Zirconia in Biocompatible Material Research

Zirconia Biocompatibility Background and Objectives

Zirconia has emerged as a prominent biocompatible material in recent decades, revolutionizing various fields of medical and dental applications. The journey of zirconia in biomedical research dates back to the late 1960s when its potential for orthopedic implants was first recognized. Since then, the material has undergone significant developments, leading to its widespread use in dental prosthetics, implant abutments, and other medical devices.

The evolution of zirconia as a biocompatible material has been driven by the increasing demand for alternatives to traditional metallic implants. Its exceptional mechanical properties, including high flexural strength and fracture toughness, coupled with its aesthetic appeal, have positioned zirconia as a superior choice in many biomedical applications. The material's ability to withstand high stresses while maintaining its structural integrity has made it particularly attractive for load-bearing implants.

One of the key factors contributing to zirconia's success in biomedical applications is its excellent biocompatibility. The material exhibits minimal ion release and low bacterial adhesion, reducing the risk of adverse reactions and infections. Furthermore, zirconia's ability to osseointegrate effectively with surrounding bone tissue has been a significant advantage in implant dentistry and orthopedics.

The technological advancements in zirconia processing have played a crucial role in expanding its applications. The development of yttria-stabilized zirconia (YSZ) has addressed the issue of low-temperature degradation, enhancing the material's long-term stability in physiological environments. Additionally, innovations in computer-aided design and manufacturing (CAD/CAM) technologies have enabled the production of highly precise and customized zirconia-based medical devices.

As research in this field progresses, the objectives for zirconia in biocompatible materials continue to evolve. Current goals include further improving the material's mechanical properties, enhancing its resistance to aging, and developing novel surface treatments to optimize tissue integration. There is also a growing interest in exploring zirconia-based composites that combine the benefits of zirconia with other biocompatible materials to create multifunctional implants.

The future of zirconia in biomedical applications looks promising, with ongoing research focusing on expanding its use in regenerative medicine and tissue engineering. Scientists are exploring the potential of zirconia scaffolds for bone regeneration and investigating its role in drug delivery systems. These advancements aim to address the increasing demand for personalized medicine and improve patient outcomes across various medical disciplines.

Market Analysis for Zirconia-Based Biomaterials

The global market for zirconia-based biomaterials has experienced significant growth in recent years, driven by increasing demand for dental and orthopedic implants. This market segment is expected to continue its upward trajectory due to several key factors. The aging population in many developed countries has led to a rise in age-related dental and bone disorders, creating a substantial need for biocompatible materials like zirconia. Additionally, the growing awareness of aesthetic dentistry and the preference for metal-free implants have further boosted the demand for zirconia-based solutions.

In the dental sector, zirconia has gained popularity as a material for crowns, bridges, and implants due to its excellent biocompatibility, high strength, and natural appearance. The dental zirconia market has shown robust growth, with a particularly strong demand in cosmetic dentistry applications. The orthopedic segment, while smaller, is also expanding as zirconia-based materials find increasing use in hip and knee implants, benefiting from their wear resistance and low friction properties.

Geographically, North America and Europe currently dominate the zirconia biomaterials market, owing to advanced healthcare infrastructure and higher adoption rates of innovative medical technologies. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by improving healthcare access, rising disposable incomes, and an increasing elderly population in countries like China and Japan.

The market is characterized by intense competition among key players, including major dental and orthopedic implant manufacturers as well as specialized biomaterials companies. These firms are investing heavily in research and development to enhance the properties of zirconia-based materials and expand their applications in the biomedical field.

Despite the positive outlook, the market faces challenges such as the high cost of zirconia-based implants compared to traditional materials and the need for specialized training for dental and orthopedic professionals in working with these advanced materials. Regulatory hurdles and the lengthy approval process for new biomaterials also pose potential obstacles to market growth.

Looking ahead, technological advancements in manufacturing processes, such as 3D printing of zirconia implants, are expected to open new opportunities and potentially reduce production costs. The development of novel zirconia composites with enhanced properties could further expand the application range of these materials in the biomedical field, potentially driving market growth in the coming years.

Current Challenges in Zirconia Biocompatibility

Despite the widespread use of zirconia in biomedical applications, several challenges persist in ensuring its optimal biocompatibility. One of the primary concerns is the potential for phase transformation of zirconia from tetragonal to monoclinic structure, which can lead to surface roughening and microcracking. This transformation, known as low-temperature degradation (LTD), can compromise the mechanical properties and long-term stability of zirconia implants, potentially leading to premature failure.

Another significant challenge is the control of surface properties to enhance cell adhesion and proliferation. While zirconia exhibits excellent biocompatibility, its relatively inert surface can sometimes result in suboptimal cell attachment compared to other bioactive materials. Researchers are exploring various surface modification techniques, such as plasma treatment and chemical etching, to improve the surface energy and topography of zirconia. However, achieving a balance between enhanced bioactivity and maintaining the material's mechanical integrity remains a complex task.

The potential release of zirconium ions into the surrounding tissues is another area of concern. Although zirconia is generally considered bioinert, there is ongoing research to fully understand the long-term effects of zirconium ion release, particularly in load-bearing applications where micro-motion and wear can occur. Ensuring the stability of zirconia under various physiological conditions and minimizing ion leaching is crucial for its safe use in long-term implants.

Furthermore, the integration of zirconia with other materials in composite structures presents challenges in maintaining uniform biocompatibility. For instance, when used in dental implants with titanium abutments, the interface between zirconia and titanium can be a potential weak point, both mechanically and biologically. Developing seamless integration techniques that preserve the biocompatibility of both materials is an ongoing area of research.

Lastly, the manufacturing processes for zirconia implants can significantly impact their biocompatibility. Factors such as sintering temperature, cooling rates, and post-processing treatments can affect the material's microstructure, surface properties, and ultimately its interaction with biological tissues. Standardizing these processes to ensure consistent biocompatibility across different manufacturing batches and techniques remains a challenge in the industry.

Existing Zirconia Biocompatibility Solutions

01 Zirconia synthesis and processing methods

Various methods for synthesizing and processing zirconia are explored, including sol-gel techniques, hydrothermal processes, and chemical vapor deposition. These methods aim to control the crystalline structure, particle size, and purity of zirconia for different applications.- Zirconia synthesis and processing methods: Various methods for synthesizing and processing zirconia are described, including techniques for controlling particle size, crystalline structure, and purity. These methods can involve different precursors, reaction conditions, and post-processing steps to achieve desired properties for specific applications.

- Zirconia-based dental materials: Zirconia is widely used in dental applications due to its biocompatibility, strength, and aesthetic properties. Innovations in this area include improved formulations for dental prosthetics, coatings, and composite materials that enhance durability and mimic natural tooth appearance.

- Zirconia in ceramic composites and coatings: Zirconia is incorporated into various ceramic composites and coatings to enhance mechanical properties, thermal resistance, and wear resistance. These materials find applications in industries such as aerospace, automotive, and electronics.

- Stabilized zirconia for high-temperature applications: Stabilized zirconia, often achieved through doping with other elements, is used in high-temperature applications such as thermal barrier coatings, solid oxide fuel cells, and oxygen sensors. Research focuses on improving stability, conductivity, and performance under extreme conditions.

- Zirconia nanoparticles and their applications: Zirconia nanoparticles are developed for various applications, including catalysis, optics, and advanced materials. Research in this area focuses on controlling particle size, shape, and surface properties to tailor the nanoparticles for specific uses in fields such as energy, environmental remediation, and biomedicine.

02 Zirconia-based dental materials

Zirconia is widely used in dental applications due to its biocompatibility and mechanical properties. Innovations in this field include zirconia-based dental implants, crowns, and bridges, as well as techniques for improving their aesthetics and durability.Expand Specific Solutions03 Zirconia in advanced ceramics and composites

Zirconia is incorporated into advanced ceramic materials and composites to enhance their mechanical, thermal, and electrical properties. These materials find applications in aerospace, automotive, and industrial sectors.Expand Specific Solutions04 Stabilized zirconia for high-temperature applications

Stabilized zirconia, often achieved through doping with other elements, is developed for high-temperature applications such as thermal barrier coatings, solid oxide fuel cells, and oxygen sensors. The focus is on improving thermal stability and ionic conductivity.Expand Specific Solutions05 Zirconia nanoparticles and their applications

Research on zirconia nanoparticles explores their unique properties and potential applications in various fields, including catalysis, optics, and biomedicine. Methods for controlling nanoparticle size, shape, and surface properties are investigated.Expand Specific Solutions

Key Players in Zirconia Biocompatible Materials

The research on zirconia in biocompatible materials is in a mature stage, with a growing market driven by increasing demand in medical and dental applications. The global zirconia market size is expected to reach significant value in the coming years. Technologically, zirconia has established itself as a reliable biocompatible material, with ongoing research focusing on enhancing its properties and expanding applications. Companies like Kyocera Corp., Toyota Motor Corp., and 3M Innovative Properties Co. are leading industrial players, while academic institutions such as The University of Sydney, Zhejiang University, and Nanyang Technological University contribute to advancing the field through fundamental research and innovation. The collaboration between industry and academia is driving further improvements in zirconia's biocompatibility and performance.

Kyocera Corp.

Toyota Motor Corp.

Innovations in Zirconia Biocompatibility Research

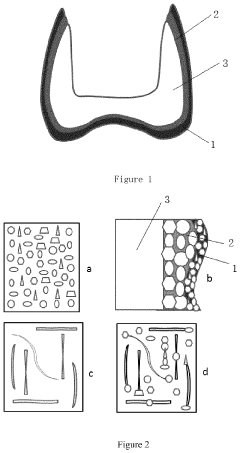

- A bioactive zirconia denture with a gradient structure featuring a biomimetic nano-gradient outer surface layer and a micron-gradient inner layer, comprising zirconia nanocrystals and microncrystals with nanopores and micropores, respectively, to enhance biocompatibility and biological activity through surface adsorption of proteins and cells.

- A single-stage plasma electrolytic oxidation (PEO) method is employed to directly form bioceramic coatings containing hydroxyapatite, apatite, and calcium-based phases on zirconium, using an electrolyte solution of calcium acetate and calcium glycerophosphate, optimizing parameters like current density and time to achieve improved mechanical properties and adhesion.

Regulatory Framework for Biocompatible Materials

The regulatory framework for biocompatible materials, including zirconia, is a critical aspect of their development and application in medical devices and implants. In the United States, the Food and Drug Administration (FDA) plays a pivotal role in overseeing the safety and efficacy of these materials. The FDA's Center for Devices and Radiological Health (CDRH) is responsible for regulating medical devices, including those incorporating zirconia and other biocompatible materials.

The regulatory process for biocompatible materials typically involves several stages, beginning with premarket approval (PMA) or the 510(k) clearance process, depending on the device classification. For novel materials like zirconia, manufacturers often need to provide extensive data on biocompatibility, mechanical properties, and long-term stability. This includes in vitro and in vivo studies, as well as clinical trials when necessary.

Internationally, the regulatory landscape for biocompatible materials varies, but there are efforts to harmonize standards. The International Organization for Standardization (ISO) has developed several standards relevant to biocompatible materials, such as ISO 10993 for biological evaluation of medical devices. These standards are often recognized by regulatory bodies worldwide, facilitating global market access for manufacturers.

In the European Union, the Medical Device Regulation (MDR) and the In Vitro Diagnostic Regulation (IVDR) govern the approval and use of biocompatible materials in medical applications. These regulations emphasize a life-cycle approach to device safety and performance, requiring ongoing monitoring and reporting of device performance and safety data.

Specific to zirconia, regulatory bodies often require manufacturers to demonstrate its long-term stability, particularly in light of concerns about low-temperature degradation. This may involve accelerated aging studies and comprehensive mechanical testing to ensure the material's durability in physiological conditions.

Regulatory frameworks also address the manufacturing processes for biocompatible materials. Good Manufacturing Practice (GMP) guidelines are crucial for ensuring consistent quality and safety of zirconia and other biocompatible materials used in medical devices. These guidelines cover aspects such as raw material sourcing, processing conditions, and quality control measures.

As research on zirconia in biocompatible materials progresses, regulatory frameworks continue to evolve. Emerging areas of focus include the development of standards for 3D-printed zirconia implants and the evaluation of nanostructured zirconia materials. Regulatory bodies are also increasingly considering the environmental impact of biocompatible materials, including their lifecycle and disposal.

Environmental Impact of Zirconia Biomaterial Production

The production of zirconia biomaterials has significant environmental implications that warrant careful consideration. The manufacturing process involves several stages, each with its own environmental impact. Mining of zirconium-containing minerals, primarily zircon, is the first step. This extractive process can lead to habitat disruption, soil erosion, and potential water pollution if not managed properly. The subsequent refining and purification stages require substantial energy inputs, contributing to greenhouse gas emissions and resource depletion.

The synthesis of zirconia powder, often through chemical precipitation or sol-gel methods, involves the use of various chemicals and solvents. These processes can generate hazardous waste streams that need proper treatment and disposal to prevent environmental contamination. The high-temperature sintering required to produce dense zirconia ceramics is particularly energy-intensive, further adding to the carbon footprint of production.

Water usage is another critical environmental factor in zirconia biomaterial production. Large volumes of water are consumed during mining, processing, and manufacturing stages. This can strain local water resources, especially in water-scarce regions. Moreover, wastewater from these processes may contain suspended solids, heavy metals, and other pollutants that require treatment before discharge.

The production of zirconia biomaterials also generates air emissions, including particulate matter and volatile organic compounds. These emissions can contribute to local air quality issues if not properly controlled. Additionally, the transportation of raw materials and finished products adds to the overall environmental impact through fuel consumption and associated emissions.

However, it's important to note that zirconia biomaterials offer significant environmental benefits in their application. Their durability and long lifespan in medical implants reduce the need for replacements, thereby decreasing the overall environmental impact of healthcare interventions. Furthermore, advancements in production technologies are continually improving efficiency and reducing environmental footprints.

Efforts to mitigate the environmental impact of zirconia biomaterial production include implementing cleaner production techniques, optimizing energy use, and adopting closed-loop water systems. Recycling of production waste and the use of renewable energy sources in manufacturing processes are also becoming more prevalent. As the demand for biocompatible materials grows, balancing production needs with environmental stewardship remains a crucial challenge for the industry.