Ammonium hydroxide in the synthesis of hybrid organic-inorganic materials

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Material Synthesis Background and Objectives

Hybrid organic-inorganic materials have emerged as a fascinating class of advanced materials that combine the unique properties of organic and inorganic components at the molecular level. The synthesis of these materials has gained significant attention in recent years due to their potential applications in various fields, including optics, electronics, catalysis, and biomedicine. The use of ammonium hydroxide in the synthesis of hybrid materials represents a crucial area of research, as it plays a vital role in controlling the structure and properties of the resulting materials.

The development of hybrid organic-inorganic materials can be traced back to the early 1990s when researchers began exploring the integration of organic molecules into inorganic frameworks. This interdisciplinary field has since experienced rapid growth, driven by the desire to create materials with tailored properties that surpass those of their individual components. The synergistic combination of organic and inorganic moieties allows for the design of materials with enhanced mechanical, thermal, and chemical stability, as well as unique optical and electronic properties.

Ammonium hydroxide has emerged as a key component in the synthesis of hybrid materials due to its ability to act as both a base and a structure-directing agent. Its role in controlling pH, influencing hydrolysis and condensation reactions, and directing the assembly of organic and inorganic building blocks has made it an indispensable tool in the synthesis of various hybrid structures, including sol-gel derived materials, mesoporous hybrids, and organic-inorganic nanocomposites.

The primary objective of research in this field is to develop a comprehensive understanding of the mechanisms by which ammonium hydroxide influences the formation and properties of hybrid organic-inorganic materials. This includes investigating its impact on reaction kinetics, morphology control, and the incorporation of organic molecules into inorganic networks. Additionally, researchers aim to explore novel synthetic strategies that leverage the unique properties of ammonium hydroxide to create hybrid materials with enhanced functionality and performance.

Another crucial goal is to establish structure-property relationships in these hybrid systems, enabling the rational design of materials for specific applications. This involves studying how variations in synthesis parameters, such as ammonium hydroxide concentration, reaction temperature, and precursor composition, affect the final material properties. By gaining insights into these relationships, researchers can develop predictive models and design guidelines for the synthesis of tailored hybrid materials with desired characteristics.

Furthermore, the research aims to expand the range of hybrid materials that can be synthesized using ammonium hydroxide-based approaches. This includes exploring new combinations of organic and inorganic components, as well as investigating the potential for creating hierarchical structures and multifunctional materials. The ultimate objective is to unlock the full potential of hybrid organic-inorganic materials and pave the way for their widespread adoption in various technological applications.

The development of hybrid organic-inorganic materials can be traced back to the early 1990s when researchers began exploring the integration of organic molecules into inorganic frameworks. This interdisciplinary field has since experienced rapid growth, driven by the desire to create materials with tailored properties that surpass those of their individual components. The synergistic combination of organic and inorganic moieties allows for the design of materials with enhanced mechanical, thermal, and chemical stability, as well as unique optical and electronic properties.

Ammonium hydroxide has emerged as a key component in the synthesis of hybrid materials due to its ability to act as both a base and a structure-directing agent. Its role in controlling pH, influencing hydrolysis and condensation reactions, and directing the assembly of organic and inorganic building blocks has made it an indispensable tool in the synthesis of various hybrid structures, including sol-gel derived materials, mesoporous hybrids, and organic-inorganic nanocomposites.

The primary objective of research in this field is to develop a comprehensive understanding of the mechanisms by which ammonium hydroxide influences the formation and properties of hybrid organic-inorganic materials. This includes investigating its impact on reaction kinetics, morphology control, and the incorporation of organic molecules into inorganic networks. Additionally, researchers aim to explore novel synthetic strategies that leverage the unique properties of ammonium hydroxide to create hybrid materials with enhanced functionality and performance.

Another crucial goal is to establish structure-property relationships in these hybrid systems, enabling the rational design of materials for specific applications. This involves studying how variations in synthesis parameters, such as ammonium hydroxide concentration, reaction temperature, and precursor composition, affect the final material properties. By gaining insights into these relationships, researchers can develop predictive models and design guidelines for the synthesis of tailored hybrid materials with desired characteristics.

Furthermore, the research aims to expand the range of hybrid materials that can be synthesized using ammonium hydroxide-based approaches. This includes exploring new combinations of organic and inorganic components, as well as investigating the potential for creating hierarchical structures and multifunctional materials. The ultimate objective is to unlock the full potential of hybrid organic-inorganic materials and pave the way for their widespread adoption in various technological applications.

Market Analysis for Hybrid Organic-Inorganic Materials

The market for hybrid organic-inorganic materials has been experiencing significant growth in recent years, driven by their unique properties and diverse applications across multiple industries. These materials combine the advantages of both organic and inorganic components, offering enhanced performance characteristics that are highly sought after in various sectors.

In the electronics industry, hybrid organic-inorganic materials are gaining traction for use in flexible displays, solar cells, and sensors. The global market for organic electronics is projected to reach $79 billion by 2027, with hybrid materials playing a crucial role in this growth. The automotive sector is another key market, where these materials are used in lightweight components and advanced coatings, contributing to improved fuel efficiency and durability.

The construction industry is adopting hybrid organic-inorganic materials for smart windows, self-cleaning surfaces, and high-performance insulation. This sector's demand is expected to grow steadily, driven by increasing focus on energy-efficient buildings and sustainable construction practices. In the healthcare and biomedical fields, these materials are finding applications in drug delivery systems, tissue engineering, and medical implants, with the global biomaterials market expected to reach $260 billion by 2025.

The use of ammonium hydroxide in the synthesis of hybrid organic-inorganic materials is particularly relevant in sol-gel processing, a widely used technique for producing these materials. This method allows for precise control over material properties and has applications in coatings, ceramics, and nanocomposites. The global sol-gel products market is anticipated to grow at a CAGR of 9.5% from 2021 to 2028, indicating a strong demand for hybrid materials synthesized using this technique.

Geographically, North America and Europe are currently the largest markets for hybrid organic-inorganic materials, owing to their advanced manufacturing capabilities and strong research and development initiatives. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing investments in infrastructure, and growing adoption of advanced materials in countries like China, Japan, and South Korea.

Challenges in the market include the high cost of production for some hybrid materials and the need for standardization in manufacturing processes. However, ongoing research and development efforts are focused on addressing these issues, potentially leading to more cost-effective production methods and wider adoption across industries. As sustainability becomes increasingly important, the market is also seeing a trend towards eco-friendly hybrid materials, opening up new opportunities for growth and innovation in this sector.

In the electronics industry, hybrid organic-inorganic materials are gaining traction for use in flexible displays, solar cells, and sensors. The global market for organic electronics is projected to reach $79 billion by 2027, with hybrid materials playing a crucial role in this growth. The automotive sector is another key market, where these materials are used in lightweight components and advanced coatings, contributing to improved fuel efficiency and durability.

The construction industry is adopting hybrid organic-inorganic materials for smart windows, self-cleaning surfaces, and high-performance insulation. This sector's demand is expected to grow steadily, driven by increasing focus on energy-efficient buildings and sustainable construction practices. In the healthcare and biomedical fields, these materials are finding applications in drug delivery systems, tissue engineering, and medical implants, with the global biomaterials market expected to reach $260 billion by 2025.

The use of ammonium hydroxide in the synthesis of hybrid organic-inorganic materials is particularly relevant in sol-gel processing, a widely used technique for producing these materials. This method allows for precise control over material properties and has applications in coatings, ceramics, and nanocomposites. The global sol-gel products market is anticipated to grow at a CAGR of 9.5% from 2021 to 2028, indicating a strong demand for hybrid materials synthesized using this technique.

Geographically, North America and Europe are currently the largest markets for hybrid organic-inorganic materials, owing to their advanced manufacturing capabilities and strong research and development initiatives. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing investments in infrastructure, and growing adoption of advanced materials in countries like China, Japan, and South Korea.

Challenges in the market include the high cost of production for some hybrid materials and the need for standardization in manufacturing processes. However, ongoing research and development efforts are focused on addressing these issues, potentially leading to more cost-effective production methods and wider adoption across industries. As sustainability becomes increasingly important, the market is also seeing a trend towards eco-friendly hybrid materials, opening up new opportunities for growth and innovation in this sector.

Current Challenges in Ammonium Hydroxide-Based Synthesis

The synthesis of hybrid organic-inorganic materials using ammonium hydroxide faces several significant challenges that researchers are actively working to overcome. One of the primary issues is controlling the hydrolysis and condensation rates of the precursors. Ammonium hydroxide, being a strong base, can accelerate these reactions, making it difficult to achieve precise control over the material's structure and properties.

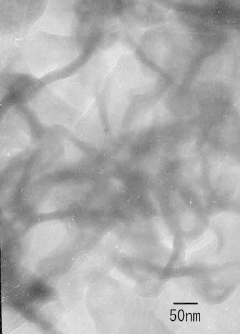

Another challenge lies in achieving uniform dispersion of organic components within the inorganic matrix. The rapid gelation induced by ammonium hydroxide can lead to phase separation or aggregation of organic molecules, resulting in inhomogeneous materials with suboptimal properties. This is particularly problematic when attempting to incorporate large organic molecules or polymers into the hybrid structure.

The porosity and surface area of the resulting materials also present challenges. While ammonium hydroxide can promote the formation of porous structures, fine-tuning the pore size distribution and maintaining high surface areas remain difficult. This is crucial for applications such as catalysis, adsorption, and sensing, where specific pore architectures are often required.

Reproducibility is another significant concern in ammonium hydroxide-based synthesis. Small variations in reaction conditions, such as temperature, concentration, or mixing speed, can lead to substantial differences in the final product. This sensitivity makes it challenging to scale up production and maintain consistent quality across batches.

The stability of the hybrid materials during and after synthesis is also a critical issue. The high pH environment created by ammonium hydroxide can potentially degrade certain organic components or lead to undesired side reactions. Additionally, the removal of ammonia and water during drying and post-synthesis treatments can cause structural collapse or changes in material properties.

Environmental and safety concerns associated with the use of ammonium hydroxide pose challenges in large-scale production. The volatile and corrosive nature of ammonia requires careful handling and specialized equipment, which can increase production costs and complexity.

Lastly, the characterization of hybrid organic-inorganic materials synthesized using ammonium hydroxide presents its own set of challenges. The complex nature of these materials often requires a combination of advanced analytical techniques to fully understand their structure, composition, and properties. Developing reliable and comprehensive characterization methods remains an ongoing area of research in this field.

Another challenge lies in achieving uniform dispersion of organic components within the inorganic matrix. The rapid gelation induced by ammonium hydroxide can lead to phase separation or aggregation of organic molecules, resulting in inhomogeneous materials with suboptimal properties. This is particularly problematic when attempting to incorporate large organic molecules or polymers into the hybrid structure.

The porosity and surface area of the resulting materials also present challenges. While ammonium hydroxide can promote the formation of porous structures, fine-tuning the pore size distribution and maintaining high surface areas remain difficult. This is crucial for applications such as catalysis, adsorption, and sensing, where specific pore architectures are often required.

Reproducibility is another significant concern in ammonium hydroxide-based synthesis. Small variations in reaction conditions, such as temperature, concentration, or mixing speed, can lead to substantial differences in the final product. This sensitivity makes it challenging to scale up production and maintain consistent quality across batches.

The stability of the hybrid materials during and after synthesis is also a critical issue. The high pH environment created by ammonium hydroxide can potentially degrade certain organic components or lead to undesired side reactions. Additionally, the removal of ammonia and water during drying and post-synthesis treatments can cause structural collapse or changes in material properties.

Environmental and safety concerns associated with the use of ammonium hydroxide pose challenges in large-scale production. The volatile and corrosive nature of ammonia requires careful handling and specialized equipment, which can increase production costs and complexity.

Lastly, the characterization of hybrid organic-inorganic materials synthesized using ammonium hydroxide presents its own set of challenges. The complex nature of these materials often requires a combination of advanced analytical techniques to fully understand their structure, composition, and properties. Developing reliable and comprehensive characterization methods remains an ongoing area of research in this field.

Existing Ammonium Hydroxide Synthesis Methodologies

01 Use in chemical processes

Ammonium hydroxide is widely used in various chemical processes as a reactant, catalyst, or pH regulator. It plays a crucial role in the synthesis of organic compounds, production of fertilizers, and treatment of industrial waste. Its alkaline properties make it suitable for neutralizing acids and controlling pH levels in different applications.- Use of ammonium hydroxide in chemical processes: Ammonium hydroxide is widely used in various chemical processes as a reactant, catalyst, or pH regulator. It plays a crucial role in the synthesis of organic compounds, production of fertilizers, and treatment of industrial waste. Its alkaline properties make it suitable for neutralizing acids and controlling pH levels in different applications.

- Application in cleaning and surface treatment: Ammonium hydroxide is utilized in cleaning formulations and surface treatment processes. It is effective in removing grease, oils, and other contaminants from various surfaces. In the semiconductor industry, it is used for etching and cleaning silicon wafers. Its ability to dissolve certain metals and oxides makes it valuable in metal surface treatment and electroplating applications.

- Role in textile and leather processing: Ammonium hydroxide finds applications in the textile and leather industries. It is used in dyeing processes to adjust pH levels and improve color fastness. In leather tanning, it helps in dehairing and liming operations. Its alkaline nature aids in breaking down proteins and preparing materials for further treatment.

- Environmental and agricultural applications: Ammonium hydroxide is employed in environmental and agricultural sectors. It is used in air pollution control systems to neutralize acidic gases. In agriculture, it serves as a source of nitrogen for fertilizers and soil amendments. Its ability to capture and store ammonia makes it valuable in reducing emissions from livestock operations and improving soil fertility.

- Use in personal care and cosmetic products: Ammonium hydroxide is utilized in various personal care and cosmetic formulations. It acts as a pH adjuster in hair dyes, helping to open the hair cuticle for better color penetration. In some skincare products, it can be used to neutralize acids or adjust the pH of formulations. Its alkaline properties also make it useful in certain depilatory creams and hair relaxers.

02 Application in cleaning and surface treatment

Ammonium hydroxide is utilized in cleaning formulations and surface treatment processes. It is effective in removing grease, oils, and other contaminants from various surfaces. In the semiconductor industry, it is used for etching and cleaning silicon wafers. It also finds applications in the textile industry for fabric treatment and in the leather industry for dehairing hides.Expand Specific Solutions03 Role in environmental applications

Ammonium hydroxide is employed in environmental applications, particularly in air pollution control and water treatment. It is used to neutralize acidic gases in flue gas desulfurization systems and to remove nitrogen oxides from industrial emissions. In water treatment, it helps in pH adjustment and ammonia removal from wastewater.Expand Specific Solutions04 Use in personal care and cosmetic products

Ammonium hydroxide is utilized in various personal care and cosmetic products. It serves as a pH adjuster in shampoos, hair dyes, and other hair care products. In some cosmetic formulations, it acts as a buffering agent or helps in the solubilization of certain ingredients. Its alkaline nature also makes it useful in certain depilatory products.Expand Specific Solutions05 Application in food processing

Ammonium hydroxide finds applications in food processing as a leavening agent and pH regulator. It is used in the production of certain types of caramel coloring and in the treatment of cocoa powder to modify its color and flavor. In some countries, it is approved as a food additive for specific purposes, subject to regulations.Expand Specific Solutions

Key Players in Hybrid Material Research and Production

The research on ammonium hydroxide in hybrid organic-inorganic materials synthesis is in a developing stage, with growing market potential due to applications in advanced materials. The technology is moderately mature, with ongoing refinements. Key players include academic institutions like Cornell University and Nankai University, alongside research organizations such as IFP Energies Nouvelles and Centre National de la Recherche Scientifique. Industrial involvement from companies like NOF Corp. and Climeworks AG suggests increasing commercial interest. The competitive landscape is diverse, with collaborations between academia and industry driving innovation in this niche but promising field.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed a novel approach for synthesizing hybrid organic-inorganic materials using ammonium hydroxide as a key reagent. Their method involves a sol-gel process where ammonium hydroxide acts as a catalyst and pH regulator, promoting the hydrolysis and condensation of metal alkoxides[1]. This technique allows for the precise control of the material's porosity and surface properties. CNRS researchers have successfully applied this method to create mesoporous silica materials with organic functional groups, demonstrating enhanced catalytic activity and selectivity in various chemical reactions[2]. The use of ammonium hydroxide in their synthesis route has led to materials with improved thermal stability and uniform pore size distribution, making them suitable for applications in catalysis, adsorption, and drug delivery systems[3].

Strengths: Precise control over material properties, enhanced catalytic activity, and improved thermal stability. Weaknesses: Potential ammonia off-gassing during synthesis, which may require additional safety measures.

Korea Research Institute of Chemical Technology

Technical Solution: KRICT has pioneered a green synthesis approach for hybrid organic-inorganic materials using ammonium hydroxide as a mild base. Their method focuses on the development of environmentally friendly processes for producing functional nanomaterials. By utilizing ammonium hydroxide, KRICT researchers have achieved a more controlled hydrolysis of metal precursors, resulting in hybrid materials with well-defined nanostructures[4]. This technique has been particularly successful in synthesizing organic-inorganic hybrid nanoparticles with core-shell structures, where the inorganic core is encapsulated by an organic shell[5]. The use of ammonium hydroxide allows for better control of the particle size and morphology, leading to materials with enhanced optical and electronic properties suitable for applications in sensors, photocatalysis, and energy storage devices[6].

Strengths: Environmentally friendly synthesis, precise control over nanostructure, and versatility in applications. Weaknesses: Potential scalability issues for large-scale production.

Innovative Approaches in Hybrid Material Synthesis

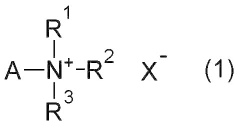

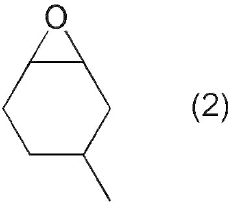

Organic/inorganic hybrid material

PatentInactiveJP2011178872A

Innovation

- A quaternary ammonium salt with polymerizable substituents and short main chains is intercalated into layered silicates, allowing for copolymerization with a monomer, enhancing dispersibility and thermal stability.

Organic/inorganic hybrid material, preparation method and fabric production thereof

PatentInactiveTW201835095A

Innovation

- Novel synthesis route combining organic dye with inorganic sol to create a multifunctional hybrid material.

- Integration of thermal insulation, heat storage, and water repellency properties in a single hybrid material.

- Use of boehmite sol and optional tetraethoxysilane to form the inorganic network, allowing for tailored properties.

Environmental Impact of Ammonium Hydroxide in Synthesis

The use of ammonium hydroxide in the synthesis of hybrid organic-inorganic materials has raised significant environmental concerns due to its potential impacts on ecosystems and human health. As a strong base and source of ammonia, ammonium hydroxide can contribute to various environmental issues if not properly managed during the synthesis process.

One of the primary environmental concerns is the release of ammonia gas into the atmosphere. Ammonia is a potent air pollutant that can lead to the formation of fine particulate matter (PM2.5) through chemical reactions with other air pollutants. This can result in reduced air quality and contribute to respiratory problems in both humans and animals. Additionally, ammonia emissions can lead to the eutrophication of water bodies, causing algal blooms and disrupting aquatic ecosystems.

The production and use of ammonium hydroxide also have implications for water pollution. Improper disposal or accidental spills of ammonium hydroxide-containing waste can contaminate water sources, leading to increased pH levels and ammonia concentrations. This can be toxic to aquatic life and potentially render water resources unsuitable for human consumption without extensive treatment.

Furthermore, the synthesis process involving ammonium hydroxide may generate hazardous waste that requires careful handling and disposal. Improper management of these wastes can lead to soil contamination and long-term environmental degradation. The accumulation of ammonium ions in soil can alter soil chemistry, affecting plant growth and microbial communities.

From a broader perspective, the production of ammonium hydroxide itself has environmental implications. The industrial processes used to manufacture ammonium hydroxide often rely on fossil fuels, contributing to greenhouse gas emissions and climate change. This indirect environmental impact should be considered when assessing the overall environmental footprint of hybrid organic-inorganic material synthesis.

To mitigate these environmental impacts, researchers and industries are exploring alternative synthesis methods and greener chemistry approaches. These include the use of less hazardous reagents, closed-loop systems to minimize emissions, and improved waste management practices. Additionally, there is a growing focus on developing more efficient synthesis processes that reduce the overall consumption of ammonium hydroxide and other potentially harmful chemicals.

As environmental regulations become more stringent, the synthesis of hybrid organic-inorganic materials using ammonium hydroxide may face increased scrutiny. This could drive innovation in the field, leading to the development of more environmentally friendly synthesis methods and materials. Future research in this area should prioritize not only the functional properties of the resulting materials but also the environmental sustainability of the synthesis process.

One of the primary environmental concerns is the release of ammonia gas into the atmosphere. Ammonia is a potent air pollutant that can lead to the formation of fine particulate matter (PM2.5) through chemical reactions with other air pollutants. This can result in reduced air quality and contribute to respiratory problems in both humans and animals. Additionally, ammonia emissions can lead to the eutrophication of water bodies, causing algal blooms and disrupting aquatic ecosystems.

The production and use of ammonium hydroxide also have implications for water pollution. Improper disposal or accidental spills of ammonium hydroxide-containing waste can contaminate water sources, leading to increased pH levels and ammonia concentrations. This can be toxic to aquatic life and potentially render water resources unsuitable for human consumption without extensive treatment.

Furthermore, the synthesis process involving ammonium hydroxide may generate hazardous waste that requires careful handling and disposal. Improper management of these wastes can lead to soil contamination and long-term environmental degradation. The accumulation of ammonium ions in soil can alter soil chemistry, affecting plant growth and microbial communities.

From a broader perspective, the production of ammonium hydroxide itself has environmental implications. The industrial processes used to manufacture ammonium hydroxide often rely on fossil fuels, contributing to greenhouse gas emissions and climate change. This indirect environmental impact should be considered when assessing the overall environmental footprint of hybrid organic-inorganic material synthesis.

To mitigate these environmental impacts, researchers and industries are exploring alternative synthesis methods and greener chemistry approaches. These include the use of less hazardous reagents, closed-loop systems to minimize emissions, and improved waste management practices. Additionally, there is a growing focus on developing more efficient synthesis processes that reduce the overall consumption of ammonium hydroxide and other potentially harmful chemicals.

As environmental regulations become more stringent, the synthesis of hybrid organic-inorganic materials using ammonium hydroxide may face increased scrutiny. This could drive innovation in the field, leading to the development of more environmentally friendly synthesis methods and materials. Future research in this area should prioritize not only the functional properties of the resulting materials but also the environmental sustainability of the synthesis process.

Scalability and Industrial Applications

The scalability and industrial applications of using ammonium hydroxide in the synthesis of hybrid organic-inorganic materials present significant opportunities and challenges. As research in this field progresses, the potential for large-scale production and diverse industrial applications becomes increasingly apparent.

One of the key advantages of using ammonium hydroxide in hybrid material synthesis is its versatility and ease of handling in industrial settings. The ability to control pH levels and facilitate the formation of uniform nanostructures makes it an attractive option for mass production. However, scaling up laboratory processes to industrial levels requires careful consideration of factors such as reaction kinetics, heat transfer, and mixing efficiency.

In terms of industrial applications, hybrid organic-inorganic materials synthesized using ammonium hydroxide show promise in various sectors. The electronics industry, for instance, can benefit from these materials in the development of advanced sensors, displays, and energy storage devices. The unique properties of these hybrids, such as tunable optical and electrical characteristics, make them suitable for next-generation electronic components.

The construction industry is another area where these materials could find significant applications. Hybrid coatings and composites synthesized with ammonium hydroxide can enhance the durability and functionality of building materials. These may include self-cleaning surfaces, improved thermal insulation, and materials with enhanced mechanical properties.

Environmental applications are also emerging as a promising field for these hybrid materials. Their potential use in water treatment, air purification, and catalytic processes for pollution control aligns well with growing global sustainability initiatives. The ability to tailor the properties of these materials through controlled synthesis with ammonium hydroxide allows for the development of highly efficient and selective environmental remediation technologies.

However, the transition from laboratory to industrial scale production faces several challenges. Ensuring consistent quality and properties of the hybrid materials when scaling up production volumes is crucial. This requires precise control over reaction conditions, which can be more difficult to maintain in large-scale reactors. Additionally, the cost-effectiveness of using ammonium hydroxide in industrial processes needs to be carefully evaluated against alternative synthesis methods.

Safety considerations and environmental regulations also play a significant role in the industrial adoption of these synthesis techniques. While ammonium hydroxide is generally considered less hazardous than some alternative reagents, proper handling and disposal protocols must be established to ensure worker safety and environmental protection in large-scale operations.

One of the key advantages of using ammonium hydroxide in hybrid material synthesis is its versatility and ease of handling in industrial settings. The ability to control pH levels and facilitate the formation of uniform nanostructures makes it an attractive option for mass production. However, scaling up laboratory processes to industrial levels requires careful consideration of factors such as reaction kinetics, heat transfer, and mixing efficiency.

In terms of industrial applications, hybrid organic-inorganic materials synthesized using ammonium hydroxide show promise in various sectors. The electronics industry, for instance, can benefit from these materials in the development of advanced sensors, displays, and energy storage devices. The unique properties of these hybrids, such as tunable optical and electrical characteristics, make them suitable for next-generation electronic components.

The construction industry is another area where these materials could find significant applications. Hybrid coatings and composites synthesized with ammonium hydroxide can enhance the durability and functionality of building materials. These may include self-cleaning surfaces, improved thermal insulation, and materials with enhanced mechanical properties.

Environmental applications are also emerging as a promising field for these hybrid materials. Their potential use in water treatment, air purification, and catalytic processes for pollution control aligns well with growing global sustainability initiatives. The ability to tailor the properties of these materials through controlled synthesis with ammonium hydroxide allows for the development of highly efficient and selective environmental remediation technologies.

However, the transition from laboratory to industrial scale production faces several challenges. Ensuring consistent quality and properties of the hybrid materials when scaling up production volumes is crucial. This requires precise control over reaction conditions, which can be more difficult to maintain in large-scale reactors. Additionally, the cost-effectiveness of using ammonium hydroxide in industrial processes needs to be carefully evaluated against alternative synthesis methods.

Safety considerations and environmental regulations also play a significant role in the industrial adoption of these synthesis techniques. While ammonium hydroxide is generally considered less hazardous than some alternative reagents, proper handling and disposal protocols must be established to ensure worker safety and environmental protection in large-scale operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!