Sodium Acetate in Nanotech: Paving the Way for Innovation

JUN 30, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate Nanotech Evolution and Objectives

Sodium acetate has emerged as a promising material in the field of nanotechnology, marking a significant evolution in its applications beyond traditional uses. Historically, sodium acetate has been widely known for its role in the food industry as a preservative and flavoring agent. However, recent advancements in materials science and nanotechnology have unveiled its potential in cutting-edge applications.

The journey of sodium acetate in nanotechnology began with the recognition of its unique properties at the nanoscale. Researchers discovered that when synthesized into nanoparticles, sodium acetate exhibits enhanced surface area-to-volume ratio, improved reactivity, and novel physicochemical characteristics. These properties have opened up a wide array of possibilities for innovation across various sectors.

One of the primary objectives in the development of sodium acetate nanotech is to harness its thermal energy storage capabilities. Sodium acetate trihydrate, in particular, has shown promise as a phase change material (PCM) for thermal energy storage systems. The goal is to develop more efficient and sustainable energy storage solutions that can contribute to the advancement of renewable energy technologies.

Another key objective is to explore the potential of sodium acetate nanoparticles in drug delivery systems. The biocompatibility and biodegradability of sodium acetate make it an attractive candidate for developing targeted drug delivery platforms. Researchers aim to create nanocarriers that can effectively encapsulate and release therapeutic agents, potentially revolutionizing cancer treatment and other medical applications.

In the field of environmental remediation, sodium acetate nanotech is being investigated for its potential in water purification and contaminant removal. The objective is to develop highly efficient and cost-effective nanomaterials that can adsorb or neutralize pollutants in water and soil, addressing pressing environmental challenges.

The evolution of sodium acetate in nanotechnology also extends to the development of smart materials and sensors. Researchers are exploring its use in creating responsive materials that can change properties based on external stimuli, such as temperature or pH. The goal is to design intelligent systems for applications in areas like packaging, textiles, and biomedical devices.

As the field progresses, a significant objective is to scale up the production of sodium acetate nanomaterials while maintaining their unique properties and ensuring cost-effectiveness. This involves optimizing synthesis methods, improving stability, and developing standardized characterization techniques to facilitate widespread adoption in industrial applications.

The journey of sodium acetate in nanotechnology began with the recognition of its unique properties at the nanoscale. Researchers discovered that when synthesized into nanoparticles, sodium acetate exhibits enhanced surface area-to-volume ratio, improved reactivity, and novel physicochemical characteristics. These properties have opened up a wide array of possibilities for innovation across various sectors.

One of the primary objectives in the development of sodium acetate nanotech is to harness its thermal energy storage capabilities. Sodium acetate trihydrate, in particular, has shown promise as a phase change material (PCM) for thermal energy storage systems. The goal is to develop more efficient and sustainable energy storage solutions that can contribute to the advancement of renewable energy technologies.

Another key objective is to explore the potential of sodium acetate nanoparticles in drug delivery systems. The biocompatibility and biodegradability of sodium acetate make it an attractive candidate for developing targeted drug delivery platforms. Researchers aim to create nanocarriers that can effectively encapsulate and release therapeutic agents, potentially revolutionizing cancer treatment and other medical applications.

In the field of environmental remediation, sodium acetate nanotech is being investigated for its potential in water purification and contaminant removal. The objective is to develop highly efficient and cost-effective nanomaterials that can adsorb or neutralize pollutants in water and soil, addressing pressing environmental challenges.

The evolution of sodium acetate in nanotechnology also extends to the development of smart materials and sensors. Researchers are exploring its use in creating responsive materials that can change properties based on external stimuli, such as temperature or pH. The goal is to design intelligent systems for applications in areas like packaging, textiles, and biomedical devices.

As the field progresses, a significant objective is to scale up the production of sodium acetate nanomaterials while maintaining their unique properties and ensuring cost-effectiveness. This involves optimizing synthesis methods, improving stability, and developing standardized characterization techniques to facilitate widespread adoption in industrial applications.

Market Demand Analysis for Sodium Acetate Nanotech

The market demand for sodium acetate in nanotechnology is experiencing significant growth, driven by its versatile applications across various industries. The global sodium acetate market, including its nanotech applications, is projected to expand at a steady rate over the next five years. This growth is primarily fueled by the increasing adoption of nanotechnology in sectors such as electronics, healthcare, and materials science.

In the electronics industry, sodium acetate nanoparticles are gaining traction for their potential in developing advanced energy storage devices and conductive materials. The miniaturization trend in electronics has created a demand for nanoscale materials that can enhance performance while reducing size, making sodium acetate nanotech solutions particularly attractive.

The healthcare sector represents another significant market for sodium acetate nanotech applications. Researchers are exploring its use in drug delivery systems, biosensors, and antimicrobial coatings. The growing emphasis on personalized medicine and targeted therapies is expected to drive further demand for sodium acetate-based nanocarriers and diagnostic tools.

In materials science, sodium acetate nanoparticles are being investigated for their potential in developing smart materials and coatings. Industries such as automotive, aerospace, and construction are showing interest in these innovations for their ability to enhance material properties like strength, durability, and thermal management.

The environmental sector is also emerging as a promising market for sodium acetate nanotech. Its applications in water treatment, air purification, and sustainable packaging are gaining attention as companies and governments focus on eco-friendly solutions. This trend aligns with the growing consumer demand for sustainable products and technologies.

Geographically, North America and Europe currently lead the market for sodium acetate nanotech applications, owing to their advanced research infrastructure and strong presence of technology companies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing R&D investments, and government initiatives to promote nanotechnology.

Despite the positive outlook, the market faces challenges such as high production costs and regulatory uncertainties surrounding nanomaterials. These factors may initially limit widespread adoption, particularly in cost-sensitive industries. However, ongoing research and development efforts are expected to address these challenges, potentially leading to more cost-effective production methods and clearer regulatory frameworks.

As the technology matures and more applications are discovered, the demand for sodium acetate in nanotech is anticipated to diversify further. This expansion is likely to create new opportunities for both established players and startups in the nanotechnology sector, fostering innovation and competition in the market.

In the electronics industry, sodium acetate nanoparticles are gaining traction for their potential in developing advanced energy storage devices and conductive materials. The miniaturization trend in electronics has created a demand for nanoscale materials that can enhance performance while reducing size, making sodium acetate nanotech solutions particularly attractive.

The healthcare sector represents another significant market for sodium acetate nanotech applications. Researchers are exploring its use in drug delivery systems, biosensors, and antimicrobial coatings. The growing emphasis on personalized medicine and targeted therapies is expected to drive further demand for sodium acetate-based nanocarriers and diagnostic tools.

In materials science, sodium acetate nanoparticles are being investigated for their potential in developing smart materials and coatings. Industries such as automotive, aerospace, and construction are showing interest in these innovations for their ability to enhance material properties like strength, durability, and thermal management.

The environmental sector is also emerging as a promising market for sodium acetate nanotech. Its applications in water treatment, air purification, and sustainable packaging are gaining attention as companies and governments focus on eco-friendly solutions. This trend aligns with the growing consumer demand for sustainable products and technologies.

Geographically, North America and Europe currently lead the market for sodium acetate nanotech applications, owing to their advanced research infrastructure and strong presence of technology companies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing R&D investments, and government initiatives to promote nanotechnology.

Despite the positive outlook, the market faces challenges such as high production costs and regulatory uncertainties surrounding nanomaterials. These factors may initially limit widespread adoption, particularly in cost-sensitive industries. However, ongoing research and development efforts are expected to address these challenges, potentially leading to more cost-effective production methods and clearer regulatory frameworks.

As the technology matures and more applications are discovered, the demand for sodium acetate in nanotech is anticipated to diversify further. This expansion is likely to create new opportunities for both established players and startups in the nanotechnology sector, fostering innovation and competition in the market.

Current State and Challenges in Sodium Acetate Nanotech

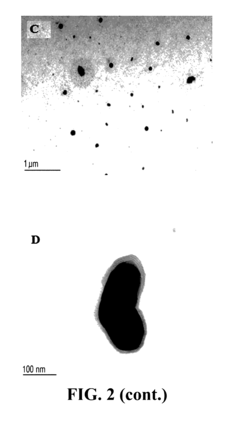

The current state of sodium acetate in nanotechnology is characterized by rapid advancements and promising applications across various fields. Sodium acetate nanoparticles have gained significant attention due to their unique properties and versatility. These nanoparticles exhibit excellent biocompatibility, low toxicity, and high stability, making them ideal candidates for biomedical applications.

In the pharmaceutical industry, sodium acetate nanoparticles are being explored as drug delivery systems. Their ability to encapsulate and release drugs in a controlled manner has shown potential in improving therapeutic efficacy and reducing side effects. Additionally, these nanoparticles have demonstrated antimicrobial properties, opening up possibilities for developing novel antibacterial coatings and materials.

The energy sector has also witnessed the integration of sodium acetate nanoparticles in thermal energy storage systems. Their phase change properties allow for efficient heat storage and release, contributing to the development of more sustainable and energy-efficient technologies.

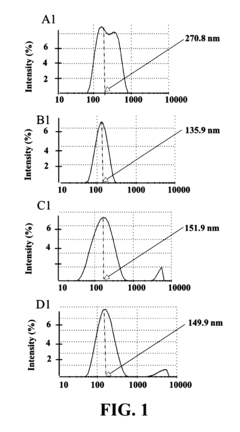

Despite these advancements, several challenges persist in the field of sodium acetate nanotechnology. One of the primary obstacles is the scalability of production processes. While laboratory-scale synthesis methods have been established, translating these techniques to industrial-scale production remains a significant hurdle. Ensuring consistent particle size distribution and maintaining the desired properties during large-scale manufacturing are critical challenges that need to be addressed.

Another challenge lies in the long-term stability of sodium acetate nanoparticles. In certain applications, such as drug delivery systems, maintaining the integrity and functionality of the nanoparticles over extended periods is crucial. Researchers are actively working on developing strategies to enhance the stability of these nanoparticles in various environmental conditions.

The controlled release of encapsulated substances from sodium acetate nanoparticles presents another challenge. Fine-tuning the release kinetics to achieve optimal therapeutic outcomes or desired functional properties requires further research and development. Additionally, understanding the interactions between sodium acetate nanoparticles and biological systems is essential for ensuring their safety and efficacy in biomedical applications.

Environmental concerns also pose challenges in the widespread adoption of sodium acetate nanotechnology. While sodium acetate is generally considered environmentally friendly, the potential long-term effects of nanoparticles on ecosystems and human health need to be thoroughly investigated. Developing sustainable production methods and addressing any potential environmental impacts are crucial for the responsible advancement of this technology.

In conclusion, sodium acetate nanotechnology shows great promise across various industries, but overcoming production scalability, stability, controlled release, and environmental challenges is essential for realizing its full potential. Continued research and collaboration between academia and industry will be crucial in addressing these challenges and paving the way for innovative applications of sodium acetate nanoparticles.

In the pharmaceutical industry, sodium acetate nanoparticles are being explored as drug delivery systems. Their ability to encapsulate and release drugs in a controlled manner has shown potential in improving therapeutic efficacy and reducing side effects. Additionally, these nanoparticles have demonstrated antimicrobial properties, opening up possibilities for developing novel antibacterial coatings and materials.

The energy sector has also witnessed the integration of sodium acetate nanoparticles in thermal energy storage systems. Their phase change properties allow for efficient heat storage and release, contributing to the development of more sustainable and energy-efficient technologies.

Despite these advancements, several challenges persist in the field of sodium acetate nanotechnology. One of the primary obstacles is the scalability of production processes. While laboratory-scale synthesis methods have been established, translating these techniques to industrial-scale production remains a significant hurdle. Ensuring consistent particle size distribution and maintaining the desired properties during large-scale manufacturing are critical challenges that need to be addressed.

Another challenge lies in the long-term stability of sodium acetate nanoparticles. In certain applications, such as drug delivery systems, maintaining the integrity and functionality of the nanoparticles over extended periods is crucial. Researchers are actively working on developing strategies to enhance the stability of these nanoparticles in various environmental conditions.

The controlled release of encapsulated substances from sodium acetate nanoparticles presents another challenge. Fine-tuning the release kinetics to achieve optimal therapeutic outcomes or desired functional properties requires further research and development. Additionally, understanding the interactions between sodium acetate nanoparticles and biological systems is essential for ensuring their safety and efficacy in biomedical applications.

Environmental concerns also pose challenges in the widespread adoption of sodium acetate nanotechnology. While sodium acetate is generally considered environmentally friendly, the potential long-term effects of nanoparticles on ecosystems and human health need to be thoroughly investigated. Developing sustainable production methods and addressing any potential environmental impacts are crucial for the responsible advancement of this technology.

In conclusion, sodium acetate nanotechnology shows great promise across various industries, but overcoming production scalability, stability, controlled release, and environmental challenges is essential for realizing its full potential. Continued research and collaboration between academia and industry will be crucial in addressing these challenges and paving the way for innovative applications of sodium acetate nanoparticles.

Existing Sodium Acetate Nanotech Solutions

01 Use of sodium acetate in chemical processes

Sodium acetate is widely used in various chemical processes as a reagent, catalyst, or buffer. It plays a role in reactions such as acetylation, esterification, and pH control. Its properties make it valuable in industrial applications and laboratory settings.- Use in chemical processes and manufacturing: Sodium acetate is widely used in various chemical processes and manufacturing applications. It serves as a key ingredient or catalyst in the production of different chemicals and materials. Its properties make it suitable for use in industrial settings, contributing to the efficiency and effectiveness of various production processes.

- Application in heat storage and thermal management: Sodium acetate is utilized in heat storage and thermal management systems. Its phase change properties make it an effective material for storing and releasing thermal energy. This application is particularly useful in heating and cooling systems, as well as in temperature-sensitive environments where maintaining consistent temperatures is crucial.

- Use in food and beverage industry: Sodium acetate finds applications in the food and beverage industry as a preservative, flavoring agent, and acidity regulator. It helps extend the shelf life of various food products and contributes to flavor enhancement. Its use in this sector is governed by food safety regulations and standards.

- Environmental and waste treatment applications: Sodium acetate is employed in environmental and waste treatment processes. It can be used in wastewater treatment, air purification systems, and other environmental remediation applications. Its properties make it effective in neutralizing certain pollutants and aiding in the treatment of industrial effluents.

- Pharmaceutical and medical uses: In the pharmaceutical and medical fields, sodium acetate is used in various formulations and treatments. It can serve as a buffering agent in intravenous fluids, a component in certain medications, and a reagent in diagnostic tests. Its applications in this sector are subject to strict quality control and regulatory standards.

02 Application in heat storage and thermal management

Sodium acetate trihydrate is utilized in heat storage systems and thermal management applications. It undergoes phase changes at specific temperatures, allowing it to store and release heat effectively. This property is exploited in heat packs, building materials, and energy storage solutions.Expand Specific Solutions03 Use in food and beverage industry

Sodium acetate finds applications in the food and beverage industry as a preservative, acidity regulator, and flavoring agent. It helps extend shelf life, maintain pH levels, and enhance taste in various food products.Expand Specific Solutions04 Application in textile and leather processing

Sodium acetate is used in textile and leather processing industries. It serves as a neutralizing agent, dyeing auxiliary, and helps in the fixation of dyes. Its properties contribute to improved color fastness and fabric quality.Expand Specific Solutions05 Use in environmental and waste treatment

Sodium acetate is employed in environmental and waste treatment processes. It can be used for pH adjustment in wastewater treatment, as a deicer for roads, and in certain bioremediation applications. Its biodegradability makes it an environmentally friendly option in some scenarios.Expand Specific Solutions

Key Players in Sodium Acetate Nanotech Industry

The sodium acetate nanotech market is in an early growth stage, with increasing research and commercial interest. While the market size remains relatively small, it shows promising potential for expansion across various industries. The technology is still evolving, with varying levels of maturity across applications. Key players like Sunamp Ltd. and Promimic AB are advancing thermal energy storage and biomaterial applications respectively, while major petrochemical companies such as Petróleo Brasileiro SA and China Petroleum & Chemical Corp. are exploring broader industrial uses. Academic institutions like Nanjing University and Trinity College Dublin are contributing to fundamental research, indicating ongoing efforts to improve the technology's capabilities and applications.

Promimic AB

Technical Solution: Promimic AB has developed a unique HAnano Surface technology that utilizes sodium acetate in nanotech applications for medical implants. Their process involves creating a nanometer-thin layer of hydroxyapatite (HA) on implant surfaces, which enhances osseointegration. The sodium acetate plays a crucial role in the sol-gel process used to create this bioactive coating. The company's technology allows for precise control of the nanostructure, resulting in a highly biocompatible surface that promotes rapid bone formation[1][2]. This innovation has shown significant improvements in implant stability and healing times in clinical studies.

Strengths: Highly biocompatible, promotes faster osseointegration, applicable to various implant materials. Weaknesses: May require specialized equipment for application, potential long-term effects still under study.

Nexdot SAS

Technical Solution: Nexdot SAS is pioneering the use of sodium acetate in quantum dot technology for advanced display and lighting applications. Their proprietary process incorporates sodium acetate as a precursor in the synthesis of high-performance quantum dots. This approach allows for precise control over the size and composition of the nanocrystals, resulting in enhanced color purity and efficiency. Nexdot's quantum dots exhibit exceptional stability and narrow emission spectra, making them ideal for next-generation displays and LED lighting[3]. The company has also developed a scalable manufacturing process that ensures consistent quality and reduces production costs, positioning them as a leader in the quantum dot market[4].

Strengths: Superior color performance, high efficiency, scalable production. Weaknesses: Potential environmental concerns with heavy metal content, competition from alternative technologies.

Core Innovations in Sodium Acetate Nanotech

Process for manufacturing colloidal nanosheets by lateral growth of nanocrystals

PatentActiveEP2633102A1

Innovation

- A process involving the progressive introduction of precursors into a solution containing initial colloidal nanocrystals and an acetate salt at controlled temperatures, allowing for the lateral growth of semiconductor nanosheets with precise thickness and lateral dimensions, avoiding parasitic formations through slow precursor injection and fine powder dispersion of the acetate salt.

Formulations for pharmaceutical agents

PatentActiveUS20160361327A1

Innovation

- In situ formation of sodium acetate is used to coat chitosan nanoparticles during the freeze-drying process, enhancing encapsulation efficiency, preventing aggregation, and achieving sustained release by forming a stable core-shell structure.

Environmental Impact of Sodium Acetate Nanotech

The environmental impact of sodium acetate nanotech is a critical consideration as this innovative technology continues to advance. Sodium acetate nanoparticles, while offering numerous benefits across various industries, also pose potential risks to ecosystems and human health that must be carefully evaluated and mitigated.

One of the primary environmental concerns is the potential release of sodium acetate nanoparticles into aquatic ecosystems. These nanoparticles can accumulate in water bodies, potentially altering pH levels and affecting the delicate balance of aquatic life. Studies have shown that certain aquatic organisms may absorb these nanoparticles, leading to bioaccumulation in the food chain. This could have far-reaching consequences for biodiversity and ecosystem stability.

Soil contamination is another area of concern. As sodium acetate nanoparticles are used in agricultural applications or released through industrial processes, they may accumulate in soil. This accumulation could potentially affect soil microorganisms, plant growth, and overall soil health. Long-term studies are needed to fully understand the impact on soil ecosystems and agricultural productivity.

Air quality is also a consideration, particularly in industrial settings where sodium acetate nanoparticles may be released as aerosols. While the particles themselves may not pose a significant inhalation risk due to their hygroscopic nature, the potential for them to act as carriers for other pollutants or to contribute to particulate matter pollution needs further investigation.

On the positive side, sodium acetate nanotech offers several environmental benefits. Its use in water treatment processes can lead to more efficient removal of contaminants, potentially improving water quality in both industrial and municipal settings. Additionally, when used in energy storage applications, sodium acetate nanoparticles can contribute to the development of more sustainable and efficient energy systems, indirectly reducing carbon emissions.

The lifecycle analysis of products incorporating sodium acetate nanotech is crucial for understanding their overall environmental impact. This includes assessing the energy and resources required for production, the environmental effects during use, and the challenges of disposal or recycling at the end of the product's life. Developing environmentally friendly production methods and establishing proper disposal protocols are essential steps in minimizing the ecological footprint of this technology.

As research in this field progresses, it is imperative to establish comprehensive environmental monitoring programs and regulatory frameworks. These should address the production, use, and disposal of sodium acetate nanoparticles to ensure that the benefits of this technology do not come at the cost of environmental degradation. Continued collaboration between scientists, industry leaders, and policymakers will be crucial in striking the right balance between technological advancement and environmental stewardship.

One of the primary environmental concerns is the potential release of sodium acetate nanoparticles into aquatic ecosystems. These nanoparticles can accumulate in water bodies, potentially altering pH levels and affecting the delicate balance of aquatic life. Studies have shown that certain aquatic organisms may absorb these nanoparticles, leading to bioaccumulation in the food chain. This could have far-reaching consequences for biodiversity and ecosystem stability.

Soil contamination is another area of concern. As sodium acetate nanoparticles are used in agricultural applications or released through industrial processes, they may accumulate in soil. This accumulation could potentially affect soil microorganisms, plant growth, and overall soil health. Long-term studies are needed to fully understand the impact on soil ecosystems and agricultural productivity.

Air quality is also a consideration, particularly in industrial settings where sodium acetate nanoparticles may be released as aerosols. While the particles themselves may not pose a significant inhalation risk due to their hygroscopic nature, the potential for them to act as carriers for other pollutants or to contribute to particulate matter pollution needs further investigation.

On the positive side, sodium acetate nanotech offers several environmental benefits. Its use in water treatment processes can lead to more efficient removal of contaminants, potentially improving water quality in both industrial and municipal settings. Additionally, when used in energy storage applications, sodium acetate nanoparticles can contribute to the development of more sustainable and efficient energy systems, indirectly reducing carbon emissions.

The lifecycle analysis of products incorporating sodium acetate nanotech is crucial for understanding their overall environmental impact. This includes assessing the energy and resources required for production, the environmental effects during use, and the challenges of disposal or recycling at the end of the product's life. Developing environmentally friendly production methods and establishing proper disposal protocols are essential steps in minimizing the ecological footprint of this technology.

As research in this field progresses, it is imperative to establish comprehensive environmental monitoring programs and regulatory frameworks. These should address the production, use, and disposal of sodium acetate nanoparticles to ensure that the benefits of this technology do not come at the cost of environmental degradation. Continued collaboration between scientists, industry leaders, and policymakers will be crucial in striking the right balance between technological advancement and environmental stewardship.

Scalability and Cost Analysis

The scalability and cost analysis of sodium acetate in nanotechnology applications is crucial for determining its viability in large-scale production and commercial implementation. As the demand for nanomaterials continues to grow, the ability to scale up production processes while maintaining cost-effectiveness becomes increasingly important.

Sodium acetate's potential for scalability in nanotech applications is promising due to its relatively simple chemical structure and well-established production methods. The compound can be synthesized through various processes, including the reaction of acetic acid with sodium hydroxide or sodium carbonate. These raw materials are readily available and relatively inexpensive, which bodes well for large-scale production.

However, the challenge lies in maintaining the precise control required for nanotech applications when scaling up production. Factors such as temperature, pH, and reaction time must be carefully monitored and controlled to ensure consistent quality and size of nanoparticles. This may necessitate significant investments in advanced manufacturing equipment and process control systems.

From a cost perspective, sodium acetate itself is relatively inexpensive compared to many other materials used in nanotechnology. This provides a significant advantage in terms of raw material costs. However, the overall cost analysis must consider additional factors such as purification processes, specialized equipment for nanoparticle synthesis, and quality control measures.

Energy consumption is another critical factor in the scalability and cost analysis. The production of sodium acetate-based nanomaterials may require less energy compared to some alternative materials, potentially leading to lower operational costs and a reduced environmental footprint. This aspect could be particularly advantageous as industries increasingly prioritize sustainable and energy-efficient production methods.

Labor costs associated with the production of sodium acetate-based nanomaterials are expected to be moderate. While skilled personnel are required for process development and quality control, the relatively straightforward nature of sodium acetate chemistry may allow for more automated production processes, potentially reducing labor costs in large-scale operations.

The potential for recycling and reuse of sodium acetate in nanotech applications could further enhance its cost-effectiveness and sustainability. Developing efficient recovery and purification methods for unused or waste sodium acetate could significantly reduce raw material costs and minimize environmental impact in large-scale production scenarios.

In conclusion, the scalability and cost analysis of sodium acetate in nanotech applications reveals a promising outlook. Its relatively low raw material cost, potential for energy-efficient production, and established synthesis methods provide a solid foundation for scalability. However, challenges in maintaining precise control during large-scale production and the need for specialized equipment must be carefully addressed to ensure economic viability and consistent product quality.

Sodium acetate's potential for scalability in nanotech applications is promising due to its relatively simple chemical structure and well-established production methods. The compound can be synthesized through various processes, including the reaction of acetic acid with sodium hydroxide or sodium carbonate. These raw materials are readily available and relatively inexpensive, which bodes well for large-scale production.

However, the challenge lies in maintaining the precise control required for nanotech applications when scaling up production. Factors such as temperature, pH, and reaction time must be carefully monitored and controlled to ensure consistent quality and size of nanoparticles. This may necessitate significant investments in advanced manufacturing equipment and process control systems.

From a cost perspective, sodium acetate itself is relatively inexpensive compared to many other materials used in nanotechnology. This provides a significant advantage in terms of raw material costs. However, the overall cost analysis must consider additional factors such as purification processes, specialized equipment for nanoparticle synthesis, and quality control measures.

Energy consumption is another critical factor in the scalability and cost analysis. The production of sodium acetate-based nanomaterials may require less energy compared to some alternative materials, potentially leading to lower operational costs and a reduced environmental footprint. This aspect could be particularly advantageous as industries increasingly prioritize sustainable and energy-efficient production methods.

Labor costs associated with the production of sodium acetate-based nanomaterials are expected to be moderate. While skilled personnel are required for process development and quality control, the relatively straightforward nature of sodium acetate chemistry may allow for more automated production processes, potentially reducing labor costs in large-scale operations.

The potential for recycling and reuse of sodium acetate in nanotech applications could further enhance its cost-effectiveness and sustainability. Developing efficient recovery and purification methods for unused or waste sodium acetate could significantly reduce raw material costs and minimize environmental impact in large-scale production scenarios.

In conclusion, the scalability and cost analysis of sodium acetate in nanotech applications reveals a promising outlook. Its relatively low raw material cost, potential for energy-efficient production, and established synthesis methods provide a solid foundation for scalability. However, challenges in maintaining precise control during large-scale production and the need for specialized equipment must be carefully addressed to ensure economic viability and consistent product quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!