Zirconia as a Catalyst for Positive Environmental Impact

Zirconia Catalysis Background and Objectives

Zirconia, a versatile metal oxide, has emerged as a promising catalyst in various environmental applications. The research on zirconia as a catalyst for positive environmental impact has gained significant momentum in recent years, driven by the growing need for sustainable and eco-friendly solutions to address global environmental challenges.

The development of zirconia-based catalysts can be traced back to the mid-20th century when researchers first recognized its potential in chemical reactions. Since then, the field has witnessed remarkable progress, with zirconia catalysts finding applications in diverse areas such as air pollution control, water treatment, and renewable energy production.

The evolution of zirconia catalysis has been closely linked to advancements in materials science and nanotechnology. Early studies focused on understanding the fundamental properties of zirconia, including its crystal structure, surface chemistry, and catalytic activity. As research progressed, scientists discovered various methods to enhance the catalytic performance of zirconia, such as doping with other elements, controlling particle size and morphology, and creating composite materials.

One of the primary objectives of current research on zirconia catalysts is to develop more efficient and environmentally benign processes for industrial applications. This includes the design of catalysts that can operate at lower temperatures, consume less energy, and produce fewer waste products. Additionally, researchers aim to improve the selectivity and stability of zirconia catalysts, enabling their use in a wider range of chemical reactions and environmental remediation processes.

Another crucial goal is to explore the potential of zirconia catalysts in addressing specific environmental challenges. For instance, studies are underway to develop zirconia-based catalysts for the removal of harmful pollutants from air and water, such as volatile organic compounds (VOCs), nitrogen oxides (NOx), and heavy metals. Furthermore, researchers are investigating the use of zirconia catalysts in the production of clean fuels and chemicals from renewable resources, contributing to the transition towards a more sustainable energy landscape.

The ongoing research also aims to uncover the underlying mechanisms of zirconia catalysis at the molecular level. By gaining a deeper understanding of how zirconia interacts with reactants and intermediates, scientists hope to design more effective catalysts tailored for specific applications. This fundamental knowledge is essential for optimizing catalyst performance and developing predictive models for catalyst behavior under various conditions.

As the field of zirconia catalysis continues to evolve, researchers are exploring innovative approaches to enhance its environmental impact. This includes the development of multifunctional catalysts that can simultaneously address multiple environmental issues, as well as the integration of zirconia catalysts with other advanced technologies such as photocatalysis and electrocatalysis. These efforts are expected to pave the way for next-generation environmental solutions that leverage the unique properties of zirconia to create a more sustainable future.

Environmental Market Demand Analysis

The global environmental market is experiencing significant growth, driven by increasing awareness of climate change, pollution, and resource depletion. Within this context, the demand for zirconia as a catalyst for positive environmental impact is gaining traction across various sectors. The automotive industry, in particular, has shown a keen interest in zirconia-based catalysts for emission control systems. As governments worldwide implement stricter emission standards, the market for advanced catalytic converters is projected to expand substantially.

In the energy sector, zirconia catalysts are finding applications in fuel cells and renewable energy technologies. The push for cleaner energy sources has created a growing market for efficient and durable catalysts that can enhance the performance of these systems. Zirconia's unique properties, such as high thermal stability and oxygen ion conductivity, make it an attractive option for these applications.

The chemical industry is another significant driver of demand for zirconia catalysts. As companies seek to develop more sustainable and environmentally friendly production processes, zirconia-based catalysts are being explored for their potential to improve reaction efficiency and reduce waste. This trend aligns with the broader movement towards green chemistry and circular economy principles.

Water treatment is emerging as a promising market for zirconia catalysts. With increasing concerns about water scarcity and pollution, there is a growing need for advanced water purification technologies. Zirconia-based catalysts have shown potential in the degradation of persistent organic pollutants and the removal of heavy metals from water, opening up new opportunities in this sector.

The agricultural sector is also showing interest in zirconia catalysts for their potential in reducing the environmental impact of fertilizers and pesticides. As sustainable agriculture practices gain importance, the market for eco-friendly agrochemical solutions is expected to grow, creating opportunities for innovative catalyst technologies.

Market analysis indicates that the Asia-Pacific region is likely to be a key growth area for zirconia catalysts, driven by rapid industrialization, stringent environmental regulations, and increasing investments in clean technologies. North America and Europe are also expected to maintain strong demand, particularly in the automotive and renewable energy sectors.

While the market potential for zirconia as an environmental catalyst is promising, it is important to note that adoption rates may vary across different industries and regions. Factors such as cost-effectiveness, scalability, and compatibility with existing systems will play crucial roles in determining the pace of market penetration. Additionally, ongoing research and development efforts to enhance the performance and versatility of zirconia catalysts will be essential in unlocking their full market potential and addressing evolving environmental challenges.

Current Zirconia Catalyst Technology Status

Zirconia catalysts have gained significant attention in recent years due to their potential for positive environmental impact. The current status of zirconia catalyst technology reflects a dynamic field with ongoing advancements and diverse applications. Zirconia-based catalysts are widely employed in various industrial processes, including petrochemical refining, emissions control, and renewable energy production.

In the petrochemical industry, zirconia catalysts play a crucial role in hydrocarbon conversion processes, such as isomerization and alkylation. These catalysts demonstrate high activity and selectivity, contributing to improved process efficiency and reduced energy consumption. The automotive sector utilizes zirconia-based catalysts in three-way catalytic converters, effectively reducing harmful emissions from vehicle exhaust.

Recent developments have focused on enhancing the catalytic performance of zirconia through various strategies. One approach involves the modification of zirconia's surface properties through doping with other elements, such as rare earth metals or transition metals. This technique has shown promising results in improving catalyst stability and selectivity for specific reactions.

Nanostructured zirconia catalysts have emerged as a significant area of research, offering increased surface area and improved catalytic activity. These materials exhibit unique properties due to their small particle size and high surface-to-volume ratio, leading to enhanced reactivity and selectivity in various chemical transformations.

The application of zirconia catalysts in environmental remediation has gained traction, particularly in water treatment and air purification processes. Zirconia-based photocatalysts have demonstrated effectiveness in degrading organic pollutants and removing heavy metals from wastewater. In air purification, zirconia catalysts are being explored for their potential in reducing volatile organic compounds (VOCs) and other atmospheric pollutants.

Researchers are also investigating the use of zirconia catalysts in renewable energy applications, such as biomass conversion and fuel cell technology. In biomass processing, zirconia catalysts show promise for the efficient conversion of lignocellulosic materials into valuable chemicals and fuels. For fuel cells, zirconia-based materials are being developed as electrolytes and electrode components, contributing to improved energy conversion efficiency.

Despite these advancements, challenges remain in optimizing zirconia catalyst performance and scalability. Ongoing research efforts are focused on improving catalyst stability, reducing deactivation rates, and developing more cost-effective synthesis methods. Additionally, there is a growing emphasis on understanding the fundamental mechanisms of zirconia catalysis at the molecular level, which could lead to the design of more efficient and selective catalysts.

Current Zirconia Catalyst Solutions

01 Environmental impact assessment of zirconia production

The production of zirconia has various environmental impacts that need to be assessed. This includes evaluating the energy consumption, greenhouse gas emissions, and resource depletion associated with mining, processing, and manufacturing zirconia-based products. Environmental impact assessments help identify areas for improvement in the production process and guide sustainable practices in the zirconia industry.- Environmental impact assessment of zirconia production: The production of zirconia has various environmental impacts that need to be assessed. This includes evaluating the energy consumption, greenhouse gas emissions, and resource depletion associated with mining, processing, and manufacturing zirconia-based products. Environmental impact assessments help identify areas for improvement in the production process to minimize negative effects on the environment.

- Recycling and waste management of zirconia materials: Proper recycling and waste management strategies are crucial for reducing the environmental impact of zirconia materials. This involves developing efficient recycling processes for zirconia-containing products, minimizing waste generation during production, and implementing safe disposal methods for non-recyclable zirconia waste. Effective waste management can help conserve resources and reduce the overall environmental footprint of zirconia use.

- Life cycle analysis of zirconia products: Conducting life cycle analyses of zirconia products is essential for understanding their environmental impact from cradle to grave. This involves assessing the environmental effects at each stage of the product's life, including raw material extraction, manufacturing, use, and end-of-life disposal. Life cycle analyses help identify opportunities for improving the sustainability of zirconia products and inform decision-making processes.

- Sustainable alternatives and improvements in zirconia production: Research and development efforts are focused on finding sustainable alternatives and improvements in zirconia production processes. This includes exploring new synthesis methods that require less energy and fewer resources, developing eco-friendly catalysts, and investigating the use of renewable energy sources in manufacturing. These advancements aim to reduce the environmental impact of zirconia production while maintaining or improving product quality.

- Environmental regulations and compliance for zirconia industry: The zirconia industry is subject to various environmental regulations and compliance requirements. This includes adhering to emission standards, implementing pollution control measures, and reporting environmental performance. Compliance with these regulations is crucial for minimizing the negative environmental impacts of zirconia production and ensuring sustainable industry practices.

02 Recycling and waste management of zirconia materials

Proper recycling and waste management of zirconia materials are crucial for reducing their environmental impact. This involves developing efficient recycling processes for zirconia-containing products, minimizing waste generation during production, and implementing safe disposal methods for non-recyclable zirconia waste. Effective waste management strategies can help conserve resources and reduce the environmental footprint of zirconia use.Expand Specific Solutions03 Life cycle analysis of zirconia products

Conducting life cycle analyses of zirconia products helps in understanding their overall environmental impact from raw material extraction to end-of-life disposal. This comprehensive approach considers factors such as energy consumption, emissions, and resource use throughout the product's lifespan. Life cycle analyses can identify opportunities for improving the sustainability of zirconia products and guide eco-friendly design choices.Expand Specific Solutions04 Sustainable alternatives and improvements in zirconia production

Research into sustainable alternatives and improvements in zirconia production aims to reduce its environmental impact. This includes exploring cleaner production methods, developing more energy-efficient processes, and investigating alternative raw materials. Innovations in this area can lead to reduced emissions, lower energy consumption, and improved overall sustainability of zirconia-based products and applications.Expand Specific Solutions05 Environmental regulations and compliance for zirconia industry

The zirconia industry is subject to various environmental regulations and compliance requirements. These regulations aim to minimize the environmental impact of zirconia production and use. Compliance involves implementing pollution control measures, adhering to emission standards, and ensuring proper handling and disposal of hazardous materials. Staying up-to-date with evolving environmental regulations is crucial for sustainable operations in the zirconia industry.Expand Specific Solutions

Key Players in Zirconia Catalysis

The research on zirconia as a catalyst for positive environmental impact is in a growth phase, with increasing market size and technological maturity. The global market for zirconia-based catalysts is expanding due to growing environmental concerns and stringent emissions regulations. Companies like Toyota Motor Corp., BASF SE, and Umicore SA are leading the development of advanced zirconia catalysts for automotive and industrial applications. Research institutions such as Dalian Institute of Chemical Physics and Zhejiang University are contributing to technological advancements. The field is characterized by ongoing innovation, with a focus on improving catalyst efficiency, durability, and cost-effectiveness. Collaborations between industry leaders and academic institutions are driving progress in this environmentally crucial technology sector.

Toyota Motor Corp.

China Petroleum & Chemical Corp.

Core Zirconia Catalysis Innovations

- A ceria-based mixed-metal oxide material with nano-crystalline structure, high surface area, and optimized pore diameters is developed, using a process that involves dissolving salts, adding urea, coprecipitating, and calcining to create a fractal morphology that enhances surface area and mass transfer characteristics, and loading with noble metals like platinum for improved catalytic activity.

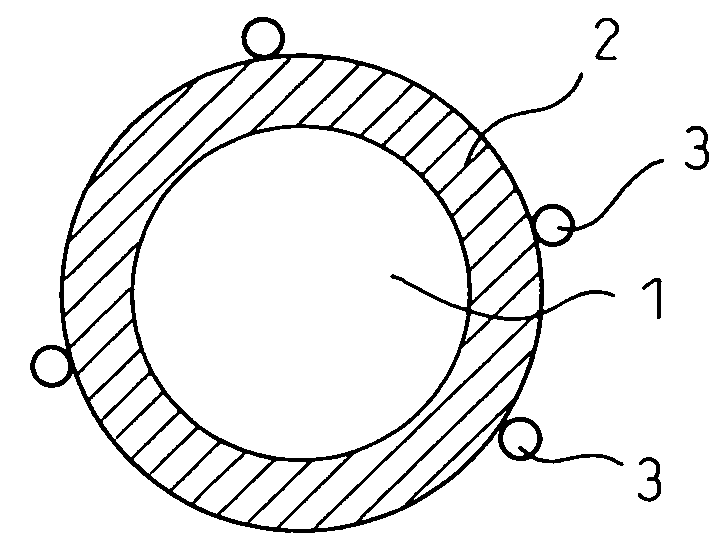

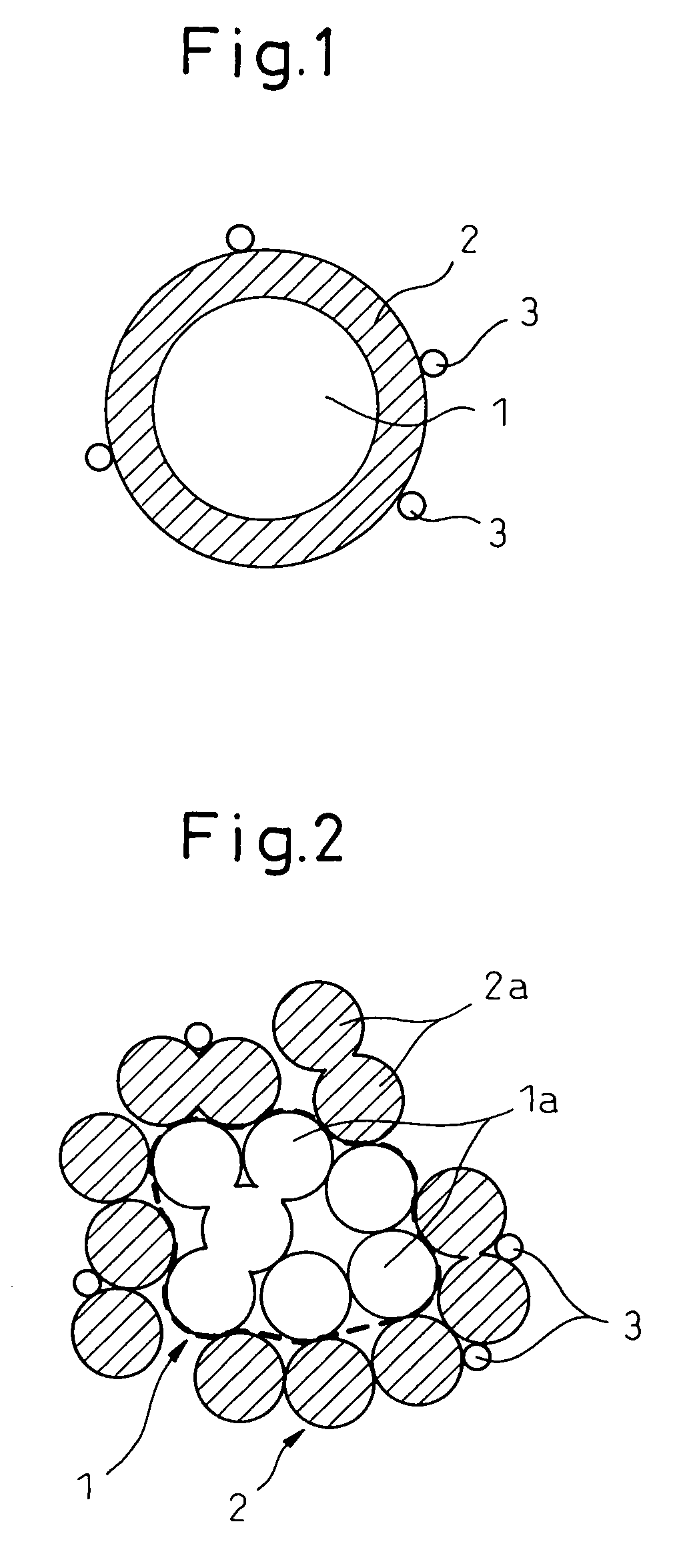

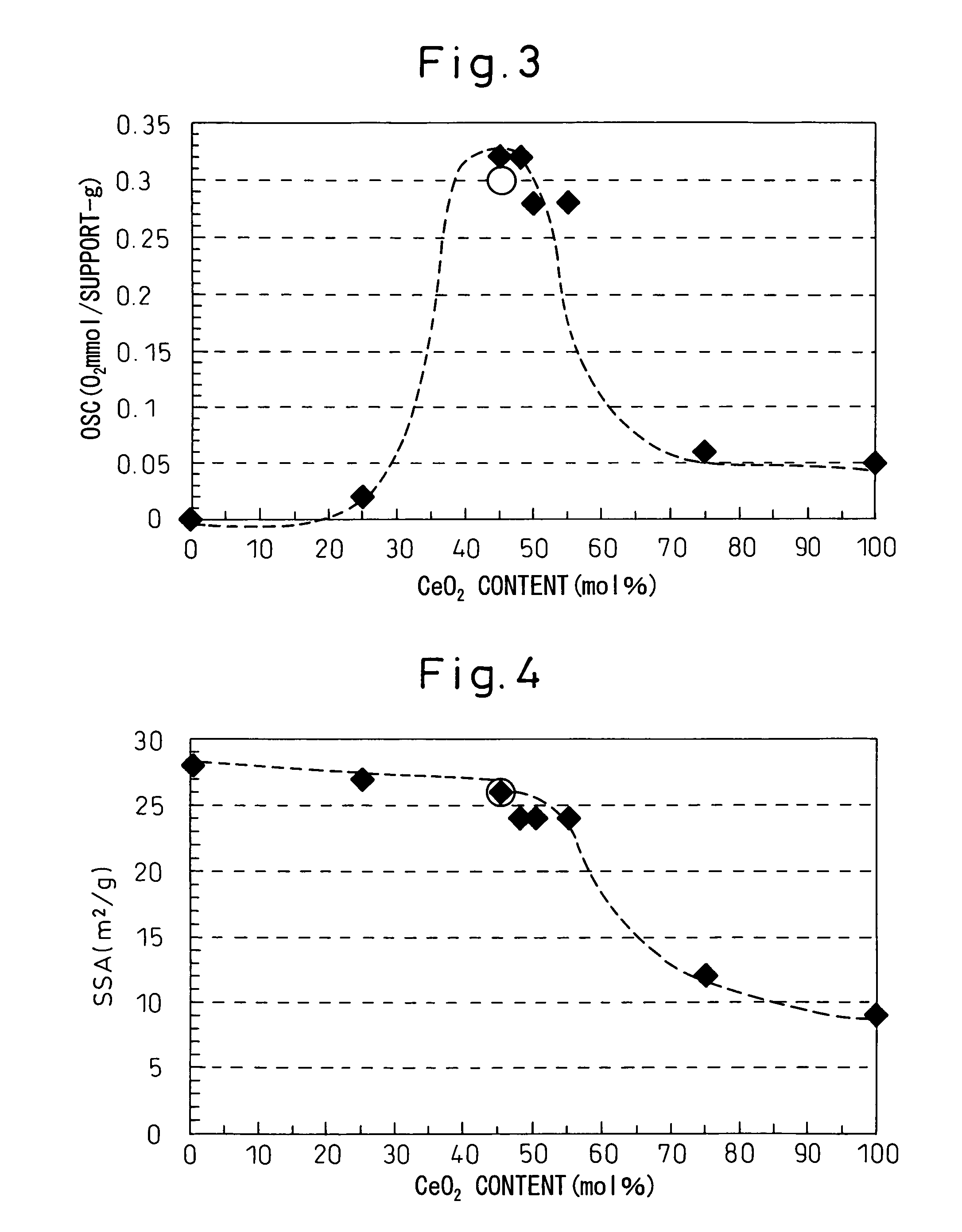

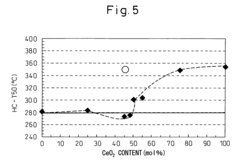

- A catalyst comprising a core part rich in ceria and a surface layer rich in zirconia, with rhodium supported on the surface layer, is developed, utilizing a sol-based process to create metal oxide particles with a specific molar fraction and particle size, and optionally incorporating alkaline earth or rare earth elements to enhance heat resistance and OSC.

Environmental Impact Assessment

The environmental impact assessment of zirconia as a catalyst for positive environmental impact reveals promising potential for sustainable development and pollution reduction. Zirconia-based catalysts have demonstrated significant efficacy in various environmental applications, particularly in the reduction of harmful emissions and the treatment of industrial waste.

In the context of air pollution control, zirconia catalysts have shown remarkable performance in reducing nitrogen oxides (NOx) emissions from automotive exhaust and industrial processes. The high thermal stability and oxygen storage capacity of zirconia enable efficient conversion of NOx into harmless nitrogen and oxygen, contributing to improved air quality in urban areas and industrial zones.

Water treatment is another area where zirconia catalysts exhibit positive environmental impact. These catalysts have proven effective in the degradation of organic pollutants in wastewater, including pharmaceutical residues, dyes, and pesticides. The ability of zirconia to catalyze advanced oxidation processes leads to the breakdown of complex organic compounds into simpler, less harmful substances, facilitating more efficient water purification and recycling.

In the realm of renewable energy, zirconia catalysts play a crucial role in enhancing the efficiency of fuel cells and electrolyzers. By promoting the conversion of chemical energy into electrical energy with minimal losses, zirconia-based materials contribute to the development of cleaner energy technologies and the reduction of greenhouse gas emissions associated with traditional power generation methods.

The use of zirconia catalysts in industrial processes also demonstrates positive environmental impacts. In petrochemical refining, zirconia-based catalysts enable more efficient cracking of hydrocarbons, leading to reduced energy consumption and lower carbon dioxide emissions. Additionally, these catalysts facilitate the production of cleaner fuels with lower sulfur content, contributing to reduced air pollution from vehicle emissions.

Furthermore, the long lifespan and recyclability of zirconia catalysts contribute to resource conservation and waste reduction. Unlike some traditional catalysts that require frequent replacement, zirconia-based materials maintain their catalytic activity over extended periods, minimizing the need for raw material extraction and catalyst disposal.

However, it is important to consider the potential environmental impacts associated with the production and end-of-life management of zirconia catalysts. The mining and processing of zirconium ores can have localized environmental effects, including habitat disruption and energy consumption. Efforts to develop more sustainable extraction methods and to optimize the lifecycle of zirconia catalysts are essential to maximize their overall positive environmental impact.

Regulatory Framework for Catalysts

The regulatory framework for catalysts plays a crucial role in ensuring the safe and responsible use of zirconia as a catalyst for positive environmental impact. Governments and international organizations have established comprehensive guidelines and standards to govern the development, production, and application of catalysts in various industries.

At the global level, the United Nations Environment Programme (UNEP) has set forth recommendations for the sustainable use of catalysts, emphasizing the importance of life cycle assessments and environmental impact studies. These guidelines encourage the adoption of green chemistry principles and the minimization of waste generation throughout the catalyst lifecycle.

In the United States, the Environmental Protection Agency (EPA) regulates catalysts under the Toxic Substances Control Act (TSCA) and the Clean Air Act. The EPA's New Chemicals Program requires manufacturers to submit premanufacture notices for new catalysts, ensuring that potential environmental and health risks are thoroughly evaluated before market introduction.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to catalysts and their precursors. REACH mandates that companies register chemical substances, including catalysts, and provide safety data to the European Chemicals Agency (ECHA). This regulation aims to protect human health and the environment while promoting innovation in the chemical industry.

In Asia, countries like Japan and China have also established regulatory frameworks for catalysts. Japan's Chemical Substances Control Law (CSCL) requires the evaluation and registration of new chemical substances, including catalysts. China's Measures for Environmental Management of New Chemical Substances set forth similar requirements for the registration and risk assessment of new catalysts.

Industry-specific regulations further shape the use of zirconia catalysts in particular applications. For instance, in the automotive sector, stringent emissions standards drive the development and implementation of advanced catalytic converters. The Euro 6 standards in Europe and Tier 3 standards in the United States set strict limits on vehicle emissions, influencing the design and composition of catalysts used in exhaust systems.

Regulatory bodies also focus on the end-of-life management of catalysts. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides guidelines for the proper disposal and recycling of spent catalysts, which often contain valuable metals and potentially harmful substances.

As research on zirconia as a catalyst for positive environmental impact progresses, regulatory frameworks are likely to evolve. Policymakers and regulatory agencies will need to stay abreast of technological advancements and adapt regulations to ensure that the benefits of zirconia catalysts are maximized while potential risks are mitigated. This may include the development of specific standards for zirconia-based catalysts, considering their unique properties and applications in environmental remediation and green chemistry.