Thermal Stability of Metal Foam Fabrication in Aerospace

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Foam Thermal Stability Background and Objectives

Metal foam materials have emerged as a revolutionary advancement in aerospace engineering over the past three decades. These lightweight cellular structures, characterized by their unique combination of high strength-to-weight ratio, excellent energy absorption capabilities, and superior thermal properties, have progressively gained attention since their initial development in the 1990s. The evolution of metal foam technology has been marked by significant improvements in manufacturing precision, material composition, and structural integrity, transitioning from laboratory curiosities to viable engineering materials for extreme environments.

The aerospace industry's continuous pursuit of weight reduction while maintaining structural integrity has been a primary driver for metal foam development. Historical data indicates that a 10% reduction in aircraft weight can result in approximately 6-8% fuel efficiency improvement, highlighting the economic and environmental significance of lightweight materials research. The thermal stability of metal foams represents a critical frontier in this technological evolution, particularly as aerospace applications increasingly demand materials capable of withstanding extreme temperature fluctuations.

Current technological trajectories point toward the integration of advanced metal foams in next-generation spacecraft, hypersonic vehicles, and thermal protection systems. The thermal stability challenge encompasses not only maintaining structural integrity at elevated temperatures but also preserving consistent thermal conductivity properties across operational temperature ranges, which typically span from -150°C to +1000°C in aerospace applications.

The primary objectives of research in metal foam thermal stability include: developing manufacturing processes that produce thermally resilient cellular structures; understanding the fundamental mechanisms of thermal degradation in various metal foam compositions; establishing standardized testing protocols for thermal stability assessment; and creating predictive models for long-term thermal performance under cyclic loading conditions.

Additionally, research aims to address the microstructural evolution of metal foams during thermal cycling, with particular focus on cell wall thinning, node junction stability, and phase transformation behaviors. The correlation between manufacturing parameters and resultant thermal stability represents another critical research objective, as preliminary studies suggest that processing conditions significantly influence high-temperature performance.

The ultimate goal is to develop metal foam materials and associated fabrication technologies that maintain dimensional stability, mechanical properties, and thermal characteristics when subjected to the extreme thermal environments encountered in aerospace applications. This includes resistance to thermal fatigue, oxidation resistance at elevated temperatures, and predictable thermal expansion behavior across operational temperature ranges.

The aerospace industry's continuous pursuit of weight reduction while maintaining structural integrity has been a primary driver for metal foam development. Historical data indicates that a 10% reduction in aircraft weight can result in approximately 6-8% fuel efficiency improvement, highlighting the economic and environmental significance of lightweight materials research. The thermal stability of metal foams represents a critical frontier in this technological evolution, particularly as aerospace applications increasingly demand materials capable of withstanding extreme temperature fluctuations.

Current technological trajectories point toward the integration of advanced metal foams in next-generation spacecraft, hypersonic vehicles, and thermal protection systems. The thermal stability challenge encompasses not only maintaining structural integrity at elevated temperatures but also preserving consistent thermal conductivity properties across operational temperature ranges, which typically span from -150°C to +1000°C in aerospace applications.

The primary objectives of research in metal foam thermal stability include: developing manufacturing processes that produce thermally resilient cellular structures; understanding the fundamental mechanisms of thermal degradation in various metal foam compositions; establishing standardized testing protocols for thermal stability assessment; and creating predictive models for long-term thermal performance under cyclic loading conditions.

Additionally, research aims to address the microstructural evolution of metal foams during thermal cycling, with particular focus on cell wall thinning, node junction stability, and phase transformation behaviors. The correlation between manufacturing parameters and resultant thermal stability represents another critical research objective, as preliminary studies suggest that processing conditions significantly influence high-temperature performance.

The ultimate goal is to develop metal foam materials and associated fabrication technologies that maintain dimensional stability, mechanical properties, and thermal characteristics when subjected to the extreme thermal environments encountered in aerospace applications. This includes resistance to thermal fatigue, oxidation resistance at elevated temperatures, and predictable thermal expansion behavior across operational temperature ranges.

Aerospace Market Requirements Analysis

The aerospace industry's demand for advanced materials with superior thermal stability has been steadily increasing over the past decade. Metal foams represent a critical material category that addresses multiple aerospace requirements simultaneously: lightweight construction, thermal management, and structural integrity under extreme conditions. Market analysis indicates that the global aerospace metal foam market is projected to grow at a compound annual growth rate of 6.8% through 2030, driven primarily by increasing aircraft production and the space exploration renaissance.

Primary market drivers for thermally stable metal foams in aerospace applications include the push for fuel efficiency, which necessitates lightweight yet strong materials capable of withstanding high temperatures. Commercial aviation manufacturers seek materials that can reduce aircraft weight by 15-20% while maintaining or improving safety margins. Defense aerospace applications require materials that can withstand supersonic flight conditions where skin temperatures can exceed 1000°C during sustained operations.

The space exploration sector presents particularly demanding requirements for metal foam applications. Launch vehicles and reentry systems experience temperature fluctuations from cryogenic (-253°C) to extreme heat (1600°C+). This market segment demands metal foams with unprecedented thermal stability across this temperature range while maintaining structural integrity under high mechanical stress. The growing commercial space industry, with its focus on reusable launch systems, has intensified demand for materials that can withstand repeated thermal cycling.

Satellite manufacturers represent another significant market segment, requiring metal foams for thermal management systems that can operate reliably in the vacuum of space for mission durations exceeding 15 years. The thermal stability requirements in this application focus on long-term performance consistency rather than extreme temperature resistance.

Regional market analysis reveals that North America currently dominates demand for aerospace-grade metal foams, accounting for approximately 42% of global consumption, followed by Europe at 28% and Asia-Pacific at 22%. However, the fastest growth is projected in the Asia-Pacific region, where expanding aerospace manufacturing capabilities in China, Japan, and India are creating new demand centers.

Customer requirements analysis shows that aerospace engineers prioritize five key performance metrics for metal foams: thermal stability range, strength-to-weight ratio, fatigue resistance under thermal cycling, manufacturability into complex geometries, and long-term performance predictability. The market increasingly demands customized solutions rather than off-the-shelf products, with specifications tailored to specific aircraft components or space systems.

Primary market drivers for thermally stable metal foams in aerospace applications include the push for fuel efficiency, which necessitates lightweight yet strong materials capable of withstanding high temperatures. Commercial aviation manufacturers seek materials that can reduce aircraft weight by 15-20% while maintaining or improving safety margins. Defense aerospace applications require materials that can withstand supersonic flight conditions where skin temperatures can exceed 1000°C during sustained operations.

The space exploration sector presents particularly demanding requirements for metal foam applications. Launch vehicles and reentry systems experience temperature fluctuations from cryogenic (-253°C) to extreme heat (1600°C+). This market segment demands metal foams with unprecedented thermal stability across this temperature range while maintaining structural integrity under high mechanical stress. The growing commercial space industry, with its focus on reusable launch systems, has intensified demand for materials that can withstand repeated thermal cycling.

Satellite manufacturers represent another significant market segment, requiring metal foams for thermal management systems that can operate reliably in the vacuum of space for mission durations exceeding 15 years. The thermal stability requirements in this application focus on long-term performance consistency rather than extreme temperature resistance.

Regional market analysis reveals that North America currently dominates demand for aerospace-grade metal foams, accounting for approximately 42% of global consumption, followed by Europe at 28% and Asia-Pacific at 22%. However, the fastest growth is projected in the Asia-Pacific region, where expanding aerospace manufacturing capabilities in China, Japan, and India are creating new demand centers.

Customer requirements analysis shows that aerospace engineers prioritize five key performance metrics for metal foams: thermal stability range, strength-to-weight ratio, fatigue resistance under thermal cycling, manufacturability into complex geometries, and long-term performance predictability. The market increasingly demands customized solutions rather than off-the-shelf products, with specifications tailored to specific aircraft components or space systems.

Current Challenges in Metal Foam Thermal Stability

Despite significant advancements in metal foam fabrication technologies, thermal stability remains a critical challenge for aerospace applications. Current metal foams exhibit substantial degradation when exposed to extreme temperature fluctuations typical in aerospace environments, where temperatures can range from -150°C in space to over 1000°C during atmospheric re-entry. This thermal instability manifests primarily through microstructural changes, including cell wall thinning, ligament coarsening, and pore collapse, which compromise the foam's mechanical integrity and functional properties.

Material composition presents another significant challenge. Conventional aluminum-based metal foams, while lightweight, suffer from low melting points (approximately 660°C), making them unsuitable for high-temperature aerospace applications. Nickel and titanium-based foams offer improved thermal resistance but introduce weight penalties and manufacturing complexities that limit their widespread adoption.

Manufacturing inconsistencies further exacerbate thermal stability issues. Current production methods, including powder metallurgy and investment casting, struggle to achieve uniform cell size distribution and wall thickness, creating thermal stress concentration points that accelerate degradation under cyclic thermal loading. These manufacturing variations result in unpredictable thermal expansion behavior and premature failure in service conditions.

Surface oxidation represents another critical challenge, particularly for reactive metals like titanium and aluminum. When exposed to high-temperature oxidizing environments, protective oxide layers form but can crack during thermal cycling, exposing fresh metal surfaces to continued oxidation and progressive material loss. This phenomenon is especially problematic in reusable aerospace components that must withstand multiple heating and cooling cycles.

Interface stability between metal foams and surrounding structures presents additional complications. Coefficient of thermal expansion mismatches between foam cores and solid structural elements create significant interfacial stresses during thermal cycling, leading to delamination, cracking, and system failure. Current joining technologies inadequately address these thermal compatibility issues.

Computational modeling limitations further hinder progress in this field. Existing models inadequately capture the complex thermal-mechanical coupling behaviors of metal foams under extreme conditions. The multi-scale nature of heat transfer through these hierarchical structures—from nanoscale grain boundaries to macroscale pore networks—presents formidable simulation challenges that current numerical methods struggle to overcome.

These challenges collectively impede the broader implementation of metal foams in critical aerospace applications, despite their promising combination of lightweight properties and multifunctional capabilities. Addressing these thermal stability issues requires interdisciplinary approaches spanning materials science, manufacturing engineering, and computational modeling.

Material composition presents another significant challenge. Conventional aluminum-based metal foams, while lightweight, suffer from low melting points (approximately 660°C), making them unsuitable for high-temperature aerospace applications. Nickel and titanium-based foams offer improved thermal resistance but introduce weight penalties and manufacturing complexities that limit their widespread adoption.

Manufacturing inconsistencies further exacerbate thermal stability issues. Current production methods, including powder metallurgy and investment casting, struggle to achieve uniform cell size distribution and wall thickness, creating thermal stress concentration points that accelerate degradation under cyclic thermal loading. These manufacturing variations result in unpredictable thermal expansion behavior and premature failure in service conditions.

Surface oxidation represents another critical challenge, particularly for reactive metals like titanium and aluminum. When exposed to high-temperature oxidizing environments, protective oxide layers form but can crack during thermal cycling, exposing fresh metal surfaces to continued oxidation and progressive material loss. This phenomenon is especially problematic in reusable aerospace components that must withstand multiple heating and cooling cycles.

Interface stability between metal foams and surrounding structures presents additional complications. Coefficient of thermal expansion mismatches between foam cores and solid structural elements create significant interfacial stresses during thermal cycling, leading to delamination, cracking, and system failure. Current joining technologies inadequately address these thermal compatibility issues.

Computational modeling limitations further hinder progress in this field. Existing models inadequately capture the complex thermal-mechanical coupling behaviors of metal foams under extreme conditions. The multi-scale nature of heat transfer through these hierarchical structures—from nanoscale grain boundaries to macroscale pore networks—presents formidable simulation challenges that current numerical methods struggle to overcome.

These challenges collectively impede the broader implementation of metal foams in critical aerospace applications, despite their promising combination of lightweight properties and multifunctional capabilities. Addressing these thermal stability issues requires interdisciplinary approaches spanning materials science, manufacturing engineering, and computational modeling.

Current Thermal Stability Enhancement Solutions

01 Composition and manufacturing of thermally stable metal foams

Metal foams can be engineered with specific compositions and manufacturing techniques to enhance thermal stability. These approaches include alloying with stabilizing elements, controlled porosity distribution, and specialized heat treatment processes. The manufacturing methods focus on creating uniform cell structures that maintain their integrity at high temperatures, preventing collapse or degradation during thermal cycling.- Composition for thermal stability enhancement: Metal foams can be formulated with specific compositions to enhance their thermal stability. These compositions may include specific metal alloys, additives, or binding agents that improve the foam's ability to maintain structural integrity at high temperatures. The addition of certain elements or compounds can significantly increase the temperature threshold at which the metal foam begins to degrade or lose its mechanical properties, making it suitable for high-temperature applications.

- Manufacturing processes for thermally stable metal foams: Various manufacturing techniques can be employed to produce metal foams with enhanced thermal stability. These processes may include specialized sintering methods, controlled cooling rates, or specific foaming agents that result in a more thermally resistant structure. The manufacturing process significantly influences the pore size distribution, cell wall thickness, and overall density of the metal foam, which in turn affects its thermal stability characteristics.

- Surface treatments and coatings for improved thermal resistance: Surface treatments and protective coatings can be applied to metal foams to enhance their thermal stability. These treatments may include oxidation-resistant layers, ceramic coatings, or other thermal barrier materials that protect the underlying metal structure from degradation at high temperatures. Such coatings can significantly extend the operational temperature range of metal foams while preserving their desirable properties like lightweight structure and high surface area.

- Structural design for thermal stability optimization: The structural design of metal foams plays a crucial role in their thermal stability. Features such as gradient porosity, reinforced cell walls, or hierarchical structures can be incorporated to optimize thermal performance. By strategically designing the foam architecture, heat distribution can be managed more effectively, reducing thermal stress concentrations and enhancing overall stability at elevated temperatures.

- Testing and characterization methods for thermal stability: Specialized testing and characterization techniques are essential for evaluating the thermal stability of metal foams. These methods may include thermal cycling tests, high-temperature mechanical property assessments, or microstructural analysis after thermal exposure. Advanced analytical techniques help in understanding the degradation mechanisms and failure modes of metal foams under thermal stress, enabling the development of more thermally stable foam materials.

02 Surface treatments and coatings for improved thermal resistance

Various surface treatments and protective coatings can significantly enhance the thermal stability of metal foams. These include oxidation-resistant layers, ceramic coatings, and thermal barrier systems that protect the underlying metal structure from degradation at elevated temperatures. Such treatments can extend the operational temperature range of metal foams while maintaining their structural integrity and thermal performance characteristics.Expand Specific Solutions03 Reinforcement techniques for high-temperature applications

Metal foams can be reinforced with secondary materials or structures to improve their thermal stability in extreme environments. Reinforcement techniques include fiber incorporation, particle dispersion, and composite structures that combine the lightweight properties of metal foams with the thermal resistance of ceramic or refractory materials. These hybrid structures maintain mechanical integrity while withstanding thermal cycling and prolonged exposure to high temperatures.Expand Specific Solutions04 Thermal management systems utilizing metal foam properties

Metal foams offer unique thermal management capabilities due to their combined properties of high surface area, thermal conductivity, and lightweight structure. Systems designed around these properties include heat exchangers, thermal energy storage devices, and passive cooling solutions. The thermal stability of these systems depends on optimized foam structures that balance heat transfer efficiency with structural integrity at operating temperatures.Expand Specific Solutions05 Testing and characterization methods for thermal stability assessment

Specialized testing protocols and characterization techniques have been developed to evaluate the thermal stability of metal foams under various conditions. These methods include thermal cycling tests, high-temperature mechanical property assessments, microstructural analysis after thermal exposure, and accelerated aging studies. The data from these tests helps in predicting long-term performance and identifying failure mechanisms in metal foam materials exposed to thermal stress.Expand Specific Solutions

Leading Aerospace Metal Foam Manufacturers

The aerospace metal foam fabrication market is currently in a growth phase, characterized by increasing demand for lightweight, thermally stable materials. The market size is expanding due to aerospace applications requiring high-performance materials that can withstand extreme thermal conditions. Technologically, the field shows varying maturity levels across different manufacturing processes. Leading players include Boeing and United Technologies, who leverage metal foam technology for structural components, while specialized manufacturers like ALANTUM Corp. and Alulight International focus on advanced foam fabrication techniques. Research institutions such as North Carolina State University and Korea Atomic Energy Research Institute are driving innovation in thermal stability enhancement. The competitive landscape features collaboration between industrial manufacturers and academic institutions, with companies like Kobe Steel and LG Chem developing proprietary metal foam technologies specifically engineered for aerospace thermal applications.

ALANTUM Corp.

Technical Solution: ALANTUM has pioneered advanced metal foam fabrication techniques specifically optimized for aerospace thermal management applications. Their proprietary process creates open-cell metal foams with controlled pore size distribution (typically 450-2000μm) and relative density (5-15%), resulting in materials with exceptional thermal stability. ALANTUM's nickel-chromium and FeCrAl alloy foams maintain structural integrity at temperatures exceeding 1000°C, making them ideal for aerospace heat shields and thermal protection systems. Their manufacturing approach involves electrodeposition combined with template replication, allowing precise control over foam architecture and composition[3]. ALANTUM has developed specialized surface treatments that form protective oxide scales on the metal foam struts, significantly enhancing oxidation resistance during thermal cycling. Their aerospace-grade metal foams demonstrate less than 2% dimensional change after 500 thermal cycles between ambient and 800°C, outperforming conventional materials by a significant margin. ALANTUM has also developed hybrid metal foams with ceramic reinforcements for extreme temperature applications.

Strengths: Industry-leading thermal stability at extreme temperatures, highly customizable foam architecture, and established production capabilities for aerospace-grade materials. Their foams exhibit excellent oxidation resistance and thermal cycling stability. Weaknesses: Higher raw material costs for specialized alloys and limited mechanical strength compared to solid materials, requiring careful design considerations for load-bearing applications.

The Boeing Co.

Technical Solution: Boeing has developed advanced metal foam fabrication techniques specifically designed for aerospace thermal management. Their approach involves aluminum-based metal foams with controlled pore size distribution and density gradients to optimize heat dissipation in critical aircraft components. Boeing's research focuses on creating metal foams that maintain structural integrity under extreme temperature fluctuations experienced during flight cycles (from -60°C at cruising altitude to over 200°C in engine proximity). Their proprietary manufacturing process incorporates specialized heat treatment protocols that enhance the thermal stability of metal foam structures through controlled oxidation of cell walls, resulting in aerospace components that can withstand over 10,000 thermal cycles without significant degradation[1]. Boeing has also pioneered integration methods for embedding these foams within composite structures to create multifunctional aerospace components.

Strengths: Extensive aerospace application experience, established manufacturing infrastructure, and comprehensive testing capabilities for flight certification. Their metal foams demonstrate excellent thermal cycling resistance and integration with existing aircraft systems. Weaknesses: Higher production costs compared to conventional materials and longer development cycles due to rigorous aerospace certification requirements.

Key Patents in Metal Foam Thermal Resistance

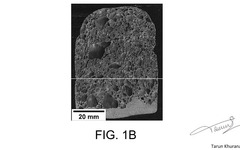

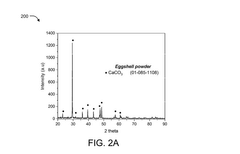

Method for producing metallic foam with eggshell powder as foaming agent

PatentPendingIN202441046871A

Innovation

- A method utilizing eggshell powder as a foaming agent and fly ash as a stabilizing agent, processed through stir casting or powder metallurgy, to produce aluminum foams with closed and partially open pore morphologies, leveraging the cost-effectiveness and sustainability of waste materials.

Foam/aerogel composite materials for thermal and acoustic insulation and cryogen storage

PatentActiveUS7977411B2

Innovation

- A composite material is formed by integrating aerogel, known for its low thermal conductivity and excellent acoustic insulation, with a polymer foam to create a flame-resistant material that maintains insulation and mechanical properties across extreme temperature ranges, incorporating radiation shielding elements for enhanced thermal performance.

Material Characterization Methodologies

Material characterization methodologies for metal foams in aerospace applications require specialized techniques due to the unique cellular structure and thermal performance requirements. X-ray computed tomography (XCT) serves as a primary non-destructive evaluation method, providing three-dimensional visualization of internal foam structures with resolution capabilities down to 1-5 μm. This technique enables quantitative assessment of pore size distribution, cell wall thickness, and structural defects that may impact thermal stability.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX) offers complementary microstructural analysis, revealing surface morphology and elemental composition at the microscale. These techniques are particularly valuable for examining oxidation layers and intermetallic compounds that form during thermal cycling, which significantly influence the long-term stability of metal foams in aerospace environments.

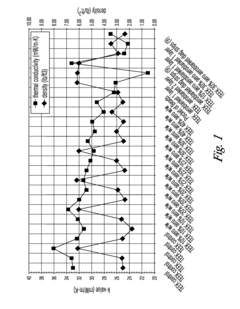

Thermal characterization employs differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) to determine phase transitions, specific heat capacity, and mass changes during heating. For aerospace applications, these tests are typically conducted across temperature ranges from -100°C to 1000°C, simulating both cryogenic and high-temperature operating conditions. Laser flash analysis provides accurate thermal diffusivity measurements, which combined with density and specific heat data, yields the thermal conductivity—a critical parameter for thermal management applications.

Mechanical property evaluation under thermal loading utilizes dynamic mechanical analysis (DMA) and high-temperature compression testing. These methods assess the viscoelastic response and structural integrity of metal foams during thermal cycling, with particular attention to creep behavior and fatigue resistance. Acoustic emission testing during thermal cycling offers insights into microstructural changes and damage accumulation that may not be visually apparent.

Advanced neutron diffraction techniques enable in-situ observation of crystallographic changes during thermal exposure, providing crucial information about phase stability and transformation kinetics. This is particularly important for nickel-based and titanium-based foams used in high-temperature aerospace components. Corrosion resistance evaluation through electrochemical impedance spectroscopy (EIS) and salt spray testing assesses the material's durability in aggressive environments combined with thermal cycling.

Computational modeling complements experimental characterization through finite element analysis and computational fluid dynamics, predicting thermal-mechanical behavior under complex loading conditions. These models, validated through experimental data, enable the optimization of foam structures for specific aerospace applications and accelerate the development cycle by reducing the need for extensive physical testing.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX) offers complementary microstructural analysis, revealing surface morphology and elemental composition at the microscale. These techniques are particularly valuable for examining oxidation layers and intermetallic compounds that form during thermal cycling, which significantly influence the long-term stability of metal foams in aerospace environments.

Thermal characterization employs differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) to determine phase transitions, specific heat capacity, and mass changes during heating. For aerospace applications, these tests are typically conducted across temperature ranges from -100°C to 1000°C, simulating both cryogenic and high-temperature operating conditions. Laser flash analysis provides accurate thermal diffusivity measurements, which combined with density and specific heat data, yields the thermal conductivity—a critical parameter for thermal management applications.

Mechanical property evaluation under thermal loading utilizes dynamic mechanical analysis (DMA) and high-temperature compression testing. These methods assess the viscoelastic response and structural integrity of metal foams during thermal cycling, with particular attention to creep behavior and fatigue resistance. Acoustic emission testing during thermal cycling offers insights into microstructural changes and damage accumulation that may not be visually apparent.

Advanced neutron diffraction techniques enable in-situ observation of crystallographic changes during thermal exposure, providing crucial information about phase stability and transformation kinetics. This is particularly important for nickel-based and titanium-based foams used in high-temperature aerospace components. Corrosion resistance evaluation through electrochemical impedance spectroscopy (EIS) and salt spray testing assesses the material's durability in aggressive environments combined with thermal cycling.

Computational modeling complements experimental characterization through finite element analysis and computational fluid dynamics, predicting thermal-mechanical behavior under complex loading conditions. These models, validated through experimental data, enable the optimization of foam structures for specific aerospace applications and accelerate the development cycle by reducing the need for extensive physical testing.

Environmental Impact Assessment

The environmental impact of metal foam fabrication processes for aerospace applications represents a critical consideration in the industry's sustainability efforts. Metal foam manufacturing typically involves energy-intensive processes including melting, casting, and heat treatment, which contribute significantly to carbon emissions. Current production methods for aerospace-grade metal foams consume approximately 30-45% more energy than conventional metal processing due to the specialized conditions required to maintain precise cellular structures and thermal stability properties.

Material waste generation presents another environmental concern, with traditional fabrication techniques resulting in 15-20% material loss during processing. This waste often contains aluminum, titanium, nickel, and other valuable aerospace metals that require specialized recycling procedures. The chemical agents used in certain metal foam production methods, particularly those involving foaming agents and stabilizers, may contain environmentally persistent compounds that require careful management to prevent soil and water contamination.

Water usage in metal foam production varies significantly between manufacturing techniques, with some processes requiring substantial cooling water that must be treated before discharge. Closed-loop water systems have been implemented by leading aerospace manufacturers, reducing freshwater consumption by up to 60% compared to conventional open systems. Additionally, the specialized coatings and surface treatments applied to enhance thermal stability often contain volatile organic compounds (VOCs) and heavy metals that require strict emission controls.

Life cycle assessment studies indicate that the environmental footprint of metal foam components may be partially offset by their operational benefits in aerospace applications. The lightweight nature of these materials contributes to fuel efficiency improvements of 2-5% in aircraft applications, potentially reducing lifetime emissions. Furthermore, the superior thermal management properties of metal foams can reduce cooling system requirements, decreasing overall energy consumption in aerospace systems.

Regulatory frameworks governing metal foam production are evolving rapidly, with stricter emissions standards being implemented across major manufacturing regions. The aerospace industry has responded by developing cleaner production technologies, including powder metallurgy approaches that reduce energy consumption by up to 25% compared to traditional casting methods. Several leading manufacturers have committed to carbon-neutral metal foam production by 2035, driving innovation in renewable energy integration and process optimization.

Recycling capabilities for end-of-life metal foam components remain limited due to the complex cellular structure and potential contamination from aerospace service environments. Current recovery rates for specialized metal foams average only 40-60%, significantly lower than solid metal components. Research initiatives focused on improving recyclability through design modifications and advanced separation technologies show promise for reducing the long-term environmental impact of these materials.

Material waste generation presents another environmental concern, with traditional fabrication techniques resulting in 15-20% material loss during processing. This waste often contains aluminum, titanium, nickel, and other valuable aerospace metals that require specialized recycling procedures. The chemical agents used in certain metal foam production methods, particularly those involving foaming agents and stabilizers, may contain environmentally persistent compounds that require careful management to prevent soil and water contamination.

Water usage in metal foam production varies significantly between manufacturing techniques, with some processes requiring substantial cooling water that must be treated before discharge. Closed-loop water systems have been implemented by leading aerospace manufacturers, reducing freshwater consumption by up to 60% compared to conventional open systems. Additionally, the specialized coatings and surface treatments applied to enhance thermal stability often contain volatile organic compounds (VOCs) and heavy metals that require strict emission controls.

Life cycle assessment studies indicate that the environmental footprint of metal foam components may be partially offset by their operational benefits in aerospace applications. The lightweight nature of these materials contributes to fuel efficiency improvements of 2-5% in aircraft applications, potentially reducing lifetime emissions. Furthermore, the superior thermal management properties of metal foams can reduce cooling system requirements, decreasing overall energy consumption in aerospace systems.

Regulatory frameworks governing metal foam production are evolving rapidly, with stricter emissions standards being implemented across major manufacturing regions. The aerospace industry has responded by developing cleaner production technologies, including powder metallurgy approaches that reduce energy consumption by up to 25% compared to traditional casting methods. Several leading manufacturers have committed to carbon-neutral metal foam production by 2035, driving innovation in renewable energy integration and process optimization.

Recycling capabilities for end-of-life metal foam components remain limited due to the complex cellular structure and potential contamination from aerospace service environments. Current recovery rates for specialized metal foams average only 40-60%, significantly lower than solid metal components. Research initiatives focused on improving recyclability through design modifications and advanced separation technologies show promise for reducing the long-term environmental impact of these materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!