Revolutionizing Chemical Practices with Fluoroantimonic Acid

JUN 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoroantimonic Acid Evolution and Objectives

Fluoroantimonic acid, a superacid with extraordinary chemical properties, has been a subject of fascination and research in the field of chemistry for decades. Its evolution can be traced back to the early 20th century when the concept of superacids was first introduced. The development of fluoroantimonic acid has been driven by the need for stronger acids in various industrial and research applications.

The journey of fluoroantimonic acid began with the synthesis of other strong acids, such as sulfuric acid and hydrofluoric acid. However, it was the discovery of the unique properties of antimony pentafluoride (SbF5) that paved the way for the creation of fluoroantimonic acid. The combination of hydrogen fluoride (HF) and SbF5 resulted in an acid with unprecedented strength, capable of protonating even the weakest bases.

Throughout its evolution, fluoroantimonic acid has undergone continuous refinement in terms of synthesis methods, purification techniques, and handling procedures. The primary objective has been to harness its exceptional acidity while mitigating the challenges associated with its extreme reactivity and corrosiveness.

One of the key milestones in the development of fluoroantimonic acid was the establishment of its acidity measurement on the Hammett acidity function scale. This breakthrough allowed for a more precise quantification of its acid strength, placing it at the top of the superacid hierarchy with a Hammett acidity function (H0) value of -31.3.

The objectives of fluoroantimonic acid research and development have been multifaceted. Primarily, there has been a focus on expanding its applications in organic synthesis, where its ability to catalyze reactions that are impossible with conventional acids has opened new avenues in chemical transformations. Additionally, efforts have been directed towards improving its stability and developing safer handling methods to facilitate its use in industrial settings.

Another significant objective has been to explore the fundamental chemistry of fluoroantimonic acid, including its structure, behavior in different solvents, and interactions with various substrates. This basic research aims to deepen our understanding of superacidity and potentially lead to the discovery of new chemical phenomena.

In recent years, the objectives have expanded to include the development of novel materials and processes that can benefit from the unique properties of fluoroantimonic acid. This includes applications in nanotechnology, materials science, and energy storage, where the acid's extreme protonating ability can be leveraged to create innovative solutions.

As we look towards the future, the evolution of fluoroantimonic acid continues with a focus on sustainability and green chemistry. Researchers are exploring ways to achieve similar levels of superacidity using more environmentally friendly components and processes, aiming to revolutionize chemical practices while minimizing environmental impact.

The journey of fluoroantimonic acid began with the synthesis of other strong acids, such as sulfuric acid and hydrofluoric acid. However, it was the discovery of the unique properties of antimony pentafluoride (SbF5) that paved the way for the creation of fluoroantimonic acid. The combination of hydrogen fluoride (HF) and SbF5 resulted in an acid with unprecedented strength, capable of protonating even the weakest bases.

Throughout its evolution, fluoroantimonic acid has undergone continuous refinement in terms of synthesis methods, purification techniques, and handling procedures. The primary objective has been to harness its exceptional acidity while mitigating the challenges associated with its extreme reactivity and corrosiveness.

One of the key milestones in the development of fluoroantimonic acid was the establishment of its acidity measurement on the Hammett acidity function scale. This breakthrough allowed for a more precise quantification of its acid strength, placing it at the top of the superacid hierarchy with a Hammett acidity function (H0) value of -31.3.

The objectives of fluoroantimonic acid research and development have been multifaceted. Primarily, there has been a focus on expanding its applications in organic synthesis, where its ability to catalyze reactions that are impossible with conventional acids has opened new avenues in chemical transformations. Additionally, efforts have been directed towards improving its stability and developing safer handling methods to facilitate its use in industrial settings.

Another significant objective has been to explore the fundamental chemistry of fluoroantimonic acid, including its structure, behavior in different solvents, and interactions with various substrates. This basic research aims to deepen our understanding of superacidity and potentially lead to the discovery of new chemical phenomena.

In recent years, the objectives have expanded to include the development of novel materials and processes that can benefit from the unique properties of fluoroantimonic acid. This includes applications in nanotechnology, materials science, and energy storage, where the acid's extreme protonating ability can be leveraged to create innovative solutions.

As we look towards the future, the evolution of fluoroantimonic acid continues with a focus on sustainability and green chemistry. Researchers are exploring ways to achieve similar levels of superacidity using more environmentally friendly components and processes, aiming to revolutionize chemical practices while minimizing environmental impact.

Industrial Demand Analysis for Superacids

The demand for superacids, particularly fluoroantimonic acid, in industrial applications has been steadily increasing over the past decade. This growth is primarily driven by the expanding chemical and petrochemical industries, where superacids play a crucial role in various processes. The global market for superacids is expected to continue its upward trajectory, with a significant portion of this growth attributed to fluoroantimonic acid.

In the petrochemical sector, fluoroantimonic acid is highly sought after for its exceptional catalytic properties in hydrocarbon cracking and isomerization processes. These processes are fundamental in the production of high-octane gasoline and other valuable petroleum products. The increasing global demand for cleaner and more efficient fuels has further boosted the need for advanced catalytic processes, thereby driving the demand for fluoroantimonic acid.

The electronics industry represents another major market for fluoroantimonic acid. Its unique properties make it invaluable in the etching of silicon wafers and the production of advanced semiconductor devices. As the demand for smaller, more powerful electronic components continues to rise, the need for precision etching agents like fluoroantimonic acid is expected to grow proportionally.

In the field of materials science, fluoroantimonic acid is gaining traction as a powerful tool for synthesizing novel materials. Its extreme acidity allows for reactions that are impossible with conventional acids, opening up new avenues for material development. This has led to increased interest from research institutions and advanced materials manufacturers, further expanding the market demand.

The pharmaceutical industry is also exploring the potential of fluoroantimonic acid in drug synthesis. Its ability to catalyze certain reactions under milder conditions than traditional methods makes it an attractive option for developing more efficient and cost-effective pharmaceutical production processes.

However, the demand for fluoroantimonic acid is not without challenges. The extreme corrosiveness and reactivity of the acid necessitate specialized handling and storage facilities, which can be a significant barrier to entry for some potential users. Additionally, environmental and safety concerns associated with its production and use have led to increased regulatory scrutiny in some regions.

Despite these challenges, the overall industrial demand for fluoroantimonic acid remains strong. As industries continue to seek more efficient and innovative processes, the unique properties of this superacid position it as a key enabler of technological advancements across multiple sectors. The market is expected to see continued growth, driven by ongoing research and development efforts aimed at expanding its applications and addressing its handling challenges.

In the petrochemical sector, fluoroantimonic acid is highly sought after for its exceptional catalytic properties in hydrocarbon cracking and isomerization processes. These processes are fundamental in the production of high-octane gasoline and other valuable petroleum products. The increasing global demand for cleaner and more efficient fuels has further boosted the need for advanced catalytic processes, thereby driving the demand for fluoroantimonic acid.

The electronics industry represents another major market for fluoroantimonic acid. Its unique properties make it invaluable in the etching of silicon wafers and the production of advanced semiconductor devices. As the demand for smaller, more powerful electronic components continues to rise, the need for precision etching agents like fluoroantimonic acid is expected to grow proportionally.

In the field of materials science, fluoroantimonic acid is gaining traction as a powerful tool for synthesizing novel materials. Its extreme acidity allows for reactions that are impossible with conventional acids, opening up new avenues for material development. This has led to increased interest from research institutions and advanced materials manufacturers, further expanding the market demand.

The pharmaceutical industry is also exploring the potential of fluoroantimonic acid in drug synthesis. Its ability to catalyze certain reactions under milder conditions than traditional methods makes it an attractive option for developing more efficient and cost-effective pharmaceutical production processes.

However, the demand for fluoroantimonic acid is not without challenges. The extreme corrosiveness and reactivity of the acid necessitate specialized handling and storage facilities, which can be a significant barrier to entry for some potential users. Additionally, environmental and safety concerns associated with its production and use have led to increased regulatory scrutiny in some regions.

Despite these challenges, the overall industrial demand for fluoroantimonic acid remains strong. As industries continue to seek more efficient and innovative processes, the unique properties of this superacid position it as a key enabler of technological advancements across multiple sectors. The market is expected to see continued growth, driven by ongoing research and development efforts aimed at expanding its applications and addressing its handling challenges.

Current Challenges in Fluoroantimonic Acid Production

The production of fluoroantimonic acid, one of the strongest known superacids, presents several significant challenges that hinder its widespread industrial application. These challenges stem from the acid's extreme reactivity and corrosive nature, which necessitate specialized handling and containment procedures.

One of the primary obstacles in fluoroantimonic acid production is the need for ultra-pure raw materials. The synthesis requires anhydrous hydrogen fluoride and antimony pentafluoride, both of which must be free from even trace amounts of moisture. Any water contamination can lead to rapid decomposition of the acid and potentially dangerous side reactions. This requirement for high-purity precursors significantly increases production costs and complexity.

The extreme corrosiveness of fluoroantimonic acid poses another major challenge. It reacts violently with most materials, including glass and many metals, limiting the choice of containment vessels and reaction equipment. Only a few materials, such as Teflon and certain fluoropolymers, can withstand its corrosive effects. This necessitates the use of specialized, expensive equipment throughout the production process, further driving up costs and complicating manufacturing procedures.

Safety concerns represent a critical challenge in fluoroantimonic acid production. The acid's ability to protonate even very weak bases makes it exceptionally dangerous to handle. Exposure risks include severe burns, respiratory damage, and potential long-term health effects. Implementing robust safety protocols and engineering controls is essential but adds another layer of complexity to the production process.

Scale-up and process optimization present additional hurdles. The highly exothermic nature of the acid's formation reaction requires careful temperature control, which becomes increasingly difficult at larger scales. Moreover, the acid's extreme reactivity makes it challenging to maintain consistent quality and purity in large-scale production runs.

Environmental considerations also pose significant challenges. The production process generates hazardous waste that requires specialized disposal methods. Additionally, the potential for accidental releases during production or transportation raises environmental concerns, necessitating stringent containment and emergency response measures.

Lastly, the limited commercial demand for fluoroantimonic acid presents an economic challenge. Its specialized applications in certain areas of organic synthesis and materials science do not currently justify large-scale production facilities. This limited market makes it difficult to achieve economies of scale, further contributing to the high cost of production.

One of the primary obstacles in fluoroantimonic acid production is the need for ultra-pure raw materials. The synthesis requires anhydrous hydrogen fluoride and antimony pentafluoride, both of which must be free from even trace amounts of moisture. Any water contamination can lead to rapid decomposition of the acid and potentially dangerous side reactions. This requirement for high-purity precursors significantly increases production costs and complexity.

The extreme corrosiveness of fluoroantimonic acid poses another major challenge. It reacts violently with most materials, including glass and many metals, limiting the choice of containment vessels and reaction equipment. Only a few materials, such as Teflon and certain fluoropolymers, can withstand its corrosive effects. This necessitates the use of specialized, expensive equipment throughout the production process, further driving up costs and complicating manufacturing procedures.

Safety concerns represent a critical challenge in fluoroantimonic acid production. The acid's ability to protonate even very weak bases makes it exceptionally dangerous to handle. Exposure risks include severe burns, respiratory damage, and potential long-term health effects. Implementing robust safety protocols and engineering controls is essential but adds another layer of complexity to the production process.

Scale-up and process optimization present additional hurdles. The highly exothermic nature of the acid's formation reaction requires careful temperature control, which becomes increasingly difficult at larger scales. Moreover, the acid's extreme reactivity makes it challenging to maintain consistent quality and purity in large-scale production runs.

Environmental considerations also pose significant challenges. The production process generates hazardous waste that requires specialized disposal methods. Additionally, the potential for accidental releases during production or transportation raises environmental concerns, necessitating stringent containment and emergency response measures.

Lastly, the limited commercial demand for fluoroantimonic acid presents an economic challenge. Its specialized applications in certain areas of organic synthesis and materials science do not currently justify large-scale production facilities. This limited market makes it difficult to achieve economies of scale, further contributing to the high cost of production.

Existing Applications of Fluoroantimonic Acid

01 Synthesis and production of fluoroantimonic acid

Fluoroantimonic acid is synthesized through the reaction of hydrogen fluoride and antimony pentafluoride. The production process involves careful handling of highly reactive and corrosive materials under controlled conditions. Various methods and apparatus have been developed to optimize the synthesis and ensure the purity of the final product.- Synthesis and production of fluoroantimonic acid: Fluoroantimonic acid is synthesized through the reaction of hydrogen fluoride and antimony pentafluoride. The production process involves careful handling of highly reactive and corrosive materials under controlled conditions. Various methods and apparatus have been developed to optimize the synthesis and ensure the purity of the final product.

- Applications in catalysis and organic synthesis: Fluoroantimonic acid is utilized as a powerful superacid catalyst in various organic synthesis reactions. It facilitates alkylation, isomerization, and polymerization processes. The acid's extreme acidity enables it to catalyze reactions that are difficult or impossible with conventional acid catalysts, making it valuable in the production of specialty chemicals and advanced materials.

- Use in materials science and surface treatment: Fluoroantimonic acid finds applications in materials science, particularly in surface treatment and modification of various substrates. It can be used to etch or activate surfaces, enhance adhesion properties, and create specialized coatings. The acid's unique properties allow for the development of advanced materials with improved characteristics.

- Safety and handling considerations: Due to its extreme corrosiveness and reactivity, handling fluoroantimonic acid requires stringent safety measures. Specialized equipment, containment systems, and personal protective gear are essential when working with this superacid. Proper storage, transportation, and disposal protocols must be followed to prevent accidents and environmental contamination.

- Analytical and characterization techniques: Various analytical and characterization techniques have been developed to study fluoroantimonic acid and its reactions. These include spectroscopic methods, electrochemical analysis, and specialized titration procedures. Advanced instrumentation and methodologies are employed to investigate the properties, structure, and behavior of this superacid in different chemical environments.

02 Applications in chemical reactions and catalysis

Fluoroantimonic acid is utilized as a powerful superacid catalyst in various chemical reactions. It is particularly effective in promoting alkylation, isomerization, and polymerization processes. The acid's extreme acidity enables it to catalyze reactions that are difficult or impossible with conventional acids, making it valuable in organic synthesis and petrochemical industries.Expand Specific Solutions03 Use in materials science and surface treatments

Fluoroantimonic acid finds applications in materials science, particularly in surface treatments and modifications. It can be used to etch or activate surfaces of various materials, including metals, semiconductors, and ceramics. The acid's unique properties allow for the creation of specialized surface characteristics, enhancing material performance in specific applications.Expand Specific Solutions04 Safety and handling considerations

Due to its extreme corrosiveness and reactivity, fluoroantimonic acid requires specialized safety measures and handling procedures. This includes the use of specific containment materials, personal protective equipment, and controlled environments. Proper storage, transportation, and disposal methods are crucial to prevent accidents and environmental contamination.Expand Specific Solutions05 Analytical and characterization techniques

Various analytical and characterization techniques have been developed to study fluoroantimonic acid and its reactions. These methods include spectroscopic analyses, electrochemical measurements, and computational modeling. Such techniques are essential for understanding the acid's properties, reaction mechanisms, and potential applications in different fields of chemistry and materials science.Expand Specific Solutions

Key Players in Fluoroantimonic Acid Research

The development of fluoroantimonic acid technology is in its early stages, with significant potential for growth in various chemical applications. The market size is expanding as industries recognize its powerful catalytic properties. Technologically, it's still evolving, with companies like 3M Innovative Properties Co., DuPont de Nemours, Inc., and Merck Sharp & Dohme Corp. leading research efforts. Universities such as Zhejiang University of Technology and Hunan University are contributing to academic advancements. The competitive landscape is diverse, including chemical giants like DAIKIN INDUSTRIES Ltd. and emerging players like Cf Plus Chemicals S R O, indicating a dynamic and innovative field with room for further development and commercialization.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has pioneered a novel application of fluoroantimonic acid in the production of advanced fluoropolymers. Their innovative process utilizes the superacidic properties of fluoroantimonic acid to catalyze the polymerization of fluorinated monomers under extremely low temperatures. This unique low-temperature synthesis method allows for the creation of fluoropolymers with enhanced molecular weight distribution and improved thermal stability. DAIKIN has also developed a recycling system for the acid, significantly reducing waste and environmental impact while maintaining the acid's effectiveness in multiple reaction cycles.

Strengths: Unique low-temperature polymerization process, improved product properties, and efficient acid recycling system. Weaknesses: Complex process control requirements, potential safety concerns in handling large quantities of the acid.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a proprietary process for the safe handling and application of fluoroantimonic acid in chemical synthesis. Their approach involves using specialized containment systems made of fluoropolymer materials resistant to the acid's corrosive nature. The company has also created a novel dilution technique that allows for more controlled reactions while maintaining the acid's superacidity. This method involves a gradual introduction of the acid into reaction mixtures under precisely controlled conditions, enabling its use in the production of high-value fluorinated compounds and catalysts for petrochemical processes.

Strengths: Expertise in handling highly corrosive materials, advanced containment technology, and precise control over reactions. Weaknesses: High costs associated with specialized equipment and safety measures, limited scalability for large-volume applications.

Breakthrough Innovations in Superacid Chemistry

P-doped surface coatings and process of preparation thereof

PatentActiveUS12122942B2

Innovation

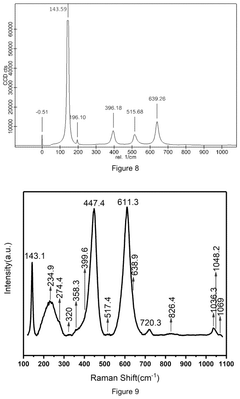

- The development of a phosphorus-doped titania (P-doped) antimicrobial coating solution is achieved by mixing a chelating agent with titanium alkoxide and orthophosphoric acid, followed by the addition of an aqueous solution, which shifts the bandgap energy into the visible spectrum, enhances doping efficiency, and maintains the anatase phase at higher temperatures, thereby enabling activation under both UV and visible light.

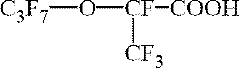

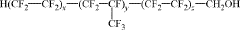

Process to reduce the concentration of fluoroorganic acidic compounds in aqueous dispersions

PatentPendingUS20230312776A1

Innovation

- A process involving the formation of a mixture with a pH value of less than 6, using a dispersion of fluoroorganic polymer particles and a protic solvent, reacting the fluoroorganic acidic compounds with an alkylamine to form a hydrophobic ionic compound, and separating this compound from the mixture into distinct phases for efficient removal.

Safety Protocols for Superacid Handling

Handling fluoroantimonic acid, one of the strongest known superacids, requires stringent safety protocols due to its extreme corrosiveness and reactivity. The primary focus of safety measures is to prevent any direct contact with the acid and to mitigate the risks associated with its use in chemical processes.

Personal protective equipment (PPE) is crucial when working with fluoroantimonic acid. This includes chemical-resistant suits made from materials such as Teflon or Viton, which can withstand the acid's corrosive properties. Full-face respirators with appropriate acid gas cartridges are essential to protect against harmful vapors. Double-layered gloves, with an inner layer of fluoroelastomer and an outer layer of neoprene, provide the necessary hand protection.

Specialized containment systems are required for storing and handling fluoroantimonic acid. These systems should be constructed from materials that are resistant to the acid's corrosive effects, such as PTFE (polytetrafluoroethylene) or certain grades of stainless steel. All storage containers must be tightly sealed and stored in a cool, dry, well-ventilated area away from incompatible materials.

Proper ventilation is critical in laboratories or industrial settings where fluoroantimonic acid is used. Fume hoods equipped with acid-resistant liners and exhaust systems capable of handling corrosive vapors are necessary to prevent the accumulation of toxic fumes. Regular maintenance and testing of these systems are essential to ensure their effectiveness.

Emergency response procedures must be well-established and regularly practiced. This includes having readily accessible eyewash stations and safety showers in the immediate vicinity of work areas. Spill control kits specifically designed for superacids should be available, containing neutralizing agents such as sodium bicarbonate or calcium carbonate.

Training is a fundamental aspect of safety protocols. All personnel working with or around fluoroantimonic acid must undergo comprehensive training on its properties, hazards, and proper handling techniques. This training should be regularly updated and include practical exercises in emergency response procedures.

Waste disposal of fluoroantimonic acid requires specialized procedures. Neutralization should be performed carefully and gradually, typically using a strong base such as sodium hydroxide. The neutralized waste must then be disposed of according to local environmental regulations, often requiring the services of specialized chemical waste management companies.

Implementing a rigorous monitoring system is essential to ensure compliance with safety protocols. This includes regular safety audits, equipment inspections, and environmental monitoring to detect any potential leaks or emissions. Documentation of all safety procedures, incidents, and near-misses is crucial for continuous improvement of safety measures.

Personal protective equipment (PPE) is crucial when working with fluoroantimonic acid. This includes chemical-resistant suits made from materials such as Teflon or Viton, which can withstand the acid's corrosive properties. Full-face respirators with appropriate acid gas cartridges are essential to protect against harmful vapors. Double-layered gloves, with an inner layer of fluoroelastomer and an outer layer of neoprene, provide the necessary hand protection.

Specialized containment systems are required for storing and handling fluoroantimonic acid. These systems should be constructed from materials that are resistant to the acid's corrosive effects, such as PTFE (polytetrafluoroethylene) or certain grades of stainless steel. All storage containers must be tightly sealed and stored in a cool, dry, well-ventilated area away from incompatible materials.

Proper ventilation is critical in laboratories or industrial settings where fluoroantimonic acid is used. Fume hoods equipped with acid-resistant liners and exhaust systems capable of handling corrosive vapors are necessary to prevent the accumulation of toxic fumes. Regular maintenance and testing of these systems are essential to ensure their effectiveness.

Emergency response procedures must be well-established and regularly practiced. This includes having readily accessible eyewash stations and safety showers in the immediate vicinity of work areas. Spill control kits specifically designed for superacids should be available, containing neutralizing agents such as sodium bicarbonate or calcium carbonate.

Training is a fundamental aspect of safety protocols. All personnel working with or around fluoroantimonic acid must undergo comprehensive training on its properties, hazards, and proper handling techniques. This training should be regularly updated and include practical exercises in emergency response procedures.

Waste disposal of fluoroantimonic acid requires specialized procedures. Neutralization should be performed carefully and gradually, typically using a strong base such as sodium hydroxide. The neutralized waste must then be disposed of according to local environmental regulations, often requiring the services of specialized chemical waste management companies.

Implementing a rigorous monitoring system is essential to ensure compliance with safety protocols. This includes regular safety audits, equipment inspections, and environmental monitoring to detect any potential leaks or emissions. Documentation of all safety procedures, incidents, and near-misses is crucial for continuous improvement of safety measures.

Environmental Impact Assessment

The environmental impact of fluoroantimonic acid, the world's strongest superacid, is a critical consideration in its application and handling. This highly corrosive substance poses significant risks to ecosystems and human health if not properly managed. When released into the environment, fluoroantimonic acid can cause severe damage to soil and water systems, leading to long-term ecological disruptions.

In aquatic environments, even small quantities of fluoroantimonic acid can dramatically alter pH levels, potentially causing mass die-offs of fish and other aquatic organisms. The acid's extreme reactivity can also lead to the release of toxic fluoride and antimony compounds, further exacerbating its environmental impact. Soil contamination by fluoroantimonic acid can render large areas uninhabitable for plant life and soil microorganisms, disrupting entire ecosystems and food chains.

The production and use of fluoroantimonic acid also contribute to air pollution. Volatile compounds released during its manufacture or application can lead to the formation of acid rain, impacting areas far from the original source. This can result in widespread damage to forests, crops, and infrastructure.

From a human health perspective, exposure to fluoroantimonic acid vapors or aerosols can cause severe respiratory issues, skin burns, and eye damage. Long-term exposure may lead to chronic health problems, including increased cancer risk due to the potential mutagenic properties of its components.

Waste management of fluoroantimonic acid and its byproducts presents another significant environmental challenge. Improper disposal can lead to groundwater contamination, posing long-term risks to drinking water supplies and agricultural resources. The acid's extreme reactivity also makes it a potential hazard in waste treatment facilities, requiring specialized handling and neutralization procedures.

Given these environmental concerns, strict regulations and safety protocols are essential for the production, transport, use, and disposal of fluoroantimonic acid. Industries utilizing this superacid must implement robust containment systems, employee safety measures, and emergency response plans. Additionally, ongoing research into less environmentally harmful alternatives and improved handling techniques is crucial to mitigate the potential ecological impact of this powerful chemical agent.

In aquatic environments, even small quantities of fluoroantimonic acid can dramatically alter pH levels, potentially causing mass die-offs of fish and other aquatic organisms. The acid's extreme reactivity can also lead to the release of toxic fluoride and antimony compounds, further exacerbating its environmental impact. Soil contamination by fluoroantimonic acid can render large areas uninhabitable for plant life and soil microorganisms, disrupting entire ecosystems and food chains.

The production and use of fluoroantimonic acid also contribute to air pollution. Volatile compounds released during its manufacture or application can lead to the formation of acid rain, impacting areas far from the original source. This can result in widespread damage to forests, crops, and infrastructure.

From a human health perspective, exposure to fluoroantimonic acid vapors or aerosols can cause severe respiratory issues, skin burns, and eye damage. Long-term exposure may lead to chronic health problems, including increased cancer risk due to the potential mutagenic properties of its components.

Waste management of fluoroantimonic acid and its byproducts presents another significant environmental challenge. Improper disposal can lead to groundwater contamination, posing long-term risks to drinking water supplies and agricultural resources. The acid's extreme reactivity also makes it a potential hazard in waste treatment facilities, requiring specialized handling and neutralization procedures.

Given these environmental concerns, strict regulations and safety protocols are essential for the production, transport, use, and disposal of fluoroantimonic acid. Industries utilizing this superacid must implement robust containment systems, employee safety measures, and emergency response plans. Additionally, ongoing research into less environmentally harmful alternatives and improved handling techniques is crucial to mitigate the potential ecological impact of this powerful chemical agent.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!