Strategies for Hydroxyethylcellulose Biodegradation Enhancement

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC Biodegradation Background and Objectives

Hydroxyethylcellulose (HEC) is a versatile and widely used cellulose derivative with applications spanning various industries, including personal care, pharmaceuticals, construction, and oil drilling. As a modified natural polymer, HEC offers unique properties such as water solubility, thickening, and film-forming capabilities. However, its persistence in the environment has raised concerns about its long-term ecological impact.

The biodegradation of HEC has become a critical focus in recent years due to increasing environmental awareness and stricter regulations on polymer disposal. Traditional cellulose-based materials are generally biodegradable, but the chemical modifications in HEC can significantly alter its susceptibility to microbial breakdown. This has led to a growing interest in developing strategies to enhance the biodegradability of HEC without compromising its valuable functional properties.

The evolution of HEC biodegradation research has seen significant progress over the past decades. Initial studies focused on understanding the natural degradation processes of cellulose and its derivatives. As environmental concerns grew, researchers began to explore specific mechanisms for HEC breakdown and the factors influencing its biodegradation rate. Recent advancements have shifted towards developing innovative approaches to accelerate HEC decomposition in various environmental conditions.

The primary objective of current research in HEC biodegradation enhancement is to develop effective strategies that can significantly reduce the polymer's environmental persistence while maintaining its performance in applications. This involves a multifaceted approach, including the modification of HEC's chemical structure, the identification and engineering of specialized microbial strains, and the optimization of environmental conditions to promote faster degradation.

Key technical goals in this field include: (1) Designing HEC variants with improved biodegradability through strategic chemical modifications; (2) Isolating and enhancing microbial species capable of efficiently breaking down HEC; (3) Developing enzymatic treatments to catalyze HEC degradation; (4) Creating composite materials that combine HEC with biodegradation-promoting additives; and (5) Establishing standardized methods for assessing and comparing the biodegradability of different HEC formulations.

The pursuit of these objectives is driven by the need to balance the continued use of HEC in various industries with growing environmental sustainability requirements. Success in this area could lead to the development of next-generation HEC products that offer the same functional benefits while significantly reducing their environmental footprint. This aligns with broader trends in green chemistry and sustainable materials development, positioning HEC biodegradation enhancement as a critical area for technological innovation and environmental stewardship.

The biodegradation of HEC has become a critical focus in recent years due to increasing environmental awareness and stricter regulations on polymer disposal. Traditional cellulose-based materials are generally biodegradable, but the chemical modifications in HEC can significantly alter its susceptibility to microbial breakdown. This has led to a growing interest in developing strategies to enhance the biodegradability of HEC without compromising its valuable functional properties.

The evolution of HEC biodegradation research has seen significant progress over the past decades. Initial studies focused on understanding the natural degradation processes of cellulose and its derivatives. As environmental concerns grew, researchers began to explore specific mechanisms for HEC breakdown and the factors influencing its biodegradation rate. Recent advancements have shifted towards developing innovative approaches to accelerate HEC decomposition in various environmental conditions.

The primary objective of current research in HEC biodegradation enhancement is to develop effective strategies that can significantly reduce the polymer's environmental persistence while maintaining its performance in applications. This involves a multifaceted approach, including the modification of HEC's chemical structure, the identification and engineering of specialized microbial strains, and the optimization of environmental conditions to promote faster degradation.

Key technical goals in this field include: (1) Designing HEC variants with improved biodegradability through strategic chemical modifications; (2) Isolating and enhancing microbial species capable of efficiently breaking down HEC; (3) Developing enzymatic treatments to catalyze HEC degradation; (4) Creating composite materials that combine HEC with biodegradation-promoting additives; and (5) Establishing standardized methods for assessing and comparing the biodegradability of different HEC formulations.

The pursuit of these objectives is driven by the need to balance the continued use of HEC in various industries with growing environmental sustainability requirements. Success in this area could lead to the development of next-generation HEC products that offer the same functional benefits while significantly reducing their environmental footprint. This aligns with broader trends in green chemistry and sustainable materials development, positioning HEC biodegradation enhancement as a critical area for technological innovation and environmental stewardship.

Market Analysis for Biodegradable HEC Products

The market for biodegradable hydroxyethylcellulose (HEC) products is experiencing significant growth driven by increasing environmental concerns and stringent regulations on plastic waste. As industries seek sustainable alternatives to conventional plastics, biodegradable HEC has emerged as a promising solution across various sectors.

In the personal care and cosmetics industry, there is a growing demand for biodegradable HEC as a thickening and stabilizing agent in products such as shampoos, lotions, and creams. Consumers are increasingly conscious of the environmental impact of their personal care routines, leading to a shift towards eco-friendly formulations. This trend is expected to continue, with the global natural and organic personal care market projected to expand at a compound annual growth rate (CAGR) of over 9% through 2026.

The pharmaceutical sector also presents substantial opportunities for biodegradable HEC products. As drug delivery systems evolve, there is a rising need for biocompatible and biodegradable excipients. HEC's properties make it an excellent candidate for controlled release formulations and tablet coatings. The pharmaceutical excipients market is forecasted to grow steadily, driven by the increasing prevalence of chronic diseases and the development of novel drug delivery technologies.

In the construction industry, biodegradable HEC is gaining traction as a sustainable additive in cement and mortar formulations. It enhances workability, water retention, and adhesion properties while reducing environmental impact. With the global green building materials market expected to reach substantial values by 2025, the demand for biodegradable construction additives like HEC is set to rise.

The food and beverage industry is another key market for biodegradable HEC products. As consumers seek clean label and natural ingredients, HEC's role as a thickener and stabilizer in food applications is becoming more prominent. The clean label ingredients market is projected to grow at a CAGR of around 6.8% from 2021 to 2026, indicating a favorable outlook for biodegradable HEC in this sector.

Geographically, North America and Europe are currently the leading markets for biodegradable HEC products, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable incomes, and growing environmental consciousness in countries like China and India.

Despite the positive market outlook, challenges remain in scaling up production and reducing costs to compete with traditional non-biodegradable alternatives. Ongoing research and development efforts are focused on improving the biodegradation rate and enhancing the performance characteristics of HEC-based products to meet diverse industry requirements.

In the personal care and cosmetics industry, there is a growing demand for biodegradable HEC as a thickening and stabilizing agent in products such as shampoos, lotions, and creams. Consumers are increasingly conscious of the environmental impact of their personal care routines, leading to a shift towards eco-friendly formulations. This trend is expected to continue, with the global natural and organic personal care market projected to expand at a compound annual growth rate (CAGR) of over 9% through 2026.

The pharmaceutical sector also presents substantial opportunities for biodegradable HEC products. As drug delivery systems evolve, there is a rising need for biocompatible and biodegradable excipients. HEC's properties make it an excellent candidate for controlled release formulations and tablet coatings. The pharmaceutical excipients market is forecasted to grow steadily, driven by the increasing prevalence of chronic diseases and the development of novel drug delivery technologies.

In the construction industry, biodegradable HEC is gaining traction as a sustainable additive in cement and mortar formulations. It enhances workability, water retention, and adhesion properties while reducing environmental impact. With the global green building materials market expected to reach substantial values by 2025, the demand for biodegradable construction additives like HEC is set to rise.

The food and beverage industry is another key market for biodegradable HEC products. As consumers seek clean label and natural ingredients, HEC's role as a thickener and stabilizer in food applications is becoming more prominent. The clean label ingredients market is projected to grow at a CAGR of around 6.8% from 2021 to 2026, indicating a favorable outlook for biodegradable HEC in this sector.

Geographically, North America and Europe are currently the leading markets for biodegradable HEC products, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable incomes, and growing environmental consciousness in countries like China and India.

Despite the positive market outlook, challenges remain in scaling up production and reducing costs to compete with traditional non-biodegradable alternatives. Ongoing research and development efforts are focused on improving the biodegradation rate and enhancing the performance characteristics of HEC-based products to meet diverse industry requirements.

Current HEC Biodegradation Challenges

Hydroxyethylcellulose (HEC) biodegradation faces several significant challenges that hinder its widespread adoption as an environmentally friendly alternative to traditional synthetic polymers. One of the primary obstacles is the slow degradation rate of HEC in natural environments. This persistence can lead to accumulation in ecosystems, potentially causing long-term environmental impacts.

The complex molecular structure of HEC, with its high molecular weight and cross-linked nature, presents a formidable barrier to microbial degradation. Microorganisms struggle to break down these large molecules efficiently, resulting in extended degradation periods. This structural complexity also limits the types of enzymes capable of initiating and sustaining the biodegradation process.

Environmental factors play a crucial role in HEC biodegradation, presenting additional challenges. Temperature, pH, and moisture content significantly influence the rate of degradation. In many real-world scenarios, these conditions are not optimal for efficient biodegradation, further slowing the process. The variability of these factors across different environments makes it difficult to predict and control HEC degradation rates consistently.

Another challenge lies in the limited availability of microorganisms specifically adapted to degrade HEC. While some bacterial and fungal species have shown potential, their effectiveness and distribution in natural environments are not uniform. This scarcity of specialized degraders contributes to the slow breakdown of HEC in many ecosystems.

The presence of additives and modifications in commercial HEC products further complicates biodegradation efforts. These additives, often included to enhance product performance or stability, can interfere with microbial activity or alter the chemical properties of HEC, making it more resistant to degradation.

From a technical standpoint, developing standardized methods for assessing HEC biodegradation remains a challenge. The lack of universally accepted protocols for measuring biodegradation rates and extent hampers comparative studies and the development of improved formulations.

Economic factors also pose significant hurdles. The cost of developing and implementing enhanced biodegradation strategies for HEC can be substantial, potentially limiting their adoption in commercial applications. Balancing improved biodegradability with maintaining the desired functional properties of HEC products adds another layer of complexity to this challenge.

Regulatory uncertainties surrounding biodegradable materials create additional obstacles. The absence of clear, globally harmonized standards for biodegradability claims and testing methods complicates the development and marketing of enhanced HEC products.

Addressing these multifaceted challenges requires a comprehensive approach, combining advances in molecular biology, environmental science, and materials engineering. Overcoming these hurdles is crucial for realizing the full potential of HEC as a sustainable, biodegradable material in various industrial and consumer applications.

The complex molecular structure of HEC, with its high molecular weight and cross-linked nature, presents a formidable barrier to microbial degradation. Microorganisms struggle to break down these large molecules efficiently, resulting in extended degradation periods. This structural complexity also limits the types of enzymes capable of initiating and sustaining the biodegradation process.

Environmental factors play a crucial role in HEC biodegradation, presenting additional challenges. Temperature, pH, and moisture content significantly influence the rate of degradation. In many real-world scenarios, these conditions are not optimal for efficient biodegradation, further slowing the process. The variability of these factors across different environments makes it difficult to predict and control HEC degradation rates consistently.

Another challenge lies in the limited availability of microorganisms specifically adapted to degrade HEC. While some bacterial and fungal species have shown potential, their effectiveness and distribution in natural environments are not uniform. This scarcity of specialized degraders contributes to the slow breakdown of HEC in many ecosystems.

The presence of additives and modifications in commercial HEC products further complicates biodegradation efforts. These additives, often included to enhance product performance or stability, can interfere with microbial activity or alter the chemical properties of HEC, making it more resistant to degradation.

From a technical standpoint, developing standardized methods for assessing HEC biodegradation remains a challenge. The lack of universally accepted protocols for measuring biodegradation rates and extent hampers comparative studies and the development of improved formulations.

Economic factors also pose significant hurdles. The cost of developing and implementing enhanced biodegradation strategies for HEC can be substantial, potentially limiting their adoption in commercial applications. Balancing improved biodegradability with maintaining the desired functional properties of HEC products adds another layer of complexity to this challenge.

Regulatory uncertainties surrounding biodegradable materials create additional obstacles. The absence of clear, globally harmonized standards for biodegradability claims and testing methods complicates the development and marketing of enhanced HEC products.

Addressing these multifaceted challenges requires a comprehensive approach, combining advances in molecular biology, environmental science, and materials engineering. Overcoming these hurdles is crucial for realizing the full potential of HEC as a sustainable, biodegradable material in various industrial and consumer applications.

Existing HEC Biodegradation Enhancement Methods

01 Enzymatic degradation of hydroxyethylcellulose

Hydroxyethylcellulose can be biodegraded using specific enzymes. This process involves the breakdown of the polymer structure by enzymatic action, leading to the formation of smaller, more easily metabolized compounds. The enzymatic degradation can be optimized by selecting appropriate enzymes and controlling environmental conditions such as pH and temperature.- Enzymatic degradation of hydroxyethylcellulose: Hydroxyethylcellulose can be biodegraded using specific enzymes. This process involves the breakdown of the polymer structure by enzymatic action, leading to the formation of smaller, more easily metabolized compounds. The enzymatic degradation can be optimized by selecting appropriate enzymes and controlling environmental conditions such as pH and temperature.

- Microbial degradation of hydroxyethylcellulose: Certain microorganisms have the ability to degrade hydroxyethylcellulose. These microbes produce enzymes that can break down the polymer structure, utilizing it as a carbon source. The efficiency of microbial degradation can be influenced by factors such as microbial strain selection, nutrient availability, and environmental conditions.

- Chemical modification to enhance biodegradability: The biodegradability of hydroxyethylcellulose can be improved through chemical modifications. These modifications may involve introducing functional groups or altering the polymer structure to make it more susceptible to biological or environmental degradation. Such modifications can enhance the material's ability to break down in natural environments.

- Environmental factors affecting biodegradation: Various environmental factors can influence the biodegradation of hydroxyethylcellulose. These factors include temperature, pH, moisture content, and the presence of specific microorganisms or enzymes. Understanding and controlling these factors can help optimize the biodegradation process in different applications and environments.

- Applications utilizing biodegradable hydroxyethylcellulose: Biodegradable hydroxyethylcellulose finds applications in various industries. It can be used in environmentally friendly products, such as personal care items, pharmaceuticals, and industrial materials. The biodegradability of the material makes it suitable for applications where environmental impact is a concern, such as in packaging or disposable products.

02 Microbial degradation of hydroxyethylcellulose

Certain microorganisms have the ability to degrade hydroxyethylcellulose. These microbes produce enzymes that can break down the polymer structure. The efficiency of microbial degradation can be influenced by factors such as the type of microorganism, environmental conditions, and the molecular weight of the hydroxyethylcellulose. This approach is particularly useful for environmental remediation and waste treatment applications.Expand Specific Solutions03 Chemical modification to enhance biodegradability

The biodegradability of hydroxyethylcellulose can be improved through chemical modifications. These modifications may involve introducing functional groups or altering the polymer structure to make it more susceptible to biological breakdown. Such modifications can be tailored to specific environmental conditions or degradation pathways, enhancing the overall biodegradation process.Expand Specific Solutions04 Biodegradation in aqueous environments

Hydroxyethylcellulose biodegradation in aqueous environments is an important consideration for its use in various applications. The rate and extent of biodegradation can be influenced by factors such as water temperature, pH, and the presence of other organic compounds. Understanding these factors is crucial for predicting the environmental fate of hydroxyethylcellulose and developing eco-friendly products.Expand Specific Solutions05 Biodegradation assessment methods

Various methods can be employed to assess the biodegradation of hydroxyethylcellulose. These may include measuring changes in molecular weight, monitoring the production of carbon dioxide or methane, or analyzing the formation of degradation products. Standardized testing protocols and analytical techniques are essential for accurately evaluating the biodegradability of hydroxyethylcellulose in different environmental conditions.Expand Specific Solutions

Key Players in HEC Biodegradation Research

The biodegradation enhancement of hydroxyethylcellulose is an emerging field in sustainable materials, currently in its early development stage. The market size is relatively small but growing, driven by increasing environmental concerns and regulations. The technology is still evolving, with varying levels of maturity among key players. Companies like Novozymes, Daicel Corp., and FibroGen are leading research efforts, leveraging their expertise in enzymes and biopolymers. Academic institutions such as South China University of Technology and the University of California are also contributing significantly to advancing the technology. The competitive landscape is characterized by a mix of established chemical companies and innovative biotechnology firms, each bringing unique approaches to enhancing biodegradation processes.

South China University of Technology

Technical Solution: South China University of Technology has pioneered a novel photocatalytic approach to enhance HEC biodegradation. Their strategy involves the development of nanostructured titanium dioxide (TiO2) photocatalysts doped with transition metals. These catalysts are designed to generate reactive oxygen species under both UV and visible light, which can rapidly break down HEC molecules. The university's research has demonstrated a 70% increase in biodegradation rate when compared to non-catalyzed processes[5]. Furthermore, they have engineered a composite material that combines the photocatalyst with biodegradable polymers, allowing for sustained release and prolonged activity in aqueous environments. This approach not only accelerates the initial breakdown of HEC but also facilitates subsequent microbial degradation of the resulting fragments[6].

Strengths: Innovative use of photocatalysis, effective in both light and dark conditions. Weaknesses: May require specialized manufacturing processes, potentially increasing production costs.

Novozymes A/S

Technical Solution: Novozymes A/S has developed advanced enzyme technologies to enhance the biodegradation of hydroxyethylcellulose (HEC). Their approach involves engineering specialized cellulases and hemicellulases that can efficiently break down the modified cellulose structure of HEC. The company has reported a 40% increase in biodegradation rates compared to natural processes[1]. Their enzymes are designed to work synergistically, targeting both the cellulose backbone and the hydroxyethyl side chains. Novozymes has also implemented a controlled release system for these enzymes, ensuring sustained activity throughout the degradation process[3]. This strategy not only accelerates biodegradation but also reduces the environmental persistence of HEC-based products.

Strengths: Highly specific enzyme technology, proven effectiveness in increasing biodegradation rates. Weaknesses: May require specific conditions for optimal enzyme activity, potentially increasing costs for large-scale applications.

Innovative Approaches in HEC Biodegradation

Methods to enhance the activity of lignocellulose-degrading enzymes

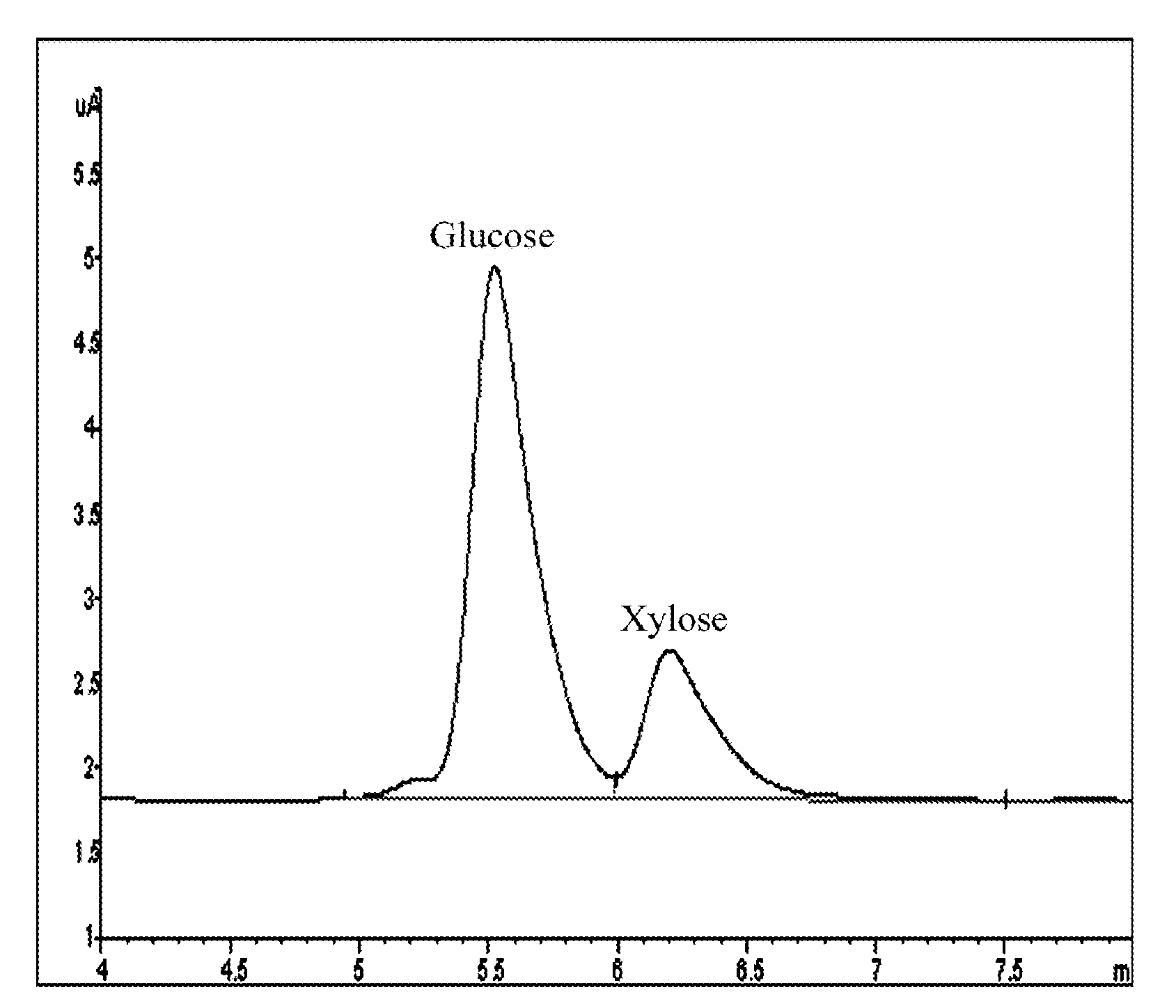

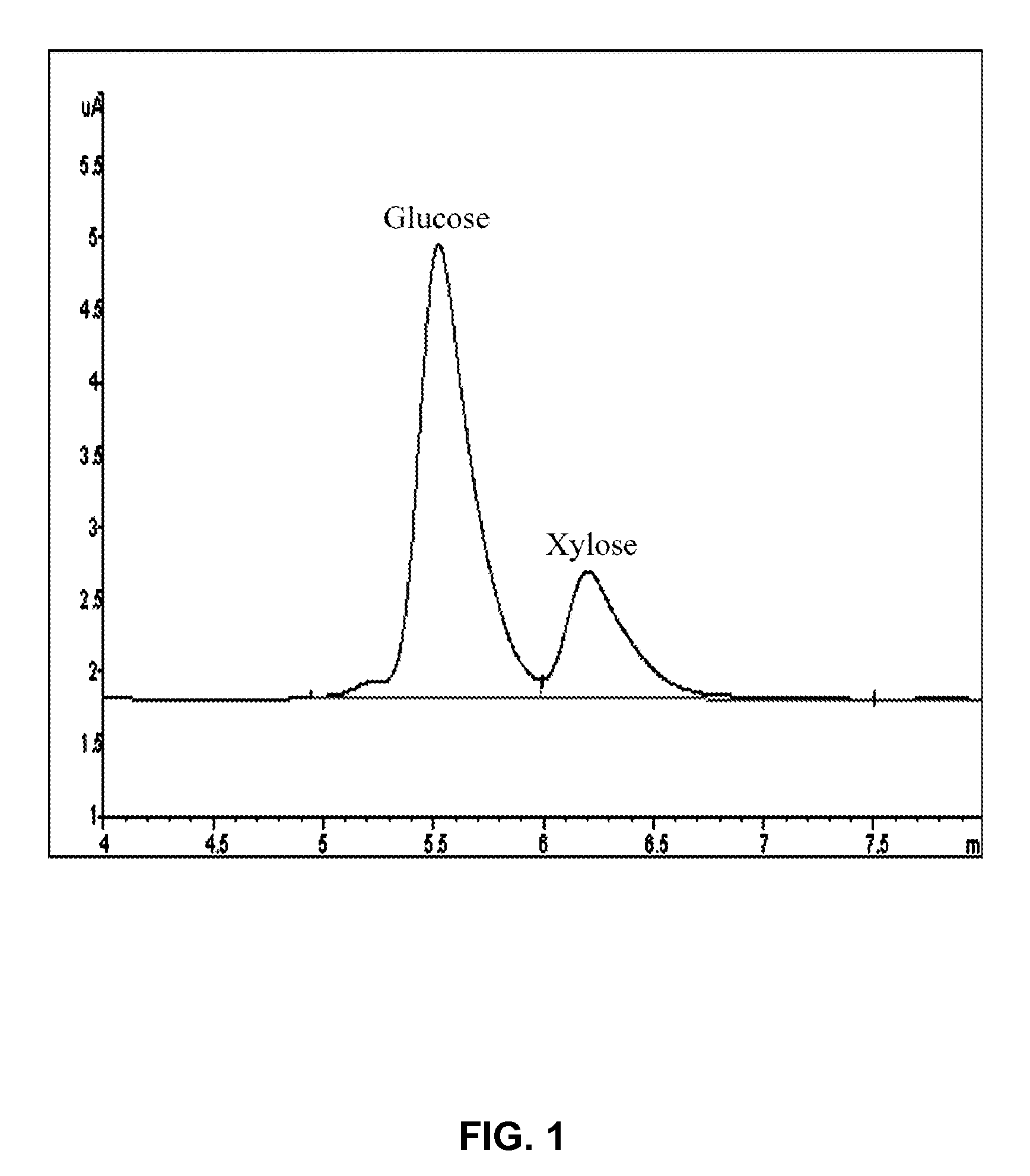

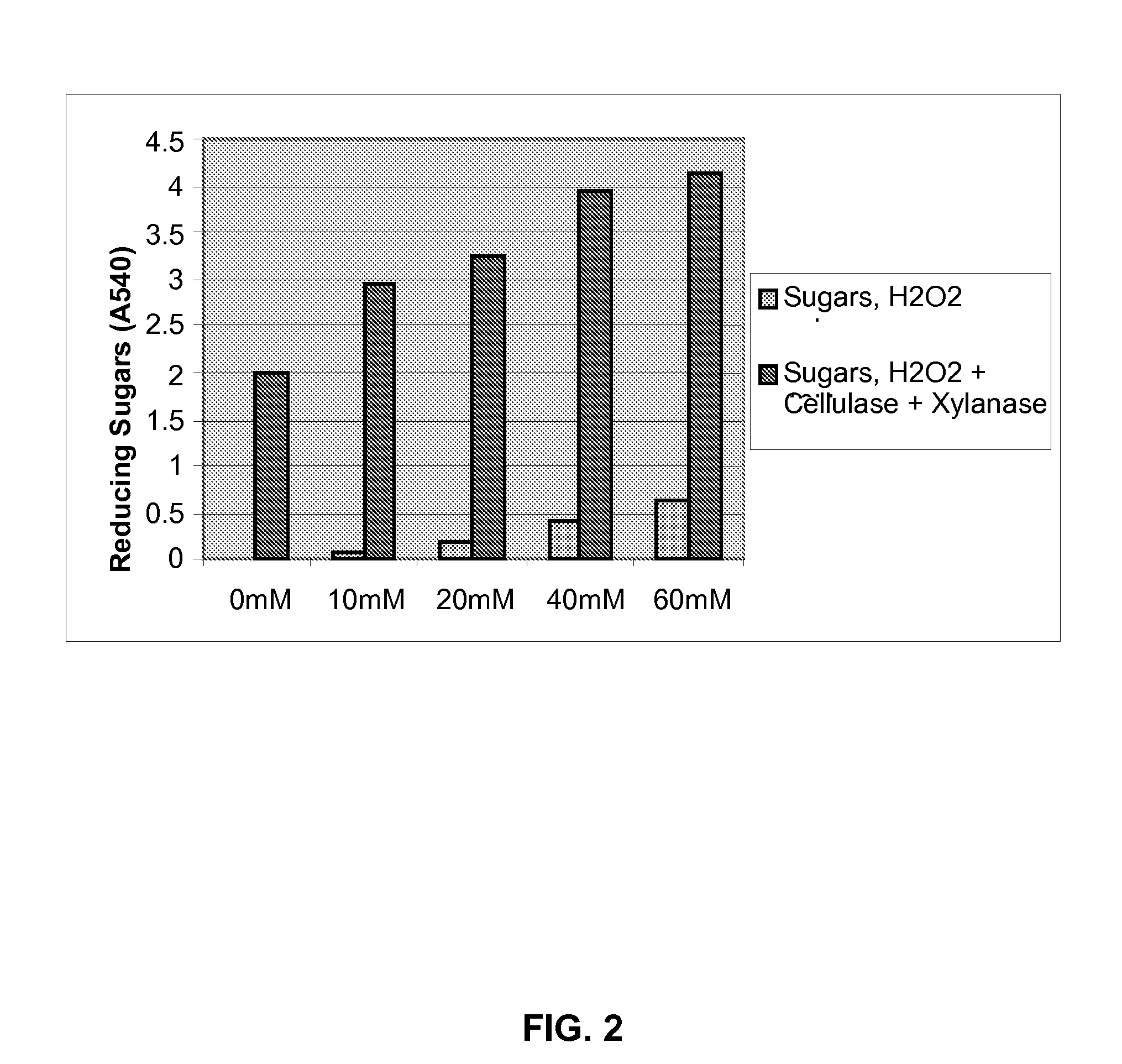

PatentInactiveUS20090004692A1

Innovation

- A method involving mild or moderate chemical treatments of lignocellulose followed by enzyme hydrolysis, using oxidizing agents, bases, or other chemicals to break down the material without generating toxic waste, allowing for simultaneous saccharification and fermentation in the same reaction vessel.

Stem cells

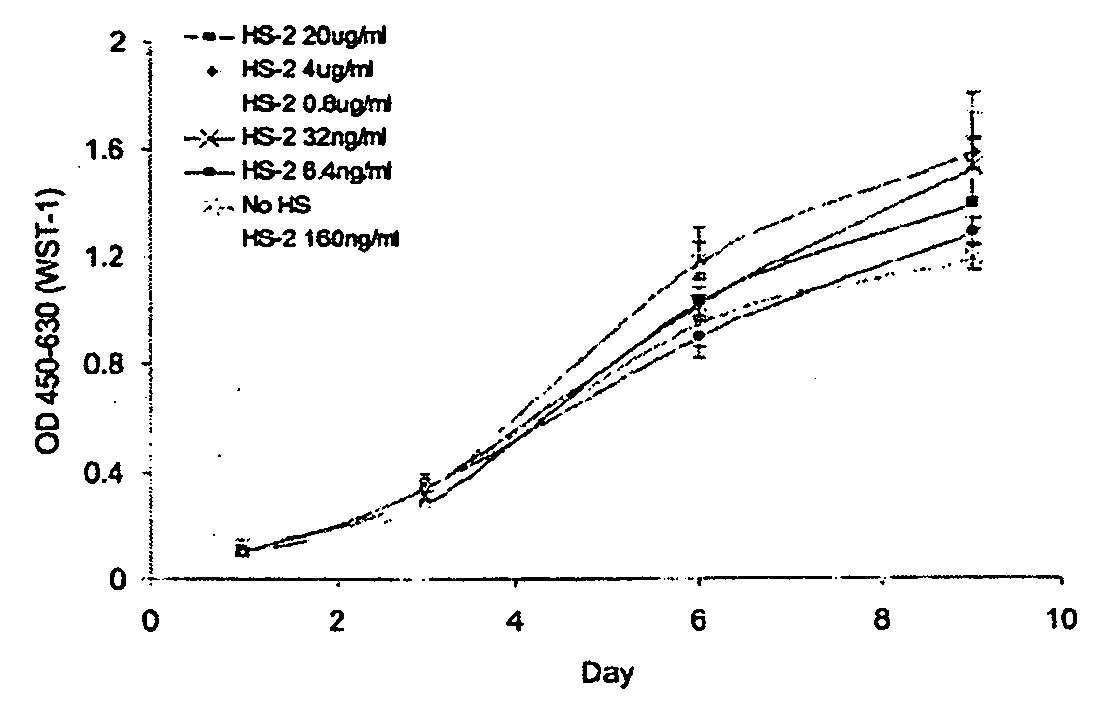

PatentInactiveUS20090148420A1

Innovation

- The use of heparan sulphate (HS) in culture media enhances stem cell proliferation and expansion, maintaining the multipotency and regenerative potential of hMSCs by promoting a microenvironment that supports their natural signaling and hormonal status, thereby increasing the yield of therapeutic numbers of stem cells without adverse effects.

Environmental Impact Assessment

The environmental impact assessment of strategies for enhancing hydroxyethylcellulose (HEC) biodegradation is crucial for understanding the potential consequences and benefits of these approaches. HEC, a widely used cellulose derivative, has applications in various industries, including personal care products, pharmaceuticals, and construction materials. While it offers numerous benefits, its persistence in the environment has raised concerns.

Biodegradation enhancement strategies for HEC aim to accelerate its decomposition in natural environments, potentially reducing its ecological footprint. However, these strategies may have both positive and negative environmental implications that need careful consideration.

One of the primary positive impacts of enhanced HEC biodegradation is the reduction of plastic pollution in aquatic and terrestrial ecosystems. By promoting faster breakdown of HEC-containing products, these strategies can help mitigate the accumulation of microplastics and reduce the overall environmental burden of persistent polymers. This could lead to improved water quality, reduced harm to marine life, and decreased soil contamination.

However, the accelerated biodegradation of HEC may also lead to increased carbon dioxide emissions in the short term. As microorganisms break down the polymer more rapidly, they release CO2 as a byproduct of their metabolic processes. This temporary increase in greenhouse gas emissions should be weighed against the long-term benefits of reduced plastic pollution.

Another consideration is the potential impact on local ecosystems. The introduction of enhanced biodegradation strategies may alter microbial communities in soil and water, potentially affecting nutrient cycles and ecosystem dynamics. While this could lead to more efficient organic matter decomposition, it may also disrupt existing ecological balances.

The use of specific enzymes or microorganisms to enhance HEC biodegradation raises questions about their potential effects on non-target organisms. Careful assessment is needed to ensure that these biological agents do not harm beneficial species or introduce unintended consequences into the environment.

Water quality is another critical factor to consider. While accelerated HEC degradation may reduce long-term water pollution, the short-term effects of increased microbial activity and the release of degradation byproducts need to be evaluated. This includes potential impacts on dissolved oxygen levels, pH, and the presence of metabolites in aquatic systems.

Lastly, the life cycle assessment of enhanced biodegradation strategies should be considered. This includes evaluating the environmental costs of producing and implementing these strategies against the benefits of reduced HEC persistence. Factors such as energy consumption, resource use, and potential chemical inputs for the enhancement process must be carefully weighed to ensure a net positive environmental impact.

Biodegradation enhancement strategies for HEC aim to accelerate its decomposition in natural environments, potentially reducing its ecological footprint. However, these strategies may have both positive and negative environmental implications that need careful consideration.

One of the primary positive impacts of enhanced HEC biodegradation is the reduction of plastic pollution in aquatic and terrestrial ecosystems. By promoting faster breakdown of HEC-containing products, these strategies can help mitigate the accumulation of microplastics and reduce the overall environmental burden of persistent polymers. This could lead to improved water quality, reduced harm to marine life, and decreased soil contamination.

However, the accelerated biodegradation of HEC may also lead to increased carbon dioxide emissions in the short term. As microorganisms break down the polymer more rapidly, they release CO2 as a byproduct of their metabolic processes. This temporary increase in greenhouse gas emissions should be weighed against the long-term benefits of reduced plastic pollution.

Another consideration is the potential impact on local ecosystems. The introduction of enhanced biodegradation strategies may alter microbial communities in soil and water, potentially affecting nutrient cycles and ecosystem dynamics. While this could lead to more efficient organic matter decomposition, it may also disrupt existing ecological balances.

The use of specific enzymes or microorganisms to enhance HEC biodegradation raises questions about their potential effects on non-target organisms. Careful assessment is needed to ensure that these biological agents do not harm beneficial species or introduce unintended consequences into the environment.

Water quality is another critical factor to consider. While accelerated HEC degradation may reduce long-term water pollution, the short-term effects of increased microbial activity and the release of degradation byproducts need to be evaluated. This includes potential impacts on dissolved oxygen levels, pH, and the presence of metabolites in aquatic systems.

Lastly, the life cycle assessment of enhanced biodegradation strategies should be considered. This includes evaluating the environmental costs of producing and implementing these strategies against the benefits of reduced HEC persistence. Factors such as energy consumption, resource use, and potential chemical inputs for the enhancement process must be carefully weighed to ensure a net positive environmental impact.

Regulatory Framework for Biodegradable Materials

The regulatory framework for biodegradable materials plays a crucial role in shaping the development and implementation of strategies for enhancing hydroxyethylcellulose (HEC) biodegradation. As environmental concerns continue to grow, governments and international organizations have established various regulations and standards to promote the use of biodegradable materials and ensure their proper disposal.

In the United States, the Federal Trade Commission (FTC) has set guidelines for environmental marketing claims, including those related to biodegradability. These guidelines require manufacturers to provide scientific evidence supporting their biodegradability claims and specify the conditions under which the material will biodegrade. The Environmental Protection Agency (EPA) also regulates the disposal of biodegradable materials through the Resource Conservation and Recovery Act (RCRA).

The European Union has implemented the EN 13432 standard, which defines the requirements for packaging to be considered compostable and biodegradable. This standard has been widely adopted and serves as a benchmark for biodegradable materials in many countries. Additionally, the EU Waste Framework Directive provides guidelines for waste management and promotes the use of biodegradable materials to reduce environmental impact.

In Japan, the Biodegradable Plastics Society (BPS) has established certification standards for biodegradable plastics, including those derived from cellulose. These standards ensure that materials meet specific biodegradation requirements and are suitable for composting or other environmentally friendly disposal methods.

International organizations, such as the International Organization for Standardization (ISO), have developed standards like ISO 14851 and ISO 14852, which provide methods for determining the aerobic biodegradability of plastic materials in an aqueous medium. These standards are essential for assessing the biodegradation potential of materials like HEC and ensuring compliance with regulatory requirements.

The regulatory landscape for biodegradable materials is continually evolving, with many countries introducing new legislation to address environmental concerns. For instance, China has recently implemented restrictions on single-use plastics and is promoting the use of biodegradable alternatives. This shift in policy has significant implications for the development and adoption of biodegradable materials, including those based on HEC.

As research into HEC biodegradation enhancement strategies progresses, it is crucial to consider the regulatory framework at every stage of development. Compliance with existing regulations and anticipation of future regulatory changes will be essential for the successful implementation of these strategies. Furthermore, collaboration between researchers, industry stakeholders, and regulatory bodies will be necessary to ensure that new biodegradation enhancement techniques meet the required standards and contribute to sustainable waste management practices.

In the United States, the Federal Trade Commission (FTC) has set guidelines for environmental marketing claims, including those related to biodegradability. These guidelines require manufacturers to provide scientific evidence supporting their biodegradability claims and specify the conditions under which the material will biodegrade. The Environmental Protection Agency (EPA) also regulates the disposal of biodegradable materials through the Resource Conservation and Recovery Act (RCRA).

The European Union has implemented the EN 13432 standard, which defines the requirements for packaging to be considered compostable and biodegradable. This standard has been widely adopted and serves as a benchmark for biodegradable materials in many countries. Additionally, the EU Waste Framework Directive provides guidelines for waste management and promotes the use of biodegradable materials to reduce environmental impact.

In Japan, the Biodegradable Plastics Society (BPS) has established certification standards for biodegradable plastics, including those derived from cellulose. These standards ensure that materials meet specific biodegradation requirements and are suitable for composting or other environmentally friendly disposal methods.

International organizations, such as the International Organization for Standardization (ISO), have developed standards like ISO 14851 and ISO 14852, which provide methods for determining the aerobic biodegradability of plastic materials in an aqueous medium. These standards are essential for assessing the biodegradation potential of materials like HEC and ensuring compliance with regulatory requirements.

The regulatory landscape for biodegradable materials is continually evolving, with many countries introducing new legislation to address environmental concerns. For instance, China has recently implemented restrictions on single-use plastics and is promoting the use of biodegradable alternatives. This shift in policy has significant implications for the development and adoption of biodegradable materials, including those based on HEC.

As research into HEC biodegradation enhancement strategies progresses, it is crucial to consider the regulatory framework at every stage of development. Compliance with existing regulations and anticipation of future regulatory changes will be essential for the successful implementation of these strategies. Furthermore, collaboration between researchers, industry stakeholders, and regulatory bodies will be necessary to ensure that new biodegradation enhancement techniques meet the required standards and contribute to sustainable waste management practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!