve grease, remove stains, and sanitize surfaces. It is particularly useful in glass cleaners, floor cleaners, and oven cleaners due to its ability to cut through tough grime and leave surfaces streak-free.Expand Specific Solutions04 Use in textile processing

In the textile industry, ammonium hydroxide is used for various purposes, including fabric treatment, dyeing, and printing. It can help to improve the color fastness of dyes, adjust the pH of textile processing baths, and assist in the mercerization of cotton fabrics. Its alkaline properties also make it useful in removing certain types of stains from textiles.Expand Specific Solutions05 Environmental and agricultural applications

Ammonium hydroxide has applications in environmental protection and agriculture. It is used in air pollution control systems to neutralize acidic gases, in wastewater treatment to adjust pH levels, and as a source of nitrogen in fertilizers. In agriculture, it can be applied directly to soil or used in the production of other nitrogen-based fertilizers to improve crop yields.Expand Specific Solutions

Key Players in Ammonium Hydroxide Cosmetic Industry

The research on ammonium hydroxide in cosmetics formulation is in a mature stage, with a well-established market and significant industry players involved. The global cosmetics market, valued at over $500 billion, provides a substantial backdrop for this technology. Major companies like L'Oréal, Shiseido, and Unilever are at the forefront, leveraging their extensive R&D capabilities to optimize ammonium hydroxide usage in various cosmetic applications. The technology's maturity is evident in its widespread adoption across different product categories, from hair dyes to skincare. However, ongoing research by companies such as Henkel and Beiersdorf suggests potential for further innovation and refinement in formulation techniques and safety assessments.

L'Oréal SA

Technical Solution: L'Oréal has developed innovative formulations using ammonium hydroxide in hair coloring products. Their research focuses on optimizing the pH balance and improving color penetration. They have patented a hair dyeing composition containing ammonium hydroxide as an alkalizing agent, which enhances dye uptake and provides long-lasting color results[1]. L'Oréal's formulation also includes specific polymers that work synergistically with ammonium hydroxide to protect the hair fiber during the coloring process, reducing damage and improving overall hair quality[2].

Strengths: Extensive research and patented formulations, improved color penetration and longevity. Weaknesses: Potential for scalp irritation in sensitive individuals, strong ammonia odor.

Shiseido Co., Ltd.

Technical Solution: Shiseido has conducted research on incorporating ammonium hydroxide in skincare formulations, particularly in exfoliating and pH-adjusting products. They have developed a unique approach that combines ammonium hydroxide with natural plant extracts to create gentle yet effective exfoliating treatments[3]. Their formulation utilizes a controlled-release system that gradually releases ammonium hydroxide, allowing for a sustained exfoliating effect while minimizing skin irritation[4]. Shiseido has also explored the use of ammonium hydroxide in pH-adjusting toners to optimize skin absorption of subsequent skincare products.

Strengths: Innovative controlled-release system, combination with natural ingredients. Weaknesses: Limited application range, potential for skin sensitivity in some users.

Innovative Uses of Ammonium Hydroxide in Cosmetics

Cosmetic composition comprising at least one alkanolamine, at least one amino acid, and at least one alkali metal or alkaline earth metal or ammonium hydroxide

PatentWO2025017108A1

Innovation

- A cosmetic composition comprising at least one alkanolamine, one or more amino acids or their derivatives, and one or more alkali metal, alkaline earth metal, or ammonium hydroxides, with specific ratios of these components to achieve effective hair smoothing and straightening.

Cosmetic composition and method for producing the same

PatentInactiveJP2013112627A

Innovation

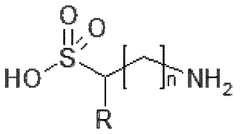

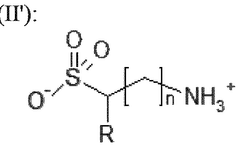

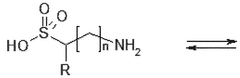

- A cosmetic composition comprising polyamino acids formed by polymerizing hydrophilic and neutral amino acids in the presence of an ammonium hydroxy acid salt, which acts as a catalyst and solvent, allowing for high moisturizing performance without stickiness.

Safety and Regulatory Considerations for Ammonium Hydroxide

The use of ammonium hydroxide in cosmetic formulations is subject to strict safety and regulatory considerations. Regulatory bodies worldwide, including the U.S. Food and Drug Administration (FDA) and the European Commission, have established guidelines for its use in personal care products.

In the United States, the FDA regulates ammonium hydroxide as an indirect food additive and a pH adjuster in cosmetics. The Cosmetic Ingredient Review (CIR) Expert Panel has evaluated its safety and concluded that ammonium hydroxide is safe for use in cosmetic formulations when applied in the present practices of use and concentration.

The European Union's Cosmetic Regulation (EC) No. 1223/2009 permits the use of ammonium hydroxide in cosmetic products, subject to specific concentration limits. The Scientific Committee on Consumer Safety (SCCS) has assessed its safety profile and provided recommendations for its use in various cosmetic applications.

Safety considerations for ammonium hydroxide in cosmetics primarily focus on its potential for skin and eye irritation. Manufacturers must ensure that the final product's pH is within an acceptable range to minimize the risk of adverse reactions. Additionally, proper labeling and packaging requirements must be met to inform consumers about the presence of ammonium hydroxide and any necessary precautions.

Occupational safety is another crucial aspect when working with ammonium hydroxide in cosmetic manufacturing. Proper handling procedures, personal protective equipment, and ventilation systems are essential to protect workers from potential exposure risks.

Environmental regulations also play a role in the use of ammonium hydroxide in cosmetics. Manufacturers must adhere to guidelines for proper disposal and wastewater management to minimize environmental impact.

As the cosmetic industry continues to evolve, ongoing research and safety assessments are necessary to ensure the continued safe use of ammonium hydroxide in cosmetic formulations. Regulatory bodies regularly review and update their guidelines based on new scientific evidence and emerging safety concerns.

In the United States, the FDA regulates ammonium hydroxide as an indirect food additive and a pH adjuster in cosmetics. The Cosmetic Ingredient Review (CIR) Expert Panel has evaluated its safety and concluded that ammonium hydroxide is safe for use in cosmetic formulations when applied in the present practices of use and concentration.

The European Union's Cosmetic Regulation (EC) No. 1223/2009 permits the use of ammonium hydroxide in cosmetic products, subject to specific concentration limits. The Scientific Committee on Consumer Safety (SCCS) has assessed its safety profile and provided recommendations for its use in various cosmetic applications.

Safety considerations for ammonium hydroxide in cosmetics primarily focus on its potential for skin and eye irritation. Manufacturers must ensure that the final product's pH is within an acceptable range to minimize the risk of adverse reactions. Additionally, proper labeling and packaging requirements must be met to inform consumers about the presence of ammonium hydroxide and any necessary precautions.

Occupational safety is another crucial aspect when working with ammonium hydroxide in cosmetic manufacturing. Proper handling procedures, personal protective equipment, and ventilation systems are essential to protect workers from potential exposure risks.

Environmental regulations also play a role in the use of ammonium hydroxide in cosmetics. Manufacturers must adhere to guidelines for proper disposal and wastewater management to minimize environmental impact.

As the cosmetic industry continues to evolve, ongoing research and safety assessments are necessary to ensure the continued safe use of ammonium hydroxide in cosmetic formulations. Regulatory bodies regularly review and update their guidelines based on new scientific evidence and emerging safety concerns.

Environmental Impact of Ammonium Hydroxide in Cosmetics

The use of ammonium hydroxide in cosmetics formulations has raised concerns about its potential environmental impact. As a widely used pH adjuster and buffering agent, ammonium hydroxide plays a significant role in various cosmetic products. However, its environmental implications require careful consideration.

One of the primary environmental concerns associated with ammonium hydroxide is its potential to contribute to eutrophication in aquatic ecosystems. When released into water bodies, ammonium hydroxide can break down into ammonia and hydroxide ions. Excess ammonia in water can lead to algal blooms, which deplete oxygen levels and harm aquatic life. This process can disrupt the delicate balance of aquatic ecosystems and potentially impact biodiversity.

Furthermore, the production of ammonium hydroxide involves energy-intensive processes, contributing to greenhouse gas emissions. The manufacturing process typically requires the reaction of ammonia with water, which often relies on fossil fuel-based energy sources. As the cosmetics industry continues to grow, the cumulative environmental impact of ammonium hydroxide production becomes increasingly significant.

Another environmental consideration is the potential for ammonia emissions during the use and disposal of cosmetic products containing ammonium hydroxide. Although the concentrations used in cosmetics are generally low, the widespread use of these products can result in cumulative releases of ammonia into the atmosphere. Atmospheric ammonia can contribute to the formation of fine particulate matter, impacting air quality and potentially affecting human health.

The disposal of cosmetic products containing ammonium hydroxide also raises concerns about soil and groundwater contamination. Improper disposal methods may lead to the leaching of ammonium compounds into soil and water systems, potentially affecting soil chemistry and microbial communities. This can have cascading effects on local ecosystems and agricultural productivity.

However, it is important to note that the cosmetics industry has been making efforts to address these environmental concerns. Many companies are exploring alternative pH adjusters and buffering agents with lower environmental impacts. Additionally, advancements in green chemistry are leading to more sustainable production methods for ammonium hydroxide and its alternatives.

Regulatory bodies are also taking steps to mitigate the environmental impact of cosmetic ingredients. For instance, the European Union's REACH regulation requires manufacturers to assess and manage the risks associated with chemicals, including their environmental impact. This has led to increased scrutiny of ingredients like ammonium hydroxide and encouraged the development of more environmentally friendly alternatives.

In conclusion, while ammonium hydroxide serves important functions in cosmetics formulations, its environmental impact cannot be overlooked. The cosmetics industry faces the challenge of balancing product efficacy with environmental responsibility. As research continues and regulations evolve, it is likely that more sustainable alternatives and improved production methods will emerge, helping to minimize the environmental footprint of cosmetic products.

One of the primary environmental concerns associated with ammonium hydroxide is its potential to contribute to eutrophication in aquatic ecosystems. When released into water bodies, ammonium hydroxide can break down into ammonia and hydroxide ions. Excess ammonia in water can lead to algal blooms, which deplete oxygen levels and harm aquatic life. This process can disrupt the delicate balance of aquatic ecosystems and potentially impact biodiversity.

Furthermore, the production of ammonium hydroxide involves energy-intensive processes, contributing to greenhouse gas emissions. The manufacturing process typically requires the reaction of ammonia with water, which often relies on fossil fuel-based energy sources. As the cosmetics industry continues to grow, the cumulative environmental impact of ammonium hydroxide production becomes increasingly significant.

Another environmental consideration is the potential for ammonia emissions during the use and disposal of cosmetic products containing ammonium hydroxide. Although the concentrations used in cosmetics are generally low, the widespread use of these products can result in cumulative releases of ammonia into the atmosphere. Atmospheric ammonia can contribute to the formation of fine particulate matter, impacting air quality and potentially affecting human health.

The disposal of cosmetic products containing ammonium hydroxide also raises concerns about soil and groundwater contamination. Improper disposal methods may lead to the leaching of ammonium compounds into soil and water systems, potentially affecting soil chemistry and microbial communities. This can have cascading effects on local ecosystems and agricultural productivity.

However, it is important to note that the cosmetics industry has been making efforts to address these environmental concerns. Many companies are exploring alternative pH adjusters and buffering agents with lower environmental impacts. Additionally, advancements in green chemistry are leading to more sustainable production methods for ammonium hydroxide and its alternatives.

Regulatory bodies are also taking steps to mitigate the environmental impact of cosmetic ingredients. For instance, the European Union's REACH regulation requires manufacturers to assess and manage the risks associated with chemicals, including their environmental impact. This has led to increased scrutiny of ingredients like ammonium hydroxide and encouraged the development of more environmentally friendly alternatives.

In conclusion, while ammonium hydroxide serves important functions in cosmetics formulations, its environmental impact cannot be overlooked. The cosmetics industry faces the challenge of balancing product efficacy with environmental responsibility. As research continues and regulations evolve, it is likely that more sustainable alternatives and improved production methods will emerge, helping to minimize the environmental footprint of cosmetic products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!