Sodium Acetate: Benefits in Laboratory Safety and Procedures

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate Overview

Sodium acetate, a versatile chemical compound with the formula CH3COONa, plays a significant role in laboratory safety and procedures. This salt of acetic acid is widely used in various scientific and industrial applications due to its unique properties and benefits. In its anhydrous form, sodium acetate appears as a white, odorless powder, while its trihydrate form manifests as transparent crystals.

The compound's chemical structure consists of a sodium cation (Na+) paired with an acetate anion (CH3COO-). This ionic bond contributes to its high solubility in water, making it an excellent choice for aqueous solutions in laboratory settings. Sodium acetate's pH-buffering capacity is one of its most valuable attributes, allowing it to maintain stable pH levels in chemical reactions and biological systems.

In terms of physical properties, sodium acetate exhibits a melting point of 324°C (615°F) in its anhydrous form, while the trihydrate melts at 58°C (136°F). Its solubility in water increases with temperature, reaching approximately 76 g/100 mL at 20°C (68°F). This temperature-dependent solubility is exploited in various applications, including the creation of supersaturated solutions for demonstrating crystallization processes.

The compound's safety profile is generally favorable, with low toxicity and minimal environmental impact when used and disposed of properly. However, like all chemicals, proper handling and storage procedures must be followed to ensure laboratory safety. Sodium acetate is hygroscopic, meaning it readily absorbs moisture from the air, which can affect its properties and shelf life if not stored correctly.

In laboratory procedures, sodium acetate serves multiple functions. It is commonly used as a buffering agent in biochemical experiments, helping to maintain optimal pH levels for enzymatic reactions and protein studies. Its role in electrophoresis buffers is particularly noteworthy, as it aids in the separation and analysis of biological molecules.

Furthermore, sodium acetate is employed in organic synthesis as a mild base and nucleophile. Its ability to form supersaturated solutions makes it an excellent candidate for demonstrating principles of crystallization and phase changes in educational settings. The compound's heat-releasing properties during crystallization also make it useful in the production of heat packs for therapeutic applications.

In conclusion, sodium acetate's diverse properties and applications make it an indispensable compound in laboratory settings. Its contributions to safety, pH control, and various experimental procedures underscore its importance in scientific research and education. As we delve deeper into its specific benefits and applications, it becomes clear that sodium acetate is a cornerstone chemical in modern laboratory practices.

The compound's chemical structure consists of a sodium cation (Na+) paired with an acetate anion (CH3COO-). This ionic bond contributes to its high solubility in water, making it an excellent choice for aqueous solutions in laboratory settings. Sodium acetate's pH-buffering capacity is one of its most valuable attributes, allowing it to maintain stable pH levels in chemical reactions and biological systems.

In terms of physical properties, sodium acetate exhibits a melting point of 324°C (615°F) in its anhydrous form, while the trihydrate melts at 58°C (136°F). Its solubility in water increases with temperature, reaching approximately 76 g/100 mL at 20°C (68°F). This temperature-dependent solubility is exploited in various applications, including the creation of supersaturated solutions for demonstrating crystallization processes.

The compound's safety profile is generally favorable, with low toxicity and minimal environmental impact when used and disposed of properly. However, like all chemicals, proper handling and storage procedures must be followed to ensure laboratory safety. Sodium acetate is hygroscopic, meaning it readily absorbs moisture from the air, which can affect its properties and shelf life if not stored correctly.

In laboratory procedures, sodium acetate serves multiple functions. It is commonly used as a buffering agent in biochemical experiments, helping to maintain optimal pH levels for enzymatic reactions and protein studies. Its role in electrophoresis buffers is particularly noteworthy, as it aids in the separation and analysis of biological molecules.

Furthermore, sodium acetate is employed in organic synthesis as a mild base and nucleophile. Its ability to form supersaturated solutions makes it an excellent candidate for demonstrating principles of crystallization and phase changes in educational settings. The compound's heat-releasing properties during crystallization also make it useful in the production of heat packs for therapeutic applications.

In conclusion, sodium acetate's diverse properties and applications make it an indispensable compound in laboratory settings. Its contributions to safety, pH control, and various experimental procedures underscore its importance in scientific research and education. As we delve deeper into its specific benefits and applications, it becomes clear that sodium acetate is a cornerstone chemical in modern laboratory practices.

Lab Safety Market Analysis

The laboratory safety market has experienced significant growth in recent years, driven by increasing awareness of workplace safety, stringent regulations, and the growing emphasis on research and development across various industries. The global lab safety market size was valued at approximately $2.5 billion in 2020 and is projected to reach $3.8 billion by 2026, growing at a CAGR of around 7.2% during the forecast period.

The market for laboratory safety equipment and supplies encompasses a wide range of products, including personal protective equipment (PPE), safety cabinets, fume hoods, eye wash stations, and chemical storage solutions. Among these, PPE holds the largest market share due to its essential role in protecting laboratory personnel from various hazards.

Geographically, North America dominates the lab safety market, accounting for over 35% of the global market share. This can be attributed to the presence of stringent safety regulations, well-established research infrastructure, and high investment in R&D activities. Europe follows closely, while the Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization and increasing focus on research and development in countries like China and India.

The COVID-19 pandemic has further accelerated the growth of the lab safety market, with increased demand for PPE and other safety equipment in laboratories involved in vaccine development and testing. This has led to a surge in production and innovation in lab safety products, with manufacturers focusing on developing more effective and comfortable safety solutions.

Key players in the lab safety market include 3M Company, Honeywell International Inc., Kimberly-Clark Corporation, and Thermo Fisher Scientific Inc. These companies are continuously investing in research and development to introduce innovative products and gain a competitive edge in the market.

The increasing adoption of automation and digitalization in laboratories is also influencing the lab safety market. Smart safety systems, IoT-enabled monitoring devices, and AI-powered risk assessment tools are gaining traction, offering enhanced safety measures and real-time data analysis for better decision-making.

As laboratories continue to evolve and handle more complex and potentially hazardous materials, the demand for advanced safety solutions is expected to rise. This includes specialized equipment for handling nanomaterials, biohazardous substances, and radioactive materials. The growing focus on sustainable and eco-friendly lab practices is also driving the development of green safety solutions, such as recyclable PPE and energy-efficient safety cabinets.

The market for laboratory safety equipment and supplies encompasses a wide range of products, including personal protective equipment (PPE), safety cabinets, fume hoods, eye wash stations, and chemical storage solutions. Among these, PPE holds the largest market share due to its essential role in protecting laboratory personnel from various hazards.

Geographically, North America dominates the lab safety market, accounting for over 35% of the global market share. This can be attributed to the presence of stringent safety regulations, well-established research infrastructure, and high investment in R&D activities. Europe follows closely, while the Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization and increasing focus on research and development in countries like China and India.

The COVID-19 pandemic has further accelerated the growth of the lab safety market, with increased demand for PPE and other safety equipment in laboratories involved in vaccine development and testing. This has led to a surge in production and innovation in lab safety products, with manufacturers focusing on developing more effective and comfortable safety solutions.

Key players in the lab safety market include 3M Company, Honeywell International Inc., Kimberly-Clark Corporation, and Thermo Fisher Scientific Inc. These companies are continuously investing in research and development to introduce innovative products and gain a competitive edge in the market.

The increasing adoption of automation and digitalization in laboratories is also influencing the lab safety market. Smart safety systems, IoT-enabled monitoring devices, and AI-powered risk assessment tools are gaining traction, offering enhanced safety measures and real-time data analysis for better decision-making.

As laboratories continue to evolve and handle more complex and potentially hazardous materials, the demand for advanced safety solutions is expected to rise. This includes specialized equipment for handling nanomaterials, biohazardous substances, and radioactive materials. The growing focus on sustainable and eco-friendly lab practices is also driving the development of green safety solutions, such as recyclable PPE and energy-efficient safety cabinets.

Current Applications

Sodium acetate has found widespread applications in various laboratory settings, contributing significantly to safety and procedural efficiency. In analytical chemistry, it serves as a crucial buffer component, helping maintain stable pH levels in solutions. This property is particularly valuable in biochemical assays and enzyme studies, where precise pH control is essential for accurate results.

In organic synthesis, sodium acetate acts as a mild base and nucleophile, facilitating numerous reactions. It is commonly used in esterification processes, serving as both a catalyst and a reactant. Its role in the Perkin reaction for the synthesis of cinnamic acids and their derivatives is particularly noteworthy, demonstrating its versatility in organic transformations.

The compound's use extends to electrochemistry, where it functions as an electrolyte in certain electroplating processes. Its ability to form stable complexes with metal ions makes it valuable in metal recovery and purification procedures, contributing to more environmentally friendly laboratory practices.

In microbiology and molecular biology, sodium acetate plays a crucial role in DNA precipitation techniques. When combined with ethanol, it effectively precipitates nucleic acids, allowing for their isolation and purification. This application is fundamental in various genetic engineering and molecular cloning procedures.

Sodium acetate's thermal properties make it an excellent candidate for use in reusable heat packs. These packs, often used in laboratory settings for controlled heating of samples or maintaining temperature during experiments, exploit the compound's ability to release heat upon crystallization from its supersaturated solution.

In spectroscopy, sodium acetate serves as a standard reference material for calibrating instruments, particularly in infrared spectroscopy. Its well-defined spectral characteristics make it an ideal compound for ensuring the accuracy of spectroscopic measurements.

The compound's role in safety extends to its use as a less corrosive alternative to sodium hydroxide in certain neutralization processes. This application is particularly relevant in waste treatment procedures within laboratories, where it helps in the safe disposal of acidic waste.

Sodium acetate's hygroscopic nature makes it useful in desiccation processes, where it can be employed to create controlled humidity environments for sensitive experiments or storage of moisture-sensitive materials.

In biochemistry, sodium acetate is utilized in gel electrophoresis buffers, contributing to the separation and analysis of proteins and nucleic acids. Its ability to maintain a stable ionic environment is crucial for the reliability of these analytical techniques.

In organic synthesis, sodium acetate acts as a mild base and nucleophile, facilitating numerous reactions. It is commonly used in esterification processes, serving as both a catalyst and a reactant. Its role in the Perkin reaction for the synthesis of cinnamic acids and their derivatives is particularly noteworthy, demonstrating its versatility in organic transformations.

The compound's use extends to electrochemistry, where it functions as an electrolyte in certain electroplating processes. Its ability to form stable complexes with metal ions makes it valuable in metal recovery and purification procedures, contributing to more environmentally friendly laboratory practices.

In microbiology and molecular biology, sodium acetate plays a crucial role in DNA precipitation techniques. When combined with ethanol, it effectively precipitates nucleic acids, allowing for their isolation and purification. This application is fundamental in various genetic engineering and molecular cloning procedures.

Sodium acetate's thermal properties make it an excellent candidate for use in reusable heat packs. These packs, often used in laboratory settings for controlled heating of samples or maintaining temperature during experiments, exploit the compound's ability to release heat upon crystallization from its supersaturated solution.

In spectroscopy, sodium acetate serves as a standard reference material for calibrating instruments, particularly in infrared spectroscopy. Its well-defined spectral characteristics make it an ideal compound for ensuring the accuracy of spectroscopic measurements.

The compound's role in safety extends to its use as a less corrosive alternative to sodium hydroxide in certain neutralization processes. This application is particularly relevant in waste treatment procedures within laboratories, where it helps in the safe disposal of acidic waste.

Sodium acetate's hygroscopic nature makes it useful in desiccation processes, where it can be employed to create controlled humidity environments for sensitive experiments or storage of moisture-sensitive materials.

In biochemistry, sodium acetate is utilized in gel electrophoresis buffers, contributing to the separation and analysis of proteins and nucleic acids. Its ability to maintain a stable ionic environment is crucial for the reliability of these analytical techniques.

Safety Enhancement Methods

01 Safety measures in industrial applications

Sodium acetate is widely used in industrial processes, and safety measures are implemented to ensure its safe handling and storage. These measures include proper ventilation systems, protective equipment for workers, and specialized storage containers to prevent contamination or accidental release.- Safety measures in industrial applications: Sodium acetate is widely used in industrial processes, and safety measures are implemented to ensure its safe handling and storage. These measures include proper ventilation systems, protective equipment for workers, and specialized containment methods to prevent accidental release or exposure.

- Environmental impact and disposal: The safety of sodium acetate extends to its environmental impact and proper disposal methods. Techniques have been developed to minimize its ecological footprint, including waste treatment processes and recycling methods that ensure safe disposal while reducing potential harm to the environment.

- Food and pharmaceutical safety: Sodium acetate is used in food preservation and pharmaceutical formulations. Safety assessments and regulations ensure its appropriate use in these applications, including guidelines for maximum allowable concentrations and testing protocols to verify its purity and absence of harmful contaminants.

- Transportation and storage safety: Safe transportation and storage of sodium acetate are crucial to prevent accidents and maintain its integrity. Specialized containers, packaging methods, and storage conditions have been developed to ensure the compound remains stable and does not pose risks during transit or long-term storage.

- Safety in consumer products: Sodium acetate is used in various consumer products, and its safety in these applications is carefully evaluated. This includes assessing potential skin irritation, toxicity, and other health effects. Product formulations and usage instructions are designed to ensure consumer safety when using items containing sodium acetate.

02 Environmental impact and disposal

The safety of sodium acetate extends to its environmental impact and proper disposal methods. Techniques have been developed to minimize its ecological footprint, including waste treatment processes and recycling methods that reduce the release of potentially harmful byproducts into the environment.Expand Specific Solutions03 Food and pharmaceutical safety

Sodium acetate is used in food preservation and pharmaceutical formulations. Safety assessments and quality control measures are implemented to ensure its safe use in these applications, including purity standards, toxicity testing, and adherence to regulatory guidelines for food and drug safety.Expand Specific Solutions04 Chemical stability and reactivity

The safety of sodium acetate is closely tied to its chemical stability and reactivity. Research has been conducted to understand its behavior under various conditions, including temperature changes and interactions with other substances, to prevent potential hazards in storage and use.Expand Specific Solutions05 Safety in consumer products

Sodium acetate is used in various consumer products, and safety considerations are paramount in these applications. This includes developing safe formulations for personal care products, household cleaners, and other consumer goods, as well as implementing appropriate labeling and usage instructions to ensure consumer safety.Expand Specific Solutions

Key Manufacturers

The sodium acetate market is in a mature stage, with established applications in laboratory safety and procedures. The global market size for sodium acetate is estimated to be moderate, driven by its use as a buffer solution and de-icing agent. Technologically, sodium acetate production is well-established, with companies like Amgen, Abbott Laboratories, and Zhejiang Yishu Environmental Protection Technology Co., Ltd. having developed efficient manufacturing processes. Research institutions such as China Agricultural University and the Institute of Process Engineering, Chinese Academy of Sciences continue to explore new applications, potentially expanding the market. However, innovation in this field is incremental rather than disruptive, indicating a stable but slowly evolving technological landscape.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering has developed advanced safety protocols for handling sodium acetate in laboratory settings. They have implemented a comprehensive approach that includes the use of specialized containment systems and personal protective equipment. Their research has shown that sodium acetate can be effectively used as a buffer solution in various biochemical processes, improving the stability of reactions[1]. They have also explored its potential as a less hazardous alternative to more corrosive chemicals in certain industrial applications, reducing overall laboratory risks[3].

Strengths: Expertise in process engineering and safety protocols. Weaknesses: May be limited to research applications rather than commercial implementations.

Brown University

Technical Solution: Researchers at Brown University have conducted extensive studies on the applications of sodium acetate in improving laboratory safety. They have developed novel protocols for using sodium acetate as a less hazardous alternative in organic synthesis reactions, reducing the overall risk profile of certain chemical processes[7]. Their work has also explored the use of sodium acetate in the development of safer, more environmentally friendly de-icing solutions for laboratory walkways and outdoor research facilities. Additionally, they have investigated the potential of sodium acetate-based hydrogels for controlled release of chemicals in laboratory experiments, potentially reducing exposure risks[8].

Strengths: Broad research capabilities and interdisciplinary approach. Weaknesses: May focus more on academic research rather than practical industry applications.

Innovative Uses

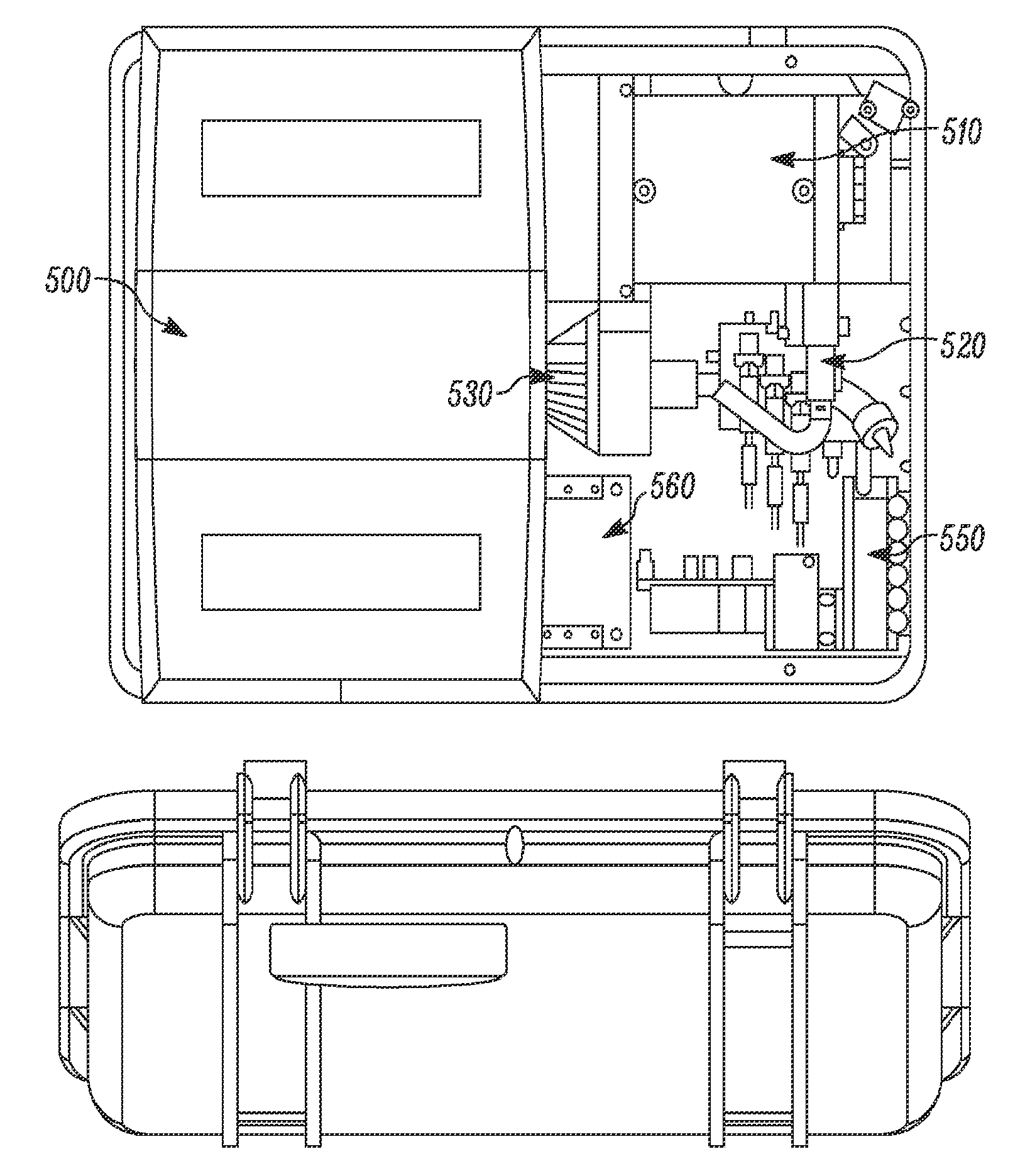

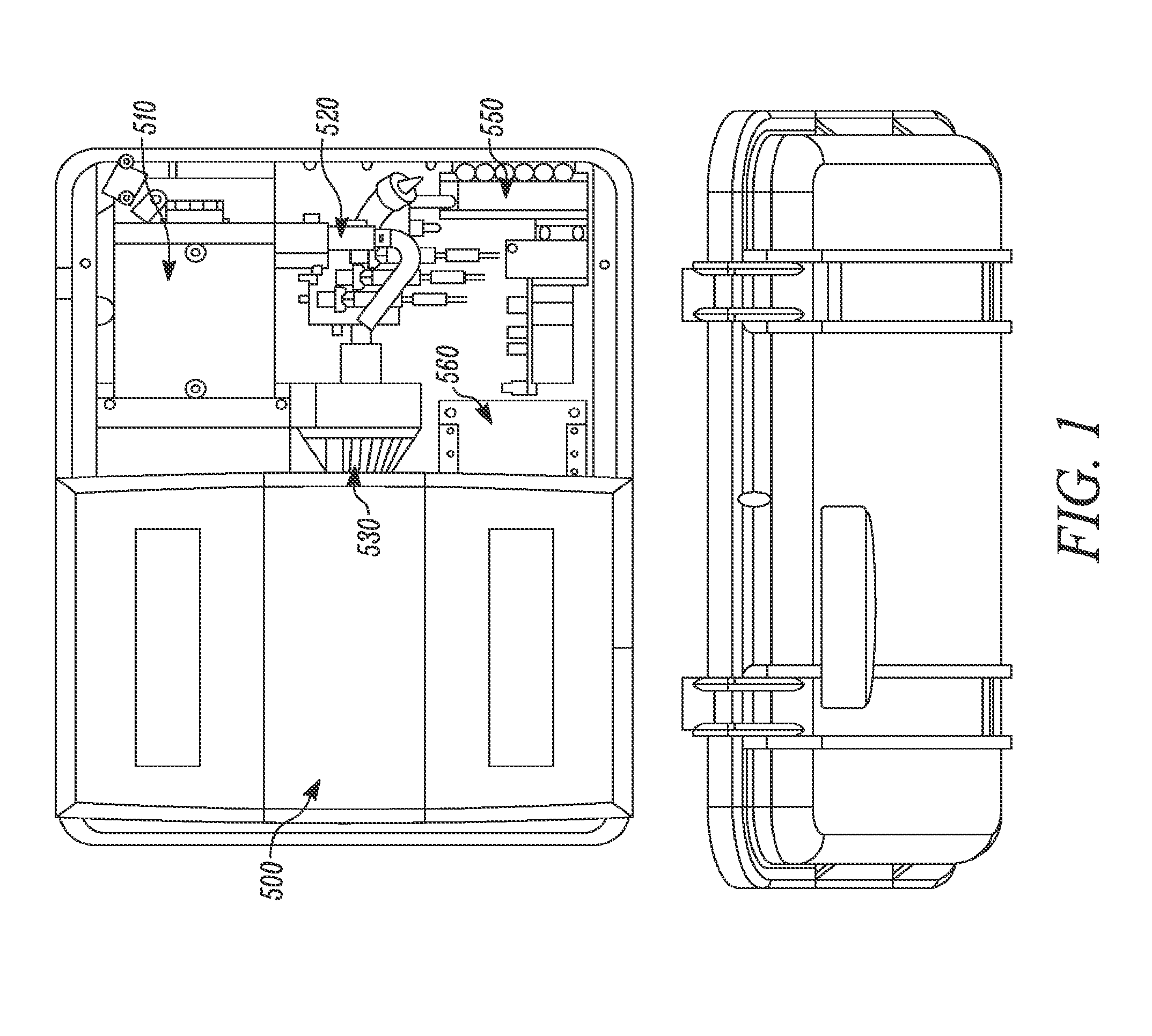

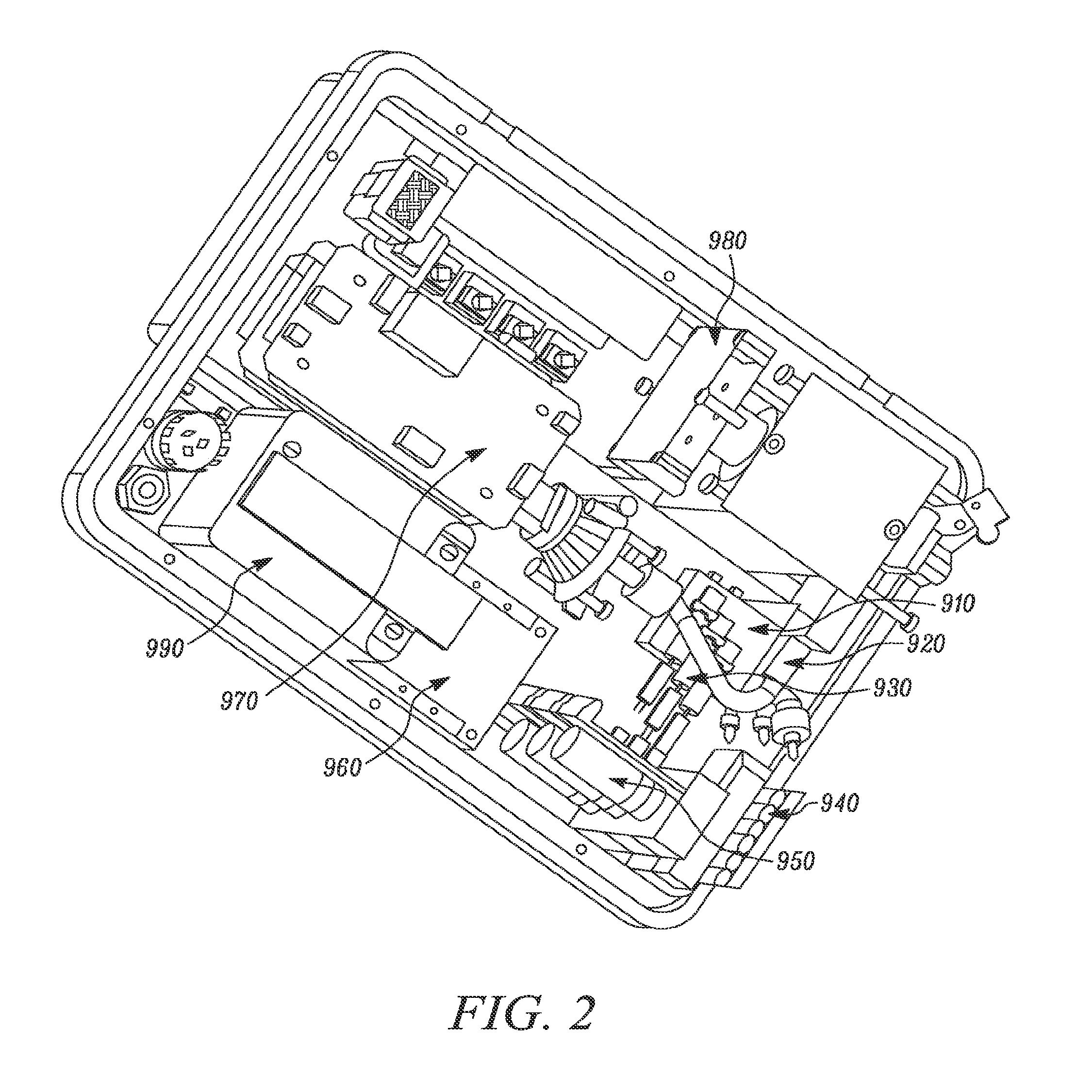

Detection apparatus

PatentInactiveUS20120196304A1

Innovation

- Development of portable detection apparatuses with removable assay chambers and reagent packs that include a graphic user interface, capable of detecting a wide range of agents using interchangeable assay chambers and reagents, and utilizing technologies like light scattering labels and nanocrystals for sensitive detection.

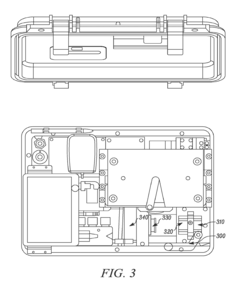

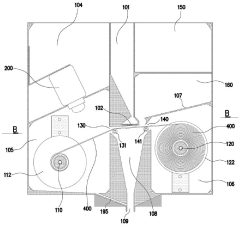

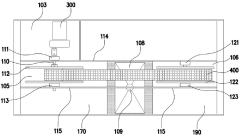

Instrument for continuously and automatically carrying out biochemical inspection and analysis

PatentPendingCN115267222A

Innovation

- Design a continuous automatic biochemical inspection and analysis instrument, including a sample inlet, equipment compartment A, isolation compartment and equipment compartment C. It uses a micro-reduced motor to drive the tape test paper, combined with optical analysis equipment and a central control system, to achieve automatic sample processing and detection.

Regulatory Compliance

Regulatory compliance is a critical aspect of laboratory safety and procedures when working with sodium acetate. The use of this compound is subject to various regulations and guidelines set forth by governmental agencies and professional organizations to ensure safe handling, storage, and disposal.

In the United States, the Occupational Safety and Health Administration (OSHA) provides guidelines for the safe use of sodium acetate in laboratory settings. These regulations include proper labeling of containers, maintaining up-to-date safety data sheets (SDS), and implementing appropriate engineering controls and personal protective equipment (PPE) for handling the substance.

The Environmental Protection Agency (EPA) also regulates the disposal of sodium acetate and its solutions. Laboratories must adhere to specific waste management protocols to prevent environmental contamination and ensure compliance with the Resource Conservation and Recovery Act (RCRA).

Internationally, the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Laboratories working with sodium acetate must comply with GHS requirements for labeling, classification, and safety data sheet preparation.

Many countries have their own regulatory bodies that oversee chemical safety in laboratories. For instance, the European Chemicals Agency (ECHA) enforces the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which impacts the use of sodium acetate in European laboratories.

Compliance with these regulations often requires laboratories to implement comprehensive chemical hygiene plans and conduct regular safety training for personnel. This includes educating staff on proper handling techniques, emergency procedures, and the use of appropriate PPE when working with sodium acetate.

Laboratories must also maintain accurate records of sodium acetate usage, storage, and disposal to demonstrate compliance during inspections. This may involve implementing inventory management systems and conducting regular audits to ensure adherence to regulatory requirements.

Furthermore, many research institutions and universities have their own internal policies and procedures that supplement governmental regulations. These may include specific protocols for the procurement, storage, and use of sodium acetate, as well as guidelines for conducting risk assessments before incorporating the compound into experimental procedures.

As regulations evolve, laboratories must stay informed about changes that may affect their use of sodium acetate. This often requires designating a safety officer or compliance specialist to monitor regulatory updates and ensure ongoing adherence to current standards.

In the United States, the Occupational Safety and Health Administration (OSHA) provides guidelines for the safe use of sodium acetate in laboratory settings. These regulations include proper labeling of containers, maintaining up-to-date safety data sheets (SDS), and implementing appropriate engineering controls and personal protective equipment (PPE) for handling the substance.

The Environmental Protection Agency (EPA) also regulates the disposal of sodium acetate and its solutions. Laboratories must adhere to specific waste management protocols to prevent environmental contamination and ensure compliance with the Resource Conservation and Recovery Act (RCRA).

Internationally, the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Laboratories working with sodium acetate must comply with GHS requirements for labeling, classification, and safety data sheet preparation.

Many countries have their own regulatory bodies that oversee chemical safety in laboratories. For instance, the European Chemicals Agency (ECHA) enforces the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which impacts the use of sodium acetate in European laboratories.

Compliance with these regulations often requires laboratories to implement comprehensive chemical hygiene plans and conduct regular safety training for personnel. This includes educating staff on proper handling techniques, emergency procedures, and the use of appropriate PPE when working with sodium acetate.

Laboratories must also maintain accurate records of sodium acetate usage, storage, and disposal to demonstrate compliance during inspections. This may involve implementing inventory management systems and conducting regular audits to ensure adherence to regulatory requirements.

Furthermore, many research institutions and universities have their own internal policies and procedures that supplement governmental regulations. These may include specific protocols for the procurement, storage, and use of sodium acetate, as well as guidelines for conducting risk assessments before incorporating the compound into experimental procedures.

As regulations evolve, laboratories must stay informed about changes that may affect their use of sodium acetate. This often requires designating a safety officer or compliance specialist to monitor regulatory updates and ensure ongoing adherence to current standards.

Environmental Impact

Sodium acetate, a common laboratory chemical, has significant implications for environmental impact when considering its use in laboratory safety and procedures. The production, use, and disposal of sodium acetate can affect various aspects of the environment, necessitating careful consideration and management.

In terms of production, sodium acetate is typically synthesized through the reaction of acetic acid with sodium hydroxide or sodium carbonate. This process requires energy and resources, contributing to carbon emissions and resource depletion. However, compared to many other laboratory chemicals, the environmental footprint of sodium acetate production is relatively low due to its simple synthesis process and the abundance of raw materials.

The use of sodium acetate in laboratory settings generally has minimal direct environmental impact. As a non-volatile and stable compound, it poses little risk of atmospheric pollution or contamination during normal handling and use. Its low toxicity to aquatic life and rapid biodegradability further reduce potential environmental harm from accidental spills or releases.

Disposal of sodium acetate presents both challenges and opportunities from an environmental perspective. As a biodegradable substance, it can be safely disposed of in wastewater systems in small quantities, where it will naturally break down without causing significant harm to aquatic ecosystems. However, large-scale disposal requires more careful management to prevent localized pH changes or oxygen depletion in water bodies.

One notable environmental benefit of sodium acetate is its potential to replace more hazardous chemicals in certain laboratory procedures. For instance, its use as a less corrosive de-icing agent can reduce the environmental impact of winter maintenance in laboratory settings. Additionally, its application in buffer solutions can minimize the need for more environmentally problematic alternatives.

The recyclability of sodium acetate solutions presents another environmental advantage. In some applications, such as hand warmers or phase change materials, sodium acetate can be reused multiple times, reducing waste generation and the need for continuous production of new materials. This circular approach aligns well with principles of sustainable chemistry and waste reduction in laboratory practices.

However, it is crucial to consider the indirect environmental impacts associated with the widespread use of sodium acetate. The energy consumption for heating and cooling sodium acetate solutions in various applications, as well as the packaging and transportation of the chemical, contribute to its overall environmental footprint. Laboratories and industries using sodium acetate should therefore strive to optimize these processes to minimize energy use and associated emissions.

In conclusion, while sodium acetate generally presents a favorable environmental profile compared to many other laboratory chemicals, its impact is not negligible. Responsible use, efficient production methods, and proper disposal practices are essential to maximize its benefits in laboratory safety and procedures while minimizing negative environmental consequences.

In terms of production, sodium acetate is typically synthesized through the reaction of acetic acid with sodium hydroxide or sodium carbonate. This process requires energy and resources, contributing to carbon emissions and resource depletion. However, compared to many other laboratory chemicals, the environmental footprint of sodium acetate production is relatively low due to its simple synthesis process and the abundance of raw materials.

The use of sodium acetate in laboratory settings generally has minimal direct environmental impact. As a non-volatile and stable compound, it poses little risk of atmospheric pollution or contamination during normal handling and use. Its low toxicity to aquatic life and rapid biodegradability further reduce potential environmental harm from accidental spills or releases.

Disposal of sodium acetate presents both challenges and opportunities from an environmental perspective. As a biodegradable substance, it can be safely disposed of in wastewater systems in small quantities, where it will naturally break down without causing significant harm to aquatic ecosystems. However, large-scale disposal requires more careful management to prevent localized pH changes or oxygen depletion in water bodies.

One notable environmental benefit of sodium acetate is its potential to replace more hazardous chemicals in certain laboratory procedures. For instance, its use as a less corrosive de-icing agent can reduce the environmental impact of winter maintenance in laboratory settings. Additionally, its application in buffer solutions can minimize the need for more environmentally problematic alternatives.

The recyclability of sodium acetate solutions presents another environmental advantage. In some applications, such as hand warmers or phase change materials, sodium acetate can be reused multiple times, reducing waste generation and the need for continuous production of new materials. This circular approach aligns well with principles of sustainable chemistry and waste reduction in laboratory practices.

However, it is crucial to consider the indirect environmental impacts associated with the widespread use of sodium acetate. The energy consumption for heating and cooling sodium acetate solutions in various applications, as well as the packaging and transportation of the chemical, contribute to its overall environmental footprint. Laboratories and industries using sodium acetate should therefore strive to optimize these processes to minimize energy use and associated emissions.

In conclusion, while sodium acetate generally presents a favorable environmental profile compared to many other laboratory chemicals, its impact is not negligible. Responsible use, efficient production methods, and proper disposal practices are essential to maximize its benefits in laboratory safety and procedures while minimizing negative environmental consequences.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!